Abstract

This research was focused on the eco-friendly treatment of deep-sea mining tailings in the sea areas and mainly dealt with evaluating the optimal conditions by comparing aluminum sulfate (AS), which had been proven recently to have an effect as a heavy metal extractant, with ethylenediaminetetraacetic acid (EDTA) in terms of environmental and economic feasibility. Harmful heavy metals in the manganese nodules (2%, w/v) were chemically washed by mixing with each EDTA and AS concentration for 16 elapsed times. Copper, zinc, nickel, and cadmium, which could have a fatal effect due to their high total content or high bioavailable content, were selected as the primary treatment target materials. The content of harmful heavy metals was 293.2 times more for nickel when compared with environmental standards of various countries. When 1% AS was used as the extractant, the removal efficiency of harmful heavy metals compared to the bioavailable content was 32.77% on average. It has been verified that multi-stage treatment could be necessary, and the short treatment time could be an important factor. Within a short elapsed time (3 h), the remediation efficiency of zinc and nickel under the 1% AS condition was higher than with 0.1 M EDTA. In terms of environmental and economic feasibility, it was verified that the use of 1% AS would be reasonable. The results of this research could be valuably applied to process design and optimization as basic data presented before the development of remediation technologies in the future.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With developing human activities, the demand for mineral resources is being continuously increased (Watzel et al., 2020). The total amounts of remained mineral resources and their grades have been rapidly decreasing while their prices increased (Gorman & Dzombak, 2018). Developed countries have been continuously interested in marine mineral resources containing large amounts of useful metals (iron, manganese, copper, nickel, etc.), and are also planning for commercial development by securing exclusive exploration rights for deep-sea mineral resources (Moon et al., 2020). Since the environment may commonly conflict with development, it could be necessary to consider treatment and management based on a life-cycle perspective to minimize environmental impact and pollution for sustainable development. Mining tailings, inevitably generated when developing mineral resources, contain a large amount of harmful heavy metals in fine particles, less than 63 μm, which may give a fatal impact on the environment and ecosystem when disposed of in a natural environment (Lee & Kim, 2020). Currently, there are about 2500 industrial-sized mines worldwide, and 99.3% of them dispose of mining tailings on land (Kwong et al., 2019). Due to economic, spatial, and temporal restrictions, transporting mining tailings by ship and treating them on land could not be easily conducted in countries like Korea (Rep. of) (Lee & Kim, 2022). So it could be essentially required to treat mining tailings in the sea areas (on-site/ex-situ).

When mining tailings are disposed of in sea areas, the natural environment including marine life could be affected apparently by fine particles such as turbidity production or gill occlusion. Harmful heavy metals in fine particles could be accumulated in marine life and then in human beings, like in the Minamata disaster (G et al., 2022; Meena et al., 2018; Yorifuji et al., 2017). Recently, international environmental standards have been prepared to manage deep-sea mining in the marine environment by the London Protocol, 1996 (LP), under the International Maritime Organization (IMO) and the International Seabed Authority (ISA) (International Seabed Authority [ISA], 2019; Kim & Kim, 2019; Lodge et al., 2014; Ramirez-Llodra et al., 2015). It could be essential to reduce harmful heavy metals before disposal in compliance with the international environmental guidelines to be prepared. Although various countries are interested in deep-sea tailings disposal, only a few research results related to treatment or disposal in sea areas have been reported until now (Vare et al., 2018).

To treat deep-sea mining tailings in the sea areas, it could be essential to overcome the limitations in the marine environment (sea weather conditions, space, infrastructure, etc.), and the development of eco-friendly remediation technologies that do not affect the marine environment and ecosystem is urgently required (Lee & Kim, 2019). Since the use of highly reactive or toxic substances could be extremely limited in the sea areas, the effect of extracting harmful heavy metals by aluminum sulfate (AS) was evaluated together with ethylenediaminetetraacetic acid (EDTA), a common traditional commercial extractant, in previous research (Lee & Kim, 2022). Both removal efficiency and optimum additive conditions were verified for the AS conditions compared to that of EDTA. These research results could be successfully applied as basic data for the development of commercial remediation technologies and actual process design to protect the marine environment as well as the terrestrial environment.

2 Materials and Methods

2.1 Site Characterization

The Clarion-Clipperton Fracture Zone (CCFZ), located in the Northeast Pacific Ocean, is exploration areas for manganese nodules noted by various countries and multinational corporations, and Korea has secured exclusive development rights in the locations 10°27.3′N ~ 10°32.7′N, 131°22.68′W ~ 131°17.22′W in 2002 (Fig. 1).

