Abstract

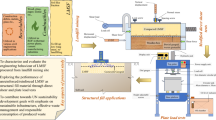

Landfill-mined soil-like fraction (LMSF) is the fraction of legacy municipal solid waste (MSW) obtained from landfill mining. LMSF is emerging as a potential sustainable fill material, due to its soil-like particle size distribution, and availability in large quantities in towns/cities. However, very limited efforts have been made in earlier studies to evaluate the geotechnical properties of LMSF and to ascertain its suitability as a sustainable fill material for various infrastructure projects. In this regard, the present study conducts a detailed experimental investigation to evaluate the physical, chemical, mineralogical, and geotechnical properties of LMSF. It has been noted that the physical properties of LMSF are comparable to well-graded sand with gravel; however, the presence of organic matter introduces some cohesion and compressibility in LMSF. The evaluation of the geotechnical properties of LMSF suggests favourable shear strength characteristics with low compressibility; while the maximum dry unit weight has been observed to be relatively low. It is inferred from the study that LMSF with/without stabilization can be utilized as a potential fill material for different applications such as embankment, reinforced wall, subgrade improvement, general backfill, filling of low-lying areas and structural fill applications for low to moderate loading. Efforts have also been made to understand the sustainability aspects related to the utilization of LMSF in terms of environmental, social, and economic benefits, along with the challenges associated with LMSF. The findings of the study are quite encouraging for exploring LMSF as a sustainable fill material, a small step towards building sustainable infrastructure for the future.

Similar content being viewed by others

Data availability

Data can be made available on request to the corresponding author.

Abbreviations

- AASHTO:

-

American Association of State Highway and Transportation Officials

- As:

-

Arsenic

- ASTM:

-

American Standards for Testing of Materials

- BIS:

-

Bureau of Indian Standards

- c:

-

Cohesion

- C :

-

Economic cost of LMSF

- C’ :

-

Economic cost index

- Cc:

-

Compression index

- Cd:

-

Cadmium

- CPCB:

-

Central Pollution Control Board

- Cr:

-

Slope of unloading curve from consolidation/compression test

- C ref :

-

Economic cost of reference material (Sand)

- CU:

-

Consolidated undrained

- Cu:

-

Copper

- E :

-

Environmental impact of LMSF

- E’ :

-

Environmental impact index

- ECO2 :

-

CO2 Emissions in kg per ton of material

- EDAX:

-

Energy dispersive X-Ray

- EPA:

-

Environmental Protection Agency

- E ref :

-

Environment impact of reference material (sand)

- EU:

-

European Union

- F LP :

-

Leaching potential factor

- FTIR:

-

Fourier transform infrared

- GP:

-

Poorly graded gravel

- GW:

-

Well-graded gravel

- Hg:

-

Mercury

- ICCT:

-

International Council on Clean Transportation

- ICP:

-

Inductively Coupled Plasma

- ICP-MS:

-

Inductively Coupled Plasma Mass Spectroscopy

- IGBC:

-

Indian Green Building Council

- IRC:

-

Indian Road Congress

- IS:

-

Indian Standards

- L :

-

Service life of LMSF

- L’ :

-

Service life index

- LMSF:

-

Landfill-mined soil-like fraction

- L ref :

-

Service life factor of reference material (sand)

- MSW:

-

Municipal solid waste

- Ni:

-

Nickel

- OWC:

-

Optimum water content

- Pb:

-

Lead

- PSD:

-

Particle size distribution

- R :

-

Performance of LMSF

- R’ :

-

Performance Index

- R l :

-

Shear strength of LMSF

- R ref :

-

Performance of reference material (sand)

- R s :

-

Shear strength of sand

- S l :

-

Settlement ratio for LMSF

- SP:

-

Poorly graded sand

- S s :

-

Settlement ratio for sand

- SW:

-

Well graded sand

- UCS:

-

Unconfined compression strength

- UNEP:

-

United Nations Environmental Programme

- US ATSDR:

-

United States Agency for Toxic Substances and Disease Registry

- USEPA:

-

United States Environmental Protection Agency

- UU:

-

Unconsolidated undrained

- WHO:

-

World Health Organization

- XRD:

