Abstract

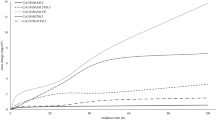

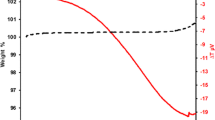

Ti–48Al–2Cr–2Mo–(0 and 0.5 at %) Si intermetallic alloys were synthesized by electric current- assisted sintering (ECAS). Microstructures of the alloys were characterized using scanning electron microscopy (SEM), electron diffraction spectroscopy (EDS), and X-ray diffraction (XRD) methods of analysis. It was found that the microstructures of the produced alloys consist of α2-Ti3Al and γ-TiAl phases. The cycle oxidation behaviors of the alloys were carried out between 700 and 900°C temperatures for 180 h in air. The oxide scale has comprised the TiO2 and Al2O3 mixture layer, intermediate Al2O3 layer, and outermost TiO2 layer. The oxidation rate constants and activation energies of the alloys were calculated.

Similar content being viewed by others

REFERENCES

S. Ye, H. Hao, W. Mo, K. Yu, L. Litao, C. Deng, and P. Yu, “Effects of cold compacting pressure on the expansion behavior of Ti-48Al during sintering,” J. Alloy Compd. 673, 399–404 (2016).

Z. Zhang, M. Xu, C. Z. Zhang, J. C. Han, Y. F. Chen, F. T. Kong, and Y. Y. Chen, “Microstructure homogeneity and mechanical properties of large-size as-cast high Nb containing TiAl alloy ingot,” Phys. Met. Metallogr. 119, 953–960 (2018).

Y. Garip and O. Ozdemir, “Comparative study of the oxidation and hot corrosion behaviors of TiAl–Cr intermetallic alloy produced by electric current activated sintering,” J. Alloy Compd. 780, 364–377 (2019).

A. Banu, M. Marcu, S. Petrescu, N. Ionescu, and A. Paraschiv, “Effect of niobium alloying level on the oxidation behavior of titanium aluminides at 850°C,” Int. J. Miner., Metall. Mater. 23, 1452–1457 (2016).

C. Liu, X. Lu, F. Yang, W. Xu, Z. Wang, and X. Qu, “Metal injection moulding of high Nb-containing TiAl alloy and its oxidation behaviour at 900°C,” Metals 8, 1–14 (2018).

A. Brotzu, F. Felli, and D. Pilone, “Effect of alloying elements on the behaviour of TiAl-based alloys,” Intermetallics 54, 176–180 (2014).

D. J. Kim, D. Y. Seo, H. Saari, T. Sawatzky, and Y.‑W. Kim, “Isothermal oxidation behavior of powder metallurgy beta gamma TiAl–2Nb–2Mo alloy,” Intermetallics 19, 1509–1516 (2011).

S. Grasso, Y. Sakka, and G. Maizza, “Electric current activated/assisted sintering (ECAS): a review of patents 1906–2008,” Sci. Technol. Adv. Mater. 10, 1–24 (2009).

Y. Garip and O. Ozdemir, “Hot corrosion behavior of Ti–48Al and Ti–48Al–2Cr intermetallic alloys produced by electric current activated sintering,” Metall. Mater. Trans. A 49, 2455–2462 (2018).

R. Orru, R. Licheri, A. M. Locci, A. Cincotti, and G. Cao, “Consolidation/synthesis of materials by electric current activated/assisted sintering,” Mater. Sci. Eng., R 63, 127–287 (2009).

D.-B. Lee, “Effect of Cr, Nb, Mn, V, W and Si on high temperature oxidation of TiAl alloys,” Met. Mater. Int. 11, 141–147 (2005).

Y. Shida and H. Anada, “The effect of various ternary additives on the oxidation behavior of TiAl in high-temperature air,” Oxid. Met. 45, 197–219 (1996).

H. Li, Q. Cao, and Z. Zhu, “Oxidation behaviour of Super 304H stainless steel in supercritical water,” Corros. Eng., Sci. Technol. 53, 293–301 (2008).

E. Godlewska, M. Mitoraj, F. Devred, and B. E. Nieuwenhuys, “Reactivity of a Ti–45.9Al–8Nb alloy in air at 700–900°C,” J. Therm. Anal. Calorim. 88, 225–230 (2007).

D. Y. Seo, T. D. Nguyen, and D. B. Lee, “Oxidation of powder metallurgy (PM) Ti–48% Al–2% Cr–2% Nb–(0–1%) W alloys between 800 and 1000oC in air,” Oxid. Met. 74, 145–156 (2010).

K. Kothari, R. Radhakrishnan, and N. M. Wereley, “Advances in gamma titanium aluminides and their manufacturing techniques,” Prog. Aeronaut. Sci. 55, 1–16 (2012).

X. Liu, K. You, Z. Wang, M. Zhang, and Z. He, “Effect of Mo-alloyed layer on oxidation behavior of TiAl-based alloy,” Vacuum 89, 209–214 (2013).

D. J. Kim, D. Y. Seo, Q. Yang, H. Saari, T. Sawatzky, and Y.-W. Kim, “Isothermal oxidation behaviour of beta gamma powder metallurgy TiAl–4Nb–3Mn alloys,” Can. Metall. Q. 50, 416–424 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Garip, Y., Ozdemir, O. Investigation of Cyclic Oxidation Behavior of (Cr, Mo, Si)-Containing (α2 + γ) TiAl-Based Alloys Synthesized by ECAS Sintering. Phys. Metals Metallogr. 121, 322–329 (2020). https://doi.org/10.1134/S0031918X20040043

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20040043