Manganese nodules used in this research were collected from specific areas (Fig. 1) in March 2018 using a free fall grab and a box corer (Lee & Kim, 2022). After natural drying on the vessel, they were crushed with a jaw crusher and a ball mill in the laboratory. The crushed manganese nodules were classified by particle size through auto-sieving (Fritsch Analysette 3 Pro Vibratory Sieve Shaker, Germany) (> 63 μm, 20 ~ 63 μm, < 20 μm), and stored at room temperature 25 °C (Fig. 2) (Kim & Kim, 2019).

2.2 Preparation

2.2.1 Manganese Nodules

In consideration of the lower limit (~ about 100 μm) of the ore-dressing process on a vessel during the actual development of deep-sea mineral resources, the manganese nodules (nodules) used for the experiments were selected in the size of 20 ~ 63 μm (Lee & Kim, 2019). The nodule samples were diluted with ultrapure water (SARTORIUS, Germany) in consideration of the solid–liquid ratio (1:10 ~ 1:20) of a general commercial treatment process and used to prepare 2% (w/v) concentration.

2.2.2 Ethylenediaminetetraacetic Acid and Aluminum Sulfate

The concentration conditions of the additives were set to 4 each way in order to identify the characteristics of the extraction of harmful heavy metals from the sample (EDTA: 0.01 M, 0.03 M, 0.05 M, 0.1 M/AS: 0.1%, 0.3%, 0.5%, 1%). Afterwards, the concentration of the additive mixed with the nodules was replaced as follows. EDTA 0.01, 0.03, 0.05, and 0.1 M were expressed as conditions 1, 2, 3, and 4, respectively, and AS 0.1, 0.3, 0.5, and 1% were expressed as conditions 5, 6, 7, and 8, respectively. Additives were prepared using ultrapure water as a solvent for each concentration. EDTA and AS were purchased from JUNSEI (CAS No. 60–00-04) and KANTO Chemical (CAS No. 7784–31-8) in Japan. The purity percentages of each chemical were 99.5% and 51.0 ~ 57.5%, respectively.

2.3 Remediation Experiments

In a glass vial with an effective volume of 60 mL, 20 mL of a 2% (w/v) nodule sample and 20 mL of each concentration of additive were injected. The reaction was carried out while mixing at 80 rotations per minute (rpm) using a magnetic bar (cross type) and a stirrer for a total of 16 elapsed time conditions from 5 min to 168 h (Kim & Kim, 2019). The liquid and solid phases were separated by a centrifuge (Sorvall™ ST 40 Centrifuge, Thermo Fisher Scientific, USA) at 4200 rpm for 1 h from the mixture in which the reaction was completed according to each elapsed time condition (Lee & Kim, 2019). The separated liquid was collected with a plastic syringe (30 mL), filtered through an acrylic filter (0.45 μm), and was used as a sample for analysis while refrigerated at 4 °C. In order to have representativeness of the data, the experiment was repeated a total of three times, and at least three repetitions were set for each experiment (Lee & Kim, 2022).

2.4 Analysis of Harmful Heavy metals

Harmful heavy metals, copper (Cu), zinc (Zn), nickel (Ni), and cadmium (Cd), extracted in the liquid phase were analyzed with a UV–Vis spectrophotometer (DR-5000, Hach, USA) according to US EPA Methods (8506, 8009, 10220 and 10217).

2.5 Verification of Analytical Recovery

In order to confirm the reliability of the analysis, analytical recovery was performed for each analysis. As standard materials for each heavy metal, Cu (1.19786.0500, Merck Co, Germany), Zn (1.19806.0500, Merck Co, Germany), Ni (1.19792.0500, Merck Co, Germany), and Cd (1.19777.0500, Merck Co, Germany), were used. The average recovery rates were about 96.1 ± 4.1% for Cu, 95.5 ± 6.0% for Zn, 98.3 ± 2.5% for Ni, and 97.9 ± 4.0% for Cd, respectively.

