Abstract

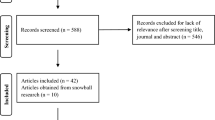

Manifold aspects, such as the booming market for superior quality food items with increased shelf life and the escalating concern to mitigate plastic trash due to plastic packaging have motivated researchers and food industrialists to explore sustainable eco-friendly packaging solutions extensively. Biodegradable polymers are being rigorously investigated to replace conventional plastics that are toxic, non-biodegradable, and detrimental to the marine ecosystem. The scientific methodology for the prudent selection of biodegradable polymer among the frequently used biopolymers for food packaging is being reported here. The data were extracted from the available literature. A hybrid multi-criteria decision-making framework has been developed to address the problem of material selection owing to the multiple conflicting criteria involved. Assignment of equal weights to primary criteria was selected to establish the criteria weights. Different decision-making techniques (weighted sum method (WSM), weighted product method (WPM), weighted aggregated sum product assessment method (WASPAS), and technique for order of preference by similarity to ideal solution (TOPSIS)) were used for the comparative analysis. Thereon, the different ranks obtained for each alternative were aggregated using the degree of membership technique. The robustness of the solution was checked using sensitivity analysis which was conducted by varying weights of importance using the entropy method, the CRITIC method, and the equal weights to secondary criteria. The analysis reported polylactic acid (PLA) as the most reliable polymer for food packaging applications. The sensitivity analysis concluded that the solution was without prejudice, and water vapor permeation rating was the most critical decision criterion in deciding the optimal polymer.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Food packaging’s primary objective is to safeguard and preserve the quality of food items while preserving their look, taste, fragrance, and nutritional content. As products vie for the attention of potential purchasers, there is a growing focus on developing appealing marketing strategies and refining package designs to provide more ergonomic and successful products (Shaikh et al., 2021). Single-use plastics, being lightweight, are easily swept by rain or wind into waterways, thus ending in the oceans and threatening aquatic life. Waste disposal, majorly from single-use non-biodegradable food packaging materials, has significantly contributed to the deteriorating ecological balance. Consciousness for environmental stability and governmental regulations has led to a surge in interest in sustainable materials. Packaging is promptly discarded after product use; therefore, biodegradable materials are expected to be a novel alternative to traditional materials, particularly in the food sector, to reduce plastic waste accumulation. The increased plastic use and trash output, along with the ongoing issue of plastic litter accumulation resulting from the COVID-19 pandemic, emphasizes the critical importance of supporting and prioritizing the quest for sustainable material solutions (Sarkodie & Owusu, 2021).

Sustainable materials are those that are economically feasible, easily accessible, and have a minimal negative impact on man and the environment. Manufacturing companies are readily adopting energy-efficient processes and eco-friendly materials that are in line with the concept of sustainability and may help reduce carbon footprints (Anser et al., 2020; Awan, 2019; Awan et al., 2018). Biodegradable plastics that disintegrate by the enzymatic action of living organisms including bacteria, yeast, and fungi; are considered among sustainable materials with similar properties to traditional plastics but with lower environmental impact. The classification of biodegradable polymers based on source derivation is shown in Fig. 1. As per the European Bioplastics (European Bioplastics, 2020) report, global bioplastics production capacities are expected to reach 7.59 million tons in 2026 from around 2.42 million tons in 2021. Biodegradable polymers, including PLA, PHA, starch blends, and others, currently account for more than 64% (over 1.5 million tons) of worldwide bioplastics production capacity. Due to the rapid development of polymers such as PBAT and PBS and the constant rise of PLA use, the production of biodegradable polymers is predicted to reach almost 5.3 million tons by 2026. They are becoming increasingly popular for their applications in various industries, such as packaging, agriculture, medicine, etc. to reduce the fossil fuel demand. The surge in research over the last eleven years (Fig. 2) portrays that researchers are exploring the use of biodegradable polymers for food packaging applications (as per the Scopus database). They are recognized for offering improved food shelf life while maintaining its nutritious value (Fabra & Lagaron, 2014; Shaikh et al., 2021).

For the development of sustainable products, material selection plays a crucial role. The optimal material selection not only results in reasonable manufacturing costs but also leads to durable and reliable products. Also selecting material based on a plethora of competing factors is a tedious task for a designer that necessitates complex methodologies to arrive at a viable solution. Hence, continuous efforts have been put forth toward developing effective and efficient material selection techniques. Among these, multi-criteria decision-making (MCDM) approaches have been widely exploited for material selection problems (Rahim et al., 2020; Shukla et al., 2023).

2 Literature review

2.1 Theoretical background

MCDM is a widely used approach for selecting the optimal material for a given application. It involves identifying and evaluating multiple criteria that are relevant to the decision material selection. These criteria can include physical properties, cost, availability, and environmental impact. This process uses a combination of mathematical algorithms and expert judgment to evaluate and rank the materials based on their performance across all criteria. It allows for the consideration of trade-offs between different criteria and ultimately results in the selection of the material that best meets the requirements of the application. The integration of multiple criteria into the decision-making process, resulting in a more comprehensive and accurate selection, makes MCDM an effective tool. The weighted sum method (WSM) is the oldest MCDM tool and most preferred because of its simplicity. Other commonly used techniques are the technique of ranking preferences by similarity of the ideal solutions (TOPSIS), weighted property method (WPM), analytical hierarchy process (AHP), and Vlse Kriterijumska Optimizacija Kompromisno Resenje (VIKOR) (Abdelkader et al., 2021; Goyal et al., 2021; Noryani et al., 2018).

