Abstract

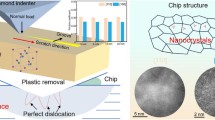

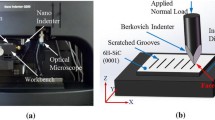

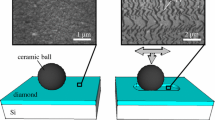

Single-point diamond scratching and nanoindentation on monocrystalline silicon wafer were performed to investigate the surface damage mechanism of Si under the contact loading. The results showed that three typical stages of material removal appeared during dynamic scratching, and a chemical reaction of Si with the diamond indenter and oxygen occurred under the high temperature. In addition, the Raman spectra of the various points in the scratching groove indicated that the Si-I to β-Sn structure (Si-II) and the following β-Sn structure (Si-II) to amorphous Si transformation appeared under the rapid loading/unloading condition of the diamond grit, and the volume change induced by the phase transformation resulted in a critical depth (ductile–brittle transition) of cut (∼60 nm ± 15 nm) much lower than the theoretical calculated results (∼387 nm). Moreover, it also led to abnormal load–displacement curves in the nanoindentation tests, resulting in the appearance of elbow and pop-out effects (∼270 nm at 20 s, 50 mN), which were highly dependent on the loading/unloading conditions. In summary, phase transformation of Si promoted surface deformation and fracture under both static and dynamic mechanical loading.

Similar content being viewed by others

References

H.K. Tönshoff, W.V. Schmieden, I. Inasaki, W. König, and G. Spur, CIRP Ann. Manuf. Technol. 39, 621 (1990).

I. Zarudi, J. Zou, W. McBride, and L.C. Zhang, Appl. Phys. Lett. 85, 932 (2004).

I. Zarudi, T. Nguyen, and L.C. Zhang, Appl. Phys. Lett. 86, 011922 (2005).

J. Yan, J. Appl. Phys. 95, 2094 (2004).

H. Shin, B. Kim, J. Kim, S. Hwang, A.S. Budiman, H. Son, K. Byun, N. Tamura, M. Kunz, D. Kim, and Y. Joo, J. Electron. Mater. 41, 712 (2012).

A.S. Budiman, G. Illya, V. Handara, W.A. Caldwell, C. Bonelli, M. Kunz, N. Tamura, and D. Verstraeten, Sol. Energy Mater. Sol. Cells 130, 303 (2014).

S.K. Tippabhotla, I. Radchenko, K.N. Rengarajan, G. Illya, V. Handara, M. Kunz, N. Tamura, and A.S. Budiman, Procedia Eng. 139, 123 (2016).

Y.G. Gogotsi, V. Domnich, S.N. Dub, A. Kailer, and K.G. Nickel, J. Mater. Res. 15, 871 (2000).

U. Schwarz, K. Syassen, K. Takemura, and M. Hanfland, Phys. Rev. Lett. 82, 1197 (1999).

M.C. Kroll, P.D. Kirchner, R.F. Cook, B.J. Hockey, and D.R. Clarke, Phys. Rev. Lett. 60, 2156 (1988).

H. Huang and J. Yan, Scr. Mater. 102, 35 (2015).

D.E. Kim and S.I. Oh, Nanotechnology 17, 2259 (2006).

A. Kailer, Y.G. Gogotsi, and K.G. Nickel, J. Appl. Phys. 81, 3057 (1997).

K. Gaál-Nagy, M. Schmitt, P. Pavone, and D. Strauch, Comput. Mater. Sci. 22, 49 (2001).

V. Domnich, Y. Gogotsi, and S. Dub, Appl. Phys. Lett. 76, 2214 (2000).

B.V. Tanikella, A.H. Somasekhar, A.T. Sowers, R.J. Nemanich, and R.O. Scattergood, Appl. Phys. Lett. 69, 2870 (1996).

T. Tian, R. Morusupalli, H. Shin, H.Y. Son, K.Y. Byun, Y.C. Joo, R. Caramto, L. Smith, Y. Shen, M. Kunz, N. Tamura, and A.S. Budiman, Procedia Eng. 139, 101 (2016).

K.N. Rengarajan, I. Radchenko, G. Illya, V. Handara, M. Kunz, N. Tamura, and A.S. Budiman, Procedia Eng. 139, 76 (2016).

J. Sun, L. Fang, J. Han, Y. Han, H. Chen, and K. Sun, Comput. Mater. Sci. 82, 140 (2014).

Y. Wang, J. Zou, H. Huang, L. Zhou, B.L. Wang, and Y.Q. Wu, Nanotechnology 18, 465705 (2007).

T.F. Page, W.C. Oliver, and C.J. McHargue, J. Mater. Res. 7, 450 (1992).

J. Yan, H. Takahashi, J.I. Tamaki, X. Gai, H. Harada, and J. Patten, Appl. Phys. Lett. 86, 181913 (2005).

T. Shibata, S. Fujii, E. Makino, and M. Ikeda, Precis. Eng. 18, 129 (1996).

J. Yan, T. Asami, H. Harada, and T. Kuriyagawa, Precis. Eng. 33, 378 (2009).

A.S. Budiman, K.R. Narayanan, N. Li, J. Wang, N. Tamura, M. Kunz, and A. Misra, Mater. Sci. Eng. A 635, 6 (2015).

A.S. Budiman, S. Han, N. Li, Q. Wei, P. Dickerson, N. Tamura, M. Kunz, and A. Misra, J. Mater. Res. 27, 599 (2012).

J. Yan, T. Asami, and T. Kuriyagawa, Precis. Eng. 32, 186 (2008).

S. Goel, X. Luo, and R.L. Reuben, Tribol. Int. 57, 272 (2013).

Q. Zhang, S. To, Q. Zhao, and B. Guo, Mater. Lett. 172, 48 (2016).

H. Wu and S.N. Melkote, J. Eng. Mater. Technol. T. ASME 134, 41011 (2012).

Z. Cheng, MSc Thesis, Materials Science and Engineering, Georgia Institute of Technology, 2004.

W.J. Zong, T. Sun, D. Li, K. Cheng, and Y.C. Liang, Int. J. Mach. Tools Manuf. 48, 1678 (2008).

Y. Gogotsi, C. Baek, and F. Kirscht, Semicond. Sci. Technol. 14, 936 (1999).

J. Zi, H. Büscher, C. Falter, W. Ludwig, K. Zhang, and X. Xie, Appl. Phys. Lett. 69, 200 (1996).

G. Viera, S. Huet, and L. Boufendi, J. Appl. Phys. 90, 4175 (2001).

I.H. Campbell and P.M. Fauchet, Solid State Commun. 58, 739 (1986).

J.R. Maclean, S.J. Clark, G.J. Ackland, P.D. Hatton, J. Crain, and R.O. Piltz, Phys. Rev. B 52, 4072 (1995).

S.A. Solin, M. Selders, R.K. Chang, R. Alben, M.F. Thorpe, D. Weaire, and R.J. Kobliska, Phys. Rev. Lett. 29, 725 (1972).

X. Li, J. Lu, B. Liu, and S. Yang, Tribol. Int. 41, 189 (2008).

H. Huang and J. Yan, Semicond. Sci. Technol. 30, 115001 (2015).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC) (Project No. 51475109) and the Research Committee of the Hong Kong Polytechnic University (RTRA). In addition, we would like to express our great thanks for the kind help from Mr. Mingtao Wu.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Q., Zhang, Q., To, S. et al. Surface Damage Mechanism of Monocrystalline Si Under Mechanical Loading. J. Electron. Mater. 46, 1862–1868 (2017). https://doi.org/10.1007/s11664-016-5251-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-5251-5