Abstract

The promotion of enhanced gas recovery (EGR) and CO2 storage is still shrouded in contention and is not well accepted, due to the excessive in situ CO2 mixing with the nascent natural gas. This adulterates the recovered CH4 and thus results in a high sweetening process cost thereby making the technique impractical. This has not only limited the field application of EGR in actual projects to a few trails but renders it uneconomical. This study aims to present, experimentally, alternating N2 injection as a potential technique for EGR and CO2 storage in sandstone rock cores. A laboratory core flooding experiment was carried out to simulate a detailed process of unsteady-state methane (CH4) displacement using Bandera grey core plug. This was carried out at 40 °C, 1500 psig, and 0.4 ml/min injection rate by alternative injection of N2 and CO2 in succession designed to suit the application based on optimum operating conditions. The results show that both CO2 storage capacity and CH4 recovery improved significantly when gas alternating gas (GAG) injection was considered. The best results were observed at lower N2 cushion volumes (1 and 2 PV). Therefore, the GAG injection method with N2 as cushion gas can potentially increase both CO2 storage and CH4 recovery of the gas reservoir. This technique if employed will assert the current position and provide vital information for further researches aimed at promoting environmental sustainability and economic viability of the EGR and CO2 sequestration processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

CO2 emissions are generalized as a significant factor responsible for inhibiting climate change that later results to increase in environmental temperature (global warming). It was predicted that there will be a rise in world temperature and sea level from 1.9 to 3.5 °C and 18–30 cm, respectively, by the year 2100. These would be accompanied by many foreseen distresses (Meehl et al. 2005). The effective simultaneous enhanced gas recovery and sequestration using CO2 injection are losing recognition due to high natural gas contamination, premature breakthrough, and high compression ratio, since it requires about six (6) molar volume of it to displaced one (1) molar volume of natural gas, thereby hindering its market and calorific which eventually render the process non-economically viable. In contrast, N2 can be recovered mostly from the air separation unit (ASU) or as byproducts of oxygen plants. It requires less compression ratio, which is why a lower amount of it is needed to create high pressure in the CH4 reservoir.

The increase in carbon credit, coupled with earlier energy demand due to population growth, has forced the exploitation of alternative sources of energy, using other fewer or zero-emission technologies (Abba et al. 2017). Natural gas is considered one of the abundant, low emission, cleanest, and affordable sources of fossil fuels (Benson et al. 2005; Al-Abri et al. 2012). Carbon dioxide (CO2) underground storage for simultaneous storage and natural gas (CH4) displacement is gaining attention worldwide (Ganjdanesh and Hosseini 2017; Raza et al. 2017). This underground storage can be in the form of oil and gas conventional reservoirs or deep saline aquifers (Abba et al. 2018). Conventional natural gas reservoirs have the potential to safely store anthropogenic CO2, due to its proven integrity of gas storing capability (Kalra and Wu 2014). Thus, in turn, issues of CO2 leakages and contamination of adjacent freshwater aquifers are minimal. This arises the need for the development of other injection techniques capable of enhancing both natural gas recovery and CO2 storage (Abba et al. 2018).

Tertiary enhanced gas recovery (EGR) and storage by CO2 injection are gaining recognition within the research environment due to its greenhouse gases (GHGs) reduction potential. Therefore, both nitrogen (N2) and CO2 can be used to increase nascent HCs yield from oil and gas reservoirs. However, CO2 drawbacks are mainly excessive mixing and high compression ratio, thus hindering the overall process uneconomically viable. In contrast, N2 can be recovered virtually from the atmospheric air, through air separation units. It requires less compression ratio than CO2, which is why a lower amount of it was needed to create high pressure in the CH4 reservoir.

The promotion of EGR is still at its infant stage due, to the excessive mixing between the injected (displacing fluid) CO2 and the nascent displaced fluid (natural gas) during the flooding process (Oldenburg and Benson 2002; Shtepani 2006; Turta et al. 2007; Sim et al. 2008, 2009; Al-abri et al. 2009; Sidiq et al. 2011; Hughes et al. 2012; Honari et al. 2013, 2015, 2016; Khan et al. 2013; Zhang et al. 2014; Patel et al 2016). This adulterates the recovered natural gas and thus reduces its heating and market value, which results in the high cost of the sweetening process to maintain its market value (Oldenburg and Benson 2002; Sim et al. 2009). This has not only limited the EGR project to a few pilot trials (Pooladi-Darvish et al. 2008) but also made the process apparently uneconomical due to unprecedented mixing with the displaced gas, which make the phenomenon to be poorly understood (Patel et al. 2016). Thus, finding a suitable technique for reducing such in situ mixing could be valuable at first by injecting a certain amount of nitrogen gas as cushion gas before the invention of CO2, which is the concept behind gas alternating gas injection.

Several authors (Xidong et al. 2019; Hughes et al. 2012; Janssen et al. 2018; Abba et al. 2018) have carried out an extensive study on how to delay CO2 breakthrough time during EGR process. Among them, Abba et al. (2018) and Xidong et al. (2019) were able to achieve reasonable improvement. Abba et al., (2018) use varying connate water concentration and was able to delay CO2 breakthrough by 20 min at a concentration of 10 wt.% sodium chloride (NaCl). On the other hand, Gu et al. (2019) use different mole ratios of CO2/N2 mixture gases in coalbed core samples. They reveal that injection of N2-rich mixtures contributes to preventing the nascent early breakthrough of injected CO2 and safely stored large volumes of CO2 into the shale sediment over the long term. Abba et al. (2019) achieved a high percentage of total CO2 injected stored at 10 wt.% salinity using solubility trapping mechanism, but with least CH4 recovery resulted from the density of connate water sealing off the narrow pore spaces within the pore matrix.

To our knowledge, no established efficient method capable of improving simultaneous natural gas recovery and CO2 storage has been highlighted. This necessitated the need for an in-depth study to develop novel approaches and ways to minimizing this complex phenomenon of gas mixing during gas–gas displacements since the two gases (CO2 and CH4) are miscible in all outcomes (Abba et al. 2018). This study aims to highlight, experimentally, the potential of using N2 as cushion gas in a novel gas alternating gas (GAG) technique to reduce or minimize excessive mixing during EGR by CO2 injection, thereby improving CH4 recovery while subsequently storing substantial volumes of CO2 in conventional natural gas reservoirs.