-

X-ray diffraction

- Zn:

-

Zinc

- Ω:

-

Sustainability coefficient

- Ω′:

-

Dimensionless sustainability coefficient

- ∅ :

-

Friction angle

- γ d :

-

Dry unit weight

- γ d -max :

-

Maximum dry unit weight

- E CO2(Extraction) :

-

CO2 emission due to extraction of material (LMSF/sand)

- E CO2(Transportation) :

-

CO2 emission due to transportation of material (LMSF/sand)

References

AASHTO Section 18 (2000) Soil-thermoplastic pipe interaction systems, Bridge design specifications

Adani F, Tambone F, Gotti A (2004) Biostabilization of municipal solid waste. Waste Manag 24:775–783. https://doi.org/10.1016/j.wasman.2004.03.007

Akbar A, Bhat JA, Mir BA (2021) Plate load tests for investigation of the load–settlement behaviour of shallow foundation on bitumen-coated geogrid reinforced soil bed. Innov Infrastruct Solut 6:80. https://doi.org/10.1007/s41062-020-00397-6

Al-Ghouti MA, Khan M, Nasser MS, Al-Saad K, Heng OE (2021) Recent advances and applications of municipal solid wastes bottom and fly ashes: insights into sustainable management and conservation of resources. Environ Technol Innov 21:101267. https://doi.org/10.1016/j.eti.2020.101267

Andersland OB, Khattak AS, Al-Khafaji AWN (1981) Effect of organic material on soil shear strength, ASTM STP28754S 226-242. https://doi.org/10.1520/STP28754S

Angin I, Aksakal EL, Oztas T, Hanay A (2013) Effects of municipal solid waste compost (MSWC) application on certain physical properties of soils subjected to freeze–thaw. Soil Tillage Res 130:58–61. https://doi.org/10.1016/j.still.2013.02.009

ASTM D427 – 04 (2004) Test Method for shrinkage factors of soils by the mercury method. ASTM international, Conshohocken, PA, US

ASTM D 422 – 63 (2007) Standard test method for particle-size analysis of soils. ASTM International, Conshohocken, PA, US. https://doi.org/10.1520/D0422-63R07E01

ASTM D 2435-04 (2011a) Standard test methods for one-dimensional consolidation properties of soils using incremental loading. ASTM international, Conshohocken, PA, US. https://doi.org/10.1520/D2435-04

ASTM D3080 – 11 (2011b) Standard test method for direct shear test of soils under consolidated drained conditions. ASTM international, Conshohocken, PA, US

ASTM D2974 – 14 (2014a) Standard test methods for moisture, ash, and organic matter of peat and other organic soils. ASTM international, Conshohocken, PA, US. https://doi.org/10.1520/D2974-14

ASTM D854 – 14 (2014b) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM international, Conshohocken, PA, US. https://doi.org/10.1520/D0854-14

ASTM D2487 – 00 (2017) Standard classification of soils for engineering purposes (unified soil classification system). ASTM international, conshohocken, PA, US. https://doi.org/10.1520/D2487-00

ASTM D4318 – 17e1 (2018) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM international, Conshohocken, PA, US. https://doi.org/10.1520/D4318-17E01

ASTM D 2321 – 20 (2020) Standard practice for underground installation of thermoplastic pipe for sewers and other gravity-flow applications. https://doi.org/10.1520/D2321-20

ASTM D3987-12, Standard practice for shake extraction of solid waste with water, ASTM International, West Conshohocken, PA, USA. (2020)

ASTM D698 – 12e2 (2021) Standard test methods for laboratory compaction characteristics of soil using standard effort (12 400 ft-lbf/ft3 (600 kN-m/m3)). ASTM international, Conshohocken, PA, US. https://doi.org/10.1520/d0698-12e02

ASTM D 2850-23 (2023) Standart test method for unconsolidated-undrained triaxial compression test on cohesive soils. ASTM international, Conshohocken, PA, US

Benson CH, Othman MA (1993) hydraulic and mechanical characteristics of a compacted municipal solid waste compost. Waste Manag Res 11:127–142

Bianchini G, Marrocchino E, Tassinari R, Vaccaro C (2005) Recycling of construction and demolition waste materials: a chemical-mineralogical appraisal. Waste Manag. https://doi.org/10.1016/j.wasman.2004.09.005

Bowles JE (1997) Foundation analysis and design, 5th edn. McGraw Hill, Singapore

Bray J, Zekkos D, Kavazanjian E, Athanasopoulos G, Riemer M (2009) Shear strength of municipal solid waste. J Geotech Geoenviron Eng 135(6):709–722

BS 1377-2 (1990) Methods of test for soils for civil engineering purposes - part 2. British standards institution, London.

