Abstract

The high Salmonella and Listeria monocytogenes risk in poultry products reinforces the urgent need for new technologies with high antimicrobial effects. In that sense, a combined technology consisting of encapsulated extra virgin olive oil (EVOO) during chicken nugget breading combined with infrared processing was hereby studied at three levels (experiments). The high in vitro EVOO antimicrobial activity (up to 74%), which was 1.2-fold higher against L. monocytogenes than Salmonella, was enhanced after encapsulation (α-cyclodextrin) by 1.5–2.0 and 1.2–1.6-fold, respectively (experiment 1). Oil-free processing (infrared and convection ovens) combined with encapsulated EVOO (2.5 and 1.6% EVOO doses) even enhanced the high in vitro antimicrobial activity of encapsulated EVOO (experiment 2). In the in vivo study (experiment 3), infrared (180 °C, 6.4 min) + convection air (120 °C, 10 min) processing combined with encapsulated EVOO (1.6 and 2.5%) within chicken nugget breading of the chicken nuggets achieved in vivo antimicrobial reductions of 60 and 80% against Salmonella and L. monocytogenes, respectively. In conclusion, this new technology including encapsulated EVOO (1.6–2.5%) within the breading of chicken nuggets and innovative oil-free processing may ensure the food safety of these poultry products very susceptible to the incidence of Salmonella and L. monocytogenes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pathogenic microorganisms are the second most reported hazard category in food after pesticide residues. In particular, Salmonella is the most reported pathogenic microorganism (70% of notifications), according to the Rapid Alert System for Food and Feed Network (RASFF), followed by Listeria monocytogenes (16% of notifications) and Escherichia coli (5% of notifications), all primarily detected in products of animal origin (EC, 2022). Salmonella enterica subsp. enterica is frequently isolated in the processing lines, and environmental samples from poultry farms and from feed raw materials. In addition, some S. enterica serovars like Salmonella enterica subsp. Enterica serovar Senftenberg (S. Senftenberg) are more resistant to low pH, thermal treatments, irradiation and desiccation than other serovars (Pedersen et al., 2008). In particular, S. Senftenberg has been associated with several foodborne outbreaks of salmonellosis in humans (Pedersen et al., 2008; Rushdy et al., 1998). L. monocytogenes is the main causal agent of listeriosis. Listeriosis incidence, although lower compared with salmonellosis incidence, is a major public health concern worldwide because it is capable of causing severe infections in susceptible populations with high lethality rates (20 to 30%). Fresh poultry meat and poultry meat products are the groups more affected by food pathogen incidence achieving 35% of the total reported food pathogen notifications in 2022 according to the RASFF annual report (EC, 2022). Such pathogen incidence risk may be increased when using minced meat products like chicken nuggets (Mor-Mur & Yuste, 2010). Indeed, a high L. monocytogenes proliferation was observed in partially cooked battered chicken nuggets during refrigeration to levels potentially hazardous for susceptible population groups (Lianou et al., 2021).

Commercialised raw and frozen chicken nuggets have been identified as a significant risk factor for contracting foodborne salmonellosis (Bucher et al., 2007). Chicken nuggets are usually produced from pre-moulded nugget-shape discs of minced chicken meat that follow the following steps: (1) battering, (2) breading and (3) cooking (conventionally deep-fat frying) to ensure its shape is maintained (Bucher et al., 2007). The commercialised chicken nuggets are only subjected to a pre-cooking step, needing a final homemade cooking step by the consumer. Cooking of chicken meat products may ensure reaching 70 °C in the centre of the meat piece being reported with very low D values at 70 °C (0.10–0.13 min) for Salmonella and L. monocytogenes in chicken products (Murphy et al., 2003). Nevertheless, the misunderstanding and confusion among consumers reading and following package labels for preparing these products may compromise their food safety (DeDonder et al., 2009). In particular, one third of the respondents from a case-controlled study believed the frozen nuggets were already cooked, requiring reheating only, with ≈ 30% indicating they either always or sometimes used a microwave (MacDougall et al., 2004). Hence, it is common that antimicrobial additives are also included in the composition of these meat products.

The actual consumer is interested in safe and healthy food products free from chemical additives and low-fat contents, among other requirements (Lusk, 2019). The high-fat content (≈ 20%), and the possible acrylamide formation (when cooking using temperatures above 120 °C), is common in chicken nuggets when using the conventional deep-fat frying method, which consists of frying oil temperatures of 175–180 °C for 0.5–3 min (depending on the nugget thickness) (Barón-Yusty et al., 2022; Faloye et al., 2021). Furthermore, the high waste volumes of cooking oil using the conventional deep-fat frying method are considered dangerous for the environment (Comission, 2000). In that sense, new technologies are developed to obtain breaded meat products with lower fat content and less acrylamide formation risk. In particular, we developed a new technology for obtaining low-fat breaded meat products, such as chicken nuggets, consisting of the inclusion of microencapsulated (using α-cyclodextrin as the carrier) olive oil into the bread crumbs combined with fat-free cooking methods (e.g. convection and infrared ovens) (Barón-Yusty et al., 2022). Indeed, this new technology reduced the fat content and acrylamide formation in the chicken nuggets by 88% and > 55%, respectively, while no remarkable sensory differences were found compared with conventional breading and deep-fat frying (Barón-Yusty et al., 2022).

