Abstract

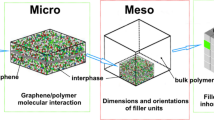

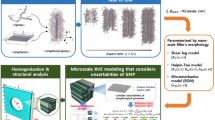

This paper presents an investigation into the homogenization of the nonlinear behavior of graphene-based soft sandwich nanocomposites via the rule of mixtures (ROM). These composites consist of soft polymers embedded with large contiguous graphene films with unit atomic thickness. They have a representative volume element with a sandwich construction exhibiting in-plane isotropy. Their unique characteristic is that they consist of a matrix and reinforcement which both behave nonlinearly. In this work, the in-plane mechanical behavior of both constituents as well as the composite is modeled via the compressible Mooney-Rivlin (MR) constitutive model. Two approaches to homogenize this nonlinear behavior are considered. The first approach, referred to as the linear ROM, applies the ROM to the initial tangent moduli of the constituents, and derives the composite’s MR coefficients from the homogenized initial tangent modulus. The second approach, referred to as the nonlinear ROM, builds on Ogden’s bounds on the strain energy density, and applies the ROM directly to the MR coefficients of the constituents to derive the composite’s MR coefficients. The predictions from both approaches are compared to the embedded element (EE) technique in Abaqus which enforces a kinematic constraint between the explicitly modeled constituents resulting in a parallel model. It is demonstrated that the nonlinear ROM approach properly homogenizes the entire nonlinear stress-stretch curve (both normal and shear), including the nonlinear Poisson effects, and embodies the correct strain energy density (SED). The linear ROM predicts reasonably the normal stress-stretch curve and the SED, but it does not capture Poisson’s ratio and the shear response well and therefore is not recommended. The nonlinear ROM is found to work for a wide range of stretch values, various reinforcement volume fractions, and loading conditions, especially for high stiffness ratios. For lower stiffness ratios (i.e., for a stiffer matrix), the nonlinear stress-stretch curves (normal and shear) and the SED are captured well by the nonlinear ROM, but not the out of plane Poisson effects, due to the assumed isotropy in the Mooney-Rivlin model. Finally, an analogous approach to determine the variational Hashin-Shtrikman bounds on the homogenized Mooney-Rivlin constants is proposed. These variational bounds are found to be tighter compared to the Voigt and Reuss bounds as expected.

Similar content being viewed by others

Availability of data and material (data transparency)

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability (software application or custom code)

NA

References

Agnelli, S., Baldi, F., Bignotti, F., Salvadori, A., Peroni, I.: Fracture characterization of hyperelastic polyacrylamide hydrogels. Eng. Fract. Mech. 203, 54–65 (2018). https://doi.org/10.1002/admi.202070066

Mo, K., Zhang, T., Yan, W., Chang, C.: Tunicate cellulose nanocrystal reinforced polyacrylamide hydrogels with tunable mechanical performance. Cellulose 25(11), 6561–6570 (2018). https://doi.org/10.1007/s10570-018-2025-7

Zhu, J., Guo, P., Chen, D., Xu, K., Wang, P., Guan, S.: Fast and excellent healing of hydroxypropyl guar gum/poly (n, n-dimethyl acrylamide) hydrogels. J. Polym. Sci. B Polym. Phys. 56(3), 239–247 (2018). https://doi.org/10.1002/polb.24514

Lu, H., Zhang, S., Guo, L., Li, W.: Applications of graphene-based composite hydrogels: a review. RSC Adv. 7(80), 51008–51020 (2017). https://doi.org/10.1039/C7RA09634H

Carr, A., Head, A., Boscoboinik, J., Bhatia, S., Eisaman, M.: Graphene/polymer interfaces: direct evidence of graphene-induced molecular reorientation in polymer films (adv. mater. interfaces 12/2020). Adv. Mater. Interf. 7. https://doi.org/10.1002/admi.202070066 (2020)

Yang, X., Zhou, T., Zwang, T., Hong, G., Zhao, Y., Viveros, R., Fu, T-M, Gao, T., Lieber, C.: Bioinspired neuron-like electronics. Nat. Mater 18. https://doi.org/10.1038/s41563-019-0292-9 (2019)

Daniel, I., Ishai, O., Daniel, I., Daniel, I.: Engineering Mechanics of Composite Materials, vol. 3. Oxford university press, New York (1994)

Li, Y., Waas, A.M., Arruda, E.M.: The effects of the interphase and strain gradients on the elasticity of layer by layer (LBL) polymer/clay nanocomposites. Int. J. Solids Struct. 48(6), 1044–1053 (2011). https://doi.org/10.1016/j.ijsolstr.2010.12.008

Raju, B., Hiremath, S.R., Mahapatra, D.R.: A review of micromechanics based models for effective elastic properties of reinforced polymer matrix composites. Compos. Struct. 204, 607–619 (2018). https://doi.org/10.1016/j.compstruct.2018.07.125