2.6 The Evaluation of Total Heavy Metal Contents and Bioavailable Contents in Manganese Nodules

The total heavy metal contents in nodules were analyzed according to the total digestion method (Sim et al., 2014). Nitric acid (HNO3, Merck Co, Germany) and perchloric acid (HClO4, Merck Co, Germany) were added to 20 mg of nodules, and the mixture was heated at about 180 °C. for 12 h. After that, hydrofluoric acid (HF, Merck Co, Germany) was added and heated again at 180 °C for 12 h to volatilize the acid. The harmful heavy metals of the sample were extracted by dissolving it with 1% nitric acid (Sim et al., 2014). The content of harmful heavy metals present in the bioavailable state was extracted by mixing and reacting 1 g of nodules and 20 mL of 1 M hydrochloric acid (HCl) for 4 h following a single extraction method (Bettiol et al., 2008; Sim et al., 2014). All harmful heavy metals extracted in the liquid phase were analyzed with an inductively coupled plasma-mass spectrometer (ICP-MS, Thermo X series, ThermoFisher, USA) (Sim et al., 2014). Total organic carbon (TOC) was determined using TOC analyzer (Shimadzu, TOC-Vcph, Japan).

3 Results and Discussions

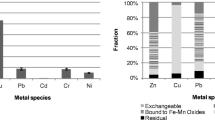

3.1 The Contents of Nodules

The content of bioavailable harmful heavy metals and total harmful heavy metals in manganese nodules were analyzed to determine whether remediation was necessary compared with environmental standards of various nations, which are discussed in Sect. 3.4.1 and confirm the effect of extracting of harmful heavy metals by additives. The total contents of harmful heavy metals were highest in the order of Ni (15,130 mg/kg), Cu (12,930 mg/kg), and Zn (1462 mg/kg). The fraction of bioavailable contents was 71.6% (1046 mg/kg), 66.7% (12.00 mg/kg), and 52.5% (6784 mg/kg) in the order of Zn, Cd, and Cu, respectively (Table 1). TOC in the nodules was only about 0.3333% (Lee & Kim, 2019).

Based on the analysis results, Cu, Zn, Ni, and Cd were selected as primary target materials to be treated essentially. This is because even a small amount may have a fatal effect due to the highest content or the highest bioavailable content.

3.2 The Characteristics of the Extraction of Harmful Heavy Metals in Nodules Depending on EDTA Concentration

Figure 3 shows the results of the extracted concentration of harmful heavy metals (Cu, Zn, Ni, and Cd) by EDTA under the concentration conditions (1, 2, 3, and 4) and elapsed times (5 m ~ 168 h). The reason that the experiment was carried out up to an elapsed time of 168 h (7 d) was to determine the ultimate maximum extraction limit for the development of commercial remediation technologies.

The highest Cu concentration was 41.19 (± 2.446) mg/L at 96 h of elapsed time, which occurred in condition 4 (Fig. 3a). As the EDTA concentration increased from condition 1 to 4, the Cu concentration also increased about 4.273 times. According to the conditions 1, 2, 3 and 4, a common tendency was confirmed to decrease to 6.664 (± 1.032) mg/L, 24.14 (± 1.653) mg/L, 22.89 (± 3.069) mg/L, and 35.53 (± 1.626) mg/L at the 168 h of elapsed time.

As the EDTA concentration increased from condition 1 to 4, the Zn concentration also increased about 6.685 times from 0.5028 (± 0.0372) mg/L to 3.361 (± 0.2962) mg/L (Fig. 3b). Zn was extracted by condition 2 on average about 0.3795 times less than condition 3 from 5 m to 6 h elapsed time, and after that period about 1.381 times higher except for 72 h. The extracted concentration by condition 3 did not show a significant difference from condition 1 until the elapsed time of 6 h, and then showed a tendency to increase by about 2.922 times.

The highest concentration of extracted Ni was 13.98 (± 0.1586) mg/L at 48 h in condition 4 (Fig. 3c). As the EDTA concentration increased from condition 1 to 4, the Ni concentration also increased about 12.53 times, but the concentration of Ni extraction by conditions 3 and 4 showed a similar trend, with difference of about 0.0752 on an average until 2 h of elapsed time. As the elapsed time increased, the extraction concentration also increased by about 3.863 times, so that an increase in the concentration of Ni extraction according to the elapsed time was apparent.

As the elapsed time increased from 5 m to 168 h, the Cd concentration increased by 7.333 times, 9.000 times, and 8.367 times under conditions 2, 3 and 4, respectively, but increased by 1.957 times at condition 1, indicating a relatively low increase rate (Fig. 3d).

