Abstract

Blending of powders is a crucial step in the production of pharmaceutical solid dosage forms. The active pharmaceutical ingredient (API) is often a powder that is blended with other powders (excipients) in order to produce tablets. The blending efficiency is influenced by several external factors, such as the desired degree of homogeneity and the required blending time, which mainly depend on the properties of the blended materials and on the geometry of the blender. This experimental study investigates the mixing behavior of acetyl salicylic acid as an API and α-lactose monohydrate as an excipient for different filling orders and filling levels in a blender. A multiple near-infrared probe setup on a laboratory-scale blender is used to observe the powder composition quasi-simultaneously and in-line in up to six different positions of the blender. Partial least squares regression modeling was used for a quantitative analysis of the powder compositions in the different measurement positions. The end point for the investigated mixtures and measurement positions was determined via moving block standard deviation. Observing blending in different positions helped to detect good and poor mixing positions inside the blender that are affected by convective and diffusive mixing.

Similar content being viewed by others

REFERENCES

Mendez ASL, de Carli G, Garcia CV. Evaluation of powder mixing operation during batch production: application to operational qualification procedure in the pharmaceutical industry. Powder Technol. 2009;198:310–3.

Harnby N. An engineering view of pharmaceutical powder mixing. Pharm Sci Technol Today. 2000;3:303–9.

Remy B, Khinast JG, Glasser BJ. Discrete element simulation of free flowing grains in a four-bladed mixer. AIChE J. 2009;55:2035–48.

Stieß M. Mechanische Verfahrenstechnik—Partikeltechnologie 1. 3rd ed. Berlin: Springer; 2009.

Hogg R. Mixing and segregation in powder evaluation, mechanisms and processes. KONA Powder Part J. 2009;27:1–15.

Lekhal A, Girard KP, Brown MA, Kiang S, Glasser BJ, Khinast JG. Impact of agitated drying on crystal morphology: KCl–water system. Powder Technol. 2003;132:119–30.

Lekhal A, Girard KP, Brown MA, Kiang S, Khinast JG, Glasser BJ. The effect of agitated drying on the morphology of l-threonine (needle-like) crystals. Int J Pharm. 2004;270:263–77.

Poux M, Fayolle P, Betrand J, Bridoux D, Bousquet J. Powder mixing: some practical rules applied to agitated systems. Powder Technol. 1991;68:213–34.

Li H, McCarthy JJ. Controlling cohesive particle mixing and segregation. Phys Rev Lett. 2003;90:184301.

Acevedo D, Muliadi A, Giridhar A, Litster J, Romañach R. Evaluation of three approaches for real-time monitoring of roller compaction with near-infrared spectroscopy. AAPS PharmSciTech. 2012;13:1005–12.

Vanarase AU, Alcala M, Rozo JIJ, Muzzio FJ, Romanach RJ. Real-time monitoring of drug concentration in a continuous powder mixing process using NIR spectroscopy. Chem Eng Sci. 2010;65:5728–33.

Maltesen M, van de Weert M, Grohganz H. Design of experiments-based monitoring of critical quality attributes for the spray-drying process of insulin by NIR spectroscopy. AAPS PharmSciTech. 2012;13:747–55.

Duong NH, Arratia P, Muzzio F, Lange A, Timmermans J, Reynolds S. A homogeneity study using NIR spectroscopy: tracking magnesium stearate in Bohle bin-blender. Drug Dev Ind Pharm. 2003;29:679–87.

Reich G. Near-infrared spectroscopy and imaging: basic principles and pharmaceutical applications. Adv Drug Deliv Rev. 2005;57:1109–43.

Roggo Y, Chalus P, Maurer L, Lema-Martinez C, Edmond A, Jent N. A review of near infrared spectroscopy and chemometrics in pharmaceutical technologies. J Pharm Biomed Anal. 2007;44:683–700.

Sekulic SS, Ward II HW, Brannegan DR, Stanley ED, Evans CL, Sciavolino ST, Haily PA, Aldridge PK. On-line monitoring of powder blend homogeneity. Anal Chem. 1996;68:509–13.

Blanco M, Baó RG, Bertran E. Monitoring powder blending in pharmaceutical processes by use of near infrared spectroscopy. Talanta. 2002;56:203–12.

Berntsson O, Danielsson L-G, Lagerholm B, Folestad S. Quantitative in-line monitoring of powder blending by near infrared reflection spectroscopy. Powder Technol. 2002;123:185–93.

El-Hagrasy AS, Drennen III JK. A process analytical technology approach to near-infrared process control of pharmaceutical powder blending. Part III: quantitative near-infrared calibration for prediction of blend homogeneity and characterization of powder mixing kinetics. J Pharm Sci. 2005;95:422–34.

Abrahamsson C. Time-Resolved Spectroscopy for Pharmaceutical Applications. Ph.D. thesis, Atomic Physics Division, Department of Physics, Lund Institute of Technology; 2005.

Karande AD, Liew CV, Heng PWS. Calibration sampling paradox in near infrared spectroscopy: a case study of multicomponent powder blend. Int J Pharm. 2010;395:91–7.

Remy B, Glasser BJ, Khinast JG. The effect of mixer properties and fill level on granular flow in a bladed mixer. AIChE J. 2010;56:336–53.

Radl S, Kalvoda E, Glasser BJ, Khinast JG. Mixing characteristics of wet granular matter in a bladed mixer. Powder Technol. 2010;200:171–89.

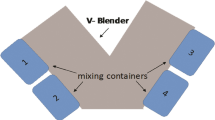

Brone D, Alexander A, Muzzio FJ. Quantitative characterization of mixing dry powders in V-blenders. AIChE J. 1998;44:271–8.

Koller DM, Posch A, Hörl G, Voura C, Radl S, Urbanetz N, Fraser SD, Tritthart W, Reiter F, Schlingmann M, Khinast JG. Continuous quantitative monitoring of powder mixing dynamics by near-infrared spectroscopy. Powder Technol. 2011;205:87–96.

El-Hagrasy AS, Morris HR, D’Amico F, Lodder RA, Drennen III JK. Near-infrared spectroscopy and imaging for the monitoring of powder blend homogeneity. J Pharm Sci. 2001;90:1298–307.

Witt W, Köhler U, List J. Experiences with dry dispersion and high-speed image analysis for size and shape characterisation. Particulate System Analysis, Stratford-upon-Avon; 2005. p. 1–5.

Kessler W. Multivariate Datenanalyse für die Pharma-, Bio- und Prozessanalytik. Weinheim: Wiley-VCH; 2007.

Wold S, Sjöström M, Eriksson L. PLS-regression: a basic tool of chemometrics. Chemometr Intell Lab Syst. 2001;58:109–30.

Momose W, Imai K, Yokota S, Yonemochi E, Terada K. Process analytical technology applied for end-point detection of pharmaceutical blending by combining two calibration free methods: simultaneously monitoring specific near-infrared peak intensity and moving block standard deviation. Powder Technol. 2011;210:122–31.

Shi Z, Cogdill RP, Short SM, Anderson CA. Process characterization of powder blending by near-infrared spectroscopy: blend end-points and beyond. J Pharm Biomed Anal. 2008;47:738–45.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scheibelhofer, O., Balak, N., Wahl, P.R. et al. Monitoring Blending of Pharmaceutical Powders with Multipoint NIR Spectroscopy. AAPS PharmSciTech 14, 234–244 (2013). https://doi.org/10.1208/s12249-012-9910-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-012-9910-4