Abstract

Purpose

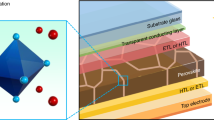

When fully developed, kesterite photovoltaics will require large quantities of earth minerals including copper, zinc, tin, and sulfur to generate electricity. This leads to questions about which material options can maximize the environmental sustainability of devices. Molybdenum is used as the back contact in kesterite photovoltaic devices, but can cause a detrimental reaction with the absorber layer limiting conversion efficiency. As a result, numerous substitutes or solutions are suggested including carbon-based back contacts. While molybdenum back contacts have been characterized in past environmental assessments, the impacts of graphene and graphite in comparison were unknown. Of paramount interest is the fact that graphene is an emerging nanomaterial with the potential to provide game-changing benefits in a variety of fields; however, the potential for human and environmental health risks to be introduced by new applications remains uncertain.

Methods

We apply life cycle assessment (LCA) to the selection of photovoltaic back contacts for emergent solar devices. Specifically, we use TRACI 2.0 to analyze impacts associated with molybdenum, graphite, and graphene back contact alternatives. For data sources, we provide calculated unit processes for graphene and graphite back contacts and utilize open source life cycle databases including the United States Life Cycle Inventory. We explore the sensitivity of the model to assumptions regarding processes and inputs using sensitivity analysis and simulation.

Results and discussion

The results demonstrate that engineering factors, such as the amount of methane used in graphene production, as well as design factors, such as the thickness of potential graphite devices, can determine whether materials substitutions will result in environmental and health gains. Without improvements to graphene production methods, we find that graphene back contacts are associated with more significant health impacts. Graphite back contacts on the other hand are associated with increases in environmental indicators—though these increases are at levels that should not prove problematic in terms of overall impacts of solar photovoltaics.

Conclusions

In conclusion, both graphite and graphene back contacts would provide potential technological improvements, but present additional risks that may need to be considered. Specific attention to graphene chemical vapor deposition improvements as well as efforts to reduce the thickness of graphite back contacts to below 5 μm are necessary to ensure that improved technical efficiency does not jeopardize the social and environmental goals of solar photovoltaics.

Similar content being viewed by others

Notes

Such price fluctuations adversely impacted the silicon photovoltaics market—providing a lesson for device researchers about the importance of considering materials abundance, market expansion, and price impacts. With the emergence of silicon solar panels in the 2000s, there followed a boom in demand for polysilicon, which caused a rise in spot prices. As the market responded and more producers came online, the spot prices plummeted from more than $475/kg in 2007 to less than $20/kg by 2014—the result of temporary oversupply of highly pure silicon to the market (Ciszek 2014). Such price volatility, though temporary, served as a warning to many producers about the long-run sustainability of developing solar photovoltaics that utilize materials subject to large price fluctuations—and especially use of materials for which increased levels of production are not sustainable.

This is based on a simple calculation, where a 100 cm*100 cm panel 0.0001 cm thick would weigh approximately 10 g given a molybdenum density of 10.2 g/cm. Cost per 100 g based on current prices as of December 2014 available from alibaba.com for molybdenum sputtering targets (Alibaba 2014).

Though by volume more graphite is used in a device, the density of molybdenum is over 4.6 times that of graphite. Thus, for a 5-μm-thick graphite layer as is modeled in this paper compared to a 1-μm-thick molybdenum layer, the mass of material used is very similar.

This primarily refers to the production of molybdenum as the dataset was accessed in an aggregated form with any co-product already allocated by mass. For the primary production of graphene or graphite back contacts, we observe no co-products. We allocated impacts to copper based on mass.

At the beginning of the project, the record device achieved 10.1 % efficiency, and during progress 11.1 % efficiency was achieved (Todorov et al. 2013). Furthermore, 10.5 % was deemed to represent a top-level device.

Though graphene thickness is an assumption, it is also a key driver as to why a graphene device may be more optimal than a graphite device. While a graphene device could be much thicker than what is modeled (7 nm), it is unlikely a graphene device would be used unless it is feasible at such thicknesses due to additional costs and reduced benefits. Thicknesses are based on personal communication and review of relevant scholarly articles, primarily Li et al. 2009; Guo et al. 2010.

We do not run this model for graphite and molybdenum because although improvements to all of the processes are likely, the graphene process is in the earliest stage of development and thus more significant refinements may be attainable during the transition to industrial scale up, as the lab-scale production methods are themselves likely to still improve.

