Abstract

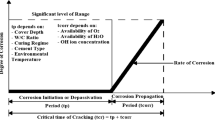

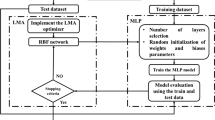

Reinforced concrete (RC) is one of the most commonly used composite materials in construction industry. Corrosion of reinforcing steel embedded in concrete is a crucial issue leading deterioration of RC structure. In this study, mathematical formulations that predict the time from corrosion initiation to corrosion cracking in RC elements subjected to accelerated corrosion test are presented. For this, the time to corrosion cracking t cr in RC elements is evaluated and developed using soft-computing techniques, namely, genetic algorithms and artificial neural networks. In the models, nine critical estimation parameters were considered. The experimental inputs are mix design properties of the concretes, curing conditions, testing age, mechanical properties of concrete, and cover thickness of RC elements. The dataset was formed by collecting 126 experimental data samples reported in the technical literature. The dataset was randomly separated into three parts for training, testing, and validating the models. Through the numerical study, the influences of various experimental factors on the duration and extent of RC corrosion-induced cracking were shown. It was found that the soft-computing based models gave reasonable predictions of t cr in RC elements. However, the neural network model performed better and the highest correlation coefficient (R) between predicted and experimental t cr values was computed as 0.998.

Similar content being viewed by others

References

Zhang R, Castel A, François R (2010) Concrete cover cracking with reinforcement corrosion of RC beam during chloride-induced corrosion process. Cem Concr Res 40:415–425

Bazant ZP (1979) Physical model for steel corrosion in concrete sea structures –theory. J Struct Div 105:1137–1153

Mehta PK (1991) Durability of concrete: fifty years of progress? In: Proceeding of 2nd international conference on durability, Montreal Canada, pp 1–31

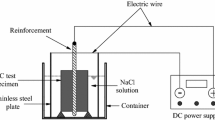

Güneyisi E, Özturan T, Gesoğlu M (2005) A study on reinforcement corrosion and related properties of plain and blended cement concretes under different curing conditions. Cement Concr Compos 27:449–461

Duffo GS, Morris W, Raspini I, Saragovi C (2004) A study of steel rebars embedded in concrete during 65 years. Corros Sci 46:2143–2157

Tuutti K (1982) Corrosion of steel in concrete. CBI Swedish Cement and Concrete Research Institute, Stockholm, p 159

Liu YP, Weyers RE (1998) Modeling the time to corrosion cracking in chloride contaminated reinforced concrete structures. ACI Mater J 95:675–681

Leeming MB (1998) Durability of concrete in and near the sea. In: Allen RTL (ed) Concrete in coastal structures. MIT Press, Telford, pp 73–98

Li CQ (2000) Corrosion initiation of reinforcing steel in concrete under natural salt spray and service loading—results and analysis. ACI Mater J 97(6):690–697

Otsuki N, Miyazato S, Diola NB, Suzuki H (2000) Influence of bending crack and water–cement ratio on chloride-induced corrosion of main reinforcing bars and stirrups. ACI Mater J 97(4):454–465

Francois R, Castel A (2001) Discussion on influence of bending crack and water–cement ratio on chloride-induced corrosion of main reinforcing bars and stirrups. ACI Mater J 98(3):276–278

Andrade C, Alonso C, Molina FJ (1993) Cover cracking as a function of rebar corrosion: part 1. Exp Test Mater Struct 26:453–464

Pantazopoulou SJ, Papoulia KD (2001) Modeling covercracking due to reinforcement corrosion in RC structures. J Eng Mech 127(4):342–351

Liu YP, Weyers RE (1998) Modeling the time to corrosion cracking in chloride contaminated reinforced concrete structures. ACI Mater J 95:675–681

Li CQ (2004) Reliability based service life prediction of corrosion affected concrete structures. J Struct Eng 130:1570–1577

Otieno MB, Beushausen HD, Alexander MG (2011) Modelling corrosion propagation in reinforced concrete structures: a critical review. Cem Concr Compos 33:240–245

Maheswaran T, Sanjayan JG (2004) A semi-closed-form solution for chloride diffusion in concrete with time-varying parameters. Mag Concr Res 56:359–366

El-Gelany MA (2001) Short-term corrosion rate measurement of OPC and HPC reinforced concrete specimens by electrochemical techniques. Mater Struct 34:426–432

Neville AM (2006) Properties of concrete, 4th edn. Pearson, Prentice Hall

Güneyisi E, Gesoğlu M, Karaboğa F, Mermerdaş K (2013) Corrosion behavior of reinforcing steel embedded in chloride contaminated concretes with and without metakaolin. Composites B 45:1288–1295

Al-Tayyib AJ, Al-Zahrani MM (1990) Corrosion of steel reinforcement in polypropylene fiber reinforced concrete structure. ACI Mater J 87(2):108–113

