Abstract

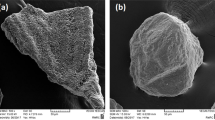

Calcareous sand is a typical problematic marine sediment because of its angular and porous particles. The effects of internal pores on the mechanical properties of calcareous sand particles have rarely been investigated. In this paper, the apparent morphology and internal structure of calcareous sand particles are determined by scanning electron microscopy and computed tomography tests, finding that the superficial pores connect inside and outside of the particles, forming a well-developed network of cavities and an internal porosity of up to 40%. The effects of particle morphology and internal porosity on the mechanical responses of particle were investigated by conducting photo-related compression test and 3D numerical simulations. Two failure modes are observed for the porous calcareous sand, i.e., compressive failure indicates that the particle skeleton is continually compressed and fragmented into small detritus without obvious splitting, and tensile failure indicates that the particles are broken into several fragments when the axial force clearly peaks. Calcareous sand particles with a high internal porosity or with small and dense pores often exhibit compressive failure, and vice versa. The particle strength is considerably reduced by increasing the internal porosity, but affected by pore size in nonlinear correlation. The crushing stress–strain points can be well fitted by an exponential curve, which is supplied for discussion.

Similar content being viewed by others

References

Afshar T, Disfanib MM, Arulrajaha A, Narsiliob GA, Emam S (2017) Impact of particle shape on breakage of recycled construction and demolition aggregates. Powder Technol 308:1–12

Alikarami R, Ando E, Gkiousas-Kapnisis M, Torabi A, Viggiani G (2015) Strain localisation and grain breakage in sand under shearing at high mean stress: insights from in situ X-ray tomography. Acta Geotech 10(1):15–30

Alonso EE, Olivella S, Pinyol NM (2005) A review of Beliche dam. Geotechnique 55(4):267–285

Altuhafi FN, Coop MR (2011) Changes to particle characteristics associated with the compression of sands. Geotechnique 61(6):459–471

Antony S, Moreno-Atanasio R, Hassanpour A (2006) Influence of contact stiffnesses on the micromechanical characteristics of dense particulate systems subjected to shearing. Appl Phys Lett 89(21):513–184

Bandara KMAS, Ranjth PG, Rathnaweera TD, Wanniarachchi WAM, Yang SQ (2020) Crushing and embedment of proppant packs under cyclic loading: an insight to enhanced unconventional oil/gas recovery. Geosci Front. https://doi.org/10.1016/j.gsf

Bono JPD, McDowell GR, Wanatowski D (2014) DEM of triaxial tests on crushable cemented sand. Granul Matter 16:563–572

Chen C, Zhang LM, Chang DS (2016) Stress–strain behavior of granular soils subjected to internal erosion. J Geotech Geoenviron Eng 142:06016014

Cheng YP, Nakata Y, Bolton MD (2003) Discrete element simulation of crushable soil. Geotechnique 53(7):633–641

Cho GC, Dodds J, Santamarina JC (2006) Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J Geotech Geoenviron Eng 132:591–602

Cil MB, Changbum S, Buscarnera G (2020) DEM modeling of grain size effect in brittle granular soils. J Eng Mech (ASCE) 146(3):04019138

Einav I (2007) Breakage mechanics—part I: theory. J Mech Phys Solids 55:1274–1297

Fu R, Hu X, Zhou B (2017) Discrete element modeling of crushable sands considering realistic particle shape effect. Comput Geotech 91:79–191

German RM (2014) Coordination number changes during powder densification. Powder Technol 253:368–376

Golchert D, Moreno R, Ghadiri M, Litster J (2004) Effect of granule morphology on breakage behaviour during compression. Powder Technol 143:84–96

Hardin BO (1985) Crushing of soil particles. J Geotech Eng 111(10):1177–1192

Huang JY, Xu SL, Hu SS (2014) Influence of particle breakage on the dynamic compression responses of brittle granular materials. Mech Mater 68:15–28

Indraratna B, Sun QD, Nimbalkar S (2014) Observed and predicted behaviour of rail ballast under monotonic loading capturing particle breakage. Can Geotech J 52:73–86

Itasca Consulting Group Inc (2015) PFC-Particle flow code, Ver. 5.0. Manual. Minneapolis: Itasca

Jaeger JC (1967) Failure of rocks under tensile conditions. Int J Rock Mech Min Sci Geomech Abstr 4(2):219–227

Jia X, Garboczi EJ (2016) Advances in shape measurement in the digital world. Particuology 26:19–31

Jin YF, Yin ZY, Wu ZX, Zhou WH (2018) Identifying parameters of easily crushable sand and application to offshore pile driving. Ocean Eng 154:416–429