Dispersion theory and equation

The term Péclet number, Pe, is a dimensionless measure of the level of dispersion by a solute which is defined as the ratio of advective to dispersive processes (Rose 1973) as reported by (Ho and Webb 2006). The degree or level of dispersion is inversely proportional to the magnitude of the Péclet number. At low Péclet numbers, the degree of dispersion is large. It is expressed as in Eq. (1).

Péclet number (ratio of convection to dispersion), L is the core sample length.

In 1963, Perkins and Johnston denoted different termed to Péclet number called medium Péclet number (Pem). Its value generally determined and describes the dominant displacement fluid region as the dispersion process progresses shown in Eq. (2):

where Pem is medium Péclet number, u = is the mean interstitial velocity (m/s), D is the diffusion coefficient (m2/s), and d is the porous medium characteristic length scale, termed as the medium-grain diameter of the sand pack, but it is poorly defined in consolidated medium (Hughes et al. 2012).

Ideally when Pem < 0.1 diffusion becomes dominants, while advective mixing dominates the dispersion process at higher medium Péclet number i.e. at Pem > 10.

Delgado, in 2001, uses the Lambda function, by plotting a graph of Lambda at different experimental times against the percent of displacing fluid in an arithmetic probability paper. The dispersion coefficient was then evaluated using Eq. (3).

where KL = longitudinal dispersion coefficient (m2/s), \(u = \frac{Q}{{\pi r^{2} \phi }}\) is the average interstitial velocity (m/s), and \(\phi\) is the porosity, L = length of porous media (m), λ90 and λ10 = are values of Lambda function at 10 and 90% effluent concentration. In this research, the lambda function techniques were used, as the fundamental equation was derived by considering inert gas (N2) as one of the displacing fluids.

Diffusion theory and equation

The diffusion coefficient (D) signifies the extent or magnitude at which a substance or fluid disperses through a unit area (m2) per unit time (s) at a given or defined unit concentration gradient. The proposed empirical model which relates the molecular diffusion, temperature, and pressure for empirical diffusion coefficient determination as revealed by (Hughes et al. 2012; Liu et al. 2015) was developed by Takahashi and Iwasaki in 1970. Also, this empirical equation has been tested by various researchers in determining the real and accurate diffusivity using Eq. (4) at conditions applicable to EGR by CO2 injection. The diffusion coefficient of CO2 in CH4 was dignified at 298–348 K and pressures of 5–15 MPa in a porous bronze plug (Takahashi and Iwasaki 1970). The results were well within the range of conditions applicable to EGR (Abba et al. 2017).

where \(D_{{{\text{CO}}_{2} ,{\text{CH}}_{4} }}\) is the molecular diffusion coefficient of CO2 in pure CH4 calculated in m2 s−1 with P in MPa and T in K. The absolute average deviation (AAD) of this correlation from the experimental data was 1.5% over the range of 298–348 K and 5–15 MPa (Abba et al. 2017, 2018). In this study, a different model was used to cater for the inclusion of nitrogen (N2) gas during the natural gas displacement and CO2 sequestration. This model equation is presented in Eq. 5. A correlation formula obtained by Fuller et al. (1966) by means of computer-aided correlation of 340 experimental points is expressed as:

where (∑ \(V_{{N_{2} }}\)) and (∑ \(V_{{CH_{4} }}\)) are the values derived from the summation of atomic diffusion volumes of N2 and CH4 molecules, respectively. These values and other simple molecules are presented in Table 1.

The equation was further simplified after inserting the values of atomic diffusion volumes and the molecular weight of nitrogen and methane. The same was applied for carbon dioxide and methane displacement mechanism. These simplified equations are presented in Eqs. (6) and (7)

where T and P are temperatures and pressure in Kelvin (K) and megapascal (MPa), respectively. For example, at the same temperature and pressure, Eq. (7) was validated using the experimental work of Abba et al, 2018. The molecular diffusion coefficient (\(D_{{{\text{CO}}_{2} ,{\text{CH}}_{4} }}\)) was found to be 22.52 × 10–8 m2/s. This value is 0.18% in absolute average deviation (AAD) when compared with Abba et al. (2018) findings.

Materials description

In this research, an experimental study approach using the core flooding system was investigated. This entitles saturating the core plug with CH4 and the injection of CO2 at different N2 gas cushion volumes. The core plug use was Bandera grey sandstone as presented in Table 2.

Materials

The core plug of dimension 1.0 inch diameter and 3.0 inch length was used as present in Table 2. This sandstone is considered a classic sedimentary rock primarily comprised of quartz, silica, and sand-sized minerals. For consistency, the porosity and permeability of the sandstone core samples were determined and compared with the ones provided by the supplier (Kocurek Industries INC, Hard Rock Division, 8535 State Highway 36 S Caldwell, TX 77836, Texas USA). The research-grade CO2, N2, and CH4 with a purity greater than 99.99% were sourced from BOC UK.

Experimental method

A sequence of experimental tests was carried out to investigate the potential of N2 as cushion gas for enhanced CH4 recovery and CO2 storage during core flooding experiment with Bandera grey core plug as the porous medium. Prior to the experiment, the core plug petrophysical properties were evaluated to endured are in synergy with the ones from the vendor. The flow behaviour of supercritical N2, CO2, and N2–CO2–CH4 interplay was studied using FLUIDATR thermodynamic software. This was vital, in understanding the flow behaviour of supercritical CO2 as it plumes transverses the pore spaces within the porous medium while displacing the nascent CH4, especially with the N2 as cushion gas. Followed to that, a laboratory core flooding experiment was conducted on the Bandera grey core plug to determine the dispersion coefficient, CH4 recovery, and percent of the CO2 injected stored of the system at different CO2 injections and N2 cushion volumes. Further to that, several runs were carried out at four different N2 cushion volumes at varying CO2 injection rates. The effluent stream rates from the core plug were recorded by the two (low and high) gas flow meters. After this, the produced gas compositions are analysed using the Agilent technologies 7890 A model gas chromatography (GC) system at an interval of 5 min elusion time through the sampling valve. The combined data are used to evaluate: one, dispersion coefficient; two, CH4 recovery; and three; percent of total CO2 injected stored at the test reservoir conditions of 1500 psig pressure and 40 °C temperature.