Detwiler RJ, Kjellsen KO, Gjorv OE (1991) Resistance to chloride intrusion of concrete cured at different temperature. ACI Mater J 88(1):19–24

Güneyisi E, Gesoğlu M (2008) A study on durability properties of high-performance concretes incorporating high replacement levels of slag. Mater Struct 41:479–493

Boğa AR, Topçu İB (2012) Influence of fly ash on corrosion resistance and chloride ion permeability of concrete. Constr Build Mater 31:258–264

Boğa AR, Topçu İB (2010) Effect of ground granulate blast-furnace slag on corrosion performance of steel embedded in concrete. Mater Des 31:3358–3365

Boğa AR, Topçu İB, Öztürk M (2012) Effect of fly-ash amount and cement type on the corrosion performance of the steel embedded in concrete. Mater Technol 46(5):511–518

Topçu İB, Boğa AR, Hocaoğlu FO (2009) Modeling corrosion currents of reinforced concrete using ANN. Autom Constr 18:145–152

Su JK, Yang CC, Wu WB, Huang R (2002) Effect of moisture content on concrete resistivity measurement. J Chin Inst Eng 25:117–122

Sadowski L (2013) Methodology for assessing the probability of corrosion in concrete structures on the basis of half-cell potential and concrete resistivity measurements. Sci World J 2013:1–8

Gulikers J (2005) Theoretical considerations on the supposed linear relationship between concrete resistivity and corrosion rate of steel reinforcement. Mater Corros 56:393–403

Sadowski L (2010) New non-destructive method for linear polarisation resistance corrosion rate measurement. Archiv Civ Mech Eng 10:109–116

Güneyisi E, Gesoğlu M, Özturan T, Özbay E (2009) Estimation of chloride permeability of concretes by empirical modeling: considering effects of cement type, curing condition and age. Constr Build Mater 23:469–481

Ashour AF, Alvarez LF, Toropov VV (2003) Empirical modeling of shear strength RC deep beams by genetic programming. Comput Struct 81:331–338

Adhikary BB, Mutsuyoshi H (2006) Prediction of shear strength of steel fiber RC beams using neural networks. Constr Build Mater 20:801–811

Goh ATC (1995) Prediction of ultimate shear strength of deep beams using neural networks. ACI Struct J 92(1):28–32

Yang Y, Soh CK (2002) Automated optimum design of structures using genetic programming. Comput Struct 80:1537–1546

Sadowski L (2013) Non-destructive investigation of corrosion current density in steel reinforced concrete by artificial neural networks. Arch Civ Mech Eng 13:104–111

Sadowski L (2010) Non-destructive evaluation of the pull-off adhesion of concrete floor layers using RBF neural network. Jo Civ Eng Manag 19:550–560

Bhargava K, Ghosh AK, Mori Y, Ramanujam S (2006) Model for cover cracking due to rebar corrosion in RC structures. Eng Struct 28:1093–1109

Shodja HM, Kiani K, Hashemian A (2010) A model for the evolution of concrete deterioration due to reinforcement corrosion. Math Comput Modell 52:1403–1422

Guzmán S, Gálvez JC, Sancho JM (2012) Modelling of corrosion-induced cover cracking in reinforced concrete by an embedded cohesive crack finite element. Eng Fract Mech 93:92–107

Shafei B, Alipour A, Shinozuka M (2012) Prediction of corrosion initiation in reinforced concrete members subjected to environmental stressors: a finite-element framework. Cem Concr Res 42:365–376

Zadeh LA (1994) Soft computing and fuzzy logic. IEEE Softw 11(6):48–56

Güneyisi E, Gesoğlu M, Özturan T, Mermerdaş K, Özbay E (2011) Properties of mortars with natural pozzolana and limestone-based blended cements. ACI Mater J 108:493–500

Koza JR (1992) Genetic programming: on the programming of computers by means of natural selection. MIT Press, Cambridge

Ferreira C (2001) Gene expression programming: a new adaptive algorithm for solving problems. Complex Syst 13(2):87–129

Gao S, Zhang Z, Cao C (2011) Road traffic freight volume forecast using support vector machine combining forecasting. J Softw 6:1680

Alexhander I, Morton H (1993) Neurons and symbols: the staff that mind is made of. Chapman and Hall, London

Arbib MA (1995) Handbook of brain theory and neural networks. MIT Press, Cambridge

Topçu İB, Sarıdemir M (2008) Prediction of mechanical properties of recycled aggregate concretes containing silica fume using artificial neural networks and fuzzy logic. Comput Mater Sci 42:74–82

Mukherjee A, Biswas SN (1997) Artificial neural networks in prediction of mechanical behavior of concrete at high temperature. Nucl Eng Des 178:1–11

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Güneyisi, E.M., Mermerdaş, K., Güneyisi, E. et al. Numerical modeling of time to corrosion induced cover cracking in reinforced concrete using soft-computing based methods. Mater Struct 48, 1739–1756 (2015). https://doi.org/10.1617/s11527-014-0269-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-014-0269-8