Unexpectedly, there was a section in which the concentration of Cd extraction rapidly increased at 40 m and 90 m for conditions 3 and 4. As the EDTA concentration increased from condition 1 to 4, the Cd concentration also increased about 9.178 times.

3.3 The Effect of Extraction for Harmful Heavy Metals in Nodules by Aluminum Sulfate

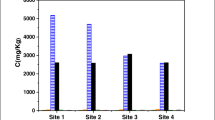

Figure 4 shows the results of the extracted concentration of harmful heavy metals (Cu, Zn, Ni, and Cd) by AS concentration (conditions 5, 6, 7, and 8) and elapsed time (5 m ~ 168 h).

Among the conditions 5, 6, 7 and 8, Cu extracted concentration according to elapsed time showed the highest value at short elapsed time within 2 h except for condition 8 (Fig. 4a). When the elapsed time reached 168 h, the extraction concentration for each condition showed a value of 0.0211 (± 0.0117) mg/L, 1.957 (± 0.2627) mg/L, 4.865 (± 0.5298) mg/L, and 11.62 (± 2.239) mg/L, which was lower than the value within 2 h or showed a similar trend.

The Zn extraction concentration of condition 5 was higher on average by about 1.431 times than condition 6 up to 6-h elapsed time (Fig. 4b). After that, as the elapsed time increased, the concentration under the condition 5 decreased from 1.031 (± 0.7236) mg/L to 0.3042 (± 0.2770) mg/L, unlike the condition 6. The Zn concentration was also the highest at 3.253 (± 2.002) mg/L under condition 8, similar to Cu, and there was no significant difference with the elapsed times.

Ni and Cd were found to be less than the detection limit due to the small extraction by condition 5. The highest Ni concentration was 6.817 (± 0.7858) mg/L at 168 h, which occurred in the condition 8 (Fig. 4c). As the AS concentration increased from condition 5 to 8, the concentration of extracted Ni also increased about 97.39 times. In all conditions (5 ~ 8), the Ni concentrations rapidly increased to an average of about 34.68 times after 24 h. The concentration of extracted Cd in the conditions 6 and 7 increased by about 6.333 times and 1.803 times as the elapsed time increased (Fig. 4d). When the elapsed time was more than 48 h, the Cd concentrations in condition 6 were about 1.347 times higher on average than in condition 7. In condition 8, the highest extracted concentration was 0.2813 (± 0.1665) mg/L at 96 h of elapsed time, but decreased to 0.1660 (± 0.0053) again when reaching 168 h of elapsed time.

3.4 Discussions

3.4.1 Reviewing the Scope of Treatment for Harmful Heavy Metals in Nodules

Since international environmental standards for deep-sea mining resource development are currently being discussed led by LP and ISA, so it could likely be set similarly to the existing standards for marine sediments (Lee & Kim, 2022). The potential impact on the marine environment was evaluated by comparing the total heavy metal content and bioavailable heavy metal content in the nodules identified in Sect. 3.1 with the marine sediment environmental standards and the ocean dumping standards of dredged materials (including marine sediments) of the USA, France, and Korea (Table 2) (Alvarez-Guerra et al., 2007; Bebianno et al., 2015; Canadian Council of Ministers of the Environment [CCME], 1999; Kim & Kim, 2019; Mulligan et al., 2010).

The total and bioavailable content of each harmful heavy metal was shown in Sect. 3.1 (Table 1). The ERL (effect range low) and TEL (threshold effects level) used in environmental standards refer that chemical concentrations below which adverse effects would be rarely observed (Bebianno et al., 2015).

In addition, the ERM (effect range medium) and PEL (probable effects level) mean that chemical concentrations above which adverse effects are expected to occur frequently (Bebianno et al., 2015). The content of harmful heavy metals in the nodules was compared with the criteria judged to may have adverse effects frequently. Compared with the most stringent environmental standards for marine sediments, the total contents of Cu, Zn, Ni, and Cd exceeded the PEL by 119.7, 5.395, 353.5, and 4.286 times, respectively. The bioavailable content was also excessive at 62.81 times, 3.860 times, 51.26 times, and 2.857 times, respectively, and the effect on living organisms is expected to be immense. The standards for ocean dumping mean that dumping at sea areas may be prohibited if the analysis shows that concentrations exceeds action level 2 (in the case of Korea (Rep. of), it corresponded to action level 1) (Mulligan et al., 2010). The total and bioavailable content of Cu, Zn, Ni, and Cd in the nodules also significantly exceeded the ocean dumping standards for dredged materials including sediments.

