Abstract

The thermomechanical coupling of rocks refers to the interaction between the mechanical and thermodynamic behaviors of rocks induced by temperature changes. The study of this coupling interaction is essential for understanding the mechanical and thermodynamic properties of the surrounding rocks in underground engineering. In this study, an improved temperature-dependent linear parallel bond model is introduced under the framework of a particle flow simulation. A series of numerical thermomechanical coupling tests are then conducted to calibrate the micro-parameters of the proposed model by considering the mechanical behavior of the rock under different thermomechanical loadings. Good agreement between the numerical results and experimental data are obtained, particularly in terms of the compression, tension, and elastic responses of granite. With this improved model, the thermodynamic response and underlying cracking behavior of a deep-buried tunnel under different thermal loading conditions are investigated and discussed in detail.

Similar content being viewed by others

References

Chaki S, Takarli M, Agbodjan W P. Influence of thermal damage on physical properties of a granite rock: Porosity, permeability and ultrasonic wave evolutions. Construction & Building Materials, 2008, 22(7): 1456–1461

Cai Y Y, Luo C H, Yu J, Zhang L M. Experimental study on mechanical properties of thermal-damage granite rock under triaxial unloading confining pressure. Journal of Geotechnical Engineering, 2015, 37: 1173–1180

Zhao F, Shi Z M, Sun Q. Fracture mechanics behavior of jointed granite exposed to high temperatures. Rock Mechanics and Rock Engineering, 2021, 54(5): 2183–2196

Li D Y, Su X L, Gao F H, Liu Z D. Experimental studies on physical and mechanical behaviors of heated rocks with prefabricated hole exposed to different cooling rates. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2022, 8(4): 125

Huang Y H, Yang S Q, Tian W L, Zhao J, Ma D, Zhang C S. Physical and mechanical behavior of granite containing preexisting holes after high temperature treatment. Archives of Civil and Mechanical Engineering, 2017, 17(4): 912–925

Sun Q, Zhang W Q, Zhu Y M, Huang Z. Effect of high temperatures on the thermal properties of granite. Rock Mechanics and Rock Engineering, 2019, 52(8): 2691–2699

Fan L F, Gao J W, Wu Z J, Yang S Q, Ma G W. An investigation of thermal effects on micro-properties of granite by X-ray CT technique. Applied Thermal Engineering, 2018, 140: 505–519

Chen Y L, Ni J, Shao W, Azzam R. Experimental study on the influence of temperature on the mechanical properties of granite under uni-axial compression and fatigue loading. International Journal of Rock Mechanics and Mining Sciences, 2012, 56: 62–66

Sun Q, Zhang W Q, Xue L, Zhang Z Z, Su T M. Thermal damage pattern and thresholds of granite. Environmental Earth Sciences, 2015, 74(3): 2341–2349

Xu X L, Kang Z X, Ji M, Ge W X, Chen J. Research of microcosmic mechanism of brittle-plastic transition for granite under high temperature. Procedia Earth and Planetary Science, 2009, 1(1): 432–437

Yin T B, Li X B, Cao W Z, Xia K W. Effects of thermal treatment on tensile strength of Laurentian granite using Brazilian test. Rock Mechanics and Rock Engineering, 2015, 48(6): 2213–2223

Yang S Q, Ranjith P G, Jing H W, Tian W L, Ju Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics, 2017, 65: 180–197

Glover P W J, Baud P, Darot M, Meredith P G, Boon S A, Leravalec M, Zoussi S, Reuschlé T. α/β phase transition in quartz monitored using acoustic emissions. Geophysical Journal International, 1995, 120(3): 775–782

Zhao Z H. Thermal influence on mechanical properties of granite: A microcracking perspective. Rock Mechanics and Rock Engineering, 2016, 49(3): 747–762

Van der Molen I. The shift of the α–β transition temperature of quartz associated with the thermal expansion of granite at high pressure. Tectonophysics, 1981, 73(4): 323–342

Branlund J M, Hofmeister A M. Thermal diffusivity of quartz to 1000 °C: Effects of impurities and the α–β phase transition. Physics and Chemistry of Minerals, 2007, 34(8): 581–595

Staněk M, Geraud Y. Granite microporosity changes due to fracturing and alteration: Secondary mineral phases as proxies for porosity and permeability estimation. Solid Earth, 2019, 10(1): 251–274