Apparatus and procedure

Apparatus

The experimental set-up consists of mainly two individual units; a core lab UFS-200 core flooding system with inbuilt Smart Flood software and packed column design Agilent 7890A gas chromatography (GC) machine model. The core flooding system, designed for 2-phase liquid/gas steady or unsteady state condition displacements, was reconfigured to accommodate additional N2 as used in the gas alternating gas injection for this study. The integrated online concentration measurement of core flooding effluents was achieved using the GC machine. These values were used in plotting the injection fluids concentration profile as the experiment progress with time. A schematic of the equipment set-up is presented in Fig. 1.

The UFS-200 core flooding system is rated to 5000 and 3750 psig overburden and pore pressure, respectively. The injection system of the equipment is made up of a pair of dual ISCO two-barrel metering pump system (A/B and C/D) for constant flow for pulseless transition and to maintain an accurate flow rate range of 0 to 200 ml/min with a maximum pressure rating of 3750 psig. The pumps are attached to a pair of two stainless-steel floating piston accumulators which are also rated for 5000 psig working pressure and temperature of 177 °C. They are designed for injection of the fluids of interest and can withstand up to 7500 psig test pressure. The hydraulic pump with a maximum of 10,000 psig pressure output was used to set the overburden confining pressure. The Smart Flood 1.0 software forms an essential unit of the system which interfaces the UFS system and the computer data-acquisition-control (DAC) system hardware and generates on-screen automatic logging of test data for all measured values like pressures, temperatures, volumes, etc., to a computer data file. A Rosemount Static DP transmitter with an accuracy of 0.0055% was responsible for measuring the differential pressures across the entire Hassler-type core holder, which was used to house the core sample. The core sample is clutch inside the core holder by a Viton rubber sleeve. A core holder heat jacket to simulate the required temperature was also employed with an accuracy of 0.1%. Dome type back pressure regulator integrated into the flooding system ensured the confinement of the desired pressures within the core holder. Such desired pressure was set using the N2 cylinder bottle. The effluents from the back-pressure regulator pass through the mass flow controllers that measure the volume of the actual effluents produced before been analysed by the GC system in place.

Procedure

The core sample was dried overnight in an oven at 105 °C for moisture removal and other volatile compounds. The dried sample was wrapped with cling film and in foil paper before inserted into a heat shrink. This is vital to avoid viscous fingering and the penetration of the gases through the sleeve into the ring-shaped core holder. It was then loaded into the core holder and staple with clamps from both ends. Hydraulic oil was then pumped into the ring-shaped core holder to provide the desired overburden pressure, which was kept 500 psig above the pore pressures to in other to avoid fracturing of the core sleeve. The heat jacket was then installed on the core holder and the temperature step-up was observed. The backpressure was engaged and CH4 was slowly injected into the core sample from the CH4 cylinder to saturate the core plug until the GC constantly read methane > 99%. N2 is then injected as cushion gas for about 20 min (1 PV) before the invention of CO2 at 0.4 ml/min injection rate. Further runs were carried out at increasing N2 cushion volumes. The experiment elapsed when the methane concentration was insignificant from the GC reading or the CO2 concentration was > 99%. At each injection time of the GC, the time was noted and the effluent composition which is then used to evaluate the dispersion coefficient, CH4 recovery, and percent of total CO2 injected stored was recorded. The investigation was carried out at 1500 psig pressure and 40 °C temperature. This condition was chosen based on a normal gas pressure reservoir with a gradient of 0.451 psi/ft, an average reservoir depth of 1 km, and a geothermal temperature of 35–40 °C/km. The core sample was dried overnight in an oven at 105 °C for moisture removal and other volatile compounds. The dried sample was wrapped with cling film and in foil paper before inserted into a heat shrink.

Results and discussion

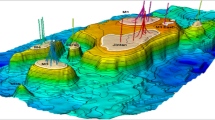

Flow behaviour of supercritical N2, CO2, and N2–CO2–CH4 during simulated EGR

The actual flow behaviour of supercritical CO2 as it plumes traverses the pore spaces within the core sample to displace the in situ methane is quite complex, especially with the inclusion of inert nitrogen gas. Investigating these complexities of displacing fluids (CO2 and N2) with regard to the nascent CH4 is vital in understanding the trends and expected outcomes of the displacement process knowing that these gases in their supercritical state have unique behaviour by exhibiting the density of a liquid but retain the viscosity of a gas (Abba et al. 2018). CO2 is 2–6 times denser than methane at all relevant reservoir conditions. Besides, CO2 had a lower mobility ratio compared to methane; thus, it was considered as a high viscosity component (Al-Hasami et al. 2005). Due to the favourability of these properties, CO2 would be migrated downwards, and this relatively would stabilize the displacement process between the injected CO2 and methane initially in place (Oldenburg and Benson 2002). The supercritical conditions of CO2, N2, and CH4 are (31.05 °C and 73.80 bar), (− 146.9 °C and 33.90 bar), and (− 82.55 °C and 46 bar), respectively. The experimental conditions employed in this study are well above that of the supercritical temperature and pressure of each single species. The fluids exhibit excellent behaviour due to the response on their transport properties to change from ambient standard conditions to that of EGR condition. A simulation of their respective properties at elevated operational conditions was carried out using FLUIDATR software to check the effects of temperature and pressure on the individual gas densities and viscosities at the stated conditions as presented in Fig. 2, 3, and 4. There are pronounced differences in their properties, with CO2 being much higher and more extreme than those of N2 and CH4. The density was said to increase as the gas pressure increases. This was more significant with CO2 especially at 500–1400 psig range, after which become constant as shown in Fig. 2. This makes CO2 approximately six (6) times denser than N2 or CH4, which signifies the possibility of storing more of it at a supercritical state. However, N2 and CH4 exhibited similar behavioural trends as the pore pressure raises, justifying why the recovered CH4 onsite mostly contain higher traces of N2 than CO2 during exploration (Xidong et al. 2019). The kinetic energy of a gas is proportional to its temperature due to the increased rate of collision with the container wall. The reverse was the case to that of liquid fluids due to high inter-molecular forces keeping them close to each other. In general, gas viscosity increases with pressure raise. However, at higher pressures (1300–2000) psig CO2 maintained high viscosity with a density like that of liquid as observed in Figs. 2 and 3. Also, at a lower temperature (18–50) °C CO2 experienced viscosity reduction similar to liquid as evidence of an about 66% reduction in viscosity at 50 °C, shown in Fig. 4. Thus, in turn, based on the proceeding statement, CO2 demonstrated strange properties behaviour compared to those of N2 and CH4 at conditions of temperature and pressure (40 °C and 1500 psig) applicable to EGR. This justifies the selection of the experimental conditions as also, reported by Abba et al. 2018. Thus, it makes the application of supercritical CO2 for the EGR process to be well accepted globally. Such unique esteem property will grossly affect the flow behaviour of the gases as will be presented in the successive sections.