Nemat-Nasser, S., Hori, M.: Micromechanics: overall properties of heterogeneous materials, vol. 37. Elsevier (2013)

Li, Y., Waas, A.M., Arruda, E.M.: A closed-form, hierarchical, multi-interphase model for composites-derivation, verification and application to nanocomposites. J. Mech. Phys. Solids 59(1), 43–63 (2011). https://doi.org/10.1016/j.jmps.2010.09.015

Liu, H., Brinson, L.C.: A hybrid numerical-analytical method for modeling the viscoelastic properties of polymer nanocomposites. J. Appl. Mech. 73(5), 758–768 (2005). https://doi.org/10.1115/1.2204961

Birman, V., Kardomateas, G.A.: Review of current trends in research and applications of sandwich structures. Compos. Part B: Eng. 142, 221–240 (2018). https://doi.org/10.1016/j.compositesb.2018.01.027

Ponte Castañeda, P, Lopez-Pamies, O., Castañeda, P P: Homogenization estimates for fiber-reinforced elastomers with periodic microstructures. Int. J. Solids Struct. 44(18-19), 5953–5979 (2007). https://doi.org/10.1016/j.ijsolstr.2007.02.003

Jiménez, F.L., Pellegrino, S.: Constitutive modeling of fiber composites with a soft hyperelastic matrix. Int. J. Solids Struct. 49(3-4), 635–647 (2012)

Yousefsani, S.A., Shamloo, A., Farahmand, F.: Nonlinear mechanics of soft composites: hyperelastic characterization of white matter tissue components. Biomech. Model. Mechanobiol., 1–11 (2019)

Hill, R.: On constitutive macro-variables for heterogeneous solids at finite strain. Proc. R. Soc. Lond. Math. Phys. Sci. 326(1565), 131–147 (1972). https://doi.org/10.1098/rspa.1972.0001

Ball, J.M.: Constitutive inequalities and existence theorems in nonlinear elastostatics. Nonlinear Anal. Mech. Heriot-Watt Symp. 1, 187–241 (1977)

Ogden, R.W.: Extremum principles in non-linear elasticity and their application to composites-I: theory. Int. J. Solids Struct. 14(4), 265–282 (1978). https://doi.org/10.1016/0020-7683(78)90037-9

Ponte Castañeda, P.: The overall constitutive behaviour of nonlinearly elastic composites. Proc. R. Soc. Lond. Math. Phys. Sci. 422(1862), 147–171 (1989). https://doi.org/10.1098/rspa.1989.0023

Ponte Castañeda, E.: A second-order homogenization method in finite elasticity and applications to black-filled elastomers. J. Mech. Phys. Solids 48(6-7), 1389–1411 (2000). https://doi.org/10.1016/s0022-5096(99)00087-3

Li, D., Yao, Y.: An approximate method to predict the mechanical properties of small volume fraction particle-reinforced composites with large deformation matrix. Acta Mech. 230(9), 3307–3315 (2019). https://doi.org/10.1007/s00707-019-02444-5

Holzapfel, G.A., Gasser, T.C., Ogden, R.W.: A new constitutive framework for arterial wall mechanics and a comparative study of material models. J. Elast Phys. Sci. Solids 61(1), 1–48 (2000)

Pandolfi, A., Holzapfel, G.A.: Three-dimensional modeling and computational analysis of the human cornea considering distributed collagen fibril orientations. J. Biomech. Eng 130(6) (2008)

Castaneda, P.P.: Second-order homogenization estimates for nonlinear composites incorporating field fluctuations: I—theory. J. Mech. Phys. Solids 50(4), 737–757 (2002)

Agoras, M., Lopez-Pamies, O., Castañeda, P.P.: A general hyperelastic model for incompressible fiber-reinforced elastomers. J. Mech. Phys. Solids 57(2), 268–286 (2009)

Lopez-Pamies, O., Idiart, M.I.: Fiber-reinforced hyperelastic solids: a realizable homogenization constitutive theory. J Eng Math 68(1), 57–83 (2010)

Aboudi, J., Volokh, K.Y.: Failure prediction of unidirectional composites undergoing large deformations. J Appl Mech 82(7) (2015)

Aboudi, J., Arnold, S.M., Bednarcyk, B.A.: Micromechanics of composite materials: a generalized multiscale analysis approach. Butterworth-Heinemann (2013)

Aboudi, J., Pindera, M-J: High-fidelity micromechanical modeling of continuously reinforced elastic multiphase materials undergoing finite deformations. Math. Mech. Solids 9(6), 599–628 (2004)

Aboudi, J.: Finite strain micromechanical analysis of rubber-like matrix composites incorporating the Mullins damage effect. Int. J. Damage Mech. 18(1), 5–29 (2009)