The content of harmful heavy metals (Cu, Zn, Ni, and Cd) in the nodules exceeded the environmental standards for marine sediments and ocean dumping standards of dredged materials in numerous countries. Cu, Zn, Ni, and Cd are the main substances to be remedied because it means that mining tailings could have a serious adverse effect on the ecosystem and the environment when directly discharged to the marine environment.

3.4.2 Evaluation of Remediation Efficiency

The remediation efficiency was evaluated by comparing bioavailable content and the harmful heavy metal concentrations removed by conditions 4 and 8, which showed the maximum extracted concentration in the results in Sects. 3.2 and 3.3 (Table 3). The reason for comparing the bioavailable content and not the total content in the nodules is that the total amount of harmful heavy metals in the nodules also includes residual content that does not affect the water quality environment and ecosystem, so there is a limit to comparing the total amount and remediation efficiency. The result values were the concentration (mg/L) of harmful heavy metals extracted in the liquid phase, and in the discussion, the converted values (mg/kg) were used in consideration of the nodules mass and the solution volume in a single experiment to compare with the removal efficiency and environmental standards.

The maximum extracted Cu concentration under condition 4 was 4119 mg/kg, dw when converted to mg/kg, dw. About 60.72% of bioavailable fraction of Cu in nodules was removed by condition 4. The extracted concentration of Zn was 336.1 mg/kg, which was about 32.13% of bioavailable Zn. About 1398 mg/kg of Ni was extracted which was about 63.72% of the bioavailable content. About 41.01 mg/kg of Cd was removed, and all Cd present in the nodules was extracted and removed. Among the target harmful heavy metals, only Cd showed 100% efficiency.

Converting the maximum extracted Cu, Zn, Ni, and Cd concentrations (mg/L) under condition 8 into mg/kg, dw is 1376 mg/kg, 325.3 mg/kg, 681.7 mg/kg, and 28.13 mg/kg, respectively. Comparing this with the bioavailable content in the nodules, 20.28% of Cu was removed, and about 31.10% and 31.07% of Zn and Ni were removed. In addition, Cd was removed by 100.0% compared to the bioavailable content in the nodules, showing the same results as condition 4.

Except for Cd, Cu, Zn, and Ni require additional treatment because the concentration of harmful heavy metals remaining in the mining tailings exceeded the environmental standards which showed the highest value for each by about 8.970 times and 16.96 times on average even after treatment with conditions 4 and 8. If condition 4 or 8 is used in the actual process design, it is judged that multi-stage treatment process of re-treating the treated material would be necessary. An important factor in multi-stage treatment would be reaction time, so it would be important to achieve high efficiency within a short elapsed time.

3.4.3 Verification of Suitable Conditions for the Extraction of Harmful Heavy Metals in Nodules

We compared and evaluated the two additives according to the following three details.

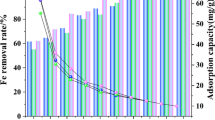

First, the removal efficiency was compared. When multi-stage treatment would be assumed based on the importance of the short elapsed time confirmed in Sect. 3.4.2, the chemical washing process design should be set within 3 h considering the generally required treatment time, which is 2 h, multiplied by the safety factor, 1.5. Therefore, since multi-stage treatment requires two or more treatments within the treatment time (3 h) except additional treatment such as dewatering, etc., the treatment efficiency up to 2 h was evaluated. Figure 5 shows the comparison of the remediation efficiency of conditions 4 and 8 in a short elapsed time of less than 3 h.

The extracted concentrations of harmful heavy metals in conditions 4 and 8 were 15.79 mg/kg and 12.25 mg/kg for Cu, 0.7385 mg/kg, 2.663 mg/kg for Zn, 2.273 mg/kg, 0.6542 mg/kg for Ni, 0.1038 mg/kg, and 0.1883 mg/kg for Cd, on average (Fig. 5). In Sects. 3.2 and 3.3 results, as the elapsed time increased, the extracted concentration of harmful heavy metals by EDTA gradually increased, while a significant amounts of harmful heavy metals were extracted by AS even within a relatively short elapsed time. In particular, Zn and Cd extracted by condition 8 showed about 3.606 times and 1.814 times higher efficiency than condition 4 within 3 h elapsed time.