References

Al-Hosiny NM, Moussa MA (2010) Characterization of carbon nanotubes (CNTs) Polymethyl methacrylate (PMMA) composite films. In: Enabling Science and Nanotechnology (ESciNano), 2010 International Conference, pp 1–2. IEEE, 2010

Alibaba (2014) Molybdenum sputter target-molybdenum sputter target manufacturers, suppliers and exporters on Alibaba.com Aluminum Sheets. In: Alibaba. http://www.alibaba.com/trade/search?fsb=y&IndexArea=product_en&CatId=&SearchText=molybdenum+sputter+target

Allen DM, Ler LT (1999) Increasing utilisation efficiency of ferric chloride etchant in industrial photochemical machining. J Environ Monit 1(1):103–108

Arvidsson R, Molander S, Sandén BA (2013) Review of potential environmental and health risks of the nanomaterial graphene. Hum Ecol Risk Assess 19(4):873–887

Bae S, Kim H, Lee Y, Xu X, Park J-S, Zheng Y, Balakrishnan J, Lei T, Kim HR, Il Song Y et al (2010) Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat Nanotechnol 5(8):574–578

Bare J (2011) TRACI 2.0: the tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Techns Environ Policy 13(5):687–696

Ciszek TF (2014) Photovoltaic materials and crystal growth research and development in the Gigawatt Era. J Cryst Growth 393:2–6

Classen M, Althaus H, Blaser S, Scharnhorst W, Tuchschmid M, Jungbluth N, Emmenegger MF (2007) Life cycle inventories of metals. Final report ecoinvent data v2.0:1945

Collier J, Wu S, Apul D (2014) Life cycle environmental impacts from CZTS (Copper Zinc Tin Sulfide) and Zn3P2 (tZinc Phosphide) thin film PV (Photovoltaic) cells. Energy 74:314–321

Cooper JS, Kahn E (2012) Commentary on issues in data quality analysis in life cycle assessment. Int J Life Cycle Assess 17(4):499–503

Cui H, Liu X, Liu F, Hao X, Song N, Yan C (2014) Boosting Cu2ZnSnS4 solar cells efficiency by a thin Ag intermediate layer between absorber and back contact. Appl Phys Lett 104:041115

Department of Defense (2013) Fiscal year 2012 annual energy management report

Eckelman MJ, Mauter MS, Isaacs JA, Elimelech M (2012) New perspectives on nanomaterial aquatic ecotoxicity: production impacts exceed direct exposure impacts for carbon nanotoubes. Environ Sci Technol 46(5):2902–2910

Environment Canada (2013) Assessment of the environmental performance of solar photovoltaic technologies

Fthenakis V, Wang W, Kim HC (2009) Life cycle inventory analysis of the production of metals used in photovoltaics. Renew Sustain Energy Rev 13(3):493–517

Gavankar S, Suh S, Keller AF (2012) Life cycle assessment at nanoscale: review and recommendations. Int J Life Cycle Assess 17(3):295–303

Green Delta TC (2013) Openlca 1.3

Guo Q, Ford GM, Yang W-C, Walker BC, Stach EA, Hillhouse HW, Agrawal R (2010) Fabrication of 7.2% efficient CZTSSe solar cells using CZTS nanocrystals. J Am Chem Soc 132(49):17384–17386

Healy ML, Dahlben LJ, Isaacs JA (2008) Environmental assessment of single-walled carbon nanotube processes. J Ind Ecol 12(3):376–393

Heijungs R, Suh S (2002) The computational structure of life cycle assessment. Vol. 11 Springer

Hillhouse H (2014) Personal communication, March 10. University of Washington Campus

Johnson AL, Entley WR, Maroulis PJ (2000) Reducing PFC gas emissions from CVD chamber cleaning. Solid State Technol 43(12):103–114

Jungbluth N, Stucki M, Flury K, Frischknecht R, Büsser S (2012) Life cycle inventories of photovoltaics. ESU-Services Ltd., Uster, Retrieved from: www.Esu-Services.Ch

Katagiri H, Jimbo K, Maw WS, Oishi K, Yamazaki M, Araki H, Takeuchi A (2009) Development of CZTS-based thin film solar cells. Thin Solid Films 517(7):2455–2460

Kidd R (2011) Army power and energy. http://www.greengov2011.org/presentations/CleanEnergy/GreenGov-2011-CleanEnergy-S5-RichardKidd.pdf

Kim J, Yang Y, Bae J, Suh S (2013) The importance of normalization references in interpreting life cycle assessment results. J Ind Ecol 17(3):385–395

Landfield Greig A (2008) Life cycle inventory of metallurgical molybdenum products. Four Elements Consulting Inc for the International Molybdenum Association, Brussels

Li X, Cai W, An J, Kim S, Nah J, Yang D, Piner R et al (2009) Large-area synthesis of high-quality and uniform graphene films on copper foils. Science (New York, NY) 324(5932):1312–1314. doi:10.1126/science.1171245

Matson RJ, Jamjoum O, Buonaquisti AD, Russell AD, Kazmerski LL, Sheldon P, Ahrenkiel RK (1984) Metal contacts to CuInSe2. Solar Cells 11(3):301–305