Bertoldi, K., Lopez-Pamies, O.: Some remarks on the effect of interphases on the mechanical response and stability of fiber-reinforced elastomers. J. Appl. Mech. 79(3). https://doi.org/10.1115/1.4006024 (2012)

Rudykh, S., Debotton, G.: Instabilities of hyperelastic fiber composites: micromechanical versus numerical analyses. J. Elast. 106(2), 123–147 (2011). https://doi.org/10.1007/s10659-011-9313-x

Slesarenko, V., Rudykh, S.: Microscopic and macroscopic instabilities in hyperelastic fiber composites. J. Mech. Phys. Solid 99, 471–482 (2017). https://doi.org/10.1016/j.jmps.2016.11.002

Galich, P.I., Slesarenko, V., Li, J., Rudykh, S.: Elastic instabilities and shear waves in hyperelastic composites with various periodic fiber arrangements. Int. J. Eng. Sci. 130, 51–61 (2018). https://doi.org/10.1016/j.ijengsci.2018.05.003

Arora, N., Batan, A., Li, J., Slesarenko, V., Rudykh, S.: On the influence of inhomogeneous interphase layers on instabilities in hyperelastic composites. Materials 12(5), 763 (2019). https://doi.org/10.3390/ma12050763

R.W., O, H., H: Large deformation isotropic elasticity - on the correlation of theory and experiment for incompressible rubberlike solids. Proc. R. Soc. Lond. Math. Phys. Sci. 326(1567), 565–584 (1972). https://doi.org/10.1098/rspa.1972.0026

Lopez-Pamies, O.: A new ı1-based hyperelastic model for rubber elastic materials. Comptes Rend. Mecanique - C R MEC 338, 3–11 (2010). https://doi.org/10.1016/j.crme.2009.12.007

Sacks, M.S.: Biaxial mechanical evaluation of planar biological materials. J. Elast. Phys. Sci. Solids 61(1), 199–246 (2000)

Kong, T., Wang, L., Wyss, H.M., Shum, H.C.: Capillary micromechanics for core–shell particles. Soft Matter 10(18), 3271–3276 (2014)

Rapoff, A.J., Heisey, D.M., Vanderby, Jr., R.: A probabilistic rule of mixtures for elastic moduli. J. Biomech. 32(2), 189–193 (1999)

Vercher, A., Giner, E., Arango, C., Tarancón, J.E., Fuenmayor, F.J.: Homogenized stiffness matrices for mineralized collagen fibrils and lamellar bone using unit cell finite element models. Biomech. Model. Mechanobiol. 13(2), 437–449 (2014)

Goh, K.L., Holmes, D.F., Lu, H-Y, Richardson, S., Kadler, K.E., Purslow, P.P., Wess, T.J.: Ageing changes in the tensile properties of tendons: influence of collagen fibril volume fraction. J. Biomech. Eng. 130(2) (2008)

Esmizadeh, E., Naderi, G., Ghoreishy, M.H.R.: Modification of theoretical models to predict mechanical behavior of PVC/NBR/organoclay nanocomposites. J. Appl. Polym. Sci. 130(5), 3229–3239 (2013). https://doi.org/10.1002/app.39556

Bencherif, S.A., Srinivasan, A., Horkay, F., Hollinger, J.O., Matyjaszewski, K., Washburn, N.R.: Influence of the degree of methacrylation on hyaluronic acid hydrogels properties. Biomaterials 29(12), 1739–1749 (2008). https://doi.org/10.1016/j.biomaterials.2007.11.047

Wei, X., Fragneaud, B., Marianetti, C., Kysar, J.: Nonlinear elastic behavior of graphene: ab initio calculations to continuum description. Phys. Rev. B 80. https://doi.org/10.1103/PhysRevB.80.205407 (2009)

Papageorgiou, D.G., Kinloch, I.A., Young, R.J.: Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 90, 75–127 (2017). https://doi.org/10.1016/j.pmatsci.2017.07.004

Cao, G.: Atomistic studies of mechanical properties of graphene. Polymers 6(9), 2404–2432 (2014). https://doi.org/10.3390/polym6092404

Hou, X.-H., Xu, X.-J., Meng, J.-M., Ma, Y.-B., Deng, Z.-C.: Elastic constants and phonon dispersion relation analysis of graphene sheet with varied poisson’s ratio. Compos. Part B: Eng. 162, 411–424 (2019). https://doi.org/10.1016/j.compositesb.2018.12.133

Shah, P.H., Batra, R.C.: Elastic moduli of covalently functionalized single layer graphene sheets. Comput. Mater. Sci. 95, 637–650 (2014). https://doi.org/10.1016/j.commatsci.2014.07.050

