Abstract

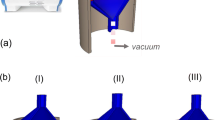

Particle matter and NOx emission are the most significant pollutants of combustion processes, particularly so for the conversion of biomass to energy. Currently, reduction of these pollutants is addressed through particle filters and catalytic processes. Therefore, catalytic activation of filter materials seems to be a practical way to reduce NOx and fine particle emission (PM10) simultaneously at small and medium furnaces. Regularly used methods to achieve this rely on the impregnation process. However, alternatives for materials with low wettability are needed. An alternative developed and discussed in this article consists of simultaneous synthesis of filter and catalyst through hard template sintering, where the catalyst is integrated into the porous medium during the fabrication of the filter. This sintering method provides an integrated catalytic filter. Through this method, up to 2% of catalyst loading was achieved in the synthesis of four catalytic filters. The performance of these new catalysts was evaluated under downscale industrial conditions and compared with an ordinary impregnated catalyst. Finally, a dust aging treatment was applied on the catalysts in order to see the long-term influence of fine dust particles on the NOx conversion.

Similar content being viewed by others

Notes

2.4 Filtration Test on Support Information.

Abbreviations

- E a :

-

Activation energy [J]

- A :

-

Adsorption coefficient [−]

- Ѳ:

-

Coverage [−]

- u :

-

Face velocity [m/s]

- k :

-

Permeability [m2]

- ε:

-

Porosity [−]

- P :

-

Pressure [mBar]

- T :

-

Temperature [°C]

- β :

-

Temperature coefficient [−]

- Fl :

-

Volumetric flow [L/min]

- μ i :

-

Molar fraction of species i [−]

References

Thomas Nussbaumer, Michael Oser: Evaluation of Biomass Combustion based Energy Systems by Cumulative Energy Demand and Energy Yield Coefficient, International Energy Agency IEA Bioenergy Task 32 and Swiss Federal Office of Energy, Verenum press, Version 1.0, Zurich, January 2004

JOINT RESEARCH CENTRE, Institute for Prospective Technological Studies. Seville, “Integrated Pollution Prevention and Control (IPPC) Reference Document on Best Available Techniques in the Large Volume Organic Chemical Industry” (2002)

Heidenreich, S., Nacken, M., Hackel, M., Schaub, G.: Catalytic filter elements for combined particle separation and nitrogen oxides removal from gas streams. Powder Technol. 180(1), 86–90 (2008)

Nova, I., Tronconi, E.: Urea-SCR technology for deNOx after treatment of diesel exhausts. Springer, Berlin (2014)

Narula, C.K., Daw, C.S., Hoard, J.W., Hammer, T.: Materials issues related to catalysts for treatment of diesel exhaust. Int. J. Appl. Ceram. Technol. 2(6), 452–466 (2005)

Liu, G., Gao, P.-X.: A review of NO x storage/reduction catalysts: mechanism, materials and degradation studies. Catal Sci Technol. 1(4), 552–568 (2011)

Nacken, M., Heidenreich, S., Hackel, M., Schaub, G.: Catalytic activation of ceramic filter elements for combined particle separation, NO x removal and VOC total oxidation. Appl. Catal. B Environ. 70(1), 370–376 (2007)

Choi, J.-H., Kim, S.-K., Bak, Y.-C.: The reactivity of V2O5-WO3-TiO2 catalyst supported on a ceramic filter candle for selective reduction of NO. Korean J. Chem. Eng. 18(5), 719–724 (2001)

Vergunst, T., Kapteijn, F., Moulijn, J.A.: Monolithic catalysts—non-uniform active phase distribution by impregnation. Appl. Catal. A Gen. 213(2), 179–187 (2001)

Du, X., Gao, X., Hu, W., Yu, J., Luo, Z., Cen, K.: Catalyst Design Based on DFT Calculations: Metal Oxide Catalysts for Gas Phase NO Reduction. J. Phys. Chem. C. 118(25), 13617–13622 (2014)

Pietrzyk, P., Sojkaab, Z.: DFT modeling and spectroscopic investigations into molecular aspects of DeNO x catalysis. Stud. Surf. Sci. Catal. 171, 27–65 (2007)

