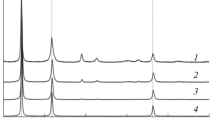

A process was developed for the production of agglomerated carbonyl nickel powders with spherical particles ranging from 45 to 71 μm. The powders are intended to make spongy oxide/nickel cathodes. The idea relied on the separation of integral and local compaction effects in the sintering of agglomerated powders. The morphology and particle size of the powders were examined by scanning electron microscopy using a Superprobe-733 analyzer. The nickel powders were chemically tested to determine their carbon content with automatic coulometric titration by pH values employing an AN-7529U rapid analyzer. The agglomerated carbonyl nickel powders with spherical 45–71 μm particles were produced from PNK-1L5 carbonyl nickel powders with average particle sizes of 4 μm by annealing without mechanical grinding. The optimum process of producing nickel powders with 45–71 μm particles involves stage-by-stage annealing of agglomerated particles at 400, 500, and 600°C for 0.5 h with intermediate sifting through sieves 071 and 045. Testing of the spongy oxide/nickel cathodes produced in compliance with the agglomeration process for the fine PNK-1L5 nickel powders showed that they could be used to replace the PNK-2K10 nickel powders.

Similar content being viewed by others

References

G.A. Kudintseva, A.I. Melnikov, A.V. Morozov, and B.P. Nikonov, Thermionic Cathodes [in Russian], N.D. Deviatkov (ed.), Energiya, Moscow–Leningrad (1966), p. 368.

A.B. Kiselev, Metal Oxide Cathodes Based on Electron Devices [in Russian], Izd. MFTI, Moscow (2001), p. 240.

V.G. Syrkin and V.N. Babin, Gas Grows Metals [in Russian], Nauka, Moscow (1986), p. 190.

GOST 26849–86, Pore Size Determination Method. Powder Materials [in Russian], intr. March 26 (1986).

V.V. Skorokhod and Yu.M. Solonin, “Relationship between integral and local densification in the sintering of porous solids,” Powder Metall. Met. Ceram., 22, No. 12, 985–989 (1983).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 7–8 (540), pp. 16–23, 2021.

Rights and permissions

About this article

Cite this article

Hetman, O., Izunova, O., Samelyuk, A. et al. Highly Active Granular Nickel Powders for Multi-Batch Production of Spongy Oxide Cathodes. Powder Metall Met Ceram 60, 396–402 (2021). https://doi.org/10.1007/s11106-021-00252-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00252-y