Second, in order to check economic feasibility, the unit costs of EDTA and AS were investigated considering the amount of additive required for processing 1 kg of nodules. The amounts of EDTA and AS required to treat 1 kg of nodules are 1.469 kg and 1.164 kg, respectively, considering the purity and water content. The prices of industrial-grade EDTA and AS in bulk were investigated at about 8.000 USD and 0.0103 USD per 1 kg, respectively. Therefore, it could be expected that the cost of additives per 1 kg of nodules treatment would be about 11.75 USD for EDTA use and about 0.0120 USD for AS use. When AS is used as an additive, it could be possible to reduce costs by about 99.90% compared to EDTA, so it is considered that the use of AS is about 979.2 times more economical feasibility. If commercial remediation technologies for deep-sea mining tailings are developed in the near future, the ore-dressing conditions should have to be specified, and then accordingly, economic feasibility should be considered by optimizing the solid–liquid ratio of treatment processes. Thus, these results may be successfully used to develop actual remediation technologies for the future.

Third, the environmental impact of the use of additives was evaluated by referring to previous studies. EDTA has been frequently used for chemical washing treatment of soil contaminated with harmful heavy metals. However, recent studies have shown that EDTA is a synthetic chelating agent that is not easily decomposed because it binds easily with metals. EDTA causes secondary contamination due to such toxicity, so studies on washing agents to replace it are being actively conducted (Feng et al., 2020; Gluhar et al., 2020). On the other hand, AS is non-toxic and is a versatile material that is widely used as a coagulant precipitant in the terrestrial environment.

When remedying soil contaminated with harmful heavy metals, in general, the lower the pH of the chelating agent solution, the greater the extraction efficiency of the harmful heavy metals (Tandy et al., 2004). This pH adjustment processes will require high equipment requirements (Wu et al., 2015). As mentioned in the introduction, the use of highly reactive materials to treat nodules in the sea areas is extremely limited. Therefore, in this study, deionized water with a pH of about 7.790 was used without pH adjustment (this is similar to the pH of actual seawater).

The pH of conditions 4 and 8 was about 4 or less on average and for AS, when mixing with nodules, a high extraction efficiency of harmful heavy metals was achieved due to the low pH as well as the ion exchange mechanism. In addition, the following results suggested that waste water with a lower pH than the surrounding sea waters will be generated. Therefore, it is judged that it is necessary to treat wastewater in the sea areas, and it will be possible to treat it with currently actively used technologies such as ion exchange membrane filtration. And a treatment method without using strong acids or bases should be applied in sea areas for future. Also, in connection with this, solidification·stabilization treatment and technologies in the sea areas should be developed in each field to minimize the impact of fine particles in the waste water.

As a result of integrating efficiency and economic and environmental feasibility, AS could be considered very suitable as an extractant for the treatment of mining tailings generated during the development of deep-sea mineral resources. As the concentration of AS increases from 0.1 to 1%, the extraction effect of harmful heavy metals tends to increase by about 54.98 times on average, so it could be verified that the condition 8 was the optimized additive concentration in this experimental condition. This was due to the ion exchange effect of AS (Kim, 2021), and a study on the evaluation of the effect of chemical washing treatment of harmful heavy metals with higher concentrations of AS will be reported subsequently. AS is expected to be used not only as a chemical washing agent for deep sea mining tailings but also in terrestrial soils, so, it will be necessary to compare and evaluate whether agents used as flocculants similar to AS can also be used like chemical washing agents.

4 Conclusions

-

1)

Deep-sea mining tailings were highly polluted with harmful heavy metals (Cu, Zn, Ni, and Cd) compared to the environmental standards of numerous countries and could have a serious impact on the marine environment and ecosystem, so proper remediation should be required before disposal in the sea.

-

2)

Based on research results, when EDTA was used, there was a clear tendency to increase the extraction effect of harmful heavy metals according to elapsed time and additive concentration. Unlike EDTA, when using AS, the extraction effect of harmful heavy metals was high even in a short elapsed time (3 h), and it was confirmed that the extraction effect increased according to the concentrations of additive.

-

3)

The remediation efficiency of the condition 8 (AS 1%) within a short elapsed time (3 h) considering the multi-stage treatment was about 2.710 times higher or similar to condition 4 without pH adjustment.

-

4)

Considering economic and environmental feasibility, the condition 8 (AS 1%) was verified as an appropriate additive that could be applied to the development of remediation technologies for processing mining tailings in the sea areas.