The viscosity is said to be increasing at the beginning of the displacement process until the mobility of the displacing phase is less than that of the displaced phase; this makes the mobility ratio to be less than one (unity). Such a state does maximize gas recovery and sweeps efficiency, due to negligible premature mixing, by providing a sharp viscosity gradient at the displacement front without experiencing viscous fingering effect. A condition in which a combination of two fluids escape some part of the reservoir as it progresses along, forming irregular, or fingered profile. Fingering is relatively a routine problem in reservoirs with gas-injection wells (Al-Abri et al. 2012). Fingering effects result mostly in an unproductive sweeping action, which bypasses many recoverable gas volumes, with a premature breakthrough of displacing fluids. In Fig. 5, both the N2 injection (CH4–N2) and CO2 injection (CH4–CO2) display a lower mobility ratio at their respective critical conditions. The mobility ratio of CH4–N2 displacement was low compared to CH4–CO2 at pressure (100–800 psig) below CO2 critical points (33.9 °C and 1070 psig). This means the effect of viscous fingering was minimal as the N2 plume transverse through the core spaces as against that of CO2. The effect of pressure on the CH4–CO2 mobility ratio was insignificance above its supercritical state and remains almost constant thereafter. Overall, the supercritical state of gases plays an important role in investigating their flow behaviour with maximum recovery efficiency, creating an even flood front with minimum risk to viscous fingering effect.

On the other hand, the mobility of CH4–CO2 displacement was ascending as the temperature increase due to an increase in density with temperature and pressure down the reservoir. However, a reverse scenario was observed for that of the CH4–N2 process as the temperature increases to 100 °C as observed in Fig. 6. This is so because as the temperature increases CH4–N2 system experienced a high rise in diffusion coefficient compared to those of CH4–CO2 and CO2–N2 as shown later in Fig. 7. Thus, in turn, CH4–CO2 system mobility is more sensitive to change in temperature and pressure compared to that of CH4–N2 during EGR and storage.

The developed Eqs. (6), (7) derived from the fundamental (first principle) correlation [Eq. (5)] as reported by Fuller et al. (1966) were used to simulate the effect of pressure and temperature for N2–CH4, CO2–CH4, and CO2–N2 interaction behaviours. This simulation was carried out at constant temperatures of 30, 40, and 50 °C, respectively, at a varying pressure of 100–2000 psig for the stated interactions. In Fig. 7, the molecular diffusion coefficient increases with a roughly constant value of 1.5 m2/s at constant temperatures of 30, 40, and 50 °C over the pressure ranges. These values were more pronounced for CH4–N2 interaction than that of CH4–CO2 due to the high density and molecular weight of carbon dioxide compared to that of nitrogen at reservoir condition. Meanwhile, above 1500 psig of pressure, the diffusion coefficient trend was the same for all the temperatures and the decline rate was less notable.

Temperature plays a significant role in determining the extent of diffusion when two fluids are in contact with each other especially of the same phase. The higher the temperature, the more the kinetic energy due to high collision velocity, which invariably results in the high molecular diffusion coefficient. Such evidence can be seen in Eqs. (6), (7) with the temperature component (in Kelvin) being the rise to the order of 1.75. Viscosities and atomic diffusion also contribute to measuring the overall diffusion coefficient of binary mixtures. Further to that, atoms or molecules with higher viscosities and diffusion volumes do result in lower molecular diffusion coefficient value compared to those with lower viscosities and diffusion volumes, respectively. Figure 8 presents a plot of diffusion coefficient against temperature. The CH4–N2 binary mixture shows a high periodic increase as the temperature rise to 120 °C (393.15 K). However, a lower rise was experienced for the case of the CH4–CO2 mixture. This was due to high density, viscosity, and diffusion volume of CO2 at the supercritical condition as against that of N2. Also, a similar trend was observed for that of the CO2–N2 binary mixture.

Core flooding experiment

The recovery efficiency and percent of total CO2 injected stored were analysed by a laboratory displacement system of an experiment to evaluate the concentration profiles of the interacting gases. This involved the injection of N2 and CO2 into the Bandera grey core plug at a condition reasonable for the EGR process.