Chandana N, Goli VSNS, Mohammad A, Singh DN (2021) Characterization and utilization of landfill-mined-soil-like-fractions (LFMSF) for sustainable development: a critical appraisal. Waste Biomass Valor. https://doi.org/10.1007/s12649-020-01052-y

Chen YM, Zhan TLT, Wei HY, Ke H (2009) Aging and compressibility of municipal solid wastes. Waste Manag 29(1):86–95. https://doi.org/10.1016/j.wasman.2008.02.024

Cola S, Cortellazzo G (2005) The shear strength behaviour of two peaty soils. Geotech Geol Eng 23(6):679–695. https://doi.org/10.1007/s10706-004-9223-9

Corcione C, Ferrari F, Striani R, Minosi S, Pollini M, Paladini F, Panico A, Fazio R, Visconti P, Greco A (2019) An innovative green process for the stabilization and valorization of the organic fraction of municipal solid waste. Appl Sci. https://doi.org/10.3390/app9214516

CPCB (2019) Guidelines for disposal of legacy waste (Old Municipal Solid Waste). Central pollution control board. Ministry of environment, forest and climate change. Government of India

CSE (2020) Clean it right: dumpsite management in India (2020). School of circular economy, Anil Agarwal environment training institute (AAETI), Centre for science and environment, New Delhi, India

Davies PJ, Ferguson J, Bubela B (1975) Dolomite and organic material. Nature 255:472–474. https://doi.org/10.1038/255472a0

Dixon N, Jones DRV (2004) Engineering properties of municipal solid waste. Geotext Geomembr. https://doi.org/10.1016/j.geotexmem.2004.11.002

Earthfill and Rockfill Part 645 (2015) Construction inspection national engineering handbook, United States Department of Agriculture

Elshorbagy WA, Mohamed AMO (2000) Evaluation of using municipal solid waste compost in landfill closure caps in arid areas. Waste Manag 20:499–507

EPA530-F-97-001 (1997) Landfill reclamation, United States environmental protection agency, Washington DC, US

Esguerra JL, Krook J, Svensson N, Van Passel S (2019) assessing the economic potential of landfill mining: review and recommendations. Detritus 8:125–140. https://doi.org/10.31025/2611-4135/2019.13883

Goel G, Kalamdhad AS (2017) Degraded municipal solid waste as partial substitute for manufacturing fired bricks. Constr Build Mater 155:259–266. https://doi.org/10.1016/j.conbuildmat.2017.08.067

Goli VSNS, Singh P, Singh DN (2022) Investigations on characteristics of landfill-mined-soil-like-fractions and their dependency on organic matter. Process Saf Environ Prot 162:795–812. https://doi.org/10.1016/j.psep.2022.04.052

Guyer JP (2012) An introduction to fill and backfill for structures. ISBN-13: 978-1980973430

Hogland W (2002) Remediation of an old landfill site: soil analysis, leachate quality and gas production. Environ Sci Pollut Res 1:49–54

Hull R, Krogmann U, Strom P (2005) Composition and characteristics of excavated materials from a New Jersey landfill. J Environ Eng. https://doi.org/10.1061/(ASCE)0733-9372(2005)131:3(478)

Hyun P, Borinara P, Hong KD (2011) Geotechnical considerations for end-use of old municipal solid waste landfills. Int J Environ Res 5(3):573–584

ICCT (2017) Fuel consumption standards for heavy duty vehicles in India: policy update, international council of clean transportation.

