Abstract

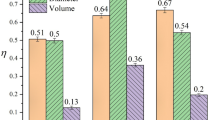

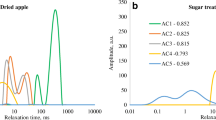

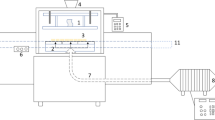

Microwave drying is usually combined with vacuum environment in conjunction with hot air flow to draw the moisture rapidly. The moisture content of the vegetables undergoing drying is hard to measure online. This research designed a microwave vacuum drying (MVD)-low-field nuclear magnetic resonance (NMR) smart device and investigated the feasibility of NMR method for online measurement of state of moisture during MVD. The relation between the signal amplitude (A 2) and the true moisture content (M 1) of six kinds of vegetables (mushroom, carrot, potato, lotus, edamame, vegetable corn) was fitted to estimate if NMR can measure the M 1 of vegetables directly. Results showed that A 2 and M 1 of different fresh vegetables had no single empirical mathematical model to fit. However, for each kind of these vegetables, the A 2 and corresponding M 1 in different MVD stages showed a significant linear relationship. The predicted moisture content (M 2) of mushroom: M 2 = 5.25351 × 10−4 A 2 − 0.34042, R = 0.996; carrot: M 2 = 5.78756 × 10−4 A 2 − 0.14108, R = 0.998; potato: M 2 = 3.10019 × 10−4 A 2 − 0.10612, R = 0.991; lotus: M 2 = 2.32415 × 10−4 A 2 − 0.01573, R = 0.998; edamame: M 2 = 3.13310 × 10−4 A 2 − 0.4198, R = 0.996; vegetable corn: M 2 = 1.69461 × 10−4 A 2 − 0.09063, R = 0.995. The linear models between M 2 and A 2 were able to estimate the end point (M 1 < 8%) of MVD with a high accuracy (P > 0.950).

Similar content being viewed by others

References

Aguiló-Aguayo, I., Downey, G., Keenan, D. F., Lyng, J. G., Brunton, N., & Rai, D. K. (2014). Observations on the water distribution and extractable sugar content in carrot slices after pulsed electric field treatment. Food Research International, 64, 18–24.

Ambros, S., Bauer, S., Shylkina, L., Foerst, P., & Kulozik, U. (2016). Microwave-vacuum drying of lactic acid bacteria: influence of process parameters on survival and acidification activity. Food and Bioprocess Technology, 9(11), 1901–1911.

Askari, G., Emam-Djomeh, Z., & Mousavi, S. (2013). Heat and mass transfer in apple cubes in a microwave-assisted fluidized bed drier. Food and Bioproducts Processing, 91(3), 207–215.

Avhad, M. R., & Marchetti, J. M. (2016). Mathematical modelling of the drying kinetics of Hass avocado seeds. Industrial Crops and Products, 91, 76–87.

Badea, E., Şendrea, C., Carşote, C., Adams, A., Blümich, B., & Iovu, H. (2016). Unilateral NMR and thermal microscopy studies of vegetable tanned leather exposed to dehydrothermal treatment and light irradiation. Microchemical Journal, 129, 158–165.

Bauer, K., Kulenkampff, J., Henninges, J., & Spangenberg, E. (2016). Lithological controls on gas hydrate saturation: insights from signal classification of NMR downhole data. EGU General Assembly Conference Abstracts, 18, 13152.

Bertram, H. C., Karlsson, A. H., & Andersen, H. J. (2003). The significance of cooling rate on water dynamics in porcine muscle from heterozygote carriers and non-carriers of the halothane gene—a low-field NMR relaxation study. Meat Science, 65(4), 1281–1291.

Chandramohan, V., & Talukdar, P. (2017). Estimation of equilibrium moisture content and drying time of potato through hot air drying. In A. Saha, D. Das, R. Srivastava, P. Panigrahi, K. Muralidhar (Eds.), Fluid mechanics and fluid power–contemporary research. Lecture notes in mechanical engineering (pp. 205–213). New Delhi: Springer.

Fullerton, G. D., Potter, J. L., & Dornbluth, N. C. (1982). NMR relaxation of protons in tissues and other macromolecular water solutions. Magnetic Resonance Imaging, 1(4), 209–226.