The concept of N2 as a cushion gas during enhanced gas recovery

The principle behind the whole concept of the core flooding experiment for CH4 displacement in a porous medium is well understood using the concept of dispersion theory and its governing equations. For example, establishing the dominant mechanism of displacement as the displacing gases (N2 and CO2) transverses the core samples are prerequisites to avoid excessive mixing during the EGR process. If the medium Péclet number in Eq. (2) is less than 0.1, diffusion dominates and the flow is driven by the concentration gradient, and the transport is influenced by the mobility ratio, as evident in most of the experimental EGR process. However, when the Péclet number is above 10 advective mixing dominates due to the turbulence and eddy current effects and the flow is driven by velocity gradient as seen in most displacement at higher injection velocity. In this experiment, the Péclet number was 0.02, meaning the dominant displacement is by diffusion. The rate of gas miscibility during the natural gas displacement process mostly depends on the injection rate of the displacing species. The higher the rate the more mixing will be recorded, and invariably more contaminated CH4 will be recorded. This was why most researches on CO2 injections were tailored toward storage rather than CH4 recovery. The injected amount of N2 prior to the CO2 injection acts as a barrier by creating a thin film layer between CO2 and CH4, making it difficult for the carbon dioxide to penetrate and disperse into the methane due to the blanketing nature of nitrogen. This affirmed the use of N2 for reservoir pressure maintenance for decades. The introduction of N2 displaces a larger amount of the CH4 until it reached its breakthrough; this allows most of the CO2 later injected to be trapped within the rock space without mixing with the nascent CH4. More so, at the time the CO2 reaches its breakthrough a substantial volume of CH4 has been recovered already since the CO2 will find it difficult to disperse itself into the methane due to the presence of nitrogen gas which acted like a barricaded wall between the CO2 and CH4. A decline in the dispersion coefficient was observed as the cushion gas volume increases; thus, less gas miscibility was noticed with higher CO2 storage compared to the conventional CO2 flooding. This signifies the feasibility and potential N2 as a cushioning medium on CH4 swept recovery efficiency and CO2 storage for both social and economic benefits.

The variation of effluents against the total injected gases in pore volumes

The breakthrough indicates the first contact point at which the injected gas species (CO2 and N2) trespass the length scale of the core sample during the laboratory experimental runs. The later the breakthrough the more the sweep efficiency and invariably the volumes of CO2 stored. On the other hand, the shorter the breakthrough, the larger the dispersion coefficient; an indication for excessive mixing and product contamination. This results in natural gas production with low calorific value and high purification cost, rendering the process uneconomical. The breakthrough points were determined from the plots of the concentration profiles against total gas injection as presented in Fig. 9. The effluents mole fraction was measured online using the integrated GC machine as seen from the experimental set-up. Five sets of breakthrough points were measured at 1, 2, 3, and 5 PV of injected gas species. It was observed that there was a delay in the CO2 breakthrough as the cushion gas volume increases from 1 to 5 PV. This was so because injecting N2 into the gas-bearing formation can cause a large volume of nascent methane displacement from the reservoir by lowering the partial pressure of CH4 due to its high conductivity and invariably increase its recovery (Jessen et al. 2008). This accounted for approximately 150% delayed in breakthrough compared to conventional CO2 injection as evidence in Fig. 9.

The changes in effluent concentration with displacement were ascertained by conventional and gas alternating gas (GAG) displacement simulation (Figs. 10, 11). The N2 breakthrough occurred when about 6 PV of it been injected into the core sample. This value was roughly 2 times that of the conventional CO2 injection. The injected pore volume of the CO2 was earlier detected by the gas chromatography at the same injection temperature and pressure, due to its high diffusion volume. The diffusion volumes of CO2 and N2 are 26.9 and 18.5 cm3, respectively (Fuller et al. 1966). In comparison with conventional N2 displacement, the breakthrough time of N2 increases when the cushion gas was employed. The increase was highest at 2 PV cushion gas volume. As expected, more product contamination of N2 was recorded as the volume of N2 injected into the system increases. The least contamination was noticed at lower cushion volume with 19% nitrogen contaminants compared to 75% contamination at 5 PV of injected cushion gas. Due to the high cost of natural gas purification, designing an experiment with high product purity is paramount for the economic viability of such a process. Thus, the level of product contamination will be considered in selecting the best and optimum cushion gas volume. Similarly, a prolonged CO2 breakthrough time was recorded at the highest cushion gas volume (5 PV), this was 5.8 PV more than conventional CO2 flooding. This also resulted in a higher volume of total injected CO2 stored due to lower penetration and dispersion coefficient as later present in Table 4. The combined effect for all the runs is presented in Fig. 12. Thus, in turn, the breakthrough of CO2 can be delayed by increasing N2 cushion gas volume. Overall, a minimum of 3.2 PV delayed longer than the traditional CO2 injection was recorded across all the cushion gas volume tested. It evidence that the presence of impurity (N2) causes large changes in supercritical CO2 behaviour as reported by several authors (Xidong et al. 2019; Hughes et al. 2012; Janssen et al. 2018; Abba et al. 2018). To reduce the high cost of gas separation, a longer breakthrough with minimum miscibility is preparable for experimental gas injection (Xiangchen et al. 2018). It is worth noting that higher displacement efficiency is obtained at lower cushion volume. The optimization of breakthrough time and displacement efficiency should be expected for the success of the GAG injection process.

Dispersion coefficient and dispersivity

Dispersion can be defined as an irreversible mixing that exists during miscible displacements reported by Adepoju et al. (2013). This phenomenon occurs mainly due to molecular diffusion and mechanical dispersion as the experiment progress, while the displacing fluids CO2 and N2 tend to mix with the displaced CH4 as shown in the concentration profile plots. The displacement efficiency in miscible flooding is grossly affected by in situ mixing taking place inside the core spaces of the core plug. Also, a transition or mixing zone called ‘displacement front’ develops when the concentration of methane decreases from > 99% to < 1% as aforementioned in Sect. 4. The dispersion observed reported in Table 5 was used to quantify the nascent mixing as the CO2 plumes transverses through the porous media. These values were evaluated using empirical evaluation [Eq. (3)] and laboratory experiments by analysing the concentration of CO2 relative to that of CH4 in the produced effluent stream with the aid of the GC machine. Several repeated experimental displacement tests were carried out to check for uncertainty and repeatability of the research method and set-up. However, such results were demonstrated in our previous publication. The medium Péclet number (Pem) was determined using Eq. (2), in that the characteristic length scale of mixing, d (µm), was obtained from the work of Abba et al. (2019). This value was found to be 57.15 µm for Bandera grey, such value was used in Eq. (2) to determine the dominant phenomenon of displacement mechanism. The Pem value was calculated to be 0.02, meaning diffusion is the dominant mechanism since its value is < 0.1 as stated in Sect. 2.1. Also, the dispersivity \(\left( { \alpha } \right)\), an empirical property of a porous medium, is responsible for characteristic dispersion of the medium by comparing the components of pore velocity to that of dispersion coefficient. This value was 0.0007 m as reported in our previous work. Thus, in turn, both the medium Péclet number and dispersivity were well within the range obtained by (Abba et al. 2018; Hughes et al. 2012) for consolidated rocks.