Biodegradable polymers are an encouraging development in the field of food packaging, as they have the potential to reduce the environmental impact of packaging materials (Mentis et al., 2022; Tansel & Yildiz, 2011). The use of biodegradable polymers promotes the efficient and sustainable use of resources that aligns with resource theory which posits the use of scarce resources in a sustainable manner. They also reduce the pressure on landfills by breaking down naturally, which also reduces the pollution caused by the transportation of waste and the need for additional landfills (Hellstrand et al., 2009). This further mitigates the costs associated with packaging waste disposal supporting the economic theory that puts forth the idea of making decisions that balance costs and benefits to maximize profits (Hellstrand et al., 2010). The application of MCDM techniques for evaluating the competing materials in terms of cost and other criteria and then selecting the best optimal is a savage of crucial time resource. The competing theory of production suggests that biodegradable polymers could also help to create a more sustainable production process by reducing the environmental impact of packaging materials. The MCDM approach can help firms to identify the most sustainable material option that meets their specific needs and aligns with their sustainable goals (Walsh, 2011). This approach allows for a comprehensive evaluation of different materials based on multiple criteria. The theory of sustainability endorses the utilization of biodegradable polymers as they play a critical role in minimizing the ecological impact of the packaging industry (Aktaş & Demirel, 2021; Khedrigharibvand et al., 2019). However, it’s important to note that biodegradable polymers alone may not be enough to achieve sustainable packaging. Other important factors to consider are the production process, recycling, and end-of-life management of the packaging. Green economics theory and the MCDM approach are complementary in promoting sustainable material selection. The theory highlights the importance of considering the environmental impact of economic decisions, while the MCDM approach provides a methodology for evaluating options based on multiple criteria in a systematic and objective way. Corporate social responsibility theory also highlights the importance of companies taking responsibility for the environmental impact of their products, and the use of biodegradable polymers can demonstrate a commitment to sustainable practices. The implementation of biodegradable polymers may also be beneficial for companies and their brand reputation as it indicates their commitment to sustainability (Dummett, 2006; Hasan et al., 2022; Kaur & Sharma, 2018). Hence, this study of developing an MCDM framework for biodegradable polymer selection for food packaging is essential as it aligns with the various theories focused on environment and sustainable development.

2.2 Empirical literature

Depending on the application, each material possesses preferential attributes, which makes them superior compared to others. In the literature, authors have emphasized certain critical qualities to be considered while selecting materials for food packaging products. Materials with high mechanical properties, high melting point, and good barrier properties are preferred for such applications. Biodegradability, compostability, non-toxicity, availability, and cost are the other factors considered (Balakrishnan et al., 2014; Shaikh et al., 2021). The authors (Shaikh et al., 2021) reviewed the biodegradable food packaging materials and the form in which they are being used. The commonly used biodegradable polymers reported were polyhydroxybutyrate (PHB), polylactic acid (PLA), polyglycolide (PGA), polycaprolactone (PCL), polybutylene succinate (PBS), polybutylene adipate-co-terephthalate (PBAT) and polypropylene carbonate (PPC), plant-based proteins and polysaccharides. The study summarized the applications of polymers in pure and blended forms. A review of the sustainable materials alternative to conventional petrochemical-based materials for food packaging was presented by (Asgher et al., 2020). It was reported that PHAs, PLA, and plant-based polysaccharides were the most exploited biopolymers for packaging films.

Numerous studies on the material selection process for sustainable product development have been reported in the literature (Agrawal, 2021; Bhadra & Dhar, 2022; Liang et al., 2021; Ocampo, 2019; Venkatesh et al., 2018; Wakeel et al., 2021). (Mahajan et al., 2022) performed a selection process of natural fiber for the development of sustainable composites with PLA biopolymer for non-structural applications. The authors employed a hybrid MCDM framework in which TOPSIS, VIKOR, and PROMETHEE II were the ranking techniques. In a study, (Sanyang et al., 2017) selection of optimal biopolymer to be reinforced with natural fiber for the production of automotive interior spare tire cover was discussed by applying MCDM techniques; DLM and WPM. Most of the above studies conducted are in the automobile sector and have utilized multiple MCDM methods for analysis. The reason is, each technique may result in considerable differences in material selection outcomes, making it challenging to rely on a single method (Yang et al., 2019). Very few studies (Salwa et al., 2019, 2020; Sanyang & Sapuan, 2015) were conducted for consumer product applications, such as food packaging which has become an essential part in the day to day life. (Salwa et al., 2020) discussed the most suitable starch (among wheat, maize, potato, cassava, sago, and rice) as matrix in biocomposites for takeout food packaging design. It utilized hybrid entropy-AHP technique for optimal material selection with the conflicting criteria of strength, barrier property, weight, and cost. (Salwa et al., 2019) exploited the AHP technique for developing selection system for natural fiber as reinforcement in green composites for food packaging applications. The primary criteria for selection process were the strength, moisture resistance, weight, and cost. Sensitivity analysis validated the reliability of the results provided by the system. (Sanyang & Sapuan, 2015) developed an expert system (if–then rule-based system) for selection of bio-based polymers for the packaging of food items using Exsys Corvid software. The system selected the PLA as an optimal material after screening the polymers based on the barrier and mechanical properties only. This study didn't consider the cost parameter.

To the best of the authors' knowledge, only these limited studies on material selection for food packaging applications have been reported in the literature. The holistic approach to material selection with the reliability of results and the contributing factors affecting selection is still lacking. This unified approach is essential for the product designer to understand the significant and insignificant criteria considered for the selection. Other than this, the reported studies have utilized subjective weighting criteria methods which may result in biasness. Also, the results reported were based on only a single method. To address this gap, an integrated framework of material selection is developed for the less explored area of biodegradable food packaging materials. Firstly, this study identifies the essential attributes of food packaging material as per the literature. Secondly, the attributes are weighted utilizing the objective weighting method to avoid the biasness. Thereon, the polymers are judged by multiple methods and results are analyzed and aggregated using degree of membership (DoM) method. Thirdly, the reliability of the findings is validated by sensitivity analysis. Based on the analysis, the most critical criterion is suggested. The methodology adopted for this study and the results is outlined in Sect. 3 and Sect. 4, respectively. The analysis is concluded in Sect. 5.