Fundo, J. F., Amaro, A. L., Madureira, A. R., Carvalho, A., Feio, G., Silva, C. L., et al. (2015). Fresh-cut melon quality during storage: an NMR study of water transverse relaxation time. Journal of Food Engineering, 167, 71–76.

Giri, S., & Prasad, S. (2007). Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. Journal of Food Engineering, 78(2), 512–521.

Hills, B., Takacs, S., & Belton, P. (1990). A new interpretation of proton NMR relaxation time measurements of water in food. Food Chemistry, 37(2), 95–111.

Huang, M., Wang, Q., Zhang, M., & Zhu, Q. (2014). Prediction of color and moisture content for vegetable soybean during drying using hyperspectral imaging technology. Journal of Food Engineering, 128(1), 24–30.

Jiang, H., Zhang, M., Liu, Y., Mujumdar, A. S., & Liu, H. (2013). The energy consumption and color analysis of freeze/microwave freeze banana chips. Food and Bioproducts Processing, 91(4), 464–472.

Jiang, J., Dang, L., Yuensin, C., Tan, H., Pan, B., & Wei, H. (2017). Simulation of microwave thin layer drying process by a new theoretical model. Chemical Engineering Science, 162, 69–76.

Kumar, S., Gautam, S., & Sharma, A. (2015). Hurdle technology including chlorination, blanching, packaging and irradiation to ensure safety and extend shelf life of shelled sweet corn kernels. Journal of Food Processing & Preservation, 39(6), 2340–2347.

Li, B., Yin, Q., Yin, L., Zhang, K., Chen, H., & Han, Q. (2015). Studies on characteristics and mechanism of hot air-microwave fluidized drying of lentinusedodes. Journal of Chinese Institute of Food Science and Technology, 15(5), 134–139.

Li, S., Li, X., Lamikanra, O., Luo, Q., Liu, Z., & Yang, J. (2017). Effect of cooking on physicochemical properties and volatile compounds in lotus root (Nelumbo nucifera Gaertn). Food Chemistry, 216, 316.

Lv, W., Li, S., Han, Q., Zhao, Y., & Wu, H. (2016). Study of the drying process of ginger (Zingiber officinale Roscoe) slices in microwave fluidized bed dryer. Drying Technology, 34(14), 1690–1699.

McDonald, P., Gajewicz, A., & Morrell, R. (2016). 1H NMR characterisation of pore water in cement materials. In Proceedings of the 36th Cement and Concrete Science Conference, 2016.09.05–2016.09.06, Cardiff.

Pereira, F. M. V., Rebellato, A. P., Pallone, J. A. L., & Colnago, L. A. (2015). Through-package fat determination in commercial samples of mayonnaise and salad dressing using time-domain nuclear magnetic resonance spectroscopy and chemometrics. Food Control, 48, 62–66.

Pu, Y., & Sun, D. (2017). Combined hot-air and microwave-vacuum drying for improving drying uniformity of mango slices based on hyperspectral imaging visualisation of moisture content distribution. Biosystems Engineering, 156, 108–119.

Roknul, A. S. M., Zhang, M., Wang, A. S. M., & Yuchuan. (2014). A comparative study of four drying methods on drying time and quality characteristics of stem lettuce slices (Lactuca sativa L.) Drying Technology, 32(6), 657–666.

Ruhanian, S., & Movagharnejad, K. (2016). Mathematical modeling and experimental analysis of potato thin-layer drying in an infrared-convective dryer. Engineering in Agriculture, Environment and Food, 9(1), 84–91.

Sánchez-Alonso, I., Moreno, P., & Careche, M. (2014). Low field nuclear magnetic resonance (LF-NMR) relaxometry in hake (Merluccius merluccius L.) muscle after different freezing and storage conditions. Food Chemistry, 153, 250–257.

Srivastava, A. K., Singh, U. K., & Shukla, S. K. (2015). Modelling and evaluation of thermal diffusivity and activation energy of potato slices in forced convection multi tray solar dryer. Journal of Food Science, 55(1), 218–223.

Su, Y., Zhang, M., & Mujumdar, A. S. (2015). Recent developments in smart drying technology. Drying Technology, 33(3), 260–276.

