Abstract

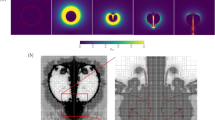

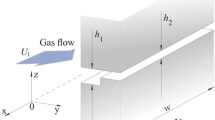

Impinging atomization of two jets is numerically simulated using the GPU (Graphics Processing Unit) accelerated moving particle semi-implicit (MPS) method. The acceleration ratio of the GPU-accelerated code is 11.75, which proves the validity of GPU acceleration. Three jet impact modes under different impinging velocities are successfully simulated. The numerical simulations successfully capture the formation of liquid films, the breaking of liquid films into liquid filaments and the breaking of liquid filaments into droplets. Under the flapping-sheet mode, i.e., the atomization phenomena, simulated atomization parameters such as spray angle, jet breakup length and Sauter mean diameter (SMD) agree well the experiment results, which proves the validity of the GPU-accelerated MPS method in the simulations of atomization problem. Thereafter, the GPU-accelerated MPS code is applied to simulate the impact atomization of double jets under typical 16 working conditions. The impinging velocity and angle can affect the atomization to a great extent. With the increasement of the impinging velocity and angle, the spray angle increases while the jet breakup length and SMD decrease, which indicates that the atomization is intensified. When the impinging momentum ratio and jet diameter ratio are not equal to 1.0, defective atomization occurs. With the increasement of the impinging momentum ratio and jet diameter ratio, the spray angle is almost same and the breakup length and SMD increase.

Similar content being viewed by others

References

Benjamin MA, Jensen RJ, Arienti M (2010) Review of atomization: current knowledge and future requirements for propulsion combustors. Atom Sprays 20(6):485–512

Nasser A (2011) Handbook of atomization and sprays theory and applications. Springer, Boston

Yang L, Zhao F, Fu Q (2014) Liquid sheet formed by impingement of two viscous jets. J Propul Power 30(4):1016–1026

Zhao F, Yang L, Mo C (2016) Characteristics of sheet formed by collision of two elliptical jets at short impact distance. J Fluids Eng 138(5):051201–051210

Zhao F, Yang L, Mo C, Qin L (2017) Spray characteristics of unlike impinging jets. J Propul Power 33(5):1260–1271

Sutton GP, Biblarz O (2016) Rocket propulsion elements. Wiley, Hoboken

Zhang PY, Wang B (2017) Effects of elevated ambient pressure on the disintegration of impinged sheets. Phys Fluids 29(4):392–400

Ryan HM, Anderson WE, Pal S, Santoro RJ (1995) Atomization characteristics of impinging liquid jets. J Propul Power 11(1):135–145

Harrje DT, Reardon FH (1972) Liquid propellant rocket combustion instability. National Aeronautics and Space Administration, Technical Report no. 19720026079

Choo YJ, Kang BS (2003) A study on the velocity characteristics of the liquid elements produced by two impinging jets. Exp Fluids 34(6):655–661

Ciezki H, Tiedt T, Kampen J, Bartels N (2005) Atomization behavior of Newtonian fluids with an impinging jet injector in dependence upon Reynolds and Weber Numbers. In: Proceedings of 41st AIAA/ASME/SAE/ASEE joint propulsion conference: no 4477

Li R, Ashgriz N (2006) Characteristics of liquid sheets formed by two impinging jets. Phys Fluids 18(8):87–104

Inamura T, Shirota M (2014) Effect of velocity profile of impinging jets on sheet characteristics formed by impingement of two round liquid jets. Int J Multiph Flow 60:149–160

Bremond N, Villermaux E (2006) Atomization by jet impact. J Fluid Mech 549:273–306

Kim JS, Kim JS et al (2007) A study on the spray characteristics of a liquid-propellant thruster injector by PIV/PDA optical measurements. In: Proceedings of 5th joint ASME/JSME fluid engineering conference: FEDSM2007-37105

Indiana C, Bellenoue M, Boust B (2015) Experimental investigations of drop size distributions with impinging liquid jets using phase-Doppler anemometer. Int J Energetic Mater Chem Propul 14(3):241–264

Rodrigues NS, Kulkarni V et al (2015) An experimental and theoretical investigation of spray characteristics of impinging jets in impact wave regime. Exp Fluids 56(3):1–13

Ashgriz N, Brocklehurst W, Talley D (2001) Mixing mechanisms in a pair of impinging jets. J Propul Power 17(3):736–749

Rey C, Ducruix S et al (2004) High frequency combustion instabilities associated with collective interactions in liquid propulsion. AIAA/ASME/SAE/ASEE Joint Propul Conf 3518:11–14

Lin SP (2003) Breakup of liquid sheets and jets. Cambridge University Press, Cambridge