Extra virgin olive oil (EVOO) and virgin olive oil are both extracted using only mechanical processes leading to high acidity levels (up to 0.80 and 2.0%, respectively), while refined olive oil is extracted using more intense oil extraction treatments (i.e. chemical treatments; leading to lower acidity levels of ≤ 0.30%) (EEC, 2022). More intense extraction treatments (i.e. chemical treatments) lead to higher losses of phenolic compounds from virgin olive oils, therefore, leading to lower antimicrobial activities (Medina et al., 2006). The antimicrobial activity of olive fruit, olive oil mill wastewaters and olive leaves, as well as other plant oils, has been well reported, which is linked to their high content of phenolic compounds (Abu-Lafi et al., 2017; Capasso et al., 1995; Fleming et al., 1973; Koutsoumanis et al., 1999; Markín et al., 2003; Medina et al., 2006; Ranalli et al., 2009). In particular, the high antimicrobial activity of olive oil has been deeply and well related to its characteristic phenolic compounds with a dialdehydic structure, mainly the dialdehydic form of decarboxymethyl elenolic acid, either free or linked to tyrosol or to hydroxytyrosol (Medina et al., 2006, 2007, 2009). In particular, EVOO in vitro studies showed high activity against Salmonella, L. monocytogenes and other food pathogens (Medina et al., 2006, 2007, 2009; Romero et al., 2007; Yakhlef et al., 2018). Nevertheless, the high in vitro EVOO antimicrobial may be highly reduced due to the interference with several food components, as observed in in vivo EVOO studies against Salmonella enterica subsp. enterica serovar Enteritidis in high-fat food (Medina et al., 2007). However, the in vivo EVOO antimicrobial activity against Salmonella and L. monocytogenes has not been studied yet in meat products.

Encapsulation of antimicrobial oily compounds (e.g. plant essential oils) has been reported to increase the efficiency of their antimicrobial properties (Göktepe et al., 2021; Plati & Paraskevopoulou, 2022). It may be explained by the controlled release kinetics of the antimicrobial compounds, avoiding the burst effect (initial microbial inhibition followed by high microbial growth of survivors) from non-encapsulated antimicrobial substances. Microencapsulation of EVOO has been studied to increase its oxidative stability (Koç et al., 2015). In addition, the oxidative stability of frozen chicken nuggets was increased using microencapsulated omega-3 fish oil (Jiménez-Martín et al., 2016). Nevertheless, the encapsulation effect on the EVOO antimicrobial activity has not been studied yet. Indeed, the incorporation of encapsulated EVOO within chicken nuggets would lead to higher antimicrobial properties than conventional deep-fat frying.

This investigation studied the effect of the inclusion of encapsulated (using α-cyclodextrin as the carrier) EVOO within the breading mix of chicken nuggets, followed by oil-free cooking methods (convection oven, infrared oven or a combined method with them), against Salmonella and L. monocytogenes compared to conventional deep-fat frying using liquid EVOO. For it, previous in vitro studies were conducted to determine the optimum EVOO dose (0.8, 1.7 or 2.5%).

Material and Methods

Materials, Cell Cultures and Cooking Equipment

Extra virgin olive oil (EVOO) (acidity ≤ 0.4%; Hojiblanca and Arbequina olive varieties) was purchased in a local supermarket (Mercadona; Cartagena, Spain). The EVOO characteristics and composition are described in Supplementary Material 1. The α-cyclodextrin was obtained from Wacker Chemie AG (Munich, Germany). Maltodextrin (PINEFLOW-T, DE10) was obtained from Matsutani Chemical Industry Co., Ltd. (Itami, Japan). Frozen discs of minced chicken meat (disc diameter ≈ 6 cm, ≈ 1 cm thickness; ≈ 10 g) were supplied by the company Fripozo S.A. (Murcia, Spain). The commercial batter mix powder (Proanda Provedora Andaluza, S.L.; Sevilla, Spain) was composed of egg albumin, thickener (E-412), salt, dextrose and spices. The commercial breadcrumb mix (Desarrollos Alimentarios S.A.; Guadalajara, Spain) was composed of wheat flour, salt, water, yeast, colouring (E-160e) and natural flavour.

Listeria monocytogenes (CECT 4032) and Salmonella enterica subsp. enterica serovar Senftenberg (CECT 4384) were acquired as freeze-dried cultures from the Spanish Type Culture Collection (CECT). The freeze-dried cultures were previously activated according to the CECT indications in Brain Heart Infusion Broth and Tryptic Soy Broth, respectively, by two culture steps (37 °C/24 h each step). All microbial materials were acquired from Scharlau Chemie (Barcelona, Spain).

A household deep-fat fryer (Professional 2 model; Taurus, Oliana, Spain) was used for the deep-fat frying method. A household convection oven (model HBC36P753; Bosh, Madrid, Spain) was used for the convection hot-air cooking method. For the infrared cooking method, an infrared oven (TT3000 model; Dosilet, Barcelona, Spain), with a continuous feeding system (a crimped wire conveyor belt at 3.75 m h−1 speed), was used, which included two mid-far infrared resistances: one resistance 11 cm over the conveyor belt and another one 3 cm below it.

Encapsulation of EVOO Using α-Cyclodextrin as Carrier

Encapsulation of EVOO was made within α-cyclodextrin by the kneading method according to previous literature (Manolikar & Sawant, 2003; Mourtzinos et al., 2007). For it, EVOO, α-cyclodextrin and maltodextrin were mixed at 1.1:1.8:1.0 weight(w):w ratio and kneaded in a mortar for 45 min. Then, the formed EVOO/α-cyclodextrin inclusion complex was maintained in a vacuum desiccator at room temperature until its use. Differential scanning calorimetry analyses (data not shown) of the obtained EVOO/α-cyclodextrin inclusion complex showed that the characteristic endothermic peak of α-cyclodextrin (180 °C) was minimised owed to water replacement by guests (EVOO) within the α-cyclodextrin molecules, which indicates the EVOO/α-cyclodextrin inclusion complex formation as previously reported (Barón-Yusty et al., 2022; Mourtzinos et al., 2007).