Meillaud F, Boccard M, Bugnon G, Despeisse M, Hänni S, Haug F-J, Persoz J, Schüttauf J-W, Stuckelberger M, Ballif C (2015) Recent advances and remaining challenges in thin-film silicon photovoltaic technology. Mater Today 18:378–384

NSF Award Search (2015) Award#1230615—SEP: a sustainable pathway to terawatt-scale solution-processed solar cells from earth abundant elements (2013). In: The National Science Foundation. http://nsf.gov/awardsearch/showAward?AWD_ID=1230615. Accessed 9 April 2015

Olson DW (2015) Graphite: USGS mineral commodity summaries, January 2015. U.S. Geological Survey

Orgassa K, Schock HW, Werner JH (2003) Alternative back contact materials for thin film Cu (in, Ga) Se2 solar cells. Thin Solid Films 431:387–391

Pehnt M (2002) Life-cycle Assessment of Fuel Cells in Mobile and Stationary Applications, Ph.D. Dissertation, VDI–Verlag Fortschrittsberichte, Vol. 6 No. 476, Dusseldorf

PE International (2015) Process data set: ferro molybdenum; primary production; production mix, at plant; (en). In: Gabi Documentation. http://gabi-documentation-2014.gabi-software.com/xml-data/processes/7fc8d435-42ba-4418-8bd5-8ea4d3b01b42.xml

Polyak D (2008) Molybdenum. United States Geological Survey (ed) Vol. 2008 minerals yearbook

Polyak D (2014) Molybdenum: USGS Mineral Commodity Summaries, January 2015. U.S. Geological Survey

Polyak D (2015) Molybdenum: USGS Mineral Commodity Summaries, January 2015. U.S. Geological Survey

R Core Team (2012) R: a language and environment for statistical computing

Scheer R, Schock H-W (2011) Chalcogenide photovoltaics: physics, technologies, and thin film devices. John Wiley & Sons

Scragg JJ, Kubart T, Wätjen JT, Ericson T, Linnarsson MK, Platzer-Björkman C (2013) Effects of back contact instability on Cu2ZnSnS4 devices and processes. Chem Mater 25:3162–3171

Shin B, Zhu Y, Bojarczuk N, Chey SJ, Guha S (2012) [High efficiency Cu2ZnSnSe4 solar cells with a TiN diffusion barrier on the molybdenum bottom contact. In: Photovoltaic Specialists Conference (PVSC), 38th IEEE. IEEE, Austin, p 000671–000673

Suk JW, Kitt A, Magnuson CW, Hao Y, Ahmed S, An J, Swan AK, Goldberg BB, Ruoff RS (2011) Transfer of CVD-grown monolayer graphene onto arbitrary substrates. ACS Nano 5(9):6916–6924

Todorov TK, Tang J, Bag S, Gunawan O, Gokmen T, Zhu Y, Mitzi DB (2013) Beyond 11% efficiency: characteristics of state-of-the-art Cu2ZnSn(S,Se)4 solar cells. Adv Energy Mater

US Census Bureau (2012) TIGER/Line shapefiles [machine-readable data files]/ prepared by the U.S. Census Bureau (2012)

US Geological Survey (2013) Mineral commodity summaries. Graphite

US Life Cycle Inventory Database (2013) National renewable energy laboratory, 2012. Accessed 19 November 2013: https://www.lcacommons.gov/nrel/search

Wadia C, Alivisatos AP, Kammen DM (2009) Materials availability expands the opportunity for large-scale photovoltaics deployment. Environ Sci Technol 43(6):2072–2077

Wender BA, Foley RW, Prado-Lopez V, Ravikumar D, Eisenberg DA, Hottle TA, Sadowski J et al (2014) Illustrating anticipatory life cycle assessment for emerging photovoltaic technologies. Environ Sci Technol 48(18):10531–10538

Zhivov A, Liesen R, Richter S, Jank R, Underwood D, Neth D, Woody A, Bjork C, Duncan S (2012) Net zero building cluster energy systems analysis for US army installations. ASHRAE Trans 118:751–766

Acknowledgments

In this completion of this paper, we acknowledge the work of Cate Fox - Lent and Igor Linkov of the Risk and Decision Science Center of the US Army Corps of Engineers. We also express our appreciation to Dr. Hugh Hillhouse (PI) and Wes Williamson of the University of Washington. This research was supported in part by the National Science Foundation under Grant Number CHE-1230615. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation. Partial support for this research came from a Eunice Kennedy Shriver National Institute of Child Health and Human Development research infrastructure grant, R24 HD042828, to the Center for Studies in Demography & Ecology at the University of Washington.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Mariska de Wild-Scholte

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 62 kb)

Rights and permissions

About this article

Cite this article

Scott, R.P., Cullen, A.C. Reducing the life cycle environmental impacts of kesterite solar photovoltaics: comparing carbon and molybdenum back contact options. Int J Life Cycle Assess 21, 29–43 (2016). https://doi.org/10.1007/s11367-015-0978-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-015-0978-4