Abstract

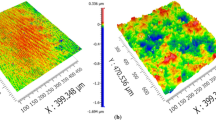

A compact WC-10Co-4Cr coating with a thickness of about 210 μm was prepared by HVOF spraying, which is mainly composed of WC, W2C, Co6W6C, Co and W phases. By taking an Si3N4 ball as counterpart, the impact wear behavior of the WC-10Co-4Cr coating and its substrate (medium carbon steel) is systematically studied under the ball-on-flat contact mode. The results show that the increase in impact velocity will significantly change the peak stress, kinetic energy and absorbed energy fraction, while the impact time remains almost unchanged. With the increase in collision cycle, the impact energy absorption of WC-10Co-4Cr coating and medium carbon steel decreased first and then remained stable. In addition, the WC-10Co-4Cr coating has higher microhardness and kinetic energy rebound effect, which inhibits plastic deformation during repeated collision, and the initiation, propagation and connection of microcracks, as well as the crushing and spalling of surface materials. When the impact velocity reaches 150 mm/s, the depth and width of the wear mark, the wear rate and the wear loss of the WC-10Co-4Cr coating are 4.61 and 75.16, 11.96 and 7.51% than those of medium carbon steel, respectively. The dominant wear mechanism of the WC-10Co-4Cr coating is delamination wear and slight oxidation, while the primary wear damage of medium carbon steel is plastic deformation, which is followed by the gradual onset of additional oxidation and fatigue wear.

Similar content being viewed by others

References

R. Song, D. Ponge, D. Raabe, J.G. Speer, and D.K. Madock, Overview of Processing, Microstructure and Mechanical Properties of Ultrafine Grained BCC Steels, Mater. Sci. Eng., A, 2006, 441(1-2), p 1-17.

Y. Kimura, T. Inoue, F. Yin, and K. Tsuzaki, Inverse Temperature Dependence of Toughness in an Ultrafine Grain-Structure Steel, Science, 2008, 320(5879), p 1057-1060.

N.N. Jia, K. Guo, Y.M. He, Y.H. Wang, J.G. Peng, and T.S. Wang, A Thermomechanical Process to Achieve Mechanical Properties Comparable to those of Quenched-tempered Medium-C Steel, Mater. Sci. Eng. A, 2017, 700, p 175-182.

B.X. Liu, K.Y. Fan, F.X. Yin, J.H. Feng, and P.G. Ji, Effect of Caliber Rolling Reduction Ratios on the Microstructure and Mechanical Properties of 45 Medium Carbon Steel, Mater. Sci. Eng. A, 2020, 774, p 138954.

X.H. Min, Y. Kimura, T. Kimura, and K. Tsuzaki, Delamination Toughening Assisted by Phosphorus in Medium-Carbon Low-Alloy Steels with Ultrafine Elongated Grain Structures, Mater. Sci. Eng. A, 2016, 649, p 135-145.

A. Chatterjee, D. Chakrabarti, A. Moitra, R. Mitra, and A.K. Bhaduri, Effect of Deformation Temperature on the Ductile–Brittle Transition Behavior of a Modified 9Cr-1Mo Steel, Mater. Sci. Eng. A, 2015, 630, p 58-70.

R. Holinski, Fundamentals of Dry Friction and Some Practical Examples, Ind. Lubr. Tribol., 2001, 53(2), p 61-65.

H.B. Han, Y.K. Gao, Y.Z. Zhang, S.M. Du, and H. Liu, Effect of Magnetic Field Distribution of Friction Surface on Friction and Wear Properties of 45 Steel in DC Magnetic Field, Wear, 2015, 328, p 422-435.

N. Vashishtha, R.K. Khatirkar, and S.G. Sapate, Tribological Behaviour of HVOF Sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr Coatings, Tribol. Int., 2016, 105, p 55-68.

W. Tillmann, D. Stangier, L. Hagen, P. Schrder, and M. Krabiell, Influence of the WC Grain Size on the Properties of PVD/HVOF Duplex Coatings, Surf. Coat. Technol., 2017, 328(15), p 326-334.

Y.Y. Santana, J.G. La Barbera-Sosa, J. Caro, E.S. Puchi-Cabrera, and M.H. Staia, Mechanical Properties and Microstructure of WC-10Co-4Cr and WC-12Co Thermal Spray Coatings Deposited by HVOF, Surf. Eng., 2008, 24(5), p 374-382.