Experimental Design

Experiment 1: In Vitro Antimicrobial Activity of Liquid and Encapsulated EVOO

The antimicrobial activities of liquid and encapsulated EVOO were studied using the well diffusion method (Abu-Lafi et al., 2017). First, 100 µL of the activated fresh culture (S. Seftenberg and L. monocytogenes) was spread-plated on Petri dishes containing Müller-Hinton agar, which were allowed to dry for 10 min in a laminar flow cabinet. Then, three holes (antimicrobial treatment, positive control and negative control) were made using a sterile cylinder (6-mm diameter). For the antimicrobial treatments, 50 µL of liquid or encapsulated EVOO, previously dissolved in water (containing 0.25% Tween 20) at 2.5, 1.7 or 0.8% (D2.5, D1.7 and D0.8), was pipetted in the corresponding hole. The EVOO doses were selected based on preliminary sensory tests with chicken nuggets including these EVOO contents (2.5, 1.7 or 0.8%; included within the nugget breading mix), followed by oil-free cooking, to achieve similar organoleptic characteristics of chicken nuggets cooked by deep-fat frying. For the positive control, 50 µL of the antibiotic oxytetracycline (100 mg L−1) was pipetted in the corresponding hole. For the negative control, 50 µL of α-cyclodextrin/maltodextrin (1.8:1, w:w), previously dissolved in water (containing 0.25% Tween 20) was pipetted in the corresponding hole. These prepared agar plates were then incubated at 37 °C for 24 h. Finally, the inhibition diameter around holes was measured by analysing the images taken with a smartphone camera (3-integrated camera photosystem of 50 + 50 + 13 MPx) using the ImageJ software (NIH, Bethesda, MD, USA). The antimicrobial activity index of EVOO treatments was calculated based on positive and negative controls using Eq. 1:

where antimicrobial treatment, positive control and negative control inhibition halo diameters were expressed in mm. Three replicates (Petri dishes) were prepared for every microorganism × EVOO status (liquid or encapsulated) × EVOO dose combination. The complete experimental design (experiments 1–3) is fully described in Fig. 1.

Experiment 2: Effect of Cooking Treatments on the EVOO Antimicrobial Activity Under In Vitro Conditions

Cell cultures (S. Seftenberg and L. monocytogenes) were activated (as previously commented in the “Materials, Cell Cultures and Cooking Equipment” section) and then incubated at 37 °C for 24 h. Subsequently, the three doses (D2.5, D1.7 and D0.8) corresponding to liquid EVOO (0.10, 0.20 or 0.30 g) or encapsulated EVOO (0.36, 0.71 or 1.06 g) were introduced in the inoculated tubes, followed by adding Tween 20 (0.25%) and vortex for 10 s. Subsequently, the prepared tubes were subjected to thermal treatments corresponding to those optimised for the chicken nuggets cooking (see the “Experiment 3: Validation (In Vivo) of the Effects of Cooking Treatments on the EVOO Antimicrobial Activity in Chicken Nuggets” section). Finally, tubes were allowed to cool down at room temperature for 10 min, and microbial loads were determined as follows.

Viable microbial counts were based on counts by tenfold serial dilutions in buffered peptone water. Briefly, aliquots (1 mL) from the corresponding dilutions were pour − plated into tryptic soy agar and incubated at 37 °C for 24 h. Results were expressed as log colony forming units (CFU) g−1. Three replicates (tubes) were prepared for every microorganism × heat treatment × EVOO status (liquid or encapsulated) × EVOO dose combination.

Experiment 3: Validation (In Vivo) of the Effects of Cooking Treatments on the EVOO Antimicrobial Activity in Chicken Nuggets

The antimicrobial effect of liquid and encapsulated EVOO incorporated within the breading mix of the chicken nugget was also tested after cooking treatments of nuggets as follows.

Battering and pathogen inoculation. Frozen chicken discs were thawed for 30 min at room temperature inside the laminar flow cabinet and then battered (the batter mix powder was previously dissolved in water at 60 g L−1 following the provider’s indications). Subsequently, battered discs were individually spot inoculated (120 µL per each side of the nugget), either S. Seftenberg or L. monocytogenes, to achieve a final concentration of ≈ 106 CFU g−1. Then, battered + inoculated discs were maintained for 10 min inside the laminar flow cabinet to ensure the inoculum attachment to the disc surface.

Breading including antimicrobial agents. The antimicrobial agents (liquid or encapsulated EVOO) were included during the breading process. Based on experiment 2 results, D1.7 and D2.5 doses were selected for S. Seftenberg and L. monocytogenes, respectively. For it, liquid EVOO (0.30 or 0.20 g for S. Seftenberg and L. monocytogenes, respectively) or encapsulated EVOO (0.71 or 0.36 g for S. Seftenberg and L. monocytogenes, respectively) was mixed and homogenised with the breadcrumb mix to obtain final EVOO loads of 1.7 or 2.5% (in weight) in the obtained chicken nuggets for S. Seftenberg and L. monocytogenes, respectively. Then, battered + inoculated chicken discs were breaded with the prepared antimicrobial breadcrumb mixes turning on each side of the discs.

Heat treatments. The selected temperature/time conditions of the different cooking methods were chosen based on preliminary experiments to obtain similar sensory characteristics (crunchy texture, external golden orange colour surface and tender meat centre) to the conventional deep-fat frying. The deep-fat frying was made at 180 °C for 30 s. The infrared treatment was made at 180 °C for 8 min. The convection oven treatment was made at 120 °C for 10 min. A combined infrared (180 °C, 6.4 min) + convection treatment (120 °C, 10 min) was also studied. All cooking treatments ensured that a cooking temperature above 70 °C was reached in the centre of the chicken nugget as observed in Supplementary Material 2. For the infrared treatment, the heat flux due to irradiance was also measured using a thermal flux meter (model HT-50-19.1 mm × 25.4 mmD; ITI, Del Mar, CA, USA) with a value of 43,200 W m−2, which is similar to previous data of cooking of chicken nuggets using the infrared oven (Ozen & Singh, 2020). Finally, chicken nuggets were allowed to cool down inside the laminar flow cabinet for 10 min before microbial analyses.

For microbial analyses, 2 nuggets (≈ 16 g) were mixed with 160 mL of buffered peptone water and then homogenised for 1 min using a stomacher (Colewort Stomacher 400 Lab, Seward Medical; London, UK). Microbial counts were based on tenfold serial dilutions in buffered peptone water. Then, aliquots (1 mL) of the pertinent dilutions were pour − plated into Tryptic Soy Agar and incubated at 37 °C for 24 h. Results were expressed as log CFU g−1. Three replicates were prepared for every microorganism × heat treatment × EVOO status (liquid or encapsulated) combination.