Jung K, Khil T, Yoon Y (2006) Effects of orifice internal flow on breakup characteristics of like-doublet injectors. J Propul Power 22(3):653–660

Squire HB (1953) Investigation of the instability of a moving liquid film. J Phys D Appl Phys 4(6):167–169

Hasson D, Peck RE (1964) Thickness distribution in a sheet formed by impinging jets. AICHE J 10(5):752–754

Ma DJ, Chen XD, Khare P, Yang V (2011) Atomization patterns and breakup characteristics of liquid sheets formed by two impinging jets. In: Proceedings of 49th AIAA aerospace sciences meeting including the new horizons forum and aerospace exposition, vol 97, pp 1–14

Chen X, Ma D, Yang V, Popinet S (2013) High-fidelity simulations of impinging jet atomization. Atom Sprays 23(12):1079–1101

Ruan C, Xing F, Huang Y, Xu L, Lu X (2017) A parametrical study of the breakup and atomization process of two impinging liquid jets. Atom Sprays 27(12):1025–1040

Li X, Arienti M, Soteriou MC (2010) Towards an efficient, high-fidelity methodology for liquid jet atomization computations. In: 48th AIAA aerospace sciences meeting including the new horizons forum and aerospace exposition

Chen X, Yang V (2019) Recent advances in physical understanding and quantitative prediction of impinging-jet dynamics and atomization. Chin J Aeronaut 32(1):45–57

Monaghan JJ (1994) Simulating free surface flows with SPH. J Comput Phys 110(2):399–406

Koshizuka S, Oka Y (1996) Moving-particle semi-implicit method for fragmentation of incompressible fluid. Nucl Sci Eng 123(3):421–434

Chen X, Xi G, Sun ZG (2014) Improving stability of MPS method by a computational scheme based on conceptual particles. Comput Methods Appl Mech Eng 278:254–271

Shibata K, Masaie I, Kondo M et al (2015) Improved pressure calculation for the moving particle semi-implicit method. Comput Part Mech 2:91–108

Duan G, Chen B, Zhang X et al (2017) A multiphase MPS solver for modeling multi-fluid interaction with free surface and its application in oil spill. Comput Methods Appl Mech Eng 320:133–161

Duan G, Chen B, Koshizuka S et al (2017) Stable multiphase moving particle semi-implicit method for incompressible interfacial flow. Comput Methods Appl Mech Eng 318:636–666

Khayyer A, Gotoh H, Falahaty H et al (2018) An enhanced ISPH-SPH coupled method for simulation of incompressible fluid-elastic structure interactions. Comput Phys Commun 232:139–164

Gotoh H, Khayyer A, Ikari H, Hori C (2014) 3D-CMPS method for improvement of water surface tracking in breaking waves. Coastal dynamics 2009-impacts of human activities on dynamic coastal processes

Gou W, Zhang S, Zheng Y (2019) Implementation of the moving particle semi-implicit method for free-surface flows on GPU clusters. Comput Phys Commun 244:13–24

Shuai Z, Koji M, Noriyuki S, Yuichi Y (2009) Improvement of basic fluid dynamics models for the COMPASS code. J Power Energy Syst 3(1):313–320

Shibata K, Masaie I, Kondo M, Murotani K, Koshizuka S (2015) Improved pressure calculation for the moving particle semi-implicit method. Comput Part Mech 2(1):91–108

Swegle J W (2000) Conservation of momentum and tensile Instability in particle methods. SANDIA technical report no. SAND 2000-1223

Tsuruta N, Khayyer A, Gotoh H (2013) A short note on dynamic stabilization of moving particle semi-implicit method. Comput Fluids 82(17):158–164

Khayyer A, Gotoh H, Shimizu Y (2017) Comparative study on accuracy and conservation properties of two particle regularization schemes and proposal of an optimized particle shifting scheme in ISPH context. J Comput Phys 332:236–256

Kondo M, Koshizuka S, Suzuki K et al (2007) Surface tension model using inter-particle force in particle method. Fluids Eng Div Summer Meet 42886:93–98

Inamura T, Shirota M (2014) Effect of velocity profile of impinging jets in sheet characteristics formed by impingment of two round liquid jets. Int J Multiph Flow 60:149–160

Jianan Li, Jun F, Weidong Y et al (2016) Quasi-direct numerical simulation on atomization characteristics of impinging jets injectors. J Propul Technol 37(4):713–725

Zhang Mengzheng Fu, Yonggui ZZ et al (1999) Spray property research and application of unlike impinging injector. J Propul Technol 20(2):73–76

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, S., Gou, W., Wang, Y. et al. Direct numerical simulation of atomization by jet impact using moving particle semi-implicit method with GPU acceleration. Comp. Part. Mech. 9, 499–512 (2022). https://doi.org/10.1007/s40571-021-00424-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-021-00424-y