3 Methodology

The detailed methodology for the selection of optimal biodegradable polymer for food packaging applications is depicted in Fig. 3. Excel (MS Office) was used to carry out the statistics.

3.1 Determination of criteria and alternatives

It is important to conduct the selection based on the attributes/ characteristics essential for food packaging. Sustainable materials should be cost-effective; therefore, considering the cost of the material was vital. (Shaikh et al., 2021) highlights the basic attributes necessary for food packaging. Table 1 illustrates the criteria that could influence the material selection in the application domain. The barrier properties of packaging material are critical for preserving the moisture content of the packed food and preventing external contamination. Since packaging materials are often used for once, low-cost packaging is the main emphasis for the food packaging industry.

Though the polymers extracted from biomass resources (polysaccharides, lipids, and proteins) have potential gas barrier properties, but are highly water sensitive. Also, it is difficult to process them with conventional equipment (Fabra & Lagaron, 2014). Therefore, biodegradable polymers derived from renewable resources (from micro-organisms and biotechnology) and petrochemical resources are considered for current investigation. PHAs, PLA, PCL, PBS, and PBAT have been widely explored for food packaging applications in the available literature. These polymers are also blended with other biodegradable polymers to enhance their properties. Among PHAs, PHB and its co-polymer PHBV are the most reported (Gurunathan et al., 2015; Jamshidian et al., 2010; Smith, 2005). As per the data available for the selected criteria, PLA, PBS, PBAT, PCL, and PHB are the polymers considered for the selection analysis.

3.2 MCDM techniques for optimal material selection

The selection of feasible material is crucial in the early design phase accompanying the process selection to reduce production costs. MCDM refers to picking the best feasible solution based on predefined criteria and scenarios that often occur in daily life. The MCDM techniques applied to rank the biodegradable polymers in this study are WSM, WPM, WASPAS, and TOPSIS. The numeric values of the alternatives (candidate materials), \(A_{i} (i\,= \,1, \ldots ,\,x)\) corresponding to each SC (material properties), \({\text{SC}}_{k} (k\, = \,{1}\,, \ldots ,\,z)\) is illustrated in the decision matrix (DM). The criterion weights are evaluated by assigning equal weights to primary criteria (EW-PC) using Eq. (1).

where, \(w_{j}\) represents the weight of the primary criteria and \(N_{PC}\) represents the number of PC. The \(w_{j}\) weight is equally allocated among the secondary criteria as given in Eq. (2).

where, \(w_{k}\) denotes the SC weight and \(N_{SC_{j}}\) is the number of SC for jth PC.

Normalization techniques are used in MCDM approaches to allow aggregation of criteria using numerical and comparative data. The wrong selection of data normalization method can significantly impact the final ranking thus affecting the engineering design decisions. It benefits the optimal selection by its properties of handling negative values, capability in removing scales, preventing rank reversal, and maintaining symmetry in cost and benefit criteria. The authors (Jahan & Edwards, 2015) have listed thirty-one such methods for enhancing the engineering design material selection process. For the MCDM techniques utilized in this study, the normalization methods are given in Table 2.

In Table 2, the \(r_{{{\text{ik}}}}\) is the DM and \(n_{{{\text{ik}}}}\) represents the normalized decision matrix (NDM). After normalizing the data using the equations given in Table 2, the ranks are obtained by the various MCDM techniques described as follows:

3.2.1 WSM

The utility/performance value (\(p_{i}\)) of the ith alternative is obtained as given in Eq. (3). The alternative with the highest (\(p_{i}\)) is ranked first.

3.2.2 WPM

The multiplicative relative importance (\(q_{i}\)) of the ith alternative is calculated using Eq. (4). The most preferred alternative is the one with the highest importance.

3.2.3 WASPAS

Generalizing and integrating additive and multiplicative approaches are proposed using the joint generalized criterion (\(Q_{i}\)), as illustrated in Eq. (5). The alternative with the highest amount of \(Q_{i}\) is positioned first.

3.2.4 TOPSIS

The weighted NDM \((v_{ik})\) is determined using Eq. (6). Then the optimal solution is determined by minimizing the Euclidean distance from the best ideal solution (\(V_{k}^{ + }\)) and maximizing the same from the worst ideal solution (\(V_{k}^{ - }\)). The best ideal for a benefit criterion is the highest value and for the cost criterion is the least value as given by Eq. (7). Similarly, the worst ideal for a benefit criterion is the minimum value and maximum value for the cost criterion as given by Eq. (8). The separation measures, \(S_{i}^{ + }\) and \(S_{i}^{ - }\), of ith alternative from the best ideal and worst ideal are determined by Eqs. (9) and (10), respectively. Using these separation measures, the relative closeness (\(P_{i}\)) in terms of similarity to the best ideal solution is computed by Eq. (11). The alternatives are ranked in decreasing order of closeness value.

where, \(J^{ + }\) and \(J^{ - }\) are the benefit and cost attributes.

3.3 Final rank evaluation

There is a high possibility of varying ranks determined through several MCDM techniques. Each MCDM method has its merits and demerits that perplex a decision maker to prefer one method over another. Hence, to attain the gains of various methods an aggregate technique is used. (Yang et al., 2019) proposed the DoM method to assess the materials’ final ranking. The steps involved in this approach are listed below.