Girma, K.B., Lorenz, V., Blaurock, S., Edelmann, F.T.: Coordination Chemistry of Acrylamide. 6 Synthesis and Coordination Compounds of N-Pyrazolylpropanamide-a Versatile Acrylamide-derived Ligand. Z. Anorg. Allg. Chem. 634(2), 267–273 (2008)

Barszcz, B., Głowiak, T., Jezierska, J., Tomkiewicz, A.: Synthesis of new pyrazole-containing binuclear and mononuclear Cu (II) complexes: crystal structure, EPR, magnetic and spectroscopic properties. Polyhedron. 23(8), 1309–1316 (2004)

Zhu, Y., Hua, Z., Zhou, J., Wang, L., Zhao, J., Gong, Y., Wu, W., Ruan, M., Shi, J.: Hierarchical Mesoporous Zeolites: Direct Self-Assembly Synthesis in a Conventional Surfactant Solution by Kinetic Control over the Zeolite Seed Formation. Chem Eur J. 17(51), 14618–14627 (2011)

Lee, Y.-R., Kim, J., Ahn, W.-S.: Synthesis of metal-organic frameworks: A mini review. Korean J. Chem. Eng. 30(9), 1667–1680 (2013)

MacGillivray, L.R.: Metal-organic frameworks: design and application. In: John Wiley \& Sons (2010)

Faust, T.: “Poraver Datenblatt” (2003). [Online]. Available: https://www.poraver.com/us/technical-data-poraver/. Accessed: 10–02-2017.

Shishkin, A.: Synthesis and functionalization of zeolites for NH3-SCR applications. Chalmers University of Technology (2016).

“Filterelement.” [Online]. Available: https://www.mc-techgroup.com/Ersatzteilsuche/#q=filterelement. Accessed: 10–02-2018.

Chal, R., Gérardin, C., Bulut, M., van Donk, S.: Overview and Industrial Assessment of Synthesis Strategies towards Zeolites with Mesopores. ChemCatChem. 3(1), 67–81 (2011)

Davis, M.E., Garcia-Martinez, J., Li, K. (eds.): Mesoporous Zeolites: Preparation, Characterization and Applications. John Wiley \& Sons, Hoboken (2015)

Yampolskii, Y., Freeman, B.: Membrane gas separation. ISBN:9780470665626 . Wiley Online Library, (2010).

Ramachandran, B., Herman, R.G., Choi, S., Stenger, H.G., Lyman, C.E., Sale, J.W.: Protocol for Laboratory Testing of SCR Catalyst Samples. Catal. Today. 55(3), 281–290 (2007)

DIN 66118 (2016-10). Particle Size Analysis - Size Analysis By Air Classification - Fundamentals. German Institute for Standardisation.(2016).

Wegner, Particle Technology Laboratory, Lecture Micro- and NanopaMicro and Nanoparticle Technologie. https://www.ethz.ch/content/dam/ethz/special-interest/mavt/process-engineering/particle-technology-laboratory-dam/documents/lectures/micronano/script/10_MNP_Separations-II_FS18.pdf. (2006). Accessed 4 Nov 2018

Verrein Deutsche Ingeniur. Guideline 2066 BLATT 11. Particulate matter measurement - Dust measurement in flowing gases. (2006).

Boningari, T., Ettireddy, P.R., Somogyvari, A., Liu, Y., Vorontsov, A., McDonald, C.A., Smirniotis, P.G.: Influence of elevated surface texture hydrated titania on Ce-doped Mn/TiO 2 catalysts for the low-temperature SCR of NOx under oxygen-rich conditions. J. Catal. 325, 145–155 (2015)

Andana, T., Piumetti, M., Bensaid, S., Veyre, L., Thieuleux, C., Russo, N., Fino, D., Quadrelli, E.A., Pirone, R.: CuO nanoparticles supported by ceria for NOx-assisted soot oxidation: insight into catalytic activity and sintering. Appl. Catal. B Environ. 216, 41–58 (2017)

Boningari, T., Pappas, D.K., Ettireddy, P.R., Kotrba, A., Smirniotis, P.G.: Influence of SiO2 on M/TiO2 (M= Cu, Mn, and Ce) Formulations for Low-Temperature Selective Catalytic Reduction of NO x with NH3: Surface Properties and Key Components in Relation to the Activity of NO x Reduction S1. Ind Eng. Chem. Res. 54(8), 2261–2273 (2015)

Easterling, Vencon G., "The Effects of Ceria Addition on Aging and Sulfation of Lean NOx Traps for Stand Alone and LNT-SCR Applications" Theses and Dissertations--Chemical and Materials Engineering. 17. (2013).