Saavedra Flores, E., Ajaj, R., Adhikari, S., Dayyani, I., Friswell, M., Castro-Triguero, R.: Hyperelastic tension of graphene. Appl. Phys. Lett. 106, 061901 (2015). https://doi.org/10.1063/1.4908119

Zhou, J., Huang, R.: Internal lattice relaxation of single-layer graphene under in-plane deformation. J. Mech Phys. Solids 56, 1609–1623 (2008). https://doi.org/10.1016/j.jmps.2007.07.013

Jhon, Y., Jhon, Y.M., Yeom, G., Jhon, M.: Orientation dependence of the fracture behavior of graphene. Carbon 66, 619 (2014). https://doi.org/10.1016/j.carbon.2013.09.051

Lee, C., Wei, X., Kysar, J., Hone, J.: Measurement of the elastic properties and intrinsic strength of monolayer graphene. Sci. (New York, N.Y.) 321, 385–8 (2008). https://doi.org/10.1126/science.1157996

Nye, J.F.: Physical properties of crystals. Clarendon Press (1992)

Kumar, N., Rao, V.V.: Hyperelastic Mooney-Rivlin model: determination and physical interpretation of material constants. Parameters 2(10), 01 (2016)

Smith, M.: Abaqus/standard user’s manual, version 2018. Dassault Systèmes Simulia Corp, US (2018)

Rai, A., Subramanian, N., Chattopadhyay, A.: Investigation of damage mechanisms in CNT nanocomposites using multiscale analysis. Int. J. Solids Struct. 120, 115–124 (2017)

Lebedev, O.V., Ozerin, A.N., Abaimov, S.G.: Multiscale numerical modeling for prediction of piezoresistive effect for polymer composites with a highly segregated structure. Nanomaterials 11(1), 162 (2021)

Matveeva, A.Y., Böhm, H.J., Kravchenko, G., van Hattum, F.W.J.: Investigation of the embedded element technique for modelling wavy CNT composites. Comput. Mater. Cont 42, 1–23 (2014)

Rai, A., Subramanian, N., Koo, B., Chattopadhyay, A.: Multiscale damage analysis of carbon nanotube nanocomposite using a continuum damage mechanics approach. J. Compos. Mater. 51(6), 847–858 (2017)

Dolbow, J., Harari, I.: An efficient finite element method for embedded interface problems. Int. J. Numer. Methods Eng. 78(2), 229–252 (2009)

Jancar, J., Douglas, J.F., Starr, F.W., Kumar, S.K., Cassagnau, P., Lesser, A.J., Sternstein, S.S., Buehler, M.J.: Current issues in research on structure–property relationships in polymer nanocomposites. Polymer 51(15), 3321–3343 (2010)

Bernardo, L.F.A., Amaro, A.P.B.M., Pinto, D.G., Lopes, S.M.R.: Modeling and simulation techniques for polymer nanoparticle composites–a review. Comput Mater Sci 118, 32–46 (2016)

Garimella, H.T., Menghani, R.R., Gerber, J.I., Sridhar, S., Kraft, R.H.: Embedded finite elements for modeling axonal injury. Ann. Biomed. Eng. 47(9), 1889–1907 (2019). https://doi.org/10.31224/osf.io/2dx5e

Hashin, Z., Shtrikman, S.: On some variational principles in anisotropic and nonhomogeneous elasticity. J. Mech. Phys. Solids 10(4), 335–342 (1962)

Hashin, Z., Shtrikman, S.: A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 11(2), 127–140 (1963)

Elías-Zúñiga, A., Baylón, K., Ferrer, I., Serenó, L., Garcia-Romeu, M.L., Bagudanch, I., Grabalosa, J., Pérez-Recio, T., Martínez-Romero, O., Ortega-Lara, W., et al.: On the rule of mixtures for predicting stress-softening and residual strain effects in biological tissues and biocompatible materials. Materials 7(1), 441–456 (2014)

Acknowledgements

The authors would like to acknowledge Profs. Matthew Eisaman and Toshio Nakamura of Stony Brook University for their invaluable review of this study.

Funding

This work was supported by Stony Brook University’s Germination Space Funding Award.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study. Conceptualization: (Kedar Kirane). Methodology: (Mersim Redzematovic and Kedar Kirane). Formal analysis and investigation: (Mersim Redzematovic and Kedar Kirane). Writing — original draft preparation: (Mersim Redzematovic). Writing — review and editing: (Kedar Kirane). Funding acquisition: (Kedar Kirane). Resources: (Kedar Kirane). Supervision: (Kedar Kirane)

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Redzematovic, M., Kirane, K. Homogenization of the Mooney-Rivlin coefficients of graphene-based soft sandwich nanocomposites. Mech Soft Mater 3, 6 (2021). https://doi.org/10.1007/s42558-021-00036-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42558-021-00036-9