Methane recovery

The methane produced was determined based on the total volume and composition of core flooding system effluents recorded by the gas flow meters and gas chromatography. The core flooding experiment was terminated when an insignificance composition (< 0.5%) of CH4 or (> 99.5%) of CO2 was noticed from the GC as shown in Fig. 13 with only CO2 peak noticeable. These volumes are a fraction of the original gas in place (OGIP) in the Bandera grey core plug. The result is presented in Fig. 14. As can be observed, the worst CH4 recovery was realized when pure CO2 was injected; this was due to high diffusion volume and low minimum miscibility pressure (MMP) effect as it plumes transverses through the core plug during the displacement process. Considering the GAG injection, the run with 5 PV of cushion gas produced 44.39% CH4 recovery. This poor sweep efficiency was a result of early N2 detection by the GC due to the high volume of it injected and demonstrate similar property behaviour with CH4 as discussed in Sect. 4.1.

Prior to the core flooding experiment, the OGIP of the Bandera grey core plug was evaluated using the well-known gas reservoir equation [Eq. (8)] as reported by (Abba et al. 2017, 2018).

where G is the original gas in place in scm3, Pv is the pore volume in cm3, sw is the initial water of saturation fraction (sw = 0 for a dry run), and Bg is gas formation volume factor in cm3/scm3 for this research. This was then used to determine the percentage of CH4 recovery as shown in Fig. 14 and Table 3.

Furthermore, the CH4 recovery was highest for conventional N2 and 1 PV cushion gas experimental runs. However, not only the 1 PV cushion gas gives high recovery, but also the CH4 recovered happens to experience the least impurity with 19% N2 contamination. This signifies the potential application of N2 gas during the enhanced gas recovery process.

Carbon dioxide injection and storage

In this study, the amount of CO2 stored during the gas alternating gas injections was evaluated and recorded using Eq. (9) as reported by Xidong et al. (2019).

where \(V_{{t,{\text{injected}} - {\text{CO}}_{2} }}\) is the volume of injected CO2 recorded by the high-pressure syringe pump at time t and \(C_{{t,{\text{CO}}_{2} }}\) is the CO2 mole percent in the effluent at time t recorded by the gas chromatography (GC) analyser.

The exit effluents from the core holder were measured using the gas mass flow controller, while the displacing gases were introduced to the system via the ISCO pumps A/B and C/D through cells A and B as presented in Fig. 1. Both pumps were set at a constant flow rate of 0.4 ml/min, and the total injection time was recorded from the online core flooding logging data. For example, to inject 8 cm3 (1 PV) of the cushion gas (N2), the ISCO pump A/B was run for 20 min at the set flow rate, i.e. 0.4 cm3/min × 20 min = 8 cm3 or 1 PV. Thus, to measure the amount of the rest cushion volumes, the injection period was increased to 40, 60, and 90 min. To evaluate the total CO2 injected, the total injection time at the end of each experimental test was obtained and the value was multiplied with the known injection rate after taken out the N2 injection time before introducing the CO2 into the Bandera grey core sample. For instant, at 1 PV cushion gas, the total injection time was 186.15 as shown in Table 5 in the ‘Appendix’ section. This means the actual CO2 injection period is 166.15 min (186.15–20 min). Thus, the total volume of CO2 injected was 66.46 cm3 (0.4 cm3/min × 166.15 min). This value was the same as 8.8 PV of total CO2 injected. The same procedure is applied to the other experimental runs as shown in Table 4, more so, to evaluate the amount of CH4 present in the core plug after saturation and before displacing gases injection. The OGIP technique in Eq. (8) was used since the pore volume of the Bandera grey core sample is known. The total volume of CH4 in the core sample was measured to be 115 PV, and is presented in Table 2. The total CO2 injected stored is presented in Table 4. From Table 4, it is adequate to know that the most significant amount of total CO2 injected stored of 59.76% was recorded at 2 PV of cushion gas. This was characterized by the large pressure drop (dP) as shown in Fig. 15. The least storage was seen when conventional CO2 injection was applied. This could be due to the high dispersion coefficient (5.02 × 10–8 m2/s) obtained during the pure CO2 injection scenario since this parameter is a key for the economy of the enhanced CH4 recovery projects (Du et al., 2019). Meanwhile, lower dispersion coefficient weakens the instantaneous mixing effect of CO2 and CH4 that inhibits the rapid breakthrough of the injected CO2. As such, the injection of N2 as cushion gas can effectively delay or prolonged the breakthrough point, and invariably and sequester more CO2 over the long run (Xidong et al. 2019).

In consequence, to examine the displacement efficiency in terms of CH4 recovery and CO2 sequestration, Tables 3 and 4 were combined to generate Table 5. Looking at the later Table, there was an improvement in both recovery and storage when gas alternating gas injection technique was employed as against that of conventional CO2 injection. This was so because, as the displacement process proceeds, N2 does act as a barrier by creating a thin film layer between CO2 and CH4, making it difficult for carbon dioxide to penetrate and disperse into the methane due to the blanketing nature of nitrogen. This can be seen, where the least dispersion coefficient of 2.59 × 10–8 m2/s was recorded at the highest cushion gas volume of 5 PV.

Based on the literature consulted, it is quite difficult to achieve simultaneous CH4 recovery and CO2 storage using conventional injection. For example, Abba et al., (2019) in their work reported high CO2 storage of 63.13% at 10 wt.% connate water. The same run yielded the poorest CH4 recovery factor of 16.44% (combined of 79.57%). ‘Their reason was due to the restrictive flow when CO2 traverses the core sample as a result of higher salinity of the connate water sealing off the narrower pore spaces within the pore matrix due to its density’. This means one must be compromised at the expense of the other. However, in this study both were improved compared to conventional single injection. A combination of 124.57% (59.76% CO2 storage and 64.81% CH4 recovery) was recorded at 2 PV of cushion gas. The same run gives the second least dispersion coefficient with a prolonged breakthrough point. With the results from the CH4 recovery efficiency, CO2 storage, and dispersion coefficient, it is apparent that the best and optimum cushion gas volumes for this study occur at 2 PV.