Statistical Analyses

Differences between treatments were tested at a 0.05 level of probability with the R studio software. The effects of heat treatment, EVOO status (liquid or encapsulated) and EVOO dose were tested with a three-way (heat treatment, EVOO status and EVOO dose) analysis of variance, followed by a multiple comparison test (Tukey HSD) to identify the differences between factors. All experiments were repeated three times, and the results are reported as mean values (3 experiments) ± standard deviation.

Results and Discussion

Experiment 1: In Vitro Antimicrobial Activity of Liquid and Encapsulated EVOO

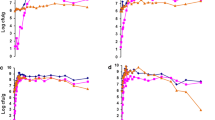

The in vitro antimicrobial activity of EVOO (liquid and encapsulated) was studied against the food pathogens (S. Senftenberg and L. monocytogenes) in experiment 1 using the well diffusion method. EVOO induced an antimicrobial activity against the studied food pathogens that ranged from 22 to 74% (Fig. 2). The antimicrobial activity of vegetable oils from olive fruits has been reported in scientific literature scarcely (Karaosmanoglu et al., 2010; Medina et al., 2006). Those authors reported very high antimicrobial activities (> 5–6 log units of reduction after 1 h of contact of olive oils within a liquid phase–phosphate buffer supplemented with a surfactant) containing the target microorganism—in virgin oils from Spanish (Arbequina and Picual) and Turkish (Burhaniye and Nizip) olive varieties. Radford et al. (1991) also found a high inhibition of Salmonella enteritidis growth when mayonnaise was prepared with extra virgin olive oil (Greek or Italian). Tassou and Nychas (1994) also reported the inhibition of Staphylococcus aureus growth in milk when supplemented with 2% of phenolic extract of olives. Nevertheless, such inhibitory effect was not observed when oleuropein was tested against S. enteritidis inoculated in milk (Tassou & Nychas, 1995). The high antimicrobial activity of virgin olive oils reported in the literature has been related to their characteristic phenolic profile, which is not present in other vegetable oils like sunflower, corn, rapeseed, soybean and cotton oils (Medina et al., 2006). In particular, the sum of the major phenolic compounds in EVOO (2-(3,4-dihydroxyphenyl) ethanol (also known as hydroxytyrosol), 2-(4-dihydroxyphenyl) ethanol (tyrosol), oleuropein-aglycone di-aldehyde and decarboxymethyl ligstroside aglycone) showed the highest correlation (R2 = 0.83) with cell viability of S. Enteritidis (Medina et al., 2006).

Antimicrobial activity (well diffusion method) of liquid or encapsulated extra virgin olive oil (EVOO) (liquid or encapsulated), at different doses (2.5% (D2.5); 1.7% and 0.8%), under in vitro conditions against Salmonella enterica subsp. enterica serovar Senftenberg and Listeria monocytogenes (mean value (n = 3) ± SD)

Attending to the studied food pathogens, the antimicrobial activity of EVOO was 1.2-fold higher against L. monocytogenes (Gram-positive bacteria) compared with S. Senftenberg (Gram-negative bacteria) (Fig. 2). The higher activity of EVOO against Gram-positive bacteria compared with Gram-negative bacteria has been previously reported (Karaosmanoglu et al., 2010; Medina et al., 2006). The higher susceptibility to EVOO may be explained by the outer membrane characteristic of the bacterial membrane, which may protect against the diffusion of the phenolic compounds through the cell-protecting structures.

The antimicrobial activity increased (p < 0.05) as the EVOO doses did with values of 21.7, 35.0 and 49.0% for the D0.8, D1.7 and D2.5 doses, respectively, in S. Senftenberg (Fig. 2A). The same finding was also observed (p < 0.05) for L. monocytogenes, with values of 25.3, 43.5 and 58.9% for the D0.8, D1.7 and D2.5 doses, respectively (Fig. 2B). Interestingly, the dose increments were highly correlated (R2 > 0.99; data not shown) to the antimicrobial activity increments. Medina et al. (2006) reported that EVOO concentrations of 50% within a phosphate buffer (enriched with a surfactant) inoculated with L. monocytogenes or S. Enteritidis led to non-detected (inhibition higher than 5 log units) microbial loads. Previously, we successfully reduced the olive oil content (mainly from EVOO) in chicken nuggets from 20% (conventional deep-fat frying) to 2.5% using a new technology based on encapsulated EVOO powder incorporated into the nugget breading process combined with oil-free cooking (Barón-Yusty et al., 2022). Indeed, the in vitro data of the present study indicate that an EVOO content of 2.5% in a food product is enough to reduce the pathogen loads by more than 50%.

The antimicrobial activity of encapsulated EVOO was also studied (Fig. 2). The encapsulation of EVOO increased (p < 0.05) the antimicrobial activity of liquid EVOO by 1.5–2.0 and 1.2–1.6-fold against S. Senftenberg and L. monocytogenes, respectively. The encapsulation × dose interaction was significant (p < 0.05) for S. Senftenberg. Nevertheless, no influence of the dose on the enhanced antimicrobial effect due to encapsulation was observed for L. monocytogenes (p > 0.05) for the encapsulation × dose interaction. This finding agrees with the commented higher susceptibility of S. Senftenberg to EVOO compared with L. monocytogenes. The increased EVOO antimicrobial activity with the encapsulation may be explained by the controlled EVOO release from this cyclodextrin inclusion complex, as previously characterised by our group (Barón-Yusty et al., 2022). Hence, the controlled release of the EVOO antimicrobial compounds avoided the burst effect (López-Gómez et al., 2023; Muñoz-Shugulí et al., 2022) of non-encapsulated antimicrobial treatments, which is characterised by an initial high antimicrobial effect followed by high microbial growth of the survivor microorganisms.