Konrad J, Salami Y (2018) Particle breakage in granular materials-a conceptual framework. Can Geotech J 55(5):710–719

Kuang DM, Long ZL, Guo RQ, Yu PY (2020) Experimental and numerical investigation on size effect on crushing behaviors of single calcareous sand particles. Mar Georesour Geotechnol. https://doi.org/10.1080/1064119X.2020.1725194

Kuwajima K, Hyodo M, Hyde AF (2009) Pile bearing capacity factors and soil crushabiity. J Geotech Geoenviron Eng 135(7):901–913

Kwag JM, Ochiai H, Yasufuku N (1999) Yielding stress characteristics of carbonate sand in relation to individual particle fragmentation strength. In: AI-Shafei K (ed) Engineering for calcareous sediments. Balkema, Rotterdam, pp 79–86

Lade PV, Yamamuro JA, Bopp PA (1996) Significance of particle crushing in granular materials. J Geotech Eng 122(4):309–316

Lade PV, Liggio CD, Nam J (2009) Strain rate, creep, and stress drop creep experiments on crushed coral sand. J Geotech Geoenviron Eng 135(7):941–953

Liang F, Sayed M, Muntasheri GAAL, Chang FF, Li L (2016) A comprehensive review on proppant technologies. Petroleum 2(1):26–39

Lim WL, McDowell GR (2007) The importance of coordination number in using agglomerates to simulate crushable particles in the discrete element method. Geotechnique 57(8):701–705

Lobo GR, Vallejio LE (2005) Discrete element method evaluation of granular crushing under direct shear test conditions. J Geotech Geoenviron Eng 131:1295–1300

Luan L, Ding X, Zheng C, Kouretzis GP, Wu Q (2020) Dynamic response of pile groups subjected to horizontal loads. Can Geotech J 57(4):469–481

Luan L, Zheng C, Kouretzis GP, Ding X (2020) Dynamic analysis of pile groups subjected to horizontal loads considering coupled pile-to-pile interaction. Comput Geotech 117:103276

Lv YR, Liu JG, Xiong ZM (2019) One-dimensional compressive behaviour of dry calcareous sand at high strain. J Rock Mech Geotech Eng 11(1):192–201

Lv YR, Li X, Wang Y (2020) Particle breakage of calcareous sand at high strain rates. Powder Technol 366:776–787

Lv YR, Li F, Liu YW, Fan PX, Wang MY (2017) Comparative study of coral sand and silica sand in creep under general stress states. Can Geotech J 54(11):1601–1611

Lv YR, Wang Y, Zuo DJ (2019) Effects of particle size on dynamic constitutive relation and energy absorption of calcareous sand. Powder Technol 356:21–30

Ma L, Li Z, Wang M, Wei H, Fan P (2019) Effects of size and loading rate on the mechanical properties of single coral particles. Powder Technol 342:961–971

McDowell GR, Amon A (2000) The application of Weibull statistics to the fracture of soil particles. Soils Found 40(5):133–141

Mcdowell GR, De Bono JP (2013) On the micro mechanics of one-dimensional normal compression. Geotechnique 63(11):895–908

McDowell GR (2002) On the yielding and plastic compression of sand. Soils Found 42(1):139–145

Mehmet BC, Changbum S, Giuseppe B (2020) DEM modeling of grain size effect in brittle granular soils. J Eng Mech 146(3):04019138

Mesri G, Vardhanabhuti B (2009) Compression of granular materials. Can Geotech J 46(4):369–392

Minh NH, Cheng YP (2013) A DEM investigation of the effect of particle-size distribution on one-dimensional compression. Géotechnique 63(1):44–53

Morioka BT, Nicholson PG (2000) Evaluation of the liquefaction potential of calcareous sand. In: Proceedings of the tenth international offshore and polar engineering conference, Seattle, USA 11, pp 494–500

Nakata Y, Hyde AFL, Hyodo M, Murata H (1999) A probabilistic approach to sand particle crushing in the triaxial test. Geotechnique 49(5):567–583

Nakata Y, Kato Y, Hyodo M, Hyde AFL, Murata H (2001) One-dimensional compression behaviour of uniformly graded sand related to single particle crushing strength. Soils Found 41(2):39–51

Omidvar M, Iskander M, Bless S (2012) Stress–strain behavior of sand at high strain rates. Int J Impact Eng 49:192–213

Ovalle C, Dano C (2020) Effects of particle size-strength and size-shape correlations on parallel grading scaling. Geotech Lett 10(2):191–197