Step 1: Construct the rank frequency matrix, (\({RF} = \left( {rf}_{ig} \right)_{x\, \times \,x}\)), where \({rf}_{ig}\) denotes the occurrences of ith alternative for gth position in the ranking list by different MCDM methods, and \({rf}_{ig}\) is computed by Eq. (12).

where, \(\delta_{{ig}}^{{{(}m{)}}}\) is the rank state variable and M denotes the number of MCDM methods.

Step 2: Compute the membership degree matrix, (\(\Phi = \left( {\varphi_{ig}} \right)_{x\, \times \,x}\)), where \(\varphi_{ig}\) denotes the membership degree of ith alternative for gth position. It is calculated using Eq. (13).

Step 3: Determine the final rank index (RIi) with the help of Eq. (14). Derive the alternative’s rank by configuring the rank index in ascending order.

4 Results and discussion

4.1 Determining weights of importance and ranks of alternatives

The data considered for the various attributes (OPR, WVPR, MT, TS, TM, EB, and cost) of the biodegradable polymers is compiled from the available literature and the DM, \(r_{ik}\) is represented in Table 3 (Jamshidian et al., 2010; Shaikh et al., 2021; Smith, 2005; Wu et al., 2021). The “weights of importance” is attained by the EW-PC method using Eqs. (1) and (2) and is given in Table 4. Utilizing these attribute weights, the scores (utility score/ performance score) for each material are derived by distinct MCDM methods (WSM, WPM, WASPAS, and TOPSIS), referring to the approach illustrated in Sect. 3.2. Polymers are ranked based on the scores computed by different decision-making methods as shown in Table 5. It can be noticed that PLA has been positioned first by all the ranking techniques except the TOPSIS method. TOPSIS method has suggested PHB as the best polymer which is ranked second by all other methods.

As can be seen, each alternative achieves varied scores due to the difference in computing approaches used by the methodologies, making it difficult to determine the best material by favoring one technique over the other. Hence, the DoM method (Sect. 3.3) aids in computing the aggregated ranks based on the membership/contribution of an alternative to the ranking positions (Table 5). According to the aggregate ranking list generated by the DoM technique, PLA has taken the top spot, which suggests that PLA is the most suitable biodegradable polymer for food packaging applications among the materials investigated in this study. In a study, a rule-based system also suggested PLA as the most suitable bio-derived polymer for food packaging applications (Sanyang & Sapuan, 2015). The thermoplastic nature of PLA and its ease of processing with conventional processes have expanded its applications in the packaging industry (Komal et al., 2020). Being a biodegradable biopolymer, PLA is not only environmentally friendly but also an economically viable material that society can easily adapt for the packaging of daily food items. Food science researchers have investigated PLA to be fit for short shelf life fresh food packaging (fruits and vegetables). PLA is majorly used in clamshell packaging format due to its excellent mechanical protection (Almenar et al., 2008; Jamshidian et al., 2010). The lowest rank of PCL may be ascribed to its low melting point and high cost as both these criteria have the largest weighted value.

In order to analyze the strength of the monotonic relationship between the MCDM methods, spearman’s rank correlation coefficient (\(r_{s}\)) is determined by Eq. (15). Its value lies between − 1 and 1. The value of 1 depicts the perfect correlation, whereas − 1 means the perfect disagreement.

where, d indicates the rank difference between two methods and n denotes the number of alternatives. The high similarity is observed among three methods i.e., WSM, WPM and WASPAS, with the spearman’s rank correlation coefficient ranging from 0.90 to 1.00 (Table 6). WPM and WASPAS have the perfect correlation. Since none of the MCDM techniques can substantially outperform the others, the correlation study concluded WSM as the most consistent approach with the other techniques, attaining the highest average spearman’s rank correlation coefficient, avgrs of 0.83. This shows that WSM has the highest degree of agreement relative to other methods. It can be interpreted that WSM can be solely relied upon for decision-making in this case study. However, with the change in the alternatives/ attributes, the most relying method may vary. TOPSIS has the lowest correlation with WPM and WASPAS methods. Different coefficient values have been reported in the literature depending on the ranks determined by different MCDM techniques. A study utilized WSM, WPM, TOPSIS, and ELECTRE methods for the selection of internal layout design of ship. The methods were compared for the two cases in which criteria were weighted using objective (Entropy) and subjective (Monte Carlo simulation) techniques. In both the cases, correlation observed was maximum between WSM and WPM and least between WPM and TOPSIS. TOPSIS had the weakest avgrs value of 0.9940 and 0.5477 when the criteria were weighted using Entropy method and Monte Carlo simulation, respectively. (Jafaryeganeh et al., 2020). The poor correlation coefficient of TOPSIS as compared to other methods may be accounted for the reason that WSM, WPM, and WASPAS use utility-based approach whereas the former is distance-based approach. In a study, the authors (Abdelkader et al., 2021) conducted five case studies of material selection in diverse fields using hybrid MCDM. It reported TOPSIS and CODAS (distance-based approaches) had the least average Spearman’s rank correlation coefficient among the six different MCDM techniques (TOPSIS, WSM, COPRAS, WPM, ARAS, and CODAS). WSM and WPM showed a strong correlation with a coefficient value of 0.87.

The use of sustainable polymers can help manufacturers reduce the costs associated with plastic waste disposal, comply with regulations and improve their reputation among consumers. The integration of different theories, such as resource, sustainability, green economics, and corporate social responsibility can provide a deeper understanding of the subject and help researchers to develop a holistic approach to sustainable material selection. The polymer selection from the developed framework aligns with the resource theory, as it demonstrates that PLA is an efficient and readily available resource for food packaging. The competing theory of production highlights that the production process of PLA is energy-efficient and eco-friendly, which makes it a sustainable option. The theory of sustainability supports the decision as it takes into account the long-term environmental and social impacts of the polymer. Green economics theory is also satisfied as it is economically feasible and has a minimal negative impact on the environment. Aligning with the concept of corporate social responsibility theory, it has a positive impact on society and satisfies the social obligations of the corporate sector.

