Abstract

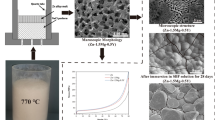

In this study, β type Ti‒29Nb‒13Ta‒4.6Zr alloys coated with biphasic calcium phosphate (BCP) reinforced with rutile-TiO2 compounds by sol-gel technique to evaluate its possible usage in biomaterial science. Calcium nitrate tetrahydrate (Ca(NO3)2∙4H2O), di-ammonium hydrogen phosphate (NH4)2HPO4), ammonium hydroxide (NH4OH), and titanium (IV) propoxide (Ti(OC3H7)4) (Merck, Germany) were used as precursors for producing the BCP-only and BCP/TiO2 composite coatings. Synthesis and coating procedure, surface morphology, adhesion strength, and corrosion results of the coated samples have been investigated in details. XRD technique has been used in order to characterization of BCP phases. The morphological observations of coatings were determined by using a scanning electron microscopy (SEM). In-vitro corrosion behaviors of the coatings have been determined with polarization method in Ringer’s electrolyte at body temperature. It was found that the BCP/TiO2 coating synthesized on TNTZ alloy has higher scratch resistance than BCP-only coating due to its containing rutile-TiO2 compounds. In addition, it can be said that the BCP/TiO2 coated sample was less susceptibility to corrosion than the BCP-only coatings and uncoated TNTZ sample in simulated body fluid.

Highlights

-

A new method has been proposed for production of biphasic calcium phosphate (BCP).

-

The phase has been coated on the β type Ti‒29 Nb‒13Ta‒4.6Zr (TNTZ) alloys by sol-gel.

-

The coating has higher adhesion resistance if the BCP phase contains TiO2 compounds.

-

In-vitro resistances of the coatings were found higher than uncoated TNTZ alloy.

Similar content being viewed by others

References

Dikici B, Esen Z, Duygulu O, SG (2015) Advances in metallicBiomaterials. In: Niinomi M, Narushima T, Nakai M (eds) Advances in metallic biomaterials: tissues, materials and biological reactions. Springer Berlin Heidelberg, Berlin, Heidelberg, pp 275–303

Niinomi M (2002) Recent metallic materials for biomedical applications. Metall Mater Trans A 33:477–486. https://doi.org/10.1007/s11661-002-0109-2

Niinomi M (1998) Mechanical properties of biomedical titanium alloys. Mater Sci Eng A 243:231–236. https://doi.org/10.1016/S0921-5093(97)00806-X

Kuroda D, Niinomi M, Morinaga M et al. (1998) Design and mechanical properties of new i type titanium alloys for implant materials. Mater Sci Eng A 243:244–249. https://doi.org/10.1016/S0921-5093(97)00808-3

Niinomi M, Akahori T, Katsura S et al. (2007) Mechanical characteristics and microstructure of drawn wire of Ti–29Nb–13Ta–4.6Zr for biomedical applications. Mater Sci Eng C 27:154–161. https://doi.org/10.1016/j.msec.2006.04.008

Niinomi M, Boehlert CJ (2015) Titanium alloys for biomedical applications. In: Niinomi M, Narushima T, Nakai M (eds) Advances in metallic biomaterials: tissues, materials and biological reactions. Springer-Verlag, Berlin, Heidelberg, p 179–213

Ratner DB, Brunette DM, Tengvall P, Textor M, Thomsen P (2008) Titanium in Medicine. Proceedings of the Institution of Mechanical Engineers, Part H. J Eng Med. 1019. https://doi.org/10.1243/0954411021536432

Yilmazer H, Niinomi M, Nakai M et al. (2013) Mechanical properties of a medical β-type titanium alloy with specific microstructural evolution through high-pressure torsion. Mater Sci Eng C 33:2499–2507. https://doi.org/10.1016/j.msec.2013.01.056

Niinomi M (2003) Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci Technol Adv Mater 4:445–454. https://doi.org/10.1016/j.stam.2003.09.002

Aksakal B, Gavgali M, Dikici B (2009) The effect of coating thickness on corrosion resistance of hydroxyapatite coated Ti6Al4V and 316L SS implants. J Mater Eng Perform 19:894–899. https://doi.org/10.1007/s11665-009-9559-7

Sonmez S, Aksakal B, Dikici B (2014) Influence of hydroxyapatite coating thickness and powder particle size on corrosion performance of MA8M magnesium alloy. J Alloy Compd 596:125–131. https://doi.org/10.1016/j.jallcom.2014.01.175