Experiment 2: Effect of Cooking Treatments on the EVOO Antimicrobial Activity Under In Vitro Conditions

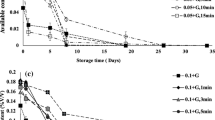

The effect of different cooking treatments (optimised for cooking of chicken nuggets) was studied in vitro for S. Senftenberg and L. monocytogenes in experiment 2 (Table 1). As observed, frying, infrared and convection treatments induced S. Senftenberg thermal reductions of 30–35% from the initial microbial loads (≈ 7.8 log CFU mL−1), while the combined heat treatment (infrared + convection) doubled the observed microbial reduction with a microbial inhibition of 66% comparing to unheated (control) samples. Higher thermal reductions (60–80% microbial reductions compared with control samples) for S. Senftenberg were observed after heat treatments. Nevertheless, lower thermal reductions (30–60% microbial reductions compared with control samples) were observed for L. monocytogenes after cooking treatments. As observed in our study, L. monocytogenes is considered one of the most heat-resistant bacteria, being then more resistant than most Salmonella serotypes (Doyle et al., 2001; O’Bryan et al., 2006).

The combination of liquid EVOO with cooking treatments incremented the EVOO antimicrobial activity (Table 1). In particular, liquid EVOO antimicrobial activity (microbial reductions using liquid EVOO compared with samples without EVOO) was enhanced by 11–27% when the heat treatments were also applied. As expected, the highest cooking-enhanced antimicrobial activity of liquid EVOO was reached with the highest dose (D2.5). In particular, for L. monocytogenes, infrared treatment enhanced by 27% the liquid EVOO antimicrobial activity, while the convection treatment led to the lowest liquid EVOO antimicrobial activity increment (11%). An intermediate situation was observed for the combined treatment, which enhanced by 20% the liquid EVOO antimicrobial activity for the D2.5 dose. The same trends were observed for the D1.7 dose, while no cooking-enhanced antimicrobial EVOO activity was observed at the lowest dose (D0.8) for L. monocytogenes. Similar tendencies were observed for S. Senftenberg, although this bacterium showed higher susceptibility compared with L. monocytogenes as previously discussed. In particular for the highest EVOO dose (D2.5), infrared, combined and convection cooking treatments enhanced the liquid EVOO antimicrobial activity by 52.2, 36.2 and 11.9%, respectively, for S. Senftenberg. The EVOO-enhanced antimicrobial activity with cooking treatments may be explained by a higher diffusion of the EVOO antimicrobial compounds (phenolic compounds) through the bacterial cell structures due to a higher thermal-induced fluency of the phospholipids present in the bacterial cell membranes. Although the antimicrobial mechanisms of phenolic compounds in bacterial cells are not well understood, there are at least three mechanisms on which several authors agree (Bouarab-Chibane et al., 2019): (i) modification of the permeability of cell membranes, formation of cytoplasmic granules and rupture of the cytoplasmic membrane; (ii) changes in various intracellular functions induced by hydrogen bonding of the phenolic compounds to enzymes through their OH groups; and (iii) modification of fungal morphology (cell wall rigidity and integrity losses) induced by different interactions with cell membranes. There is no previous literature reporting the EVOO-enhanced antimicrobial activity after cooking treatments to the best of our knowledge.

In general, encapsulation of EVOO even increased the cooking-enhanced EVOO antimicrobial activity (Table 1). Interestingly, this encapsulation benefit was even observed at the lowest dose (D0.8), which was not observed (p > 0.05) for the corresponding liquid EVOO data. In particular, cooking-enhanced EVOO antimicrobial activities against L. monocytogenes were even increased by 23–26% for infrared and frying treatments and 13% for convection and combined treatments, when EVOO was encapsulated. The same trends were also observed for the higher doses reaching cooking-enhanced antimicrobial activities with encapsulated EVOO of ≈ 30% for infrared and combined treatment. In general, higher S. Senftenberg antimicrobial activities were also observed for encapsulated EVOO after cooking treatments compared to L. monocytogenes. In particular, cooking-enhanced EVOO antimicrobial activities against S. Senftenberg were increased up to 50–56% with the infrared and frying treatments. This finding may be explained due to a higher effectiveness against S. Senftenberg than L. monocytogenes through the EVOO controlled release avoiding the previously commented burst effect. In addition, the higher susceptibility of Salmonella compared with L. monocytogenes (previously discussed) is even enhanced when the EVOO is encapsulated.

According to in vitro data, the intermediate dose (D1.7) was enough to induce similar microbial reductions compared with the highest dose (D2.5) for S. Senftenberg. However, it was necessary to increase the dose to the highest (D2.5) for the most resistant pathogen (L. monocytogenes). The encapsulated EVOO combined with the infrared treatment showed the highest antimicrobial reductions for the D2.5 and D1.6 doses against L. monocytogenes and S. Senftenberg, respectively. Nevertheless, these high antimicrobial enhancements of encapsulated EVOO when combined with fat-free cooking methods must be validated in vivo as conducted in experiment 3 since other components from the chicken nuggets (fat, proteins, additives, etc.) may interact with the EVOO phenolic compounds.

Experiment 3: Validation (In Vivo) of the Effects of Cooking Treatments on the EVOO Antimicrobial Activity in Chicken Nuggets

The in vivo EVOO antimicrobial activity against S. Senftenberg and L. monocytogenes increased when EVOO was combined with cooking treatments by 13–60 and 22–80%, respectively, for liquid EVOO data (Table 2). In particular, the low-fat cooking methods values showed enhancements of 29 and 39% for convection and infrared treatments, respectively. The observed higher EVOO antimicrobial activity when combined with thermal treatments may be explained by the formation of complexes of the EVOO antimicrobial compounds (i.e. phenolic compounds) with proteins (from the used batter powder mix; see the “Material and Methods” section) or carbohydrates (from the breadcrumbs mix composed of a flour mix), as previously reported (Schefer et al., 2021). Hence, these complexes of antimicrobial-breading mix components may lead to higher resistance of these antimicrobial phenolic compounds and consequently higher antimicrobial activity. This hypothesis may also explain the higher EVOO antimicrobial activity related to in vivo data compared to in vitro data.