-

5)

When using AS, the extraction effect of harmful heavy metals was apparently increased as the concentration increased, so it could be necessary to conduct a research to evaluate the extraction effect of harmful heavy metals using high concentrations of AS.

The results of this research will be usefully applied to process design and optimization as basic data presented prior to the development of remediation technologies in the future. The development of on-site treatment and disposal technology will also be continuously reported in connection with solidification or stabilization technologies to minimize the impact of fine particles on the marine environment when the treated products would be disposed of in the sea areas followed by remediation treatment.

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

References

Alvarez-Guerra, M., Viguri, J. R., Casado-Martínez, M. C., & Delvalls, T. À. (2007). Sediment quality assessment and dredged material management in Spain: Part II, Analysis of action levels for dredged material management and application to the Bay of Cádiz. Integrated Environmental Assessment and Management, 3(4), 539–551. https://doi.org/10.1897/IEAM_2007-016.1

Bebianno, M. J., Pereira, C. G., Rey, F., Cravo, A., Duarte, D., D’Errico, G., & Regoli, F. (2015). Integrated approach to assess ecosystem health in harbor areas. Science of the Total Environment, 514, 92–107. https://doi.org/10.1016/j.scitotenv.2015.01.050

Bettiol, C., Stievano, L., Bertelle, M., Delfino, F., & Argese, E. (2008). Evaluation of microwave-assisted acid extraction procedures for the determination of metal content and potential bioavailability in sediments. Applied Geochemistry, 23(5), 1140–1151. https://doi.org/10.1016/j.apgeochem.2007.11.008

Canadian Council of Ministers of the Environment (CCME). (1999). Canadian Sediment Quality Guidelines. for the Protection of Aquatic Life. Winnipeg. Retrieved September 30, 2022, from https://ccme.ca/en/resources/sediment.

Feng, W., Zhang, S., Zhong, Q., Wang, G., Pan, X., Xu, X., Zhou, W., Li, T., Luo, L., & Zhang, Y. (2020). Soil washing remediation of heavy metal from contaminated soil with EDTMP and PAA: Properties, optimization, and risk assessment. Journal of Hazardous Materials, 381, 120997. https://doi.org/10.1016/j.jhazmat.2019.120997

G, Alagarsamy, P, Nithiya, R, Sivasubramanian, & R, Selvakumar. (2022). Multi-ionic interaction with magnesium doped hydroxyapatite-zeolite nanocomposite porous polyacrylonitrile polymer bead in aqueous solution and spiked groundwater. Environmental Pollution, 309, 119728. https://doi.org/10.1016/j.envpol.2022.119728

Gluhar, S., Kaurin, A., & Lestan, D. (2020). Soil washing with biodegradable chelating agents and EDTA: Technological feasibility, remediation efficiency and environmental sustainability. Chemosphere, 257, 127226. https://doi.org/10.1016/j.chemosphere.2020.127226

Gorman, M. R., & Dzombak, D. A. (2018). A review of sustainable mining and resource management: Transitioning from the life cycle of the mine to the life cycle of the mineral. Resources, Conservation and Recycling, 137, 281–291. https://doi.org/10.1016/j.resconrec.2018.06.001

International Seabed Authority (ISA). (2019, March 22). Draft regulations on exploitation of mineral resources in the Area. ISBA/25/C/WP.1. Retrieved September 30, 2022, from https://isa.org.jm/files/files/documents/isba_25_c_wp1-e_0.pdf

Kim, H., & Kim, K. (2019). Remediation of heavy metals in deep-sea mining tailings by using rhamnolipid (in Korean). Journal of Korean Society of Environmental Engineers, 41(10), 524–531. https://doi.org/10.4491/KSEE.2019.41.10.524

Kim, K. R. (2021, April 1). Remediation method and system for deep-sea mine tailings. U.S.A. Patent. Application. 17221681

Kwong, Y. T. J., Apte, S. C., Asmund, G., Haywood, M. D. E., & Morello, E. B. (2019). Comparison of environmental impacts of deep-sea tailings placement versus on-land disposal. Water, Air, and Soil Pollution, 230, 287. https://doi.org/10.1007/s11270-019-4336-1

Lee, A., & Kim, K. (2019). Removal of heavy metals using rhamnolipid biosurfactant on manganese nodules. Water, Air, and Soil Pollution, 230, 258. https://doi.org/10.1007/s11270-019-4319-2

