Abstract

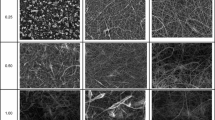

This paper reports an investigation of the effects of solvent system, solution concentration, and applied electrostatic field strength (EFS) on the morphological appearance and/or size of as-spun cellulose acetate (CA) products. The single-solvent systems were acetone, chloroform, N,N -dimethylformamide (DMF), dichloromethane (DCM), methanol (MeOH), formic acid, and pyridine. The mixed-solvent systems were acetone–DMAc, chloroform–MeOH, and DCM–MeOH. Chloroform, DMF, DCM, MeOH, formic acid, and pyridine were able to dissolve CA, forming clear solutions (at 5% w/v), but electrospinning of these solutions produced mainly discrete beads. In contrast, electrospinning of the solution of CA in acetone produced short and beaded fibers. At the same solution concentration of 5% (w/v) electrospinning of the CA solutions was improved by addition of MeOH to either chloroform or DCM. For all the solvent systems investigated smooth fibers were obtained from 16% (w/v) CA solutions in 1:1, 2:1, and 3:1 (v/v) acetone–DMAc, 14–20% (w/v) CA solutions in 2:1 (v/v) acetone–DMAc, and 8–12% (w/v) CA solutions in 4:1 (v/v) DCM–MeOH. For the as-spun fibers from CA solutions in acetone–DMAc the average diameter ranged between 0.14 and 0.37 μm whereas for the fibers from solutions in DCM–MeOH it ranged between 0.48 and 1.58 μm. After submersion in distilled water for 24 h the as-spun CA fibers swelled appreciably (i.e. from 620 to 1110%) but the physical integrity of the fibrous structure remained intact.

Similar content being viewed by others

References

Anonymous 2006. Cellulose acetate. http://www.en.wikipedia.org/wiki/Cellulose_acetate

Baumgarten PK (1971) Electrostatic spinning of acrylic microfibers. J Colloid Interface Sci 36:71–79

Bergshoef MM, Vancso GJ (1999) Transparent nanocomposites with ultrathin, electrospun nylon-4,6 fiber reinforcement. Adv Mater 11:1362–1365

Buchko CJ, Chen LC, Shen Y, Martin DC (1999) Processing and microstructural characterization of porous biocompatible protein polymer thin films. Polymer 40:7397–7407

Deitzel JM, Kleinmeyer J, Harris D, Beck Tan NC (2001) The effect of processing variables on the morphology of electrospun nanofibers and textiles. Polymer 42:261–272

Doshi J, Reneker DH (1995) Electrospinning process and applications of electrospun fibers. J Electrostat 35:151–160

Gibson PW, Schreuder-Gibson HL, Rivin D (1999) Electrospun fiber mats: transport properties. AIChE J 45:190–195

Jaeger R, Bergshoef MM, Martin i Batlle C, Schoenherr H, Vansco GJ (1998) Electrospinning of ultra thin polymer fibers. Macromol Symp 127:141–150

Jarusuwannapoom T, Hongrojjanawiwat W, Jitjaicham S, Wannatong L, Nithitanakul M, Pattamaprom C, Koombhongse P, Rangkupan R, Supaphol P (2005) Effect of solvents on electro-spinnability of polystyrene solutions and morphological appearance of resulting electrospun polystyrene fibers. Eur Polym J 41:409–421

Kim JS, Reneker DH (1999) Mechanical properties of composites using ultrafine electrospun fibers. Polym Compos 20:124–131

Liu H, Hsieh YL (2002) Ultrafine fibrous cellulose membranes from electrospinning of cellulose acetate. J Polym Sci—Polym Phys 40:2119–2129

Ma Z, Kotaki M, Ramakrishna S (2005) Electrospun cellulose nanofiber as affinity membrane. J Membrane Sci 265:115–123

Mit-uppatham C, Nithitanakul M, Supaphol P (2004) Ultrafine electrospun polyamide-6 fibers: effect of solution condition on morphology and average fiber diameter. Macromol Chem Phys 205:2327–2338

Mozga W (2006) Physical properties of liquids. http://www.trimen.pl/witek/ciecze/liquids.html

Pattamaprom C, Hongrojjanawiwat W, Koombhongse P, Supaphol P, Jarusuwannapoom T, Rangkupan R (2006) The influence of solvent properties and functionality on the electrospinnability of polystyrene nanofibers. Macromol Mater Eng 291:840–847

Reneker DH, Chun I (1996) Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 7:216–223

Son WK, Youk JH, Lee TS, Park YH (2004) Electrospinning of ultrafine cellulose acetate fibers: studies of a new solvent system and deacetylation of ultrafine cellulose acetate fibers. J Polym Sci—Polym Phys 42:5–11

Supaphol P, Mit-uppatham C, Nithitanakul M (2005) Ultrafine electrospun polyamide-6 fibers: effect of emitting electrode polarity on morphology and average fiber diameter. J Polym Sci—Polym Phys 43:3699–3712

Taepaiboon P, Rungsardthong U, Supaphol P (2006) Drug-loaded electrospun mats of poly(vinyl alcohol) fibres and their release characteristics of four model drugs. Nanotechnology 17:2317–2329

Wutticharoenmongkol P, Sanchavanakit N, Pavasant P, Supaphol P (2006) Novel bone scaffolds of electrospun polycaprolactone fibers filled with nanoparticles. J Nanosci Nanotechnol 6:514–522

Acknowledgements

The authors acknowledge partial support from (a) the National Research Council of Thailand (NRCT), (b) Chulalongkorn University (through invention and research grants from the Ratchadapesek Somphot Endowment Fund), (c) the Petroleum and Petrochemical Technology Consortium (through a Thai governmental loan from the Asian Development Bank (ADB)), and (d) the Petroleum and Petrochemical College (PPC), Chulalongkorn University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tungprapa, S., Puangparn, T., Weerasombut, M. et al. Electrospun cellulose acetate fibers: effect of solvent system on morphology and fiber diameter. Cellulose 14, 563–575 (2007). https://doi.org/10.1007/s10570-007-9113-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-007-9113-4