Abstract

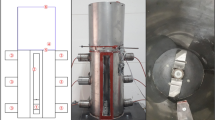

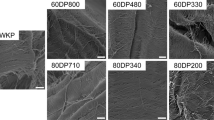

Dissolving grade pulps are used as raw material for manufacture of regenerated cellulose fibres and their use is constantly growing. Despite intensive research, there is still a need to develop cellulose dissolution-regeneration processes that would be economically viable, fulfil the pre-conditions of sustainability and would be able to meet the strict product quality requirements. The basis for creation of such a process is in deep understanding of the biomass structure and factors affecting the cellulose modification and dissolution. In this paper, the effects of the mechanical and enzymatic pre-treatments on the pore structure and alkaline solubility of dissolving grade pulp are discussed. Formation of micro- and macropores in the pulp fibres during mechanical shredding was found to correlate with the susceptibility of the fibres to enzymatic hydrolysis. The fibre porosity development during the processing was studied by a modified solute exclusion approach, which revealed differences between the effect of mild enzyme or acid hydrolysis on the pore structure of fibres. The dissolution of the modified fibres in NaOH/ZnO was evaluated and found to correlate with overall pore volume and accessible surface area analysed by the modified solute exclusion method.

Similar content being viewed by others

References

Alén R (2000) Structure and chemical composition of wood. In: P. Stenius (ed) Forest products chemistry. Fapet Oy, pp 11–58

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing methods for assay of xylanase activity. J Biotechnol 23:257–270

Bernfeld P (1955) Amylases, a and b. In: Colowick SP, Kapland NO (eds) Methods in enzymology, vol 1. Academic press, NY, pp 149–158

Berthold J, Salmen L (1997) Inverse size exclusion chromatography (ISEC) for determining the relative pore size distribution of wood pulps. Holzforschung 51:361–368

Berthold F, Gustafsson K, Sjöholm E, Lindström M (2001) An improved method for the determination of softwood kraft pulp molecular mass distributions, 11th international symposium on wood and pulping chemistry, nice, France, Vol. I, pp. 363–366

Divne C, Stahlberg J, Reinikainen T, Ruohonen L, Pettersson G, Knowles JKC, Teeri TT, Jones A (1994) The three-dimensional crystal structure of the catalytic core of cellobiohydrolase I from Trichoderma reesei. Science 265:524–528

Duchesne I, Hult E-L, Molin U, Daniel G, Iversen T, Lennholm H (2001) The influence of hemicellulose on fibril aggregation of kraft pulp fibres as reveald by FE-SEM and CP-MAS 13C-NMR. Cellulose 8:103–111

Engström AC, Ek M, Henriksson G (2006) Improved aceessibility and reactivity of dissolving pulp for the viscose process: pretreatmnet with monocomponent endoglucanase. Biomacromolecules 7:2027–2031

Esteghlalian AR, Bilodeau M, Mansfield SD, Saddler JN (2001) Do enzymatic hydrolyzability and simons’ stain reflect the changes in the accessibility of lignocellulosic substrates to cellulase enzymes? Biotechnol Prog 17(6):1049–1054

Gehmayr V, Sixta H (2011) Dissolving pulps from enzyme treated krfat pulps for viscose application. Lenzinger Berichte 89:152–160

Hämmerle FM (2011) The cellulose gap (The future of cellulose fibres). Lenzinger Berichte 89:12–21

Hänninen T, Thygesen A, Mehmood S, Madsen B, Hughes M (2012) Mechnaical processing of bast fibres: the occurrence of damage and its effect on fibre structure. Ind Crops Prod 39:7–11

Hult E-L, Larsson PT, Iversen T (2001) Cellulose fibril aggregation: an inherent property of kraft pulps. Polymer 42:3309–3314

Ibarra D, Köpche V, Ek M (2009) Exploring enzymatic treatmnets for the production of dissolving grade pulp from different wood and non-wood paper grade pulps. Holzforschung 63:721–730

IUPAC (International Union of Pure and Applied Chemistry) (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Kleywegt GJ, Zou JY, Divne C, Davies GJ, Sinning I, StaÊhlberg J, Reinikainen T, Srisodsuk M, Teeri TT, Jones TA (1997) The crystal structure of the catalytic core domain of endoglucanase I from Trichoderma reesei at 3.6AÊ resolution, and a comparison with related enzymes. J Mol Biol 272:383–397

Köpcke V (2010) Conversion of wood and non-wood paper-grade pulps into dissolving grade pulps. Doctoral thesis

Köpcke V, Ibarra D, Ek M (2008) Increasing accessibility and reactivity of paper grade pulp by enzymatic treatment for use as dissolving pulp. Nord Pulp Pap Res J 23(4):363–368

Larsson PT, Svensson A, Wågberg L (2013) A new, robust method for measuring average fibre wall pore sizes in cellulose I rich plant fibre walls. Cellulose 20:623–631

Lowry OH, Rosenbrough NH, Farr AR, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Maloney TC, Paulapuro H (1999) The formation of pores in the cell wall. J Pulp Paper Sci 25:430–436

Maloney TC, Li TQ, Weise U, Paulapuro H (1997) Intra- and inter-fibre pore closure in wet pressing. Appita J 50:301–306

Manninen M, Nieminen K, Maloney TC (2013) The swelling and pore structure of microfibrillated cellulose. Transactions of the fundamental research symposium held in Cambridge 2:765–785

Mooney CA, Mansfield SD, Beatson RP, Saddler JN (1999) The effect of fiber characteristics on hydrolysis and cellulose accessibility to softwoods substrates. Enzyme Microb Technol 25:644–650

Oksanen T, Buchert J, Viikari L (1997) The role of hemicelluloses in the hornification of bleached kraft pulps. Holzforschung 51:355–360

Penttilä P, Varnai A, Leppänen K, Peura M, Kallonen A, Jääskeläinen P, Lucenius J, Ruokolainen J, Siika-aho M, Viikari L, Serimaa R (2010) Changes in submicrometer structure of enzymatically hydrolyzed microcrystalline cellulose. Biomacromolecules 11:1