IGBC (2014) Measuring the sustainability of our construction products and materials, a short overview, irish green building council, Dublin, Ireland

INCCA Report-2 (2010) Climate change and India: A 4x4 assessment, a sectoral and regional analysis for 2030s, Indian network for climate change assessment (INCCA), ministry of environment and forests government of India

IRC (2020) Guidelines on reducing carbon footprint of road projects, draft version, Indian Road Congress, New Delhi, India

IS 1888 (1982) Code of practice for method of load test on soils, Bureau of Indian standards, New Delhi

IS 10500 (2012) Indian Standard: drinking water — specification. Bureau of Indian Standards, New Delhi 110002

Ivanova LK, Richards DJ, Smallman DJ (2008) The long-term settlement of landfill waste. Waste Res Manag 161(3):121–133. https://doi.org/10.1680/warm.2008.161.3.121

Jain P, Kim H, Townsend T (2005) Heavy metal content in soil reclaimed from a municipal solid waste landfill. Waste Manag 25:25–35. https://doi.org/10.1016/j.wasman.2004.08.009

Kaartinen T, Sormunen K, Rintala J (2013) Case study on sampling, processing and characterization of landfilled municipal solid waste in the view of landfill mining. J Clean Prod 55:56–66. https://doi.org/10.1016/j.jclepro.2013.02.036

Kaza S, Yao L, Bhada-Tata P, Van Woerden F (2018) What a waste 2.0: a global snapshot of solid waste management to 2050. Urban Development Series. Washington, DC: World Bank. https://doi.org/10.1596/978-1-4648-1329–0

Khoshand A, Fall M (2014) Geotechnical characterization of compost based biocover materials. Geotech Geol Eng 32:489–503. https://doi.org/10.1007/s10706-014-9728-9

Krook J, Svensson N, Eklund M (2012) Landfill mining: a critical review of two decades of research. Waste Manag 32:513–520. https://doi.org/10.1016/j.wasman.2011.10.015

Kurian J, Esakku S, Palanivelu K, Selvam A (2003) studies on landfill mining at solid waste dumpsites in India. Ninth international waste management and landfill symposium, Italy, 6–10 October 2003

Ma F, Sha A, Yang P, Huang Y (2016) The greenhouse gas emission from portland cement concrete pavement construction in China. Int J Environ Res Public Health 13:632. https://doi.org/10.3390/ijerph13070632

Marquez AJC, Filho PCC, Rutkowski EW, Isaac R (2019) Landfill mining as a strategic tool towards global sustainable development. J Clean Prod 226:1102–1115. https://doi.org/10.1016/j.jclepro.2019.04.057

Masi S, Caniani D, Grieco E, Lioi DS, Mancini IM (2014) Assessment of the possible reuse of MSW coming from landfill mining of old open dumpsites. Waste Manag 34:702–710. https://doi.org/10.1016/j.wasman.2013.12.013

Mills B, Naggar HE, Valsangkar A (2015) North American overview and a Canadian perspective on the use of tire-derived aggregate in highway embankment construction. Compact Grout Geosynth 22:635–655. https://doi.org/10.1016/B978-0-08-100698-6.00022-2

Monkare T, Palmroth M, Rintala J (2015) Characterization of fine fraction mined from two finish landfills. Waste Manag. https://doi.org/10.1016/j.wasman.2015.02.034

Müller HS, Haist M, Vogel M (2014) Assessment of the sustainability potential of concrete and concrete structures considering their environmental impact. Performance and lifetime. Constr Buildi Mater. https://doi.org/10.1016/j.conbuildmat.2014.01.039

Musson SE, Xu Q, Townsend TG (2008) Measuring the gypsum content of C&D debris fines. Waste Manag 28:2091–2096. https://doi.org/10.1016/j.wasman.2007.09.012

Nag R, Cummins E (2021) Cumulative Health Effects of Metal(loids) through Aggregate Environmental Pathways. EPA Research Programme 2021–2030. Environmental protection agency research report (2021). Government of Ireland.