H.B. Wang, Y.N. Li, M. Gee, H. Zhang, X.M. Liu, and X.Y. Song, Sliding Wear Resistance Enhancement by Controlling W2C Precipitation in HVOF Sprayed WC-Based Cermet Coating, Surf. Coat. Technol., 2020, 387, p 125533.

I. El Azhari, J. Barrirero, J. Garcia, F. Soldera, L. Llanes, and F. Mucklich, Atom Probe Tomography Investigations on Grain Boundary Segregation in Polycrystalline Ti(C, N) and Zr(C, N) CVD coatings, Scripta Mater., 2019, 162, p 335-340.

S.M. Dezfuli and M. Sabzi, Deposition of Ceramic Nanocomposite Coatings by Electroplating Process: A Review of Layer-Deposition Mechanisms and Effective Parameters on the Formation of the Coating, Ceram. Int., 2019, 45(17), p 21835-21842.

L. Chen, W.G. Chen, D.Y. Li, P.Y. Jing, H.Z. Yin, H.J. Wu, Y. Xie, and X.N. Wang, Effect of Nano-La2O3 Doping on the Tribological Behavior of Laser Cladded WC-12Co Coating on 65 Mn Steel Under Water Lubrication Condition, Tribol. Int., 2022, 169, p 107428.

S.L. Liu, X.P. Zheng, and G.Q. Geng, Influence of Nano-WC-12Co Powder Addition in WC-10Co-4Cr AC-HVAF Sprayed Coatings on Wear and Erosion Behaviour, Wear, 2010, 269(5-6), p 362-367.

M.H. Staia, A. Mejias, J.G. La Barbera, E.S. Puchi-Cabrera, C. Villalobos-Gutierrez, Y.Y. Santana, A. Montagne, A. Iost, and M.A. Rodriguez, Mechanical Properties of WC/Co-CNT HVOF Sprayed Coatings, Surf. Eng., 2020, 36(11), p 1156-1164.

J. Yoganandh, S. Natarajan, and S.P. Kumaresh Babu, Erosion Behaviour of WC-Co-Cr Thermal Spray Coated Grey Cast Iron under Mining Environment, Trans. Indian Instit. Metals, 2013, 66(4), p 437-443.

Y.Y. Santana, J.G. La Barbera-Sosa, A. Bencomo, J. Lesage, D. Chicot, E. Bemporad, E.S. Puchi-Cabrera, and M.H. Staia, Influence of Mechanical Properties of Tungsten Carbide–Cobalt Thermal Spray Coatings on their Solid Particle Erosion Behaviour, Surf. Eng., 2012, 28(4), p 237-243.

X. Ding, X.D. Cheng, J. Shi, C. Li, C.Q. Yuan, and Z.X. Ding, Influence of WC Size and HVOF Process on Erosion Wear Performance of WC-10Co4Cr Coatings, Int. J. Adv. Manuf. Technol., 2017, 96, p 1615-1624.

R. Khuengpukheiw, A. Wisitsoraat, and C. Saikaew, Wear Behaviors of HVOF-Sprayed NiSiCrFeB, WC-Co/NiSiCrFeB and WC-Co Coatings Evaluated using a Pin-on-disc Tester with C45 Steel Pins, Wear, 2021, 484-485, p 203699.

Q. Wang, Z.H. Chen, and Z.X. Ding, Performance of Abrasive Wear of WC-12Co Coatings Sprayed by HVOF, Tribol. Int., 2009, 42(7), p 1046-1051.

Z. Geng, S. Li, D.L. Duan, and Y. Liu, Wear Behaviour of WC-Co HVOF Coatings at Different Temperatures in Air and Argon, Wear, 2015, 330-331, p 348-353.

N. Vashishtha, S.G. Sapate, P. Bagde, and A.B. Rathod, Effect of Heat Treatment on Friction and Abrasive Wear Behaviour of WC-12Co and Cr3C2-25NiCr Coatings, Tribol. Int., 2018, 118, p 381-399.

M.X. Xie, S.H. Zhang, and M.X. Li, Comparative Investigation on HVOF Sprayed Carbide-Based Coatings, Appl. Surf. Sci., 2013, 273, p 799-805.