The incorporation of encapsulated EVOO within the chicken nuggets showed different effects after the fat-free cooking treatments depending on the studied pathogen (Table 2). For example, the antimicrobial activity using encapsulated EVOO was not incremented when using the infrared treatment for L. monocytogenes, while the same finding was observed for the convection treatment against S. Senftenberg. This may be explained by the thermal sensitivity of the EVOO antimicrobial phenolic compounds since different temperature and heat flux profiles are expected using the different cooking methods as reported in the literature (Ozen & Singh, 2020; Sakai & Hanzawa, 1994). Nevertheless, the combined cooking treatment induced antimicrobial activity enhancements of ≈ 60% when using encapsulated EVOO for both L. monocytogenes and S. Senftenberg. Lianou et al. (2018) also found that Listeria monocytogenes growth was controlled in vanilla cream pudding when an oil extract from cinnamon was used with 3–7 lower log units after 40 days at 4 °C.

Hence, the use of encapsulated EVOO within the breading of chicken nuggets may contribute to ensuring food safety, while obtaining a healthier product using the combined cooking method, which consists of two oil-free cooking methods (infrared and convection ovens). In addition, these fat-free cooking methods have a higher energy use efficiency being more economical for the food industry (Ozen & Singh, 2020; Sakai & Hanzawa, 1994). Finally, the high waste volumes resulting from conventional deep-fat frying are avoided, reducing their impact on the environment.

Conclusions

The high Salmonella and Listeria monocytogenes incidence in meat products highlights the importance to find new natural antimicrobial systems combined with healthy cooking methods in some products like chicken nuggets. The different in vitro experiments of this study showed that encapsulation of extra virgin olive oil (EVOO) increased the EVOO antimicrobial effect by approximately two folds against Salmonella and L. monocytogenes. Then, those data were validated (in vivo experiment) on inoculated (Salmonella and L. monocytogenes) chicken nuggets, which were prepared with encapsulated EVOO within the breading mix, followed by oil-free cooking. In conclusion, the addition of encapsulated EVOO within chicken nuggets (1.7 or 2.5%) followed by infrared cooking may highly contribute to ensuring the food safety of these products against Salmonella and L. monocytogenes. It would be interesting in future studies to investigate the phenolic compound changes after the different oil-free cooking methods to interrelate it with the achieved antimicrobial activity.

Data Availability

The data that support the findings of this study are not openly available due to reasons of sensitivity and are available from the corresponding author upon reasonable request.

References

Abu-Lafi, S., Al-Natsheh, M. S., Yaghmoor, R., & Al-Rimawi, F. (2017). Enrichment of phenolic compounds from olive mill wastewater and in vitro evaluation of their antimicrobial activities. Evidence-based Complementary and Alternative Medicine, 2017. https://doi.org/10.1155/2017/3706915

Barón-Yusty, M., Martínez-Hernández, G. B., Ros-Chumillas, M., Navarro-Segura, L., & López-Gómez, A. (2022). Encapsulated EVOO improves food safety and shelf life of refrigerated pre-cooked chicken nuggets. Clean Technologies, 4(1), 53–66. https://doi.org/10.3390/CLEANTECHNOL4010005/S1

Bouarab-Chibane, L., Degraeve, P., Ferhout, H., Bouajila, J., & Oulahal, N. (2019). Plant antimicrobial polyphenols as potential natural food preservatives. Journal of the Science of Food and Agriculture, 99(4), 1457–1474. https://doi.org/10.1002/JSFA.9357

Bucher, O., Holley, R. A., Ahmed, R., Tabor, H., Nadon, C., Ng, L. K., & D’Aoust, J. Y. (2007). Occurrence and characterization of Salmonella from chicken nuggets, strips, and pelleted broiler feed. Journal of Food Protection, 70(10), 2251–2258. https://doi.org/10.4315/0362-028X-70.10.2251

Capasso, R., Evidente, A., Schivo, L., Orru, G., Marcialis, M. A., & Cristinzio, G. (1995). Antibacterial polyphenols from olive oil mill waste waters. Journal of Applied Bacteriology, 79(4), 393–398. https://doi.org/10.1111/J.1365-2672.1995.TB03153.X

Comission, E. (2000). Commission Decision of 3 May 2000 replacing Decision 94/3/EC establishing a list of wastes pursuant to Article 1(a) of Council Directive 75/442/EEC on waste and Council Decision 94/904/EC establishing a list of hazardous waste pursuant to Article 1(4) of. Official Journal of the European Communities, 6.9.2000, 3–24. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02000D0532-20150601&from=EN

DeDonder, S., Jacob, C. J., Surgeoner, B. V., Chapman, B., Phebus, R., & Powell, D. A. (2009). Self-reported and observed behavior of primary meal preparers and adolescents during preparation of frozen, uncooked, breaded chicken products. British Food Journal, 111(9), 915–929. https://doi.org/10.1108/00070700910992844/FULL/PDF

Doyle, M. E., Mazzotta, A. S., Wang, T., Wiseman, D. W., & Scott, V. N. (2001). Heat resistance of Listeria monocytogenes. Journal of Food Protection, 64(3), 410–429. https://doi.org/10.4315/0362-028X-64.3.410

EC. (2022). 2022 Annual Report Alert and Cooperation Network. chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/. https://food.ec.europa.eu/system/files/2023-06/acn_annual-report_2022.pdf

EEC. (2022). COMMISSION DELEGATED REGULATION (EU) 2022/2104 of 29 July 2022 supplementing Regulation (EU) No 1308/2013 of the European Parliament and of the Council as regards marketing standards for olive oil, and repealing Commission Regulation (EEC) No 2568/91 and. https://eur-lex.europa.eu/eli/reg_del/2022/2104/oj. Accessed 11 Jul 2023.