Ovalle C, Frossard E, Dano C, Hu W, Maiolino S, Hicher PY (2014) The effect of size on the strength of coarse rock aggregates and large rockfill samples through experimental data. Acta Mech 225(8):2199–2216

Peng Y, Ding XM, Xiao Y, Deng X, Deng WT (2019) Detailed amount of particle breakage in nonuniformly graded sands under one-dimensional compression. Can Geotech J. https://doi.org/10.1139/cgj-2019-0283

Poulos HG (1989) The mechanics of calcareous sediments. John Jaeger Memorial Lecture 1988, Australian. Geomechanics, pp 8–41

Randolph MF, Finnie IM, Joer H (1993) Performance of shallow and deep foundation on calcareous soil. Department of Civil Engineering, the University of Western Australia

Rittirong A, Shang JQ, Mohamedelhassan E, Ismail MA, Randolph MF (2008) Effects of electrode configuration on electrokinetic stabilization for caisson anchors in calcareous sand. J Geotech Geoenviron Eng 134(3):352–365

Saeidi F, Yahyaei M, Powell M, Tavares LM (2017) Investigating the effect of applied strain rate in a single breakage event. Miner Eng 100:211–222

Shao XQ, Chi SC, Tao Y, Zhou XX (2020) DEM simulation of the size effect on the wetting deformation of rockfill materials based on single-particle crushing tests. Comput Geotech 123:103429

Sohn C, Zhang YD, Cil M, Buscarnera G (2017) Experimental assessment of continuum breakage models accounting for mechanical interactions at particle contacts. Granul Matter 19(4):67

Su D, Yan WM (2020) Prediction of 3D size and shape descriptors of irregular granular particles from projected 2D images. Acta Geotech 15:1533–1555

Tabassom A, Mahdi MD, Arul A, Guillermo AN, Sacha E (2017) Impact of particle shape on breakage of recycled construction and demolition aggregates. Powder Technol 308:1–12

Todisco MC, Wang W, Coop MR, Senetakis K (2017) Multiple contact compression tests on sand particles. Soils Found 57:126–140

Xiao Y, Yuan Z, Chu J, Liu H, Huang J, Luo SN, Lin J (2019) Particle breakage and energy dissipation of carbonate sands under quasi-static and dynamic compression. Acta Geotech 14(6):1741–1755

Wang XZ, Wang X, Jin ZC, Zhu CQ (2017) Investigation of engineering characteristics of calcareous soils from fringing reef. Ocean Eng 134:77–86

Yu H, Sun Z, Tang C (2006) Physical and mechanical properties of coral sand in the Nansha Islands. Mar Sci Bull 8(2):31–38

Zhang C, Nguyen GD, Einav I (2013) The end-bearing capacity of piles penetrating into crushable soils. Géotechnique 63(5):341–354

Zhang F, Li M, Peng M, Chen C, Zhang LM (2018) Three-dimensional DEM modeling of the stress–strain behavior for the gap-graded soils subjected to internal erosion. Acta Geotech 14:487–503

Zhang F, Wang T, Liu F, Peng M, Furtney J, Zhang L (2020) Modeling of fluid-particle interaction by coupling the discrete element method with a dynamic fluid mesh: implications to suffusion in gap-graded soils. Comput Geotech 124:103617

Zhang YD, Buscarnera G, Einav I (2016) Grain size dependence of yielding in granular soils interpreted using fracture mechanics, breakage mechanics and Weibull statistics. Geotechnique 66(2):149–160

Zhang YD, Buscarnera G (2018) Breakage mechanics for granular materials in surface-reactive environments. J Mech Phys Solids 112:89–108

Zheng J, Hryciw RD (2015) Traditional soil particle sphericity, roundness and surface roughness by computational geometry. Geotechnique 65(6):494–506

Zhou B, Ku Q, Lv KZ, Wang HB (2019) Three-dimensional characterization of inner pores in calcareous sand particles. J Tianjin Univ (Sci Technol) 52(s1):41–48

Zhu F, Zhao J (2019) A peridynamic investigation on crushing of sand particles. Géotechnique 69(6):526–540

Acknowledgements

The authors would like to acknowledge the support of the National Natural Science Foundation of China (No. 51779264), the Natural Science Foundation of Jiangsu Province (No. BK20171399), the Central Universities fund operating expenses (No. B200202119), and the National Natural Science Foundation of China (No. 11772117).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lv, Y., Li, X., Fan, C. et al. Effects of internal pores on the mechanical properties of marine calcareous sand particles. Acta Geotech. 16, 3209–3228 (2021). https://doi.org/10.1007/s11440-021-01223-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01223-8