S.K. Asl, M.H. Sohi, K. Hokamoto, and M. Uemura, Effect of Heat Treatment on Wear Behavior of HVOF Thermally Sprayed WC-Co Coatings, Wear, 2006, 260(11), p 1203-1208.

G.L. Hou, X.Q. Zhao, H.D. Zhou, J.J. Lu, and Y.L. An, Cavitation Erosion of Several Oxy-fuel Sprayed Coatings Tested in Deionized Water and Artificial Seawater, Wear, 2014, 311(1-2), p 81-92.

T.M. Gong, P.P. Yao, X.T. Zuo, Z.Y. Zhang, Y.L. Xiao, L. Zhao, H.B. Zhou, M.W. Deng, Q. Wang, and A.W. Zhong, Influence of WC Carbide Particle Size on the Microstructure and Abrasive Wear Behavior of WC-10Co-4Cr Coatings for Aircraft Landing Gear, Wear, 2016, 362-363, p 135-145.

J. Murthy and B. Venkataraman, Abrasive Wear Behaviour of WC-CoCr and Cr3C2-20(NiCr) Deposited by HVOF and Detonation Spray Processes, Surf. Coat. Technol., 2006, 200(8), p 2642-2652.

B. Song, Z. Pala, K.T. Voisey, and T. Hussain, Gas and Liquid-fuelled HVOF Spraying of Ni50Cr Coating: Microstructure and High Temperature Oxidation, Surf. Coat. Technol., 2017, 318(25), p 224-232.

B. Song, J.W. Murray, R.G. Wellman, Z. Pala, and T. Hussain, Dry Sliding Wear Behaviour of HVOF Thermal Sprayed WC-Co-Cr and WC-CrxCy-Ni Coatings, Wear, 2019, 442-443, p 203114.

A. Karimi, C. Verdon, and G. Barbezat, Microstructure and Hydroabrasive Wear behavior of High-velocity Oxyfuel Thermally Sprayed WC-Co(Cr) Coatings, Surf. Coat. Technol., 1993, 57(1), p 81-89.

L. Thakur and N. Arora, Sliding and Abrasive Wear Behavior of WC-CoCr Coatings with Different Carbide Sizes, J. Mater. Eng. Perform., 2013, 22(2), p 574-583.

L.F. Ma, K. Eom, J. Geringer, T.S. Jun, and K. Kim, Literature Review on Fretting Wear and Contact Mechanics of Tribological Coatings, Coatings, 2019, 9(8), p 501.

D.K. Zhang, X.H. Yang, K. Chen, and Z.F. Zhang, Fretting Fatigue Behavior of Steel Wires Contact Interface under Different Crossing Angles, Wear, 2018, 400, p 52-61.

L. Zou, D.F. Zeng, J. Wang, L.T. Lu, Y.B. Li, and Y.B. Zhang, Effect of Plastic Deformation and Fretting Wear on the Fretting Fatigue of Scaled Railway axles, Int. J. Fatigue, 2020, 132, p 105371.

C. Lyphout, G. Bolelli, E. Smazalova, K. Sato, J. Yamada, Š Houdková, L. Lusvarghi, and T. Manfredini, Influence of Hardmetal Feedstock Powder on the Sliding Wear and Impact Resistance of High Velocity Air-Fuel (HVAF) Sprayed Coatings, Wear, 2019, 430-431, p 340-354.

G. Bolelli, L. Lusvarghi, and M. Barletta, HVOF-Sprayed WC-CoCr Coatings on Al Alloy: Effect of the Coating Thickness on the Tribological Properties, Wear, 2009, 267(5), p 944-953.

J. Souza, L.C. Dolavale, and S. Camargo, Wear Mechanisms of Dental Composite Restorative Materials by Two Different in-vitro Methods, Mater. Res., 2013, 16(2), p 333-340.

Z. Wang, Z. Cai, B.Z. Chen, Q.Y. Sun, and M.H. Zhu, Low-Velocity Impact Wear Behavior of Ball-to-Flat Contact Under Constant Kinetic Energy, J. Mater. Eng. Perform., 2017, 26(11), p 5669-5679.