The economic implication of this decision is that it reduces the cost of production and it's economically feasible for the companies. The academic implication is that it provides an opportunity for further research on MCDM methods and their application in material selection problems, particularly in the field of sustainable materials. This can lead to the development of more effective and efficient techniques for selecting sustainable materials for various applications. From a research perspective, it highlights the need for further research on emerging biodegradable polymers. From a policy perspective, it emphasizes the need for government regulations to promote the use of sustainable materials for food packaging.

4.2 Sensitivity analysis

Criteria weights play a significant role in controlling the final ranks of the alternatives. Hence, assigning weights to criterion is a decisive step in decision-making. To check the robustness and durability of the solution and ensure that outcomes are bias-free, sensitivity analysis is conducted. It is an essential step that depicts the uncertainty in the output on varying the inputs to the system. The positive result indicates a reliable solution. This study performs the sensitivity analysis by varying the criteria weights using three objective weighting methods: ‘equal weight to secondary criteria’ (EW-SC), ‘CRiteria Importance Through Inter-criteria Correlation’ (CRITIC) and ‘Entropy Method’. The DM is normalized prior to gauge the weights using CRITIC and Entropy method, as mentioned in Table 7.

4.2.1 Equal weights to secondary criteria

As the title clearly describes, equal weights are allotted among the secondary criteria using Eq. (16). \(N_{SC}\) denotes the total number of secondary criteria.

4.2.2 CRITIC method

The CRITIC technique is based on quantifying two MCDM fundamentals: contrast intensity and the nature of conflicting criteria (Diakoulaki et al., 1995). The information amount communicated by kth criterion, \(C_{k}\) is given by Eq. (17).

where, \(\mu_{{kl}}\) is the linear correlation coefficient between two criteria (kth and lth) of the NDM and \(\sigma_{k}\) is the standard deviation of kth attribute which determines the contrast intensity. The attribute weights are computed by Eq. (18).

4.2.3 Entropy method

Shannon (Shannon, 1948) proposed the entropy, \(E_{k}\) concept that measures the amount of decision information each attribute contains, quantified by Eq. (19). As a result, the attribute weights are calculated by Eq. (20).

The weights of importance, \(w_{k}\) are calculated using Eqs. (16)–(20). The computed criterion weights corresponding to all the weighting methods are shown in Table 8. After applying all MCDM techniques to get rankings with varied criterion weights, the DoM approach is used to generate a final ranking list for each weighting method as described in Sect. 3.3. The comparison of polymer ranks obtained by various MCDM techniques and the aggregated rank by DoM method for different criteria weighting methods is depicted in Fig. 4. The final ranks by DoM method in the case of EW-SC weightage approach are in line with those using the EW-PC approach, even though the individual ranks had variation for both weightage techniques when using the TOPSIS methodology. It is noted that PLA has never achieved first place utilizing the TOPSIS approach. Rather, PBAT has kept the top rank in all weighting techniques except EW-PC, which has taken third overall. The polymers that attained position in the upper section have a commonality in the case of TOPSIS.

The final ranks of all the polymers obtained by the DoM method with variations in criterion preferences are portrayed in Fig. 5. In the case of the EW-SC weightage technique, the concluding positions obtained are equal to those using the EW-PC strategy. The ultimate ranks produced by the entropy approach are comparable to the EW-PC method. PLA came out on top in every category except CRITIC, where it came in second. Except for the CRITIC approach, PHB has also secured second place. On the other hand, PCL consistently secured last rank for every approach except the entropy method, where it positioned second last. As a result, the top-ranked materials performed admirably in different circumstances.

4.3 Most critical criterion

Triantaphyllou (Triantaphyllou, 2000) proposed the definition and computational steps to determine the MCC based on the absolute terms and relative terms. The author defines it as “the most critical criterion is the one for which the smallest change in its current weight will alter the existing ranking of the alternatives”. One may be interested in the change of merely the top alternative or the change of the entire ranking. In the case of the WSM technique, the minimum relative change, \(\delta_{k,\;i,\;j}^{\prime }\) in the weight of the kth criterion such that the positions of the alternatives, Ai and Aj are interchanged, is computed by Eq. (21).

where, \(p_{j} {, }p_{i}\) are the performance values and \(n_{{kj}} {, }n_{{ki}}\) are the normalized values for the kth criterion of jth and ith alternatives in NDM. The non-feasible solution “NFS” indicates that it is impossible to alter the ranks of that alternative pair with any change in criterion weight. The least percentage change in the \(w_{k}\) that can alter the current ranking of alternatives, known as criticality degree of criterion \(\left( {D_{k}^{\prime } } \right)\) is determined by Eq. (22). Further, the sensitivity coefficient of criterion, \({SCC}_{k}\) is given by Eq. (23).

For the interest in the top alternative rank only, the MCC is the one with the smallest relative value within the rows that are related to the best alternative. The criterion with the lowest relative change overall denotes the MCC of the study. Table 9 shows all possible percent changes in the criteria weights that can alter the ranks of that pair of alternatives. The absolute of the bold italic numbers in Table 9 highlights the criticality degree of criterion. Coincidently, the MCC for the PLA (top alternative) and other alternatives is the same, i.e., WVPR. It implies that if the weight of WVPR is lowered by 14.1%, PHB will be the preferred biodegradable polymer and PLA will no longer be the best choice. On determining the SCC, it is found that the most sensitive decision criterion is WVPR, followed by cost, EB, TS, OPR, MT, and TM in that order. The authors have focused on the superior barrier properties of food packaging materials and it’s cost-effectiveness (Shaikh et al., 2021).