Ghasemi S, Khamehchiyan M, Taheri A, Nikudel M R, Zalooli A. Crack evolution in damage stress thresholds in different minerals of granite rock. Rock Mechanics and Rock Engineering, 2020, 53(3): 1163–1178

Zhang Y, Zhao Y S. Thermal cracking meso-characteristic of LuHui granite. In: Proceedings of the International Conference on Mechanical Engineering and Green Manufacturing (MEGM) 2010. Xiangtan: Mechanical Engineering and Green Manufacturing, 2010

Zhao Y S, Meng Q R, Kang T H, Zhang N, Xi B P. Micro-CT experimental technology and meso-investigation on thermal fracturing characteristics of granite. Journal of Geotechnical Engineering, 2008, 27: 28–34 (in Chinese)

Chen S W, Yang C H, Wang G B. Evolution of thermal damage and permeability of Beishan granite. Applied Thermal Engineering, 2017, 110: 1533–1542

Lin W R. Permanent strain of thermal expansion and thermally induced microcracking in Inada granite. Journal of Geophysical Research. Solid Earth, 2002, 107(B10): 107

Wang H F, Bonner B P, Carlson S R, Kowallis B J, Heard H C. Thermal stress cracking in granite. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1989, 26(5): 234

Hu X D, Song X Z, Liu Y, Li G S, Shen Z H, Lyu Z H, Liu Q L. Lowest required surface temperature for thermal spallation in granite and sandstone specimens: Experiments and simulations. Rock Mechanics and Rock Engineering, 2019, 52(6): 1689–1703

Liu H, Zhang K, Liu T, Cao H, Wang Y. Experimental and numerical investigations on tensile mechanical properties and fracture mechanism of granite after cyclic thermal shock. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2022, 8(1): 18

Wang F, Konietzky H, Frühwirt T, Dai Y J. Laboratory testing and numerical simulation of properties and thermal-induced cracking of Eibenstock granite at elevated temperatures. Acta Geotechnica, 2020, 15(8): 2259–2275

Zhang Y M, Mang H A. Global cracking elements: A novel tool for Galerkin-based approaches simulating quasi-brittle fracture. International Journal for Numerical Methods in Engineering, 2020, 121(11): 2462–2480

Jang M, Yang H S. Experiment and numerical analysis for thermo-mechanical behavior of granite block. Geosystem Engineering, 2005, 8(1): 9–14

Schrank C, Fusseis F, Karrech A, Revets S, Regenauer Lieb K, Jie L. Thermal cracking of Westerly granite: From physical to numerical experiment. In: Proceedings of the EGU General Assembly Conference Abstracts. Vienna: EGU General Assembly, 2010

Yu Q L, Ranjith P G, Liu H Y, Yang T H, Tang S B, Tang C A, Yang S Q. A mesostructure-based damage model for thermal cracking analysis and application in granite at elevated temperatures. Rock Mechanics and Rock Engineering, 2015, 48(6): 2263–2282

Wang F, Konietzky H. Thermal damage evolution of granite under slow and high-speed heating conditions. Computers and Geotechnics, 2020, 123: 103590

Zhang Y M, Zhuang X Y. Cracking elements: A self-propagating strong discontinuity embedded approach for quasi-brittle fracture. Finite Elements in Analysis and Design, 2018, 144: 84–100

Zhang Y M, Zhuang X Y. Cracking elements method for dynamic brittle fracture. Theoretical and Applied Fracture Mechanics, 2019, 102: 1–9

Zhang Y M, Huang J U, Yuan Y, Mang H A. Cracking elements method with a dissipation-based arc-length approach. Finite Elements in Analysis and Design, 2021, 195: 103573

Zhang Y M, Gao Z R, Li Y Y, Zhuang X Y. On the crack opening and energy dissipation in a continuum based disconnected crack model. Finite Elements in Analysis and Design, 2020, 170: 103333

Rabczuk T, Zi G, Bordas S, Nguyen Xuan H. A simple and robust three-dimensional cracking-particle method without enrichment. Computer Methods in Applied Mechanics and Engineering, 2010, 199(37–40): 2437–2455

Rabczuk T, Belytschko T. Cracking particles: A simplified meshfree method for arbitrary evolving cracks. International Journal for Numerical Methods in Engineering, 2004, 61(13): 2316–2343