Conclusion

In this study, the Bandera grey sandstone core plug was used as the standard porous media. An empirical and experimental core flooding runs were carried out to investigate the production of methane and carbon dioxide during EGR displacement scenarios in the presence of N2 as cushion gas, to register the effects of its existence. A significant recovery and storage of CH4 and CO2 were recorded and analysed where the cushion gas volume was 2 PV; this was attributed to the inhibitory flow of the injected CO2 to disperse itself into the CH4 and was characterized by low dispersion coefficient. The worst result was obtained at the conventional CO2 injection scenario. This was due to high CO2 diffusion volume and low conductivity of CO2 as it plumes transverses through the core plug during the displacement runs. Methane recovery and carbon dioxide storage can both be influenced by the addition of N2 as cushion gas prior to CO2 injection into the reservoir. Thus, in turn, the displacement efficiency of the current research exhibits better results than that of conventional CO2 injection. However, the presence of N2 tends to increase CH4 recovery by reducing the partial pressure of methane, and at the same time act as a barrier between CO2 and CH4 creating a thin barrier making it difficult for early CO2 breakthroughs as a result of its blanketing effect. This work shows that N2 as cushion gas influences both CH4 recovery and CO2 sequestration. Further work will entail an examination of the effect of connate water salinity on this novel method. Also, the phase behaviour of mixed gases post breakthrough would be investigated.

Abbreviations

- yCO2 :

-

CO2 mole fraction

- yN2 :

-

N2 mole fraction

- D :

-

Diffusion coefficient, m2/s

- Q :

-

Flow rate mil/min

- t D :

-

Dimensionless time

- x D :

-

Dimensionless distance

- d :

-

Characteristic length scale, m

- K L :

-

Longitudinal dispersion, m2/s

- L :

-

Core sample length, mm

- L exp :

-

Experimental length, m

- μ :

-

Viscosity, cP

- P :

-

Pressure, psig

- T :

-

Temperature, K

- u :

-

Interstitial velocity, m/s

- ϕ :

-

Core porosity, %

- α :

-

Dispersivity, m

- τ :

-

Tortuosity

- Pe:

-

Péclet number

- Pem :

-

Medium Péclet number

- PV:

-

Pore volume

- r :

-

Radius of core sample, m

- λ 90 :

-

Lambda function at 90% of effluent concentration

- λ 10 :

-

Lambda function at 10% of effluent concentration

References

Abba MK, Abbas AJ, Athari A, Martin M, Bello S, Salihu MS, Nasr GG (2019) Solubility trapping as a potential secondary mechanism for CO2 sequestration during enhanced gas recovery by CO2 injection in conventional natural gas reservoirs: an experimental approach. J Nat Gas Sci Eng 71:1–12. https://doi.org/10.1016/j.jngse.2019.103002

Abba MK, Abbas AJ, Athari A, Mukhtar A, Nasr GG (2018) Experimental investigation on the impact of connate water salinity on dispersion coefficient in consolidated rocks cores during EGR by CO2 injection. J Nat Gas Sci Eng 60:190–201. https://doi.org/10.1016/j.jngse.2018.10.007

Abba MK, Abbas AJ, Nasr GG (2017) Enhanced gas recovery by CO2 injection and sequestration: effect of connate water salinity on displacement efficiency. SPE Abu Dhabi international petroleum exhibition and conference. DOI: 10.2118/188930-MS

Adepoju OO, Lake LW, Johns RT (2013) Investigation of anisotropic mixing in miscible displacements. SPE Reservoir Eval Eng 16:85–96

Al-Abri A, Sidiq H, Amin R (2012) Mobility ratio, relative permeability and sweep efficiency of supercritical CO2 and methane injection to enhance natural gas and condensate recovery: core flooding experimentation. J Nat Gas Sci Eng 9:166–171. https://doi.org/10.1016/jjngse.2012.05.011

Al-abri A, Sidiq H, Amin R (2009) Enhanced natural gas and condensate recovery by injection of pure SCCO2, pure CH4 and their mixtures: experimental investigation. In: SPE annual technical conference and exhibition, New Orleans, Louisiana, USA, Vol 4–7, pp 1–13

Al-Hasami A, Ren S, Tohidi B (2005) CO2 injection for enhanced gas recovery and geo-storage: reservoir simulation and economics. In: SPE EUROPEC/EAGE annual conference, 13e16 June. Madrid, Spain, DOI: 10.2118/94129-MS.

de Delgado EIAR (2001) “Dispersion Coefficient Determination for Inert Gas Injection (Nitrogen) in GasLayer”. Campinas: Faculty of Mechanical Engineering, State University of Campinas, 2001. Ph.D. thesis. Draft.

Du X, Gu M, Liu Z, Zhao Y, Sun F, Wu T (2019) Enhanced Shale Gas Recovery by the Injections of CO2, N2, and CO2/N2 Mixture Gases. J Energy Fuels. https://doi.org/10.1021/acs.energyfuels.9b00822

Benson S et al. (2005) Underground geological storage. Ipcc, pp.195–276.

Fuller EN, Schettler PD, Giddings JC (1966) New method for prediction of binary gas- ‘phase diffusion coefficients. Ind Eng Chem 58:18–27

Ganjdanesh R, Hosseini SA (2017) Geologic Carbon Storage Capacity Estimation Using Enhanced Analytical Simulation Tool (EASiTool). Energy Procedia 114:4690–4696. https://doi.org/10.1016/j.egypro.2017.03.1601

Honari A et al (2013) Dispersion of supercritical CO2 and CH4 in consolidated porous media for enhanced gas recovery simulations. Int J Greenhouse Gas Control 19:234–242. https://doi.org/10.1016/j.ijggc.2013.08.016

Honari A et al (2015) Enhanced gas recovery with (CO2) sequestration: the effect of medium heterogeneity on the dispersion of supercritical CO2–CH4. Int J Greenhouse Gas Control 39:39–50

Honari A et al (2016) The impact of residual water on CH4–CO2 dispersion in consolidated rock cores. Int J Greenhouse Gas Control 50:100–111. https://doi.org/10.1016/j.ijggc.2016.04.004

Ho C, Webb S (2006) Theory and Applications of Transport in Porous Media.