Naveen BP (2018) Measurement of static and dynamic properties of municipal solid waste at Mavallipura landfill site India. Int J Geo-Eng. https://doi.org/10.1186/s40703-018-0088-9

Oettle N, Matasovic N, Kavazanjian E, Rad N, Conkle C (2010) Characterization and placement of municipal solid waste as engineered fill. Global waste management symposium 2010, San Antonio, Texas

Osinubi K, Bello A (2011) Characterization of shear strength of abandoned dumpsite soils, Orita-Nigeria. Proceedings of the 15th african regional conference on soil mechanics and geotechnical engineering. 293 – 298. https://doi.org/10.3233/978-1-60750-778-9-293

Pappu A, Saxena M, Asolekar SR (2007) Solid wastes generation in India and their recycling potential in building materials. Build Environ 42(6):2311–2320. https://doi.org/10.1016/j.buildenv.2006.04.015

Parrodi J, Höllen D, Pomberger R (2018) Characterization of fine fractions from landfill mining: a review of previous investigations. Multidiscip J Waste Res Residues. 02:46–42. https://doi.org/10.31025/2611-4135/2018.13663

Patel A (2019) Chapter 9: Geotechnical investigation, Geotechnical Investigations and Improvement of Ground Conditions, Woodhead Publishing Series in Civil and Structural Engineering. Doi:https://doi.org/10.1016/B978-0-12-817048-9.00009-3

PIP CVS02100 (2014) Site preparation, excavation, and backfill specification, process industry practices, construction industry institute, University of Texas at Austin, Texas, US

Powrie W, Xu X, Richards D, Zhan L, Chen Y (2019) Mechanisms of settlement in municipal solid waste landfills. J Zhejiang Univ Sci A 20:927–947. https://doi.org/10.1631/jzus.A1900315

Qi J, Ma W, Song C (2008) Influence of freeze–thaw on engineering properties of a silty soil. Cold Reg Sci Technol 53(3):397–404. https://doi.org/10.1016/j.coldregions.2007.05.010

Ramaiah BJ, Ramana GV, Datta M (2017) Mechanical characterization of municipal solid waste from two waste dumps at Delhi, India. Waste Manag. https://doi.org/10.1016/j.wasman.2017.05.055

Rawat P, Mohanty S (2021) Experimental investigation on MSW fine mixed with fibers: fiber reinforced waste. J Hazard Toxic Radioact Waste. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000609

Reddy KR, Gangathulasi J, Parakalla NS, Hettiarachchi H, Bogner JE, Lagier T (2009) Compressibility and shear strength of municipal solid waste under short-term leachate recirculation operations. Waste Manag Res 27:578–587. https://doi.org/10.1177/0734242X09103825

Reddy K, Hettiarachchi H, Gangathulasi J, Bogner J (2011) Geotechnical properties of municipal solid waste at different phases of biodegradation. Waste Manag 31:2275–2286. https://doi.org/10.1016/j.wasman.2011.06.002

Reddy KR, Hettiarachchi H, Giri RK, Gangathulasi J (2015) Effects of degradation on geotechnical properties of municipal solid waste from orchard hills landfill USA. Int J Geosynth Ground Eng. https://doi.org/10.1007/s40891-015-0026-2

Rubinos D, Spagnoli G (2018) Utilization of waste products as alternative landfill liner and cover materials – a critical review. Crit Rev Environ Sci Technol. https://doi.org/10.1080/10643389.2018.1461495

Sanchora P, Pandey DK, Rana D, Materny A, Singh DK (2019) Impact of size and electronegativity of halide anions on hydrogen bonds and properties of 1-Ethyl-3-methylimidazolium-based ionic liquids. J Phys Chem 123(23):4948–4963. https://doi.org/10.1021/acs.jpca.9b04116

Singh MK, Sharma JS, Fleming IR (2009) Shear strength testing of intact and recompacted samples of municipal solid waste. Can Geotech J 46(10):1133–1145. https://doi.org/10.1139/T09-052

Somani M, Datta M, Ramana GV, Sreekrishnan TR (2018) Investigations on fine fraction of aged municipal solid waste recovered through landfill mining: case study of three dumpsites from India. Waste Manag Res. https://doi.org/10.1177/0734242X18782393

Song YS, Yun JM, Hong WP, Kim TM (2003) Investigation of solid waste soil as road construction material. Environ Geol 44:203–209. https://doi.org/10.1007/s00254-002-0746-1

