Abstract

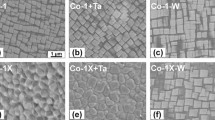

Ferrous scraps have been widely utilized as raw materials in the production of ductile irons. With increasing scrap use and repeated recycling, the concentrations of tramp elements such as copper (Cu) and tin (Sn) in the raw materials are expected to increase as they cannot be easily removed through conventional refining processes. To obtain fundamental insights into the effects of high-concentration Cu (up to 2.0 wt pct) and Sn (up to 1.0 wt pct) on the nucleation and growth of graphite on a foreign substrate, a novel approach through contact-melting of cast iron on lanthanum oxide (La2O3) substrate is utilized to study graphite nucleation and growth behavior at the alloy/substrate interface and in the bulk alloy. Enhanced graphitization at the alloy/substrate interface and in the bulk alloy are observed at varying Cu content. Copper promotes graphitization in cast iron by elevating the equilibrium liquidus temperature of graphite (TG) and increasing the carbon supersaturation (ΔC). On the other hand, Sn demonstrates stronger graphitizing effects than Cu as only a lower concentration of Sn is required to achieve a similar increase of TG and ΔC. More significantly, Sn enhances graphite nodule counts in the bulk alloy through the formation of fine La-Sn intermetallic compounds which act as effective sites for graphite nucleation.

Similar content being viewed by others

References

C. Labrecque and M. Gagné: Can. Metall. Q., 1998, vol. 37, pp. 343–78.

Z. Li and Y. Li: Metall. Mater. Trans. A 2005, vol. 36, pp. 2455–60.

J. Qing, V.L. Richards, and D.C. Van Aken: Metall. Mater. Trans. A, 2016, vol. 47, pp. 6197–6213.

D.M. Stefanescu, G. Alonso, P. Larrañaga, E. De la Fuente, and R. Suarez: Acta Mater., 2017, vol. 139, pp. 109–21.

D.M. Stefanescu, G. Alonso, P. Larrañaga, E. De La Fuente, and R. Suarez: Acta Mater., 2016, vol. 107, pp. 102–26.

G. Alonso, P. Larrañaga, E. De La Fuente, D.M. Stefanescu, A. Natxiondo, and R. Suarez: Int. J. Met., 2017, vol. 11, pp. 14–26.

S.N. Lekakh: Int. J. Met., 2020, vol. 14, pp. 1078–89.

L. Riposan, M. Chisamera, V. Uta, S. Stan, R. Naro, and D. Williams: Int. J. Met., 2014, vol. 8, pp. 65–80.

Bureau of International Recycling: World Steel Recycling in Figures 2014–2018, 2017.

K. Nakajima, O. Takeda, T. Miki, K. Matsubae, and T. Nagasaka: Environ. Sci. Technol., 2011, vol. 45, pp. 4929–36.

A.M. Omran, G.T. Abdel-Jaber, and M.M. Ali: Int. J. Eng. Res. Appl., 2014, vol. 4, pp. 90–96.

H. Horie: J. Japan Foundrymen’s Soc., 1973, vol. 45, pp. 681–9.

Y. Kataoka, T. Itoh, M. Higuchi, and K. Murai: J. Japan Foundrymen’s Soc., 1987, vol. 59, pp. 74–78.

K.L. Ng, H. Sasaki, H. Kimura, T. Yoshikawa, and M. Maeda: ISIJ Int., 2018, vol. 58, pp. 123–31.

S. Bernal, F.J. Botana, R. García, and J.M. Rodríguez-Izquierdo: React. Solids, 1987, vol. 4, pp. 23–40.

K. Yamane, H. Yasuda, A. Sugiyama, T. Nagira, M. Yoshiya, K. Morishita, K. Uesugi, A. Takeuchi, and Y. Suzuki: Metall. Mater. Trans. A, 2015, vol. 46, pp. 4937–46.

