Abstract

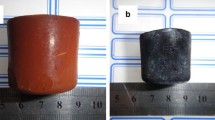

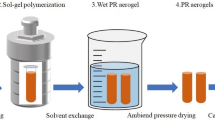

The objective of this research was to develop a high-strength carbon-fiber felt reinforced carbon/alumina aerogel (CF-C/Al2O3) with low thermal conductivity. The carbon-fiber felt reinforced resorcinol formaldehyde/alumina aerogel (CF-RF/Al2O3) was initially prepared using solgel technique followed by ambient pressure drying technique. The CF-C/Al2O3 was obtained after the thermal treatment at 1600 °C under flowing argon atmosphere. Both CF-RF/Al2O3 and CF-C/Al2O3 displayed extremely little linear shrinkages due to the high structural strength of carbon fiber felt. The compression strength of CF-C/Al2O3 were 0.50, 0.78, 1.30 and 2.35 MPa, the corresponding compressive stress at the strains of Ɛ 20%, Ɛ 30%, Ɛ 40% and Ɛ 50%, respectively. The thermal conductivity of CF-C/Al2O3 is as low as 0.284 W/(m·K) at a ultrahigh temperature 1600 °C under argon, which is only about one half of the value of carbon fiber felt (0.538 W/(m·K)). The as-synthesized CF-C/Al2O3 possessed greatly controllable and stable structure, which would be fabricated and machined to a large-scale composites and be used as high temperature thermal insulators.

Graphical abstract

Similar content being viewed by others

References

Choi J, Suh DJ (2007) Catal Surv Asia 11:123–133

Cui S, Cheng WW, Shen XD, Fan MH, Russell AT, Wu ZW, Yi XB (2011) Energy Environ Sci 4:2070–2074

Jones SM (2006) J Solgel Sci Technol 40:351–357

Lee JK, Gould GL, Rhine W (2009) J Solgel Sci Technol 49:209–220

Power M, Hosticka B, Black E, Daitch C, Norris P (2001) J Non Cryst Solids 285:303–308

Fricke J, Emmerling A (1998) J Solgel Sci Technol 13:299–303

Koziol K, Vilatela J, Moisala A, Motta M, Cunniff P, Sennett M, Windle A (2007) Science 318:1892–1895

Boday DJ, Muriithi B, Stover RJ, Loy DA (2012) J Non Cryst Solids 358:1575–1580

Li CC, Cheng XD, Li Z, Pan YL, Huang YJ, Gong LL (2017) J Non Cryst Solids 457:52–59

Wu XD, Shao GF, Shen XD, Cui S, Wang L (2016) RSC Adv 6:5561–5620

Leventis N, Leventis CS, Zhang G, Rawashdeh A (2002) Nano Lett 2:957–960

Karout A, Buisson P, Perrard A, Pierre A (2005) J Solgel Sci Technol 36:163–171

Hu LF, C WA, Huang Y (2010) J Mater Sci 45:3242–3246

Zhao JJ, Duan YY, Wang XD, Wang BX (2012) Int J Heat Mass Tranf 55:5196–5204

Yuan B, Ding S, Wang D, Wang G, Li H (2012) Mater Lett 75:204–206

Kim CY, Lee JK, Kim BI (2008) Colloids Surf A Physicochem Eng Asp 313:179–182

Meador MA, Vivod SL, McCorkle L, Quade D, Sullivan RM, Ghson LJ, Clark N, Capaclona LA (2008) J Mater Chem 18:1843–1852

Ślosarczyk A, Wojciech S, Piotr Z, Paulina J (2015) J Non Cryst Solids 416:1–3

Hsieh TH, Huang YS (2017) J Mater Sci 52:3520–3534

Cheng HM, Xue HF, Hong CQ, Zhang XH (2017) Compos Sci Technol 140:63–72

He J, Li XL, Su D, Ji HM, Wang XJ (2016) J Eur Ceram Soc 36:1487–1493

Yang XG, Sun YT, Shi DQ (2012) J Non Cryst Solids 358:519–524

Zhang RB, Hou XB, Ye CS, Wang BL (2017) J Alloys Compd 699:511–516

Dong ZJ, Xuan-ke LI (2006) New Chem Mater 34:58–61

Drach V, Wiener M, Reichenauer G, Ebert HP, Fricke (2007) J Int J Thermophys 28:1542–1562

Reichenauer G, Heinemann U, Ebert HP (2007) Colloids Surf A 300:204–210

Xie T, He YL, Hu ZJ (2013) Int J Heat Mass Tranf 58:540–552

Savage G (1993) Carbon-carbon composites. Chapman & Hall, London

Zhong Y, Kong Y, Shen XD, Cui S, Yi XB, Zhang JJ (2013) Microporous Mesoporous Mater 172:182–189

Zhong Y, Kong Y, Zhang JJ, Shen XD, Cui S (2014) J Porous Mater 21:653–658

Wiener M, Reichenauer G, Braxmeier S, Hemberger F, Ebert HP (2009) Int J Thermophys 30:1372–1385

Horiuchi T, Osaki T, Sugiyama T, Suzuki K, Mori T (2001) J Non Cryst Solids 291:187–198

Acknowledgements

The authors acknowledge the supports from the National Natural Science Foundation of China (51702156 and 51602151), the Priority Academic Program Development of Jiangsu Higher Education Institution (PAPD)—China, the Natural Science Foundation of Jiangsu Province—China (BK20161002 and BK20161003), the Scientific and Technologic Start-ups Incubation Program—Entrepreneurship Competition Winning Project (BC2016036), and Jiangsu Collaborative Innovation Center for Advanced Inorganic Function Composites.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Zhong, Y., Zhang, J., Wu, X. et al. Carbon-fiber felt reinforced carbon/alumina aerogel composite fabricated with high strength and low thermal conductivity. J Sol-Gel Sci Technol 84, 129–134 (2017). https://doi.org/10.1007/s10971-017-4485-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-017-4485-x