Yashnik, S.A., Salnikov, A.V., Vasenin, N.T., Anufrienko, V.F., Ismagilov, Z.R.: Regulation of the copper-oxide cluster structure and DeNOx activity of Cu-ZSM-5 catalysts by variation of OH/Cu 2+. Catal. Today. 197(1), 214–227 (2012)

Zhang, R., Liu, N., Lei, Z., Chen, B.: Selective transformation of various nitrogen-containing exhaust gases toward N2 over zeolite catalysts. Chem. Rev. 116(6), 3658–3721 (2016)

Lisi, L., Pirone, R., Russo, G., Stanzione, V.: Cu-ZSM5 based monolith reactors for NO decomposition. Chem. Eng. J. 154(1), 341–347 (2009)

Govender, S., Friedrich, H.B.: Monoliths: A Review of the Basics, Preparation Methods and Their Relevance to Oxidation. Catalysts. 7(2), 62 (2017)

Hasegawa, G.: Studies on porous monolithic materials prepared via sol-gel processes. Springer Science \& Business Media, Berlin (2012)

DIN EN ISO 16890-1:2017-08. Air filters for general ventilation - Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM) (ISO 16890-1:2016) (2017).

Kee, R.J., Coltrin, M.E., Glarborg, P.: Chemically reacting flow: theory and practice. John Wiley \& Sons, Hoboken (2005)

Hedayat, N., Du, Y., Ilkhani, H.: Review on fabrication techniques for porous electrodes of solid oxide fuel cells by sacrificial template methods. Renewable and Sustainable Energy ReviewsVolume 77, Pages 1221-1239. 2007.

Verein Deutsche Ingeneieur. VDI 3677 Blatt 1. “Filtering Separators” (2010).

Hauck, C. Institute for Chemical Technology and Polymer Chemistry, Fakultät für Chemie und Biowissenschaften, Karlsruhe Institute of Technology. “Numerische Simulation von Drei-Wege-Katalysatoren und SCR-Katalysatoren: Untersuchungen zu Einfluss von Alterung und erhӧhtem Druck auf die Aktivität”. PhD Thesis. (2014).

Rammelt, T., Torkashvand, B., Hauck, C., Bӧhm, J., Gläser, R., Deutschmann, O.: Nitric Oxide Reduction of Heavy-Duty Diesel Off-Gas by NH3-SCR in Front of the Turbocharger. Emission Control Science Technology. Issue 4. Pages 1–14. (2017)

Bird, R.B.: Transport phenomena. Appl. Mech. Rev. 55(1), R1–R4 (2002)

Günter, T., Pesek, J., Schäfer, K., Abai, A.B., Casapu, M., Deutschmann, O., Grunwaldt, J.-D.: Cu-SSZ-13 as pre-turbine NOx-removal-catalyst: Impact of pressure and catalyst poisons. Appl. Catal. B Environ. 198, 548–557 (2016)

Karadeniz, H., Karakaya, C., Tischer, S., Deutschmann, O.: Mass transfer effects in stagnation flows on a porous catalyst: Water-gas-shift reaction over Rh/Al2O3. Z. Phys. Chem. 229(5), 709–737 (2015)

Ergüdenler, A., Tang, W., Brereton, C.M., Lim, C.J., Grace, J.R., Gennrich, T.J.: Performance of high-temperature fabric filters under gasification and combustion conditions. Sep. Purif. Technol. 11(1), 1–16 (1997)

Smith, W., Giesse, R.: Design for Filtration Equipment. Ind. Eng. Chem. 53(7), 538–545 (1961)

Acknowledgments

The Bavarian State Ministry for Economic Affairs and Media, Energy and Technology is gratefully acknowledged for the financial support of the project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no competing interests.

Electronic supplementary material

ESM 1

(DOCX 278 kb)

Rights and permissions

About this article

Cite this article

Mateus, G., Meiller, M., Soukup, K. et al. Dust Filtration Influence on the Performance of Catalytic Filters for NOx Reduction. Emiss. Control Sci. Technol. 4, 300–311 (2018). https://doi.org/10.1007/s40825-018-0102-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40825-018-0102-x