Swati M, Joseph K (2008) Settlement analysis of fresh and partially stabilised municipal solid waste in simulated controlled dumps and bioreactor landfills. Waste Manag 28:1355–1363. https://doi.org/10.1016/j.wasman.2007.06.011

Teplý B, Vymazal T, Rovnaníková P (2018) Methodology for the quantification of concrete sustainability. MATEC Web Conf 174:01006. https://doi.org/10.1051/matecconf/201817401006

Terzaghi K (1943) Theoretical soil mechanics. John Wiley and Sons

Thomas JS, Birat JP (2013) Methodologies to measure the sustainability of materials – focus on recycling aspects. Metall Res Technol 110(1):3–16. https://doi.org/10.1051/metal/2013054

UNEP (2019) Sand and sustainability: finding new solutions for environmental governance of global sand resources, GRID-Geneva, United nations environment programme, Geneva, Switzerland. ISBN No: 978-92-807-3751-6

UNSDG (2015), United nations sustainable development goals. https://sdgs.un.org/goals

USEPA (1994) A plain English guide to the EPA part 503 biosolids rule. Washington, DC. EPA/832/R-93/003

Verma A, Prasad A, Bonal N (2023) Investigation of the long-term shear strength behavior of municipal solid waste fines stabilized with biopolymer: an experimental study. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2023.109805

Vilar O, Carvalho M (2004) Mechanical properties of municipal solid waste. J Test Eval. https://doi.org/10.1520/JTE11945

Wall DK, Zeiss C (1995) Municipal landfill biodegradation and settlement. J Environ Eng. https://doi.org/10.1061/(ASCE)0733-9372(1995)121:3(214)

World Health Organization (2017) Drinking water parameter cooperation project. Support to the revision of Annex I Council Directive 98/83/EC on the quality of water intended for human consumption (drinking water directive), recommendations

Yarbasi N, Kalkan E (2021) Freeze-thaw resistance of fine-grained soils stabilized with waste material mixtures. Int J Sci Eng Appl 10(1):001–006

Zhou C, Gong Z, Hu J, Cao A, Liang H (2014) A cost-benefit analysis of landfill mining and material recycling in China. Waste Manag. https://doi.org/10.1016/j.wasman.2014.09.029

Acknowledgement

The authors wish to sincerely acknowledge the support from Gujarat State Biotechnology Mission, Department of Science and Technology, Government of Gujarat for funding the study as part of a sponsored research project (Project id: L1Y5SU). The authors also wish to thank Ahmedabad Municipal Corporation, Ahmedabad for providing landfill mined material for the study. The authors are also thankful to Dr. Ram Wanare for his support during the procurement of the LMSF material from the landfill mining site. The authors are also thankful to their University, IITRAM for providing the necessary support and facilities for conducting the research work. The authors express their thanks to CRNTS, SAIF, IIT Bombay for facilitating the EDAX analysis of LMSF samples. Thanks, are also extended to MEMS laboratory, IIT Bombay for facilitating the XRD analysis of the LMSF samples. The authors also thank the Central Instrumentation Facility, IIT Gandhinagar for their support for ICP-MS analysis of LMSF samples. The authors acknowledge the FTIR studies (ATR-IR) conducted at IITRAM, Courtesy: SERB-DST project ECR/2016/001289 sponsored FT-IR spectrometer (Make: PerkinElmer, USA).

Funding

Gujarat State Biotechnology Mission (GSBTM), Department of Science and Technology, Government of Gujarat, India, L1Y5SU.

Author information

Authors and Affiliations

Contributions

MP: Review of literature and synthesis of data, experimental work, formal analysis, writing original draft and revising draft. PHD: Review of literature and synthesis of data, experimental work, review and editing of draft. ASR: Support in experimental work, review & editing of the draft. KKRI: Conceptualization, Visualization, Methodology, Formal analysis, Supervision, Review & editing of the draft. TND: Review & editing of the draft.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Patil, M., Dalal, P.H., Reddy, A.S. et al. Evaluation of the geotechnical characteristics of landfill mined soil like fraction (LMSF) for sustainable fill application. Multiscale and Multidiscip. Model. Exp. and Des. (2024). https://doi.org/10.1007/s41939-024-00370-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41939-024-00370-1