Lee, A., & Kim, K. (2020). New approach to remove heavy metals from wastewater by the coagulation of alginate-rhamnolipid solution with aluminum sulfate. Water, 12, 3406. https://doi.org/10.3390/w12123406

Lee, G., & Kim, K. (2022). Evaluation of feasibility of chemical washing treatment of nickel in deep-sea mining tailings by aluminum sulfate as extractant (in Korean). Journal of Korean Society of Environmental Engineers, 44(3), 77–85. https://doi.org/10.4491/KSEE.2022.44.3.77

Lodge, M., Johnson, D., Gurun, G. L., Wengler, M., Weaver, P., & Gunn, V. (2014). Seabed mining: International seabed authority environmental management plan for the Clarion-Clipperton Zone A Partnership Approach. Marine Policy, 49, 66–72. https://doi.org/10.1016/j.marpol.2014.04.006

Meena, R. A. A., Sathishkumar, P., Ameen, F., Yusoff, A. R. M., & Gu, F. L. (2018). Heavy metal pollution in immobile and mobile components of lentic ecosystems—A review. Environmental Science and Pollution Research, 25, 4134–4148. https://doi.org/10.1007/s11356-017-0966-2

Moon, I., Yoo, C., & Kim, J. (2020). Environment-friendly processing technologies of mine tailings: Research on the characteristics of mine tailings when developing of deep sea mineral resources. Economic and Environmental Geology, 53, 781–792. https://doi.org/10.9719/EEG.2020.53.6.781

Mulligan, C. N., Fukue, M., & Sato, Y. (2010). Sediments contamination and sustainable remediation. CRC Press.

Ramirez-Llodra, E., Trannum, H. C., Evenset, A., Levin, L. A., Andersson, M., Finne, T. E., Hilario, A., Flem, B., Christensen, G., Schaanning, M., & Vanreusel, A. (2015). Submarine and deep-sea mine tailing placements: A review of current practices, environmental issues, natural analogs and knowledge gaps in Norway and internationally. Marine Pollution Bulletin, 97, 13–35. https://doi.org/10.1016/j.marpolbul.2015.05.062

Sim, Y. S., Kim, K. R., & Kim, S. H. (2014). Treatability of heavy metals in the washing technology of marine sediments contaminated with organic matter (in Korean). Journal of Korean Society of Environmental Engineers, 36(12), 851–857. https://doi.org/10.4491/KSEE.2014.36.12.851

Tandy, S., Bossart, K., Mueller, R., Ritschel, J., Hauser, L., Schulin, R., & Nowack, B. (2004). Extraction of heavy metals from soils using biodegradable chelating agents. Environmental Science and Technology, 38(3), 937–944. https://doi.org/10.1021/es0348750

Vare, L. L., Baker, M. C., Howe, J. A., Levin, L. A., Neira, C., Ramirez-Llodra, E. Z., Reichelt-Brushett, A., Rowden, A. A., Shimmield, T. M., Simpson, S. L., & Soto, E. H. (2018). Scientific considerations for the assessment and management of mine tailings disposal in the deep sea. Frontiers in Marine Science, 5, 17. https://doi.org/10.3389/fmars.2018.00017

Watzel, R., Rühlemann, C., & Vink, A. (2020). Mining mineral resources from the seabed: Opportunities and challenges. Marine Policy, 114, 103828. https://doi.org/10.1016/j.marpol.2020.103828

Wu, Q., Duan, G., Cui, Y., & Sun, J. (2015). Removal of heavy metal species from industrial sludge with the aid of biodegradable iminodisuccinic acid as the chelating ligand. Environmental Science and Pollution Research, 22(2), 1144–1150. https://doi.org/10.1007/s11356-014-3365-y

Yorifuji, T., Kashima, S., Suryadhi, M. A. H., & Abudureyimu, K. (2017). Temporal trends of infant and birth outcomes in Minamata after severe methylmercury exposure. Environmental Pollution, 231, 1586–1592. https://doi.org/10.1016/j.envpol.2017.09.060

Funding

This research was supported by the Korea Institute of Ocean Science and Technology (PEA0023 and PEA0012), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lee, G., Kim, K. Applicability and Extraction Characteristics of Aluminum Sulfate as Extractant of Harmful Heavy Metals for On-Site Treatment of Deep-Sea Mining Tailings. Water Air Soil Pollut 233, 498 (2022). https://doi.org/10.1007/s11270-022-05972-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-022-05972-4