Abstract

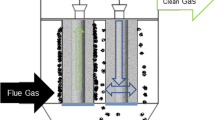

To solve the issues of serious wear, blockage, and poisoning of the catalyst in the denitration process of industrial furnaces such as glass furnaces and cement kiln, it was proposed to integrate the high-temperature dual-layer granular bed filter and the selective catalytic reduction (SCR) reactor into a device to realize the denitration of the SCR catalyst in a dust-free state. In the device, the upper part was a dual-layer granular bed filter and the lower part was a V2O5-WO3/TiO2 honeycomb ceramic catalyst. In the self-built dust removal and denitration integrated test equipment with an inner diameter of 100 mm, the effects of flue gas temperature, flue gas flow rate, nitric oxide (NO) concentration, and catalyst height on the denitration efficiency of the catalyst were investigated by orthogonal testing under dust-free conditions. The results show that the flue gas flow rate had the greatest influence on the denitration efficiency of the catalyst. With an increase in flue gas flow rate, the denitration efficiency first increased and then decreased. When the flue gas flow rate was 0.3 m/s, the denitration efficiency reached a maximum. The denitration test was carried out using flue gas with a dust concentration of 15 g/m3. The results show that the denitration efficiency continued to decrease with the deposition of dust on the catalyst surface (from an initial value of 96.51 to 80.59% at the 140th min), and the pressure drop correspondingly increased from 100 to 630 Pa. Additional integration testing of dust removal and denitration showed that the average dust removal efficiency of the integrated device for dust removal and denitration using a dual-layer granular bed filter could reach 99.84%, and the average denitration efficiency could reach 95.07%.

Similar content being viewed by others

References

Benson, S. A., Laumb, J. D., Crocker, C. R., & Pavlish, J. H. (2005). SCR catalyst performance in flue gases derived from subbituminous and lignite coals. Fuel Processing Technology., 86(5), 577–613. https://doi.org/10.1016/j.fuproc.2004.07.004.

Bemer, D., Subra, I., Morele, Y., Charvet, A., & Thomas, D. (2013). Experimental study of granular bed filtration of ultrafine particles emitted by a thermal spraying process. Journal of Aerosol Science., 63, 25–37. https://doi.org/10.1016/j.jaerosci.2013.04.005.

Chen, L. (2011). Simulation optimization of flow field and reactants blend on denitration reactors. Jinan: Shandong university.

Camposeco, R., Castillo, S., Mugica, V., Mejía-Centeno, I., & Marín, J. (2014). Role of V2O5–WO3/H2Ti3O7-nanotube-model catalysts in the enhancement of the catalytic activity for the SCR-NH3 process. Chemical Engineering Journal., 242, 313–320. https://doi.org/10.1016/j.cej.2014.01.002.

Fino, D., Russo, N., Saracco, G., & Specchia, V. (2004). A multifunctional filter for the simultaneous removal of fly-ash and NOx from incinerator flue gases. Chemical Engineering Science., 59(22-23), 5329–5336. https://doi.org/10.1016/j.ces.2004.09.029.

Guan, Y., & Hu, Y. (2004). The facilities of high-dust SCR installations. Electric Power Technology and Environmental Protection, 04, 25–27 (In Chinese).

Gao, Y. (2013). Experiment and mechanism analysis on selective catalytic reduction deNOx catalyst. Jinan, China: Shandong University.

Gan, L., Guo, F., Yu, J., & Xu, G. (2016). Improved low-temperature activity of V2O5-WO3/TiO2 for denitration using different vanadium precursors. Catalysts. https://doi.org/10.3390/catal6020025.

Heidenreich, S., Nacken, M., Hackel, M., & Schaub, G. (2008). Catalytic filter elements for combined particle separation and nitrogen oxides removal from gas streams. Powder Technology, 180(1–2), 86–90. https://doi.org/10.1016/j.powtec.2007.02.033.

Hu, F., Shi, Q., Ren, D., Wu, X., & Du, C. (2011). Discussion of key technical issues on waste heat recovery from glass-melting furnaces. Journal of Chinese Society of Power Engineering, 31(05), 381–386 (In Chinese).

Heiredal, M. L., Jensen, A. D., Thogersen, J. R., Frandsen, F. J., & Friemann, J.-U. (2013). Pilot-scale investigation and CFD modeling of particle deposition in low-dust monolithic SCR DeNOx catalysts. AIChE Journal, 59(6), 1919–1933. https://doi.org/10.1002/aic.13990.

Lv, H. (2011). Preparation of de-NOx catalysts containing V-W and their application in selective catalytic reduction of NO. Chongqing: Chongqing University.

Li, H. (2014). Selections of denitration catalyst in thermal power generation. Beijing: North China Electric Power University.

Liu, H., Liu, W., Huang, R., Yuan, P., Xi, W., Huang, X., & Wang, G. (2014). Study on performance of deactivated and regenerated catalysts for coal-fired power plant SCR denitration. Electric Power, 47(4), 139–143 (In Chinese).

Li, C. (2017). Research on SCR technology of marine diesel engine NOx. Dalian: Dalian University of Technology.

Liu, L., Ji, Z., & Luan, X. (2018). On-line fault diagnosis of high temperature ceramic filter fracture based on dynamic pressure. Journal of Mechanical Engineering, 54(22), 21–29 (In Chinese).

Li, H., Miao, J., Su, Q., Yu, Y., Chen, Y., Chen, J., & Wang, J. (2019). Improvement in alkali metal resistance of commercial V2O5–WO3/TiO2 SCR catalysts modified by Ce and Cu. Chemical routes to materials, 54, 14707–14719. https://doi.org/10.1007/s10853-019-03919-5.