Yu S Y, Ren X H, Zhang J X, Wang H J, Sun Z H. An improved form of smoothed particle hydrodynamics method for crack propagation simulation applied in rock mechanics. International Journal of Mining Science and Technology, 2021, 31(3): 421–428

Zhang Y M, Yang X Q, Wang X Y, Zhuang X Y. A micropolar peridynamic model with non-uniform horizon for static damage of solids considering different nonlocal enhancements. Theoretical and Applied Fracture Mechanics, 2021, 113: 102930

Zhang Y M, Lackner R, Zeiml M, Mang H A. Strong discontinuity embedded approach with standard SOS formulation: Element formulation, energy-based crack-tracking strategy, and validations. Computer Methods in Applied Mechanics and Engineering, 2015, 287: 335–366

Cundall P A, Strack O D L. A discrete numerical model for granular assembilies. Geotechnique, 1979, 29(1): 47–65

Zhang Y L, Shao J F, Liu Z B, Shi C, de Saxce G. Effects of confining pressure and loading path on deformation and strength of cohesive granular materials: A three-dimensional DEM analysis. Acta Geotechnica, 2019, 14(2): 443–460

Zhang Y L, Shao J F, de Saxce G, Shi C, Liu Z B. Study of deformation and failure in an anisotropic rock with a three-dimensional discrete element model. International Journal of Rock Mechanics and Mining Sciences, 2019, 120: 17–28

Cundall P A, Hart R D. Numerical modelling of discontinua. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1993, 30: 101–113

Zhang Y L, Liu Z B, Han B, Zhu S, Zhang X. Numerical study of hydraulic fracture propagation in inherently laminated rocks accounting for bedding plane properties. Journal of Petroleum Science Engineering, 2022, 210: 109798

Zhang Y L, Zhang Y P, Han B, Zhang X, Jia Y. Parameter studies on hydraulic fracturing in brittle rocks based on a modified hydromechanical coupling model. Energies, 2022, 15(7): 2687

Zhang Y L, Shao J F, Zhu S, Liu Z B, Shi C. Effect of rock anisotropy on initiation and propagation of fractures due to fluid pressurization. Acta Geotechnica, 2022, 18(4): 2039–2058

Itasca Consulting Group. User’s Manual: PFC2D-particle Flow Code in 2 Dimensions. Minneapolis: Itasca Consulting Group, 2004

Wanne T S, Young R P. Bonded-particle modeling of thermally fractured granite. International Journal of Rock Mechanics and Mining Sciences, 2008, 45(5): 789–799

Xia M, Zhao C B, Hobbs B E. Particle simulation of thermally-induced rock damage with consideration of temperature-dependent elastic modulus and strength. Computers and Geotechnics, 2014, 55: 461–473

Potyondy D O, Cundall P A. A bonded-particle model for rock. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1329–1364

Zhang Y L, Liu Z B, Shi C, Shao J F. Three-dimensional reconstruction of block shape irregularity and its effects on block impacts using an energy-based approach. Rock Mechanics and Rock Engineering, 2018, 51(4): 1173–1191

Zhang Y P, Shi C, Zhang Y L, Yang J X, Chen X. Numerical analysis of the brittle-ductile transition of deeply buried marble using a discrete approach. Computational Particle Mechanics, 2021, 8(4): 893–904

Sun Q, Chen S E, Gao Q, Zhang W Q, Geng J S, Zhang Y L. Analyses of the factors influencing sandstone thermal conductivity. Acta Geodynamica et Geomaterialia, 2017, 14: 173–180

Zhang Y L, Shao J F, Liu Z B, Shi C. An improved hydromechanical model for particle flow simulation of fractures in fluid-saturated rocks. International Journal of Rock Mechanics and Mining Sciences, 2021, 147: 104870

Zhang Y L, Han B, Zhang X, Jia Y, Zhu C. Study of interactions between induced and natural fracture effects on hydraulic fracture propagation using a discrete approach. Lithosphere, 2021: 5810181

Hu S H, Zhang G, Zhang M, Jiang X L, Chen Y F. Deformation characteristics tests and damage mechanics analysis of Beishan granite after thermal treatment. Rock and Soil Mechanics, 2016, 37: 3427–3436 (in Chinese)

Zhang Y M, Gao Z R, Wang X Y, Liu Q. Image representations of numerical simulations for training neural networks. Computer Modeling in Engineering & Sciences, 2023, 134(2): 821–833