5 Conclusion and policy implications

5.1 Research conclusions

The polymers for food packaging were assessed based on the barrier, physical, and mechanical properties, and the cost. With the support of the developed hybrid MCDM framework, a judicious selection of a biodegradable polymer for food packaging application was conducted. High similarity was obtained in the results produced by WSM, WPM and WASPAS methodology. The sensitivity analysis conducted by altering the attribute weights using the EW-SC, CRITIC, and entropy methods concluded that the solution is without prejudice.

The analysis concluded that PLA is the most appropriate material for the packaging of food items. Water vapor permeation that prolongs the shelf life and cost for commercial viability are the critical criteria for deciding the optimal biodegradable packaging polymer. Furthermore, WVPR was the most sensitive criterion, with a weight drop of 14.1% changing the alternative’s rank. All the criteria considered were crucial for the selection and none was found insignificant. The methodology adopted in this analysis is robust and can be relied on to solve material selection problems.

5.2 Policy implications

The framework can help to make better informed and efficient decisions about the selection of materials for a specific application. The developed model strengthens the implication that the product designers may use it to scrutinize the essential and inconsequential criteria for material selection with transparency and accountability. On the policy side, the framework can help to promote the use of more sustainable materials. The major challenge that needs to be addressed is the availability of data, as the model relies on accurate and complete information about the materials being evaluated. Policymakers can consider measures, such as providing funding for research and data collection, developing databases of material properties, and offering training and education programs for those who will be using the model.

The use of PLA as a food packaging material has several policy implications, both in terms of environmental benefits and economic costs. On the environmental side, PLA packaging can help to reduce the amount of plastic waste in the environment by breaking it down into natural materials after disposal. On the economical side, the major challenge is the lack of proper infrastructure for the collection, sorting, and composting of the used packaging materials. Another challenge is the cost of producing PLA packaging, which can be more expensive than traditional plastic packaging materials. This can be a barrier for small and medium-sized enterprises (SMEs) that may not have the financial resources to invest in new packaging materials. To overcome these challenges, policymakers can consider implementing measures to support the collection, sorting, and composting of used PLA packaging. Policies that address these challenges and promote the use of PLA packaging can help to reduce the environmental impact of food packaging and support the growth of a more sustainable food packaging industry. Governments across the world can regulate and mandate the use of sustainable materials for food packaging where as per the current findings, PLA can be an important game changer.

5.3 Limitations and future studies

For a purpose of thorough comparison, it is necessary to investigate biodegradable polymers for all characteristics that are acceptable for food packaging. As the qualities of bio-sourced materials differ in their place of origin and type of processing, this might affect the final selection. The selection framework developed could be enhanced with a more comprehensive attribute assessment and an extensive dataset of newer sustainable materials. Furthermore, more MCDM techniques can be incorporated for a broad base analysis. However, the inherent deficiencies of MCDM techniques may result in a non-global solution. The current analysis can be further extended and compared to the machine learning-based optimization techniques.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- CRITIC:

-

Criteria importance through inter-criteria correlation

- DM:

-

Decision matrix

- DoM:

-

Degree of Membership

- EB:

-

Elongation at break

- EW-PC:

-

Equal weights to primary criteria

- EW-SC:

-

Equal weights to secondary criteria

- MCC:

-

Most critical criterion

- MCDM:

-

Multi-criteria decision-making

- MT:

-

Melting temperature

- NDM:

-

Normalized decision matrix

- NFS:

-

Non-feasible solution

- OPR:

-

Oxygen permeation rating

- PBAT:

-

Poly (butylene adipate terephthalate)

- PBS:

-

Poly (butylene succinate)

- PC:

-

Primary criteria

- PCL:

-

Polycaprolactone

- PHB:

-

Poly (hydroxybutyrate)

- PLA:

-

Poly (lactic acid)

- SC:

-

Secondary criteria

- TM:

-

Tensile modulus

- TOPSIS:

-

Technique for order of preference by similarity to ideal solution

- TS:

-

Tensile strength

- WASPAS:

-

Weighted aggregated sum product assessment method

- WPM:

-

Weighted product method

- WSM:

-

Weighted sum method

- WVPR:

-

Water vapor permeation rating

References

Abdelkader, E. M., Al-Sakkaf, A., & Alfalah, G. (2021). Optimizing material selection using a hybridized multi-attribute decision making model. Wseas Transactions on Systems and Control, 16, 404–421. https://doi.org/10.37394/23203.2021.16.36

Agrawal, R. (2021). Sustainable material selection for additive manufacturing technologies: A critical analysis of rank reversal approach. Journal of Cleaner Production, 296, 126500. https://doi.org/10.1016/j.jclepro.2021.126500

Aktaş, N., & Demirel, N. (2021). A hybrid framework for evaluating corporate sustainability using multi-criteria decision making. Environment, Development and Sustainability, 23(10), 15591–15618. https://doi.org/10.1007/S10668-021-01311-5

Almenar, E., Samsudin, H., Auras, R., Harte, B., & Rubino, M. (2008). Postharvest shelf life extension of blueberries using a biodegradable package. Food Chemistry, 110(1), 120–127. https://doi.org/10.1016/J.FOODCHEM.2008.01.066

Anser, M. K., Yousaf, Z., Awan, U., Nassani, A. A., Abro, M. M. Q., & Zaman, K. (2020). Identifying the carbon emissions damage to international tourism: Turn a blind eye. Sustainability, 12(5), 1937. https://doi.org/10.3390/SU12051937

Asgher, M., Qamar, S. A., Bilal, M., & Iqbal, H. M. (2020). Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Research International, 137, 109625. https://doi.org/10.1016/j.foodres.2020.109625