Hughes TJ et al (2012) CO2 sequestration for enhanced gas recovery: new measurements of supercritical CO2–CH4 dispersion in porous media and a review of recent research. Int J Greenhouse Gas Control 9:457–468. https://doi.org/10.1016/jijggc.2012.05.011

Janssen MTG, Azimi F, Zitha PLJ (2018) Immiscible nitrogen flooding in bentheimer sandstones: comparing gas injection schemes for enhanced oil recovery. Soc Pet Eng. https://doi.org/10.2118/190285-MS

Jessen K, Tang G, Kosvscek AR (2008) Laboratory and simulation investigation of enhanced coalbed methane recovery by gas injection. Transport Porous Medium 73:141–159

Khan C, Amin R, Madden G (2013) Carbon dioxide injection for enhanced gas recovery and storage (reservoir simulation). Egypt J Pet 22(2):225–240

Kalra S, Wu X (2014) CO2 injection for Enhanced Gas Recovery. SPE Western North American and Rocky Mountain …, (April), pp 16–18. Available at: https://www.onepetro.org/conferencepaper/SPE-169578-MS.

Li X, Kang Y, Zhou L (2018) Investigation of gas displacement efficiency and storage capability for enhanced CH4 recovery and CO2 sequestration. J Nat Gas Sci Eng 169:485–493. https://doi.org/10.1016/j.petrol.2018.06.006

Liu S et al (2015) Laboratory experiment of CO2–CH4 displacement and dispersion in sandpacks in enhanced gas recovery. J Nat Gas Sci Eng 26:1585–1594. https://doi.org/10.1016/jngse.2015.04.021

Meehl GA, Washington WM, Collins WD, Arblaster JM, Hu A, Buja LE, Strand WG, Teng H (2005) How much more global warming and sea level rise? Science 307:1769–1772

Oldenburg CM, Benson SM (2002) CO2 injection for enhanced gas production and carbon sequestration. SPE international petroleum conference and exhibition in Mexico. DOI: 10.2118/74367-Ms

Perkins T, Johnston O (1963) A review of diffusion and dispersion in porous media. Soc Petrol Eng J 3(01):70–84. https://doi.org/10.2118/480-PA

Patel MJ, May EF, Johns ML (2016) High-fidelity reservoir simulations of enhanced gas recovery with supercritical CO2. Energy, In Press, pp 548–559. DOI: 10.1016/j.energy.2016.04.120

Pooladi-Darvish M et al. (2008) CO2 injection for enhanced gas recovery and geological storage of CO2 in the Long Coulee Glauconite F Pool, Alberta. Proceedings–SPE Annual Technical Conference and Exhibition, 4:2271–2281. Available at: https://www.scopus.com/scopus/inward/record.url?eid=2-s2.0-58849157975&partnerID=40.

Raza A et al (2017) Preliminary assessment of CO2 injectivity in carbonate storage sites. Petroleum 3(1):144–154. https://doi.org/10.1016/j.petlm.2016.11.008

Rose DA (1973) Some aspects of the hydrodynamic dispersion of solutes in porous materials. J Soil Sci 24(3):284–295

Shtepani E (2006) CO2 sequestration in depleted gas/condensate reservoirs. Proceedings—SPE Annual Technical Conference and Exhibition.

Sidiq H et al (2011) Super critical CO2-methane relative permeability investigation. J Petrol Sci Eng 78(3–4):654–663

Sim S et al. (2009) Enhanced gas recovery: effect of reservoir heterogeneity on gas–gas displacement. Canadian international petroleum conference, (June), pp 1–14

Sim SSK et al (2008) SPE 113468 enhanced gas recovery and CO2 Sequestration by injection of exhaust gases from combustion of bitumen. Changes 1:1–10

Sim SSK et al (2009) Enhanced gas recovery: factors affecting gas-gas displacement efficiency. J Can Pet Technol 48(8):49–55

Turta AT et al. (2007) Basic Investigations on Enhanced Gas Recovery by Gas–Gas Displacement.

Takahashi S, Iwasaki H (1970) The diffusion of gases at high pressures. III. The diffusion of CO2, in the CO2–CH4 system. Bull Chem Res Inst Non-Aqueous Solut Tohoku Univ 20:27–36

Xiangchen L, Yili K, Laicheng Z (2018) Investigation of gas displacement efficiency and storage capability for enhanced CH recovery and CO storage. J Petrol Sci Eng 169:485–493. http://doi.org/10.1016/j.petrol.2018.06.006

Xidong D, Min G, Zhenjian L, Yuan Z, Fulong S, Tengfei W (2019) Enhanced shale gas recovery by the injections of CO, N, and CO /N mixture gases. J Energ Fuel. https://doi.org/10.1021/acs.energyfuels.9b00822

Zhang Y, Liu S, Song Y, Zhao J, Tang L, Xing W, Jian W, Liu Z, Zhan Y (2014) Experimental investigation of CO2–CH4 displacement and dispersion in sand pack for enhanced gas recovery. Energy Procedia 61:393–397. https://doi.org/10.1016/j.egypro.2014.11.1133

Acknowledgements

The authors wish to acknowledge the Petroleum Technology Development Fund (PTDF) for the studentship and Petroleum and Gas Research Group of the University of Salford, Manchester, UK, for their support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mohammed, N., Abbas, A.J., Enyi, G.C. et al. Alternating N2 gas injection as a potential technique for enhanced gas recovery and CO2 storage in consolidated rocks: an experimental study. J Petrol Explor Prod Technol 10, 3883–3903 (2020). https://doi.org/10.1007/s13202-020-00935-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-020-00935-z