Y.P. Wu, B. Wang, S. Hong, J.F. Zhang, and Y.J. Qin, Dry Sliding Wear Properties of HVOF Sprayed WC-10Co-4Cr Coating, Trans. Indian Inst. Met., 2014, 67(4), p 581-586.

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24(8), p 981-988.

M. Sadeghilaridjani, S. Muskeri, V. Hasannaeimi, M. Pole, and S. Mukherjee, Strain Rate Sensitivity of a Novel Refractory High Entropy Alloy: Intrinsic Versus Extrinsic Effects, Mater. Sci. Eng., A, 2019, 766, p 138326.

Q. Wei, S. Cheng, K.T. Ramesh, and E. Ma, Effect of Nanocrystalline and Ultrafine Grain Sizes on the Strain Rate Sensitivity and Activation Volume: FCC Versus BCC Metals, Mater. Sci. Eng., A, 2004, 381(1), p 71-79.

S. Muskeri, V. Hasannaeimi, R. Salloom, M. Sadeghilaridjani, and S. Mukherjee, Small-scale Mechanical Behavior of a Eutectic High Entropy Alloy, Sci. Rep., 2020, 10(1), p 2669.

Y. Okitsu, N. Takata, and N. Tsuji, Mechanical Properties of Ultrafine Grained Ferritic Steel Sheets Fabricated by Rolling and Annealing of Duplex Microstructure, J. Mater. Sci., 2008, 43(43), p 7391-7396.

Z. Wang, Z.B. Cai, Y. Sun, J.F. Peng, and M.H. Zhu, Low Velocity Impact Wear Behavior of MoS2/Pb Nanocomposite Coating under Controlled Kinetic Energy, Surf. Coat. Technol., 2017, 326, p 53-62.

M. Abdollah, Impact wear mechanisms of DLC coating, Nagoya University, Nagoya, 2011.

Y.I. Oka, M. Matsumura, and T. Kawabata, Relationship between Surface Hardness and Erosion Damage Caused by Solid Particle Impact, Wear, 1993, 162-164, p 688-695.

V. Rastegar and A. Karimi, Surface and Subsurface Deformation of Wear-Resistant Steels Exposed to Impact Wear, J. Mater. Eng. Perform., 2014, 23(3), p 927-936.

D.F. Wang, B.P. Zhang, C.C. Jia, F. Gao, Y.G. Yu, K. Chu, M.N. Zhang, and X.L. Zhao, Influence of Carbide Grain Size and Crystal Characteristics on the Microstructure and Mechanical Properties of HVOF-Sprayed WC-CoCr Coatings, Int. J. Refract Metal Hard Mater., 2017, 69, p 138-152.

X.T. Luo, G.J. Yang, and C.J. Li, Multiple Strengthening Mechanisms of Cold-sprayed cBNp/NiCrAl Composite Coating, Surf. Coat. Technol., 2011, 205(20), p 4808-4813.

J.C. Aurich, P. Mayer, B. Kirsch, D. Eifler, M. Smaga, and R. Skorupski, Characterization of Deformation Induced Surface Hardening during Cryogenic Turning of AISI 347, CIRP Ann., 2014, 63(1), p 65-68.

Acknowledgments

This work was supported by Key research and development program of Jiangxi Province (20171ACE50018), Fund Project of Jiangxi Provincial Department of Education (GJJ210651), National Natural Science Foundation of China (No. 51805170) and Science Fund for Distinguished Young Scholars of Jiangxi Province (No. 20212ACB214003). In particular, the authors would like to thank Dr Fan Kunyang in the College of Mechanical Engineering of Chengdu University for her generous supply of raw materials.

Author information

Authors and Affiliations

Contributions

SL: Conceptualization, Investigation, Data curation, Writing-original, Writing-review & editing and Visualization. YW: Investigation and Data curation. MS: Methodology and Visualization. JX: Formal analysis and Visualization. QH: Supervision and Methodology. YZ: Supervision. HZ: Supervision and Project administration, Writing-review & editing and Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, S., Wang, Y., Shen, M. et al. Impact Wear Behavior of HVOF-Sprayed WC-10Co-4Cr Coating on Medium Carbon Steel Under Controlled Kinetic Energy. J Therm Spray Tech 32, 1047–1065 (2023). https://doi.org/10.1007/s11666-023-01537-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01537-x