Awan, U. (2019). Impact of social supply chain practices on social sustainability performance in manufacturing firms. International Journal of Innovation and Sustainable Development, 13(2), 198. https://doi.org/10.1504/IJISD.2019.098996

Awan, U., Kraslawski, A., & Huiskonen, J. (2018). The impact of relational governance on performance improvement in export manufacturing firms. Journal of Industrial Engineering and Management, 11(3), 349–370. https://doi.org/10.3926/jiem.2558

Balakrishnan, P., Sara, M., Pothen, L. A., Thomas, S., & Sreekala, M. S. (2014). Polymer films for packaging. Encyclopedia of Polymeric Nanomaterials. https://doi.org/10.1007/978-3-642-36199-9

Bhadra, D., & Dhar, N. R. (2022). Selection of the natural fiber for sustainable applications in aerospace cabin interior using fuzzy MCDM model. Materialia, 21, 101270. https://doi.org/10.1016/j.mtla.2021.101270

European Bioplastics. (2020). Bioplastics market data. European bioplastics. https://www.european-bioplastics.org/market/. Accessed 22 March 2022.

Diakoulaki, D., Mavrotas, G., & Papayannakis, L. (1995). Determining objective weights in multiple criteria problems: The critic method. Computers and Operations Research, 22(7), 763–770. https://doi.org/10.1016/0305-0548(94)00059-H

Dummett, K. (2006). Drivers for corporate environmental responsibility (CER). Environment, Development and Sustainability, 8(3), 375–389. https://doi.org/10.1007/S10668-005-7900-3

Fabra, M. J., & Lagaron, J. M. (2014). Biopolymers for food packaging applications. In J. S. Roman & Ma. R. Anguilar (Eds.), Smart Polymers and Their Applications (pp. 476–509). Woodhead Publishing Limited. https://doi.org/10.1533/9780857097026.2.476

Goyal, S., Garg, D., & Luthra, S. (2021). Sustainable production and consumption: Analysing barriers and solutions for maintaining green tomorrow by using fuzzy-AHP–fuzzy-TOPSIS hybrid framework. Environment, Development and Sustainability, 23(11), 16934–16980. https://doi.org/10.1007/s10668-021-01357-5

Gurunathan, T., Mohanty, S., & Nayak, S. K. (2015). A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Composites Part a: Applied Science and Manufacturing, 77, 1–25. https://doi.org/10.1016/j.compositesa.2015.06.007

Hasan, I., Singh, S., & Kashiramka, S. (2022). Does corporate social responsibility disclosure impact firm performance? An industry-wise analysis of Indian firms. Environment, Development and Sustainability, 24(8), 10141–10181. https://doi.org/10.1007/S10668-021-01859-2

Hellstrand, S., Skånberg, K., & Drake, L. (2009). The relevance of ecological and economic policies for sustainable development. Environment, Development and Sustainability, 11(4), 853–870. https://doi.org/10.1007/S10668-008-9156-1

Hellstrand, S., Skånberg, K., & Drake, L. (2010). A biophysically anchored production function. Environment, Development and Sustainability, 12(4), 573–596. https://doi.org/10.1007/S10668-009-9212-5

Jafaryeganeh, H., Ventura, M., & GuedesSoares, C. (2020). Application of multi-criteria decision making methods for selection of ship internal layout design from a Pareto optimal set. Ocean Engineering, 202, 107151. https://doi.org/10.1016/J.OCEANENG.2020.107151

Jahan, A., & Edwards, K. L. (2015). A state-of-the-art survey on the influence of normalization techniques in ranking: Improving the materials selection process in engineering design. Materials and Design, 65, 335–342. https://doi.org/10.1016/j.matdes.2014.09.022

Jamshidian, M., Tehrany, E. A., Imran, M., Jacquot, M., & Desobry, S. (2010). Poly-lactic acid: Production, applications, nanocomposites, and release studies. Comprehensive Reviews in Food Science and Food Safety, 9(5), 552–571. https://doi.org/10.1111/j.1541-4337.2010.00126.x

Kaur, A., & Sharma, P. C. (2018). Social sustainability in supply chain decisions: Indian manufacturers. Environment, Development and Sustainability, 20(4), 1707–1721. https://doi.org/10.1007/S10668-017-9961-5

Khedrigharibvand, H., Azadi, H., Teklemariam, D., Houshyar, E., De Maeyer, P., & Witlox, F. (2019). Livelihood alternatives model for sustainable rangeland management: A review of multi-criteria decision-making techniques. Environment, Development and Sustainability, 21(1), 11–36. https://doi.org/10.1007/S10668-017-0035-5

Komal, U. K., Lila, M. K., & Singh, I. (2020). PLA/banana fiber based sustainable biocomposites: A manufacturing perspective. Composites Part B: Engineering, 180, 107535. https://doi.org/10.1016/j.compositesb.2019.107535

Liang, W., Zhao, G., & Luo, S. (2021). Sustainability evaluation for phosphorus mines using a hybrid multi-criteria decision making method. Environment, Development and Sustainability, 23(8), 12411–12433. https://doi.org/10.1007/S10668-020-01175-1

Mahajan, A., Binaz, V., Singh, I., & Arora, N. (2022). Selection of natural fiber for sustainable composites using hybrid multi criteria decision making techniques. Composites Part C: Open Access, 7, 100224. https://doi.org/10.1016/j.jcomc.2021.100224

Mentis, C., Maroulis, G., Latinopoulos, D., & Bithas, K. (2022). The effects of environmental information provision on plastic bag use and marine environment status in the context of the environmental levy in Greece. Environment, Development and Sustainability. https://doi.org/10.1007/s10668-022-02465-6

Noryani, M., Sapuan, S. M., & Mastura, M. T. (2018). Multi-criteria decision-making tools for material selection of natural fibre composites: A review. Journal of Mechanical Engineering and Sciences, 12(1), 3330. https://doi.org/10.15282/jmes.12.1.2018.5.0299