Zhang Y M, Gao Z R, Wang X Y, Liu Q. Predicting the pore-pressure and temperature of fire-loaded concrete by a hybrid neural network. International Journal of Computational Methods, 2021, 19(8): 2142011

Shi C, Yang W K, Yang J X, Chen X. Calibration of micro-scaled mechanical parameters of granite based on a bonded-particle model with 2D particle flow code. Granular Matter, 2019, 21(2): 38

Han Z, Zhang L, Zhou J, Yuan G, Wang P. Uniaxial compression test and numerical studies of grain size effect on mechanical properties of granite. Journal of Engineering Geology, 2019, 27: 497–504 (in Chinese)

Zhang X P, Wong L N Y. Choosing a proper loading rate for bonded-particle model of intact rock. International Journal of Fracture, 2014, 189(2): 163–179

Bonetto F, Lebowitz J L, Bellet L R. Fourier’s Law: A Challenge to Theorists, in Mathematical Physics 2000. London: Imperial College, 2000

Plevova E, Vaculikova L, Kozusnikova A, Ritz M, Martynkova G S. Thermal expansion behaviour of granites. Journal of Thermal Analysis and Calorimetry, 2016, 123(2): 1555–1561

Zhu Z N, Yang S Q, Wang R, Tian H, Jiang G S, Dou B. Effects of high temperature on the linear thermal expansion coefficient of Nanan granite. Acta Geodaetica et Geophysica, 2022, 57(2): 231–243

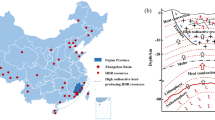

Xiang P, Xu H C, Ji H G, Li Q, Wang H. Thermal property of granite in deep strata and its effect on thermal zone of surrounding rock. Shock and Vibration, 2022, 2022: 1–9

Yurtseven H, Desticioglu M. Critical behaviour of the heat capacity near the α–β phase transition in quartz. High-Temperature Materials and Processes, 2013, 32(2): 189–194

Saxena S K. Earth mineralogical model: Gibbs free energy minimization computation in the system MgO-FeO-SiO2. Geochimica et Cosmochimica Acta, 1996, 60(13): 2379–2395

Miao S Q, Li H P, Chen G. Temperature dependence of thermal diffusivity, specific heat capacity, and thermal conductivity for several types of rocks. Journal of Thermal Analysis and Calorimetry, 2014, 115(2): 1057–1063

Pereira A H A, Miyaji D Y, Cabrelon M D, Medeiros J, Rodrigues J A. A study about the contribution of the α–β phase transition of quartz to thermal cycle damage of a refractory used in fluidized catalytic cracking units. Cerâmica, 2014, 60(355): 449–456

Sun Q, Lu C, Cao L W, Li W C, Geng J S, Zhang W Q. Thermal properties of sandstone after treatment at high temperature. International Journal of Rock Mechanics and Mining Sciences, 2016, 85: 60–66

Zhao X G, Zhao Z, Guo Z, Cai M, Li X, Li P F, Chen L, Wang J. Influence of thermal treatment on the thermal conductivity of Beishan granite. Rock Mechanics and Rock Engineering, 2018, 51(7): 2055–2074

Zhao X G, Xu H R, Zhao Z, Guo Z, Cai M, Wang J. Thermal conductivity of thermally damaged Beishan granite under uniaxial compression. International Journal of Rock Mechanics and Mining Sciences, 2019, 115: 121–136

Wang Y H, Leung S C. A particulate-scale investigation of cemented sand behavior. Canadian Geotechnical Journal, 2008, 45(1): 29–44

Wang F, Konietzky H, Fruhwirt T, Li Y W, Dai Y J. Impact of cooling on fracturing process of granite after high-speed heating. International Journal of Rock Mechanics and Mining Sciences, 2020, 125: 104155

Acknowledgements

This study was supported by the Postgraduate Research & Practice Innovation Program of Jiangsu Province (No. KYCX21_0494), the National Natural Science Foundation of China (Grant Nos. 51679071 and 41831278), and the Key Laboratory of the Ministry of Education on Safe Mining of Deep Metal Mines (No. DM2019K02).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shi, C., Zhang, Y., Zhang, Y. et al. Microdamage study of granite under thermomechanical coupling based on the particle flow code. Front. Struct. Civ. Eng. 17, 1413–1427 (2023). https://doi.org/10.1007/s11709-023-0953-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-023-0953-2