Z. Jiyang: China Foundry, 2009, vol. 6, pp. 57–69.

G.L. Rivera, R.E. Boeri, and J.A. Sikora: Scr. Mater., 2004, vol. 50, pp. 331–35.

G. Rivera, P.R. Calvillo, R. Boeri, Y. Houbaert, and J. Sikora: Mater. Charact., 2008, vol. 59, pp. 1342–48.

M. Chisamera, I. Riposan, S. Stan, C. Militaru, I. Anton, and M. Barstow: J. Mater. Eng. Perform., 2012, vol. 21, pp. 331–38.

C. Wang, T. Nagasaka, M. Hino, and S. Ban-ya: ISIJ Int., 1991, vol. 31, pp. 1336–44.

Y. Lyu: Metallogr. Microstruct. Anal., 2019, vol. 8, pp. 67–71.

Y. Lyu, Y. Sun, S. Liu, and J. Zhao: Int. J. Cast Met. Res., 2015, vol. 28, pp. 263–68.

T. Tanaka, S. Hara, and M. Okamoto: Tetsu-To-Hagane/Journal Iron Steel Inst. Japan, 1998, vol. 84, pp. 25–30.

E.A. Belenkov: Inorg. Mater., 2001, vol. 37, pp. 928–34.

A. Javaid and C.R. Loper Jr: Trans. Am. Foundrymen’s Soc., 1995, vol. 103, pp. 135–50.

T. Hareyama, T. Kowata, H. Horie, F.-J. Lei, S. Hiratsuka, and T. Yamada: J. Japan Foundry Eng. Soc., 2003, vol. 75, pp. 331–36.

T. Mori, T. Ogasawara, H. Hasegawa, T. Hatakeyama, and T. Yamada: Tetsu-To-Hagane/Journal Iron Steel Inst. Japan, 1960, vol. 46, pp. 1147–50.

M. Hino and K. Ito: Thermodynamic Data for Steelmaking, Tohoku University Publishing Co., Sendai, 2010.

B.L. Bramfitt: Metall. Trans., 1970, vol. 1, pp. 1987–95.

I.R. Harris and G.V. Raynor: J. Less Common Met., 1965, vol. 9, pp. 7–19.

Y.X. Zhao and I.L. Spain: Phys. Rev. B, 1989, vol. 40, pp. 993–7.

X. Li, S. Liu, Y. Liu, and Y. Du: J. Phase Equilibria Diffus., 2019, vol. 40, pp. 653–67.

M.L. Fornasini, P. Manfrinetti, A. Palenzona, and S.K. Dhar: Zeitschrift für Naturforsch. B, 2003, vol. 58, pp. 521–27.

V.N. Eremenko, M. V. Bulanova, P.S. Martsenyuk, and V.E. Listovnichii: Sov. Powder Metall. Met. Ceram., 1989, vol. 28, pp. 145–54.

I. Dürr and C. Röhr: Zeitschrift für Anorg. und Allg. Chemie, 2012, vol. 638, pp. 163–76.

G. Borzone, A. Borsese, and R. Ferro: Zeitschrift für Anorg. und Allg. Chemie, 1983, vol. 501, pp. 199–208.

Y.U. Kwon, M.A. Rzeznik, A. Guloy, and J.D. Corbett: Chem. Mater., 1990, vol. 2, pp. 546–50.

Acknowledgments

This work was partially supported by the Iron and Steel Institute of Japan (ISIJ) Research Promotion Grant. Hereby, the authors express their sincerest gratitude and appreciation for the financial support by ISIJ.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 1, 2020; accepted December 6, 2020.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ng, K.L., Sasaki, H., Kimura, H. et al. Effects of High-Concentration Cu and Sn on the Nucleation and Growth Behavior of Graphite on Rare-Earth Compounds During the Solidification of Cast Iron. Metall Mater Trans A 52, 902–913 (2021). https://doi.org/10.1007/s11661-020-06124-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06124-1