Ocampo, L. A. (2019). Applying fuzzy AHP–TOPSIS technique in identifying the content strategy of sustainable manufacturing for food production. Environment, Development and Sustainability, 21(5), 2225–2251. https://doi.org/10.1007/S10668-018-0129-8

Rahim, A. A. A. A., Musa, S. N., Ramesh, S., & Lim, M. K. (2020). A systematic review on material selection methods. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 234(7), 1032–1059. https://doi.org/10.1177/1464420720916765

Salwa, H. N., Sapuan, S. M., Mastura, M. T., & Zuhri, M. Y. (2020). Application of Shannon’s entropy-analytic hierarchy process (AHP) for the selection of the most suitable starch as matrix in green biocomposites for takeout food packaging design. BioResources, 15(2), 4065–4088. https://doi.org/10.15376/BIORES.15.2.4065-4088

Salwa, H. N., Sapuan, S. M., Mastura, M. T., Zuhri, M. Y. M., Melaka, M., & Jaya, H. T. (2019). Analytic hierarchy process (AHP)-based materials selection system for natural fiber as reinforcement in biopolymer composites for food packaging. BioResources, 14(4), 10014–10036.

Sanyang, M. L., Mansor, M. R., Sapuan, S. M., & Ahmed Ali, B. A. (2017). Conceptual design of biocomposites for automotive components. In M. Jawaid, M. S. Salit, & O. Y. Alothman (Eds.), Green energy and technology (pp. 101–126). Springer International Publishing. https://doi.org/10.1007/978-3-319-49382-4_5

Sanyang, M. L., & Sapuan, S. M. (2015). Development of expert system for biobased polymer material selection: Food packaging application. Journal of Food Science and Technology, 52(10), 6445–6454. https://doi.org/10.1007/s13197-015-1759-6

Sarkodie, S. A., & Owusu, P. A. (2021). Impact of COVID-19 pandemic on waste management. Environment, Development and Sustainability, 23(5), 7951–7960. https://doi.org/10.1007/S10668-020-00956-Y

Shaikh, S., Yaqoob, M., & Aggarwal, P. (2021). An overview of biodegradable packaging in food industry. Current Research in Food Science, 4, 503–520. https://doi.org/10.1016/j.crfs.2021.07.005

Shannon, C. E. (1948). A Mathematical theory of communication. The Bell System Technical Journal. https://doi.org/10.1002/j.1538-7305.1948.tb01338.x

Shukla, C., Gupta, D., Pandey, B. K., & Bhakar, S. R. (2023). Suitability assessment of different cladding materials for growing bell pepper under protected cultivation structures using multi-criteria decision-making technique. Environment, Development and Sustainability. https://doi.org/10.1007/S10668-022-02854-X

Smith, R. (2005). Biodegradable polymers for industrial applications (1st ed.). Woodhead Publishing Limited.

Tansel, B., & Yildiz, B. S. (2011). Goal-based waste management strategy to reduce persistence of contaminants in leachate at municipal solid waste landfills. Environment, Development and Sustainability, 13(5), 821–831. https://doi.org/10.1007/s10668-011-9290-z

Triantaphyllou, E. (2000). A Sensitivity Analysis Approach for MCDM Methods. In E. Triantaphyllou (Ed.), Multi-criteria decision making methods: A comparative study (Vol. 44, pp. 131–175). Springer. https://doi.org/10.1007/978-1-4757-3157-6_8

Vafaei, N., Ribeiro, R. A., & Camarinha-Matos, L. M. (2018a). Data normalisation techniques in decision making: Case study with TOPSIS method. International Journal of Information and Decision Sciences, 10(1), 19–38. https://doi.org/10.1504/IJIDS.2018.090667

Vafaei, N., Ribeiro, R. A., & Camarinha-Matos, L. M. (2018b). Selection of normalization technique for weighted average multi-criteria decision making. IFIP Advances in Information and Communication Technology, 521, 43–52. https://doi.org/10.1007/978-3-319-78574-5_4

Venkatesh, G., Nyflött, Å., Bonnerup, C., & Lestelius, M. (2018). An economic-environmental analysis of selected barrier-coating materials used in packaging food products: A Swedish case study. Environment, Development and Sustainability, 20(4), 1483–1497. https://doi.org/10.1007/S10668-017-9948-2

Wakeel, S., Bingol, S., Bashir, M. N., & Ahmad, S. (2021). Selection of sustainable material for the manufacturing of complex automotive products using a new hybrid goal programming model for best worst method-proximity indexed value method. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 235(2), 385–399. https://doi.org/10.1177/1464420720966347/ASSET/IMAGES/LARGE/10.1177_1464420720966347-FIG7.JPEG

Walsh, P. R. (2011). Creating a “values” chain for sustainable development in developing nations: Where Maslow meets Porter. Environment, Development and Sustainability, 13(4), 789–805. https://doi.org/10.1007/S10668-011-9291-Y

Wu, F., Misra, M., & Mohanty, A. K. (2021). Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Progress in Polymer Science, 117, 101395. https://doi.org/10.1016/j.progpolymsci.2021.101395

Yang, W.-C., Chon, S.-H., Choe, C.-M., & Kim, U.-H. (2019). Materials selection method combined with different MADM methods. Journal on Artificial Intelligence, 1(2), 89–100. https://doi.org/10.32604/jai.2019.07885

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mahajan, A., Singh, I. & Arora, N. An integrated multi-criteria decision-making framework for the selection of sustainable biodegradable polymer for food packaging applications. Environ Dev Sustain 26, 8399–8420 (2024). https://doi.org/10.1007/s10668-023-03052-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-023-03052-z