Mateus, G., Meiller, M., Soukup, K., & Hornung, A. (2018). Dust filtration influence on the performance of catalytic filters for NOx reduction. Emission Control Science and Technology, 4, 300–311. https://doi.org/10.1007/s40825-018-0102-x.

Ma, Q., Zhang, D., & Gan, X. (2019). Simulation of the flow field and the chemical reaction coupling of selective catalytic reduction (SCR) system using an orthogonal experiment. PLoS One, 14(7), e0216138. https://doi.org/10.1371/journal.pone.0216138.

Nacken, M., Heidenreich, S., Hackel, M., & Schaub, G. (2007). Catalytic activation of ceramic filter elements for combined particle separation, NOx removal and VOC total oxidation. Applied Catalysis B: Environmental, 70(1–4), 370–376. https://doi.org/10.1016/j.apcatb.2006.02.030.

Shi, K., Yang, G., Tian, S., Cai, Z., & Xiang, H. (2015). Study of filtration characteristics of PM2.5 by a powder-grain dual-layer granular bed. Journal of China University of Mining & Technology. https://doi.org/10.13247/j.cnki.jcumt.000277.

Shen, W., Yang, G., Liu, P., Yao, Z., Shi, H., Cui, Y., & Li, Z. (2018). Effects of temperature on the filtration characteristics of a dual-layer granular bed filter. Chemical Engineering & Technology., 41(9), 1759–1766. https://doi.org/10.1002/ceat.201800071.

Tian, S., Yang, G., Li, Z., Shi, K., Ding, G., & Hu, F. (2016). Cascade filtration properties of a dual-layer granular bed filter. Powder Technology., 301, 545–556. https://doi.org/10.1016/j.powtec.2016.06.037.

Wang, M. (2012). Experimental study on NH3-SCR denitration by MnOx loaded on bag filter cloth. Jinan: Shandong University.

Wang, X. (2017). Experimental and numerical research on the characteristics of bag filter. Jinan: Shandong University.

Wang, C., Li, C., Li, Y., Lin, H., Liu, Z., Gao, S., & Yu, J. (2019). Destructive influence of cement dust on the structure and DeNOx performance of V-based SCR catalyst. Industrial & Engineering Chemistry Research. https://doi.org/10.1021/acs.iecr.9b04268.

Xun, Q. (2014). Investigation of combining with dust removal and denitrification on the catalyst granular layer. Jinan: Shandong University.

Xiao, G., Yang, G., Yang, Q., & Tian, S. (2018). Effect of filter layer thickness on the filtration characteristics of dual layer granular beds. Powder Technology. https://doi.org/10.1016/j.powtec.2018.05.019.

Yang, G., & Zhou, J. (2007). Experimental study on a new dual-layer granular bed filter for removing particulates. Journal of China University of Mining and Technology., 335, 344–353. https://doi.org/10.1016/S1006-1266(07)60072-8.

Ye, Z., Li, H., Zeng, Y., Zhou, Y., Hu, Y., & Liu, S. (2015). Dust removal and denitration technology and engineering application of glass stove. Technology & Engineering Application, 04, 17–20 (In Chinese).

Yan, P., Zheng, C., Zhu, W., Xu, X., Gao, X., Luo, Z., Ni, M., & Cen, K. (2016). An experimental study on the effects of temperature and pressure on negative corona discharge in high-temperature ESPs. Applied Energy. https://doi.org/10.1016/j.apenergy.2015.11.040.

Yan, P., Weng, W., Zheng, C., Xu, X., Shen, Z., Gao, X., Ni, M., & Ceng, K. (2017). Experimental study on cement kiln dust removal by high-temperature electrostatic precipitator. Journal of Zhejiang University (Engineering Science). https://doi.org/10.3785/j.issn.1008-973X.2017.10.009.

Zhu, R., Guo, M., & Ouyang, F. (2008). Simultaneous removal of soot and NOx over Ir-based catalysts in the presence of oxygen. Catalysis Today., 139(1–2), 146–151. https://doi.org/10.1016/j.cattod.2008.08.017.

Zhang, S., & Xu, Z. (2012). Application of high temperature electrostatic precipitator to glass industry. China Building Material Science and Technology, 05, 18–21 (In Chinese).

Zhang, P., Wu, S., Fang, T., Chen, Y., Shi, Y., & He, Y. (2017). Deactivation and regeneration of commercial SCR catalysts used in a 660 MW coal-fired power plant. Journal of Chemical Engineering of Chinese Universities, 31(05), 1186–1192 (In Chinese).

Zong, L., Dong, F., Zhang, G., Han, W., Tang, Z., & Zhang, J. (2017). Highly efficient mesoporous V2O5/WO3–TiO2 catalyst for selective catalytic reduction of NOx: effect of the valence of V on the catalytic performance. Catalysis Surveys from Asia, 21, 103–113. https://doi.org/10.1007/s10563-017-9229-y.

Funding

This work was sponsored by the K.C. Wong Magna Fund in Ningbo University. Support was also provided by the Student Research and Innovation Project of Ningbo University (2018SRIP1723).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuan, G., Wu, H., Yang, G. et al. Integrated Dust Removal and Denitration Using a Dual-Layer Granular Bed Filter with SCR Catalyst. Water Air Soil Pollut 231, 48 (2020). https://doi.org/10.1007/s11270-020-4418-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-020-4418-0