Faloye, O. R., Sobukola, O. P., Shittu, T. A., & Bakare, H. A. (2021). Influence of frying parameters and optimization of deep fat frying conditions on the physicochemical and textural properties of chicken nuggets from FUNAAB-Alpha broilers. SN Applied Sciences, 3(2), 1–17. https://doi.org/10.1007/S42452-021-04249-5/TABLES/4

Fleming, H. P., Walter, W. M., & J., & Etchells, J. L. (1973). Antimicrobial properties of oleuropein and products of its hydrolysis from green olives. Applied Microbiology, 26(5), 777–782. https://doi.org/10.1128/AM.26.5.777-782.1973

Göktepe, S., Ocak, B., & Özdestan-Ocak, Ö. (2021). Physico-chemical, sensory, and antioxidant characteristics of olive paste enriched with microencapsulated thyme essential oil. Food and Bioprocess Technology, 14(11), 2032–2045. https://doi.org/10.1007/S11947-021-02707-X/TABLES/7

Jiménez-Martín, E., Pérez-Palacios, T., Carrascal, J. R., & Rojas, T. A. (2016). Enrichment of chicken nuggets with microencapsulated omega-3 fish oil: Effect of frozen storage time on oxidative stability and sensory quality. Food and Bioprocess Technology, 9(2), 285–297. https://doi.org/10.1007/S11947-015-1621-X/FIGURES/5

Karaosmanoglu, H., Soyer, F., Ozen, B., & Tokatli, F. (2010). Antimicrobial and antioxidant activities of Turkish extra virgin olive oils. Journal of Agricultural and Food Chemistry, 58(14), 8238–8245. https://doi.org/10.1021/JF1012105

Koç, M., Güngör, Ö., Zungur, A., Yalçın, B., Selek, İ, Ertekin, F. K., & Ötles, S. (2015). Microencapsulation of extra virgin olive oil by spray drying: Effect of wall materials composition, process conditions, and emulsification method. Food and Bioprocess Technology, 8(2), 301–318. https://doi.org/10.1007/S11947-014-1404-9/TABLES/7

Koutsoumanis, K., Lambropoulou, K., & Nychas, G. J. E. (1999). A predictive model for the non-thermal inactivation of Salmonella enteritidis in a food model system supplemented with a natural antimicrobial. International Journal of Food Microbiology, 49(1–2), 63–74. https://doi.org/10.1016/S0168-1605(99)00054-9

Lianou, A., Moschonas, G., Nychas, G. J. E., & Panagou, E. Z. (2018). Growth of Listeria monocytogenes in pasteurized vanilla cream pudding as affected by storage temperature and the presence of cinnamon extract. Food Research International, 106, 1114–1122. https://doi.org/10.1016/J.FOODRES.2017.11.027

Lianou, A., Raftopoulou, O., Spyrelli, E., & Nychas, G. J. E. (2021). Growth of Listeria monocytogenes in partially cooked battered chicken nuggets as a function of storage temperature. Foods (Basel, Switzerland), 10(3). https://doi.org/10.3390/FOODS10030533

López-Gómez, A., Navarro-Martínez, A., Garre, A., Iguaz, A., Maldonado-Guzmán, P., & Martínez-Hernández, G. B. (2023). Kinetics of carvacrol release from active paper packaging for fresh fruits and vegetables under conditions of open and closed package. Food Packaging and Shelf Life, 37, 101081. https://doi.org/10.1016/J.FPSL.2023.101081

Lusk, J. L. (2019). Consumer beliefs about healthy foods and diets. PLoS ONE, 14(10), e0223098. https://doi.org/10.1371/JOURNAL.PONE.0223098

MacDougall, L., Fyfe, M., McIntyre, L., Paccagnella, A., Cordner, K., Kerr, A., & Aramini, J. (2004). Frozen chicken nuggets and strips—A newly identified risk factor for Salmonella Heidelberg infection in British Columbia. Canada. Journal of Food Protection, 67(6), 1111–1115. https://doi.org/10.4315/0362-028X-67.6.1111

Manolikar, M. K., & Sawant, M. R. (2003). Study of solubility of isoproturon by its complexation with β-cyclodextrin. Chemosphere, 51(8), 811–816. https://doi.org/10.1016/S0045-6535(03)00099-7

Markín, D., Duek, L., & Berdícevsky, I. (2003). In vitro antimicrobial activity of olive leaves. Antimikrobielle Wirksamkeit von Olivenblättern in vitro. Mycoses, 46(3–4), 132–136. https://doi.org/10.1046/J.1439-0507.2003.00859.X

Medina, E., Brenes, M., Garcia, A., Romero, C., & De Castro, A. (2009). Bactericidal activity of glutaraldehyde-like compounds from olive products. Journal of Food Protection, 72(12), 2611–2614. https://doi.org/10.4315/0362-028X-72.12.2611

Medina, E., De Castro, A., Romero, C., & Brenes, M. (2006). Comparison of the concentrations of phenolic compounds in olive oils and other plant oils: Correlation with antimicrobial activity. Journal of Agricultural and Food Chemistry, 54(14), 4954–4961. https://doi.org/10.1021/JF0602267

Medina, E., Romero, C., Brenes, M., & De Castro, A. (2007). Antimicrobial activity of olive oil, vinegar, and various beverages against foodborne pathogens. Journal of Food Protection, 70(5), 1194–1199. https://doi.org/10.4315/0362-028X-70.5.1194

Mor-Mur, M., & Yuste, J. (2010). Emerging bacterial pathogens in meat and poultry: An overview. Food and Bioprocess Technology, 3(1), 24–35. https://doi.org/10.1007/S11947-009-0189-8/TABLES/4

Mourtzinos, I., Salta, F., Yannakopoulou, K., Chiou, A., & Karathanos, V. T. (2007). Encapsulation of olive leaf extract in β-cyclodextrin. Journal of Agricultural and Food Chemistry, 55(20), 8088–8094. https://doi.org/10.1021/jf0709698