Say Y, Aksakal B, Dikici B (2016) Effect of hydroxyapatite/SiO 2 hybride coatings on surface morphology and corrosion resistance of REX-734 alloy. Ceram Int 42:10151–10158. https://doi.org/10.1016/j.ceramint.2016.03.127

Chua PH, Neoh KG, Shi Z, Kang ET (2008) Structural stability and bioapplicability assessment of hyaluronic acid-chitosan polyelectrolyte multilayers on titanium substrates. J Biomed Mater Res - Part A 87:1061–1074. https://doi.org/10.1002/jbm.a.31854

Trujillo Na, Oldinski Ra, Ma H et al. (2012) Antibacterial effects of silver-doped hydroxyapatite thin films sputter deposited on titanium. Mater Sci Eng C 32:2135–2144. https://doi.org/10.1016/j.msec.2012.05.012

LeGeros RZ, Daculsi G, LeGeros JP (2008) Bioactive bioceramics. In: William S. Pietrzak (ed) Musculoskeletal tissue regeneration biological materials and methods. Humana Press, New Jersey, USA, pp 153–181

Ebrahimi M, Botelho MG, Dorozhkin SV (2016) Biphasic calcium phosphates bioceramics (HA/TCP): Concept, physicochemical properties and the impact of standardization of study protocols in biomaterials research. Mater Sci Eng C 71:1293–1312

Daculsi G, LeGeros RZ, Heughebaert M, Barbieux I (1990) Formation of carbonate-apatite crystals after implantation of calcium phosphate ceramics. Calcif Tissue Int 46:20–27

He G, Hu J, Wei SC et al. (2008) Surface modification of titanium by nano-TiO2/HA bioceramic coating. Appl Surf Sci 255:442–445

Nie X, Leyland A, Matthews a (2000) Deposition of layered bioceramic hydroxyapatite/TiO2 coatings on titanium alloys using a hybrid technique of micro-arc oxidation and electrophoresis. Surf Coat Technol 125:407–414

Mohammed MT, Khan ZA, Siddiquee AN (2014) Surface modifications of titanium materials for developing corrosion behavior in human body environment: a review. Procedia Mater Sci 6:1610–1618

Rosalbino F, Macciò D, Giannoni P et al. (2011) Study of the in vitro corrosion behavior and biocompatibility of Zr-2.5Nb and Zr-1.5Nb-1Ta (at%) crystalline alloys. J Mater Sci Mater Med 22:1293–1302

Xiao XF, Liu RF, Zheng YZ (2006) Characterization of hydroxyapatite/titania composite coatings codeposited by a hydrothermal-electrochemical method on titanium. Surf Coat Technol 200:4406–4413

Li H, Khor KA, Cheang P (2002) Titanium dioxide reinforced hydroxyapatite coatings deposited by high velocity oxy-fuel (HVOF) spray. Biomaterials 23:85–91

Kang J, Son M, Choe H, Brantley WA (2016) Bone-like apatite formation on manganese-hydroxyapatite coating formed on Ti-6Al-4V alloy by plasma electrolytic oxidation. Thin Solid Films 620:126–131

Farnoush H, Aghazadeh Mohandesi J, Çimenoğlu H (2015) Micro-scratch and corrosion behavior of functionally graded HA-TiO2 nanostructured composite coatings fabricated by electrophoretic deposition. J Mech Behav Biomed Mater 46:31–40

Zhao YT, Zhang Z, Dai QX et al. (2006) Microstructure and bond strength of HA(+ZrO2+Y2O3)/Ti6Al4V composite coatings fabricated by RF magnetron sputtering. Surf Coat Technol 200:5354–5363

Chou B-YY, Chang E (2002) Plasma-sprayed hydroxyapatite coating on titanium alloy with ZrO2 second phase and ZrO2 intermediate layer. Surf Coat Technol 153:84–92

Lee S-H, Kim H-W, Lee E-J et al. (2006) Hydroxyapatite-TiO2 hybrid coating on Ti implants. J Biomater Appl 20:195–208

Manso M, Langlet M, Jiménez C, Martínez-Duart JM (2002) Microstructural study of aerosol-gel derived hydroxyapatite coatings. Biomol Eng 19:63–66

