Abstract

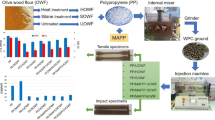

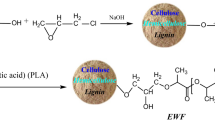

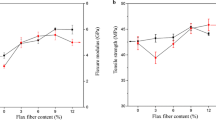

Wood flour (WF)/polypropylene (PP) composites have been made by extrusion and hot press compression molding. The composite water uptake and flexural properties were investigated. The composite fracture surfaces were studied by SEM. WF esterified with octanoyl chloride was used in WF/PP composites to improve the composites’ water resistance. Maleated polypropylene (MAPP) was also studied and compared with esterification by acid chlorides. Esterification by octanoyl chloride reduced the composite water uptake. However, the C8 chain is still not long enough to form effective entanglements with the PP matrix. So, despite enhancements in hydrophobic interactions, flexural strengths and flexural moduli decreased. MAPP (MW = 47000) polymer chains can entangle with the matrix polypropylene molecules. Therefore, when MAPP’s maleic anhydride functions esterify WF surface hydroxyls, improved water resistance and composite flexural properties were achieved. The modifier chain length is of critical importance and more important than the surface density of hydrophobic groups for improving WF–PP interfacial adhesion and composite mechanical performance.

Similar content being viewed by others

References

Clemons CM (2000) Proceedings of the 3rd international wood and natural fibre composites symposium, Kassel, Germany

Magurno A (1999) Die Angewandte Makromolekulare Chemie 272(1):99

Bledzki AK, Faruk O, Sperber VE (2006) Macromol Mater Eng 291(5):449. doi:https://doi.org/10.1002/mame.200600113

Tshabalala MA, Kingshott P, Vanlandingham MR, Plackett D (2003) J Appl Polym Sci 88:2828. doi:https://doi.org/10.1002/app.12142

Tserki V, Matzinos P, Kokkou S, Panayiotou C (2005) Compos, Part A 36:965. doi:https://doi.org/10.1016/j.compositesa.2004.11.010

Zhang C, Li KC, Simonsen J (2004) J Adhes Sci Technol 18:1603

Ellis WD, O’Dell JL (1999) J Appl Polym Sci 73:2493

Sèbe G, Tingaut P, Safoutchiama R, Pétraud M, Grelier S, Jéso BD (2004) Holzforschung 58:511. doi:https://doi.org/10.1515/HF.2004.078

Oksman K, Clemons C (1998) J Appl Polym Sci 67(9):1503

Cantero G, Arbelaiz A, Mugika F, Valea A, Mondragon I (2003) J Reinf Plast Compos 22(1):37. doi:https://doi.org/10.1177/0731684403022001495

Kaci M, Cimmino S, Silvestre C, Duraccio D, Benhamida A, Zaidi L (2006) Macromol Mater Eng 291(7):869. doi:https://doi.org/10.1002/mame.200600003

Wu JS, Yu DM, Chan CM, Kim J, Mai YW (2000) J Appl Polym Sci 76:1000

Zhang Y, Pittman CU Jr, Toghiani H, Zhang J, Xue Y (2009) Compos Interfaces (accepted)

ASTM D 790-92

ASTM D 570-98

Wu Z, Pittman CU Jr, Gardner SD (1996) Carbon 34(1):59. doi:https://doi.org/10.1016/0008-6223(95)00135-2

Tsubokawa N, Kobayashi K, Sone Y (1988) J Polym Sci, Part A: Polym Chem 26:223. doi:https://doi.org/10.1002/pola.1988.080260122

Edmondson S, Osborne VL, Huck WTS (2004) Chem Soc Rev 33:14. doi:https://doi.org/10.1039/b210143m

Kazayawoko M, Balatinecz JJ, Matuana LM (1999) J Mater Sci 34:6189. doi:https://doi.org/10.1023/A:1004790409158

Acknowledgements

This work was funded by Center for Advanced Vehicular Systems of Mississippi State University (“Hybrid composites for a hybrid car” project). This work was also partly supported by the Forest Products Laboratory at Mississippi State University. The SEM characterization was supported by MCL Follow-up Funding from Mississippi State University. The authors thank Mr. Dustin Black for performing water absorption and third-point bending measurements. The authors also thank Ms. Amanda M. Lawrence for her help in SEM characterization.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Toghiani, H., Zhang, J. et al. Studies of surface-modified wood flour/polypropylene composites. J Mater Sci 44, 2143–2151 (2009). https://doi.org/10.1007/s10853-009-3295-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3295-0