Swain, S., Samuel, D., Kar, A., & Sahoo, L. (2014). Optimization of colour parameters and drying efficiency in osmotically pretreated microwave assisted drying of yellow sweet pepper (Capsicum annum L.) using response-surface methodology. Journal of Food Research and Technology, 2(2), 67–76.

Tylewicz, U., Aganovic, K., Vannini, M., Toepfl, S., Bortolotti, V., Dalla Rosa, M., et al. (2016). Effect of pulsed electric field treatment on water distribution of freeze-dried apple tissue evaluated with DSC and TD-NMR techniques. Innovative Food Science & Emerging Technologies, 37, 352–358.

Wang, R., Zhang, M., Mujumdar, A. S., & Sun, J.-C. (2009). Microwave freeze–drying characteristics and sensory quality of instant vegetable soup. Drying Technology, 27(9), 962–968.

Wang, X., Chen, Q., Bi, J., Gao, K., Zhou, L., Wu, X., et al. (2015). Effect of hot air-pulsed sudden decompression flashing drying on moisture and microstructure in apple slices. Transactions of the Chinese Society of Agricultural Engineering, 31(20), 287–293.

Wang, Y., Zhang, M., Mujumdar, A. S., Mothibe, K. J., & Azam, S. R. (2012). Effect of blanching on microwave freeze drying of stem lettuce cubes in a circular conduit drying chamber. Journal of Food Engineering, 113(2), 177–185.

Wang, Z., Sun, J., Chen, F., Liao, X., & Hu, X. (2007). Mathematical modelling on thin layer microwave drying of apple pomace with and without hot air pre-drying. Journal of Food Engineering, 80(2), 536–544.

Xu, F., Jin, X., Zhang, L., & Chen, X. D. (2017). Investigation on water status and distribution in broccoli and the effects of drying on water status using NMR and MRI methods. Food Research International, 96, 191–197.

Xu, J., Xu, G., Zhang, X., Gu, Z., Zhang, S., & Li, H. (2013). Moisture transport in carrot during hot air drying using magnetic resonance imaging. Transactions of the Chinese Society of Agricultural Engineering, 29(12), 271–276.

Yan, K., Chu, Y., Huang, J., Jiang, M., Li, W., Wang, Y., et al. (2016). Qualitative and quantitative analyses of compound Danshen extract based on 1H NMR method and its application for quality control. Journal of Pharmaceutical and Biomedical Analysis, 131, 183–187.

Zhang, M., & Chen, G. (2007). Research progress on the energy reduce of open-type air drying process of vegetables [J]. Drying Technology & Equipment, 6, 003.

Zhang, M., Tang, J., Mujumdar, A., & Wang, S. (2006). Trends in microwave-related drying of fruits and vegetables. Trends in Food Science & Technology, 17(10), 524–534.

Zhang, X., Zhu, S., Huang, J., Xu, G., Xu, J., & Li, H. (2012). Analysis on internal moisture changes of carrot slices during drying process using low-field NMR. Transactions of the Chinese Society of Agricultural Engineering, 28(22), 282–287.

Zhao, Y., Jiang, Y., Zheng, B., Zhuang, W., Zheng, Y., & Tian, Y. (2017). Influence of microwave vacuum drying on glass transition temperature, gelatinization temperature, physical and chemical qualities of lotus seeds. Food Chemistry, 228, 167–176.

Zhou, H., Ye, Z., Yu, Z., Su, M., & Du, J. (2016). Application of low-field nuclear magnetic resonance and proton magnetic resonance imaging in evaluation of ‘Jinxiu’ yellow peach’s storage suitability. Emirates Journal of Food ands, 28(9), 633.

Funding

We acknowledge the financial support provided to us by the China Key Research Program (Contract No. 2017YFD0400901), Jiangsu Province (China) “Collaborative Innovation Center for Food Safety and Quality Control” Industry Development Program, Jiangsu Province (China) Infrastructure Project (Contract No. BM2014051); all of which have enabled us to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lv, W., Zhang, M., Bhandari, B. et al. Smart NMR Method of Measurement of Moisture Content of Vegetables During Microwave Vacuum Drying. Food Bioprocess Technol 10, 2251–2260 (2017). https://doi.org/10.1007/s11947-017-1991-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-017-1991-3