Abstract

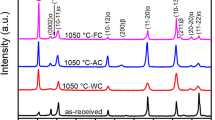

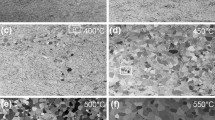

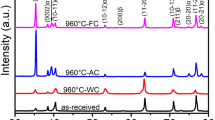

In this paper, electron backscatter diffraction and various other characterization and analysis techniques including X-ray diffraction, electron channeling contrast imaging and energy-dispersive spectrometry were jointly employed to investigate microstructural and textural changes of a hot-rolled Ti–6Al–4V (TC4) sheet after annealing at 800 °C for 5 h. In addition, the hardness variation induced by the annealing treatment is rationalized based on revealed microstructural and textural characteristics. Results show that the TC4 sheet presents a typical dual-phase (α + β) microstructure, with α-Ti as the major phase and short-rod-shaped β-Ti (minority) uniformly distributed throughout the α matrix. Most of α grains correspond to the un-recrystallized structures with a typical rolling texture (c//TD and <11–20>//ND) and dense low angle boundaries (LABs). After the annealing, the stored energy in the as-received specimen is significantly reduced, along with greatly decreased LABs density. Also, the annealing allows recrystallization and grain growth to occur, leading to weakening of the initial texture. Furthermore, the water quenching immediately after the annealing triggers martensitic transformation, which makes the high-temperature β phases be transformed into submicron α plates. The hardness of the annealed specimen is 320.5 HV, lower than that (367.0 HV) of the as-received specimen, which could be attributed to reduced LABs, grain growth and weakened texture. Nevertheless, the hardening effect from the fine martensitic plates could help to suppress a drastic hardness drop.

Similar content being viewed by others

References

P. Singh, H. Pungotra, N.S. Kalsi, Mater. Today Proc. 4, 8971 (2017)

D. Banerjee, J.C. Williams, Acta Mater. 61, 844 (2013)

R.R. Boyer, Mater. Sci. Eng. A 213, 103 (1996)

S. Dai, Y. Wang, F. Chen, Mater. Charact. 104, 16 (2015)

M. Peters, J. Kumpfert, C.H. Ward, C. Leyens, Adv. Eng. Mater. 5, 419 (2003)

P. Guo, Y. Zhao, W. Zeng, Rare Met. Mater. Eng. 44, 277 (2015)

F.J. Gil, M.P. Ginebra, J.M. Manero, J.A. Planell, J. Alloys Compd. 329, 142 (2001)

L. Zeng, T.R. Bieler, Mater. Sci. Eng. A 392, 403 (2005)

T. Fang, W. Wang, Mater. Chem. Phys. 56, 35 (1998)

P. Guo, Y. Zhao, W. Zeng, Q. Hong, Mater. Sci. Eng. A 563, 106 (2013)

G. Lütjering, Mater. Sci. Eng. A 243, 32 (1998)

S. Sun, Y. Zong, D. Shan, B. Guo, Trans. Nonferr. Met. Soc. China 20, 2181 (2010)

X. Peng, H. Guo, T. Wang, Z. Yao, Mater. Sci. Eng. A 533, 55 (2012)

S. Wang, X. Wu, Mater. Des. 36, 663 (2012)

N. Bozzolo, N. Dewobroto, T. Grosdidier, P. Barbéris, F. Wagner, Mater. Sci. Forum 467–470, 441 (2004)

N. Kherrouba, M. Bouabdallah, R. Badji, D. Carron, M. Amir, Mater. Chem. Phys. 181, 462 (2016)

M. Yang, G. Wang, T. Liu, W.J. Zhao, D.S. Xu, Acta Metall. Sin. (Engl. Lett.) 30, 745 (2017)

T. Karthikeyan, A. Dasgupta, R. Khatirkar, S. Saroja, I. Samajdar, M. Vijayalakshmi, Mater. Sci. Eng. A 528, 549 (2010)

G.C. Obasi, S. Birosca, J. Quinta Da Fonseca, M. Preuss, Acta Mater. 60, 1048 (2012)

S.A. Souza, R.B. Manicardi, P.L. Ferrandini, C.R.M. Afonso, A.J. Ramirez, R. Caram, J. Alloys Compd. 504, 330 (2010)

T. Ahmed, H.J. Rack, Mater. Sci. Eng. A 243, 206 (1998)

Y. Ning, B. Xie, H. Liang, H. Li, X. Yang, H. Guo, Mater. Des. 71, 68 (2015)

H. Liu, K. Nakata, J. Zhang, N. Yamamoto, J. Liao, Mater. Charact. 65, 1 (2012)

S. Malinov, W. Sha, Z. Guo, C. Tang, A. Long, Mater. Charact. 48, 279 (2002)

A.C. Lewis, S. Wright, JOM 65, 1221 (2013)

L. Chai, S. Wang, B. Luan, Q. Liu, Sci. China Technol. Sci. 59, 673 (2016)

Y.B. Chun, M. Battaini, C.H.J. Davies, S.K. Hwang, Metall. Mater. Trans. A 41, 3473 (2010)

G.S. Dyakonov, S. Mironov, S.V. Zherebtsov, S.P. Malysheva, G.A. Salishchev, A.A. Salem, S.L. Semiatin, Mater. Sci. Eng. A 607, 145 (2014)

F. Bridier, D.L. McDowell, P. Villechaise, J. Mendez, Int. J. Plast. 25, 1066 (2009)

M. Zhang, F. Bridier, P. Villechaise, J. Mendez, D.L. McDowell, Acta Mater. 58, 1087 (2010)

S. Wronski, M. Jedrychowski, J. Tarasiuk, B. Bacroix, Mater. Sci. Eng. A 692, 113 (2017)

Y. Wang, W. He, N. Liu, A. Chapuis, B. Luan, Q. Liu, Mater. Charact. 136, 1 (2018)

L. Chai, H. Wu, Z. Zheng, H. Guan, H. Pan, N. Guo, B. Song, J. Alloys Compd. 741, 116 (2018)

P. Luo, D.T. McDonald, W. Xu, S. Palanisamy, M.S. Dargusch, K. Xia, Scr. Mater. 66, 785 (2012)

F. Guo, H. Yu, C. Wu, Y. Xin, C. He, Q. Liu, Sci. Rep. 7, 8647 (2017)

X. Gao, L. Zhang, J. Liu, J. Zhang, Mater. Sci. Eng. A 559, 14 (2013)

Z. Tarzimoghadam, S. Sandlöbes, K.G. Pradeep, D. Raabe, Acta Mater. 97, 291 (2015)

Acknowledgements

This work was supported by the Fundamental and Cutting-Edge Research Plan of Chongqing (cstc2017jcyjAX0114 and cstc2015jcyjBX0048), the Scientific and Technological Research Program of Chongqing Municipal Education Commission (KJ1600924) and the Education Reform Project for Professional Degree Graduate of Chongqing University of Technology (ZSSD103).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Xia, JY., Chai, LJ., Wu, H. et al. EBSD Study of Microstructural and Textural Changes of Hot-Rolled Ti–6Al–4V Sheet After Annealing at 800 °C. Acta Metall. Sin. (Engl. Lett.) 31, 1215–1223 (2018). https://doi.org/10.1007/s40195-018-0768-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0768-7