Liu D-M, Yang Q, Troczynski T (2002) Sol-gel hydroxyapatite coatings on stainless steel substrates. Biomaterials 23:691–698

Xu W, Hu W, Li M, Wen C (2006) Sol-gel derived hydroxyapatite/titania biocoatings on titanium substrate. Mater Lett 60:1575–1578

Im KH, Lee SB, Kim KM, Lee YK (2007) Improvement of bonding strength to titanium surface by sol-gel derived hybrid coating of hydroxyapatite and titania by sol-gel process. Surf Coat Technol 202:1135–1138

Zhang S, Xianting Z, Yongsheng W et al. (2006) Adhesion strength of sol-gel derived fluoridated hydroxyapatite coatings. Surf Coat Technol 200:6350–6354

Sidane D, Chicot D, Yala S et al. (2015) Study of the mechanical behavior and corrosion resistance of hydroxyapatite sol-gel thin coatings on 316 L stainless steel pre-coated with titania film. Thin Solid Films 593:71–80

Feddes B, González P, Serra J et al. (2009) Characterization of thin calcium phosphate coating. In: León B, Jansen J (eds) Thin calcium phosphate coatings for medical implants. Springer, New York, New York, NY, p 25–66

Milella E, Cosentino F, Licciulli A, Massaro C (2001) Preparation and characterisation of titania/hydroxyapatite composite coatings obtained by sol-gel process. Biomaterials 22:1425–1431

Burnat B, Robak J, Batory D et al. (2015) Surface characterization, corrosion properties and bioactivity of Ca-doped TiO2 coatings for biomedical applications. Surf Coat Technol 280:291–300

Balamurugan A, Balossier G, Kannan S et al. (2007) In vitro biological, chemical and electrochemical evaluation of titania reinforced hydroxyapatite sol-gel coatings on surgical grade 316L SS. Mater Sci Eng C 27:162–171

Mobasherpour I, Heshajin MS, Kazemzadeh A, Zakeri M (2007) Synthesis of nanocrystalline hydroxyapatite by using precipitation method. J Alloy Compd 430:330–333

Metikoš-Huković M, Kwokal A, Piljac J (2003) The influence of niobium and vanadium on passivity of titanium-based implants in physiological solution. Biomaterials 24:3765–3775

Zhou YL, Niinomi M (2009) Passive films and corrosion resistance of Ti-Hf alloys in 5% HCl solution. Surf Coat Technol 204:180–186

Hsieh M-F, Perng L-H, Chin T-S (2002) Hydroxyapatite coating on Ti6Al4V alloy using a sol–gel derived precursor. Mater Chem Phys 74:245–250

Ebrahimi M, Pripatnanont P, Monmaturapoj N, Suttapreyasri S (2012) Fabrication and characterization of novel nano hydroxyapatite/β- tricalcium phosphate scaffolds in three different composition ratios. J Biomed Mater Res A 100 A:2260–2268

Galvele JR (2005) Tafel’s law in pitting corrosion and crevice corrosion susceptibility. Corros Sci 47:3053–3067

León B (2009) Pulsed laser deposition of thin calcium phosphate coatings. In: León B, Jansen J (eds) Thin calcium phosphate coatings for medical implants. Springer New York, New York, NY, p 101–155

Tamilselvi S, Raman V, Rajendran N (2006) Corrosion behaviour of Ti–6Al–7Nb and Ti–6Al–4V ELI alloys in the simulated body fluid solution by electrochemical impedance spectroscopy. Electrochim Acta 52:839–846

Oliveira N, Guastaldi A (2009) Electrochemical stability and corrosion resistance of Ti–Mo alloys for biomedical applications. Acta Biomater 5:399–405

Surmenev RA, Surmeneva MA, Ivanova AA (2014) Significance of calcium phosphate coatings for the enhancement of new bone osteogenesis - a review. Acta Biomater 10:557–579

Acknowledgements

This work was financially supported by TUBITAK (The Scientific & Technological Research Council of Turkey) under 114M437 project number.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Dikici, B., Niinomi, M., Topuz, M. et al. Synthesis of biphasic calcium phosphate (BCP) coatings on β‒type titanium alloys reinforced with rutile-TiO2 compounds: adhesion resistance and in-vitro corrosion. J Sol-Gel Sci Technol 87, 713–724 (2018). https://doi.org/10.1007/s10971-018-4755-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4755-2