Muñoz-Shugulí, C., Rodríguez-Mercado, F., Mascayano, C., Herrera, A., Bruna, J. E., Guarda, A., & Galotto, M. J. (2022). Development of inclusion complexes with relative humidity responsive capacity as novel antifungal agents for active food packaging. Frontiers in Nutrition, 8, 799779. https://doi.org/10.3389/FNUT.2021.799779/BIBTEX

Murphy, R. Y., Duncan, L. K., Beard, B. L., & Driscoll, K. H. (2003). D and z values of Salmonella, Listeria innocua, and Listeria monocytogenes in fully cooked poultry products. Journal of Food Science, 68(4), 1443–1447. https://doi.org/10.1111/J.1365-2621.2003.TB09664.X

O’Bryan, C. A., Crandall, P. G., Martin, E. M., Griffis, C. L., & Johnson, M. G. (2006). Heat resistance of Salmonella spp., Listeria monocytogenes, Escherichia coli 0157:H7, and Listeria innocua M1, a potential surrogate for Listeria monocytogenes, in meat and poultry: A review. Journal of Food Science, 71(3), R23–R30. https://doi.org/10.1111/J.1365-2621.2006.TB15639.X

Ozen, E., & Singh, R. K. (2020). Heat transfer in breaded and non-breaded chicken nuggets baked in a pilot-scale radiant wall oven. LWT, 124, 109107. https://doi.org/10.1016/J.LWT.2020.109107

Pedersen, T. B., Elmerdahl Olsen, J., & Bisgaard, M. (2008). Persistence of Salmonella Senftenberg in poultry production environments and investigation of its resistance to desiccation. 37(4), 421–427. https://doi.org/10.1080/03079450802216561

Plati, F., & Paraskevopoulou, A. (2022). Micro- and nano-encapsulation as tools for essential oils advantages’ exploitation in food applications: The case of oregano essential oil. Food and Bioprocess Technology, 15(5), 949–977. https://doi.org/10.1007/S11947-021-02746-4

Radford, S. A., Tassou, C. C., Nychas, G. J. E., & Board, R. G. (1991). The influence of different oils on the death rate of Salmonella enteritidis in homemade mayonnaise. Letters in Applied Microbiology, 12(4), 125–128. https://doi.org/10.1111/J.1472-765X.1991.TB00521.X

Ranalli, A., Marchegiani, D., Pardi, D., Contento, S., Pardi, D., Girardi, F., & Kotti, F. (2009). Evaluation of functional phytochemicals in destoned virgin olive oil. Food and Bioprocess Technology, 2(3), 322–327. https://doi.org/10.1007/S11947-008-0128-0/FIGURES/2

Romero, C., Medina, E., Vargas, J., Brenes, M., & De Castro, A. (2007). In vitro activity of olive oil polyphenols against helicobacter pylori. Journal of Agricultural and Food Chemistry, 55(3), 680–686. https://doi.org/10.1021/JF0630217/ASSET/IMAGES/LARGE/JF0630217F00007.JPEG

Rushdy, A. A., Stuart, J. M., Ward, L. R., Bruce, J., Threlfall, E. J., Punia, P., & Bailey, J. R. (1998). National outbreak of Salmonella Senftenberg associated with infant food. Epidemiology and Infection, 120(2), 125–128. https://doi.org/10.1017/S0950268897008546

Sakai, N., & Hanzawa, T. (1994). Applications and advances in far-infrared heating in Japan. Trends in Food Science & Technology, 5(11), 357–362. https://doi.org/10.1016/0924-2244(94)90213-5

Schefer, S., Oest, M., & Rohn, S. (2021). Interactions between phenolic acids, proteins, and carbohydrates—Influence on dough and bread properties. Foods, 10(11). https://doi.org/10.3390/FOODS10112798

Tassou, C. C., & Nychas, G. J. E. (1994). Inhibition of Staphylococcus aureus by olive phenolics in broth and in a model food system. Journal of Food Protection, 57(2), 120–124. https://doi.org/10.4315/0362-028X-57.2.120

Tassou, C. C., & Nychas, G. J. E. (1995). Inhibition of Salmonella enteritidis by oleuropein in broth and in a model food system. Letters in Applied Microbiology, 20(2), 120–124. https://doi.org/10.1111/J.1472-765X.1995.TB01301.X

Yakhlef, W., Arhab, R., Romero, C., Brenes, M., de Castro, A., & Medina, E. (2018). Phenolic composition and antimicrobial activity of Algerian olive products and by-products. LWT, 93, 323–328. https://doi.org/10.1016/J.LWT.2018.03.044

Acknowledgements

We give thanks to Noelia García Cañavate for her technical assistance.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. The research leading to these results received funding from the Centre for the Development of Industrial Technology (CDTI, Spain) through the project IDI-20190627.

Author information

Authors and Affiliations

Contributions

Conceptualization, Antonio López-Gómez; methodology, Antonio López-Gómez, María Ros-Chumillas, and Ginés Benito Martínez-Hernández; validation, Antonio López-Gómez; formal analysis, Marta Barón-Yusty, and Ginés Benito Martínez-Hernández; investigation, all authors; resources, Antonio López-Gómez; data curation, Ginés Benito Martínez-Hernández; writing—original draft preparation, Ginés Benito Martínez-Hernández, and Marta Barón-Yusty; writing—review and editing, Ginés Benito Martínez-Hernández, and Antonio López-Gómez; visualization, Ginés Benito Martínez-Hernández; supervision, Antonio López-Gómez; project ad-ministration, Antonio López-Gómez; funding acquisition, Antonio López-Gómez. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Barón-Yusty, M., Martínez-Hernández, G.B., Ros-Chumillas, M. et al. Innovative Combined Technology with Encapsulated EVOO and Infrared Processing Against Salmonella and Listeria monocytogenes in Breaded Poultry Products. Food Bioprocess Technol 17, 2023–2033 (2024). https://doi.org/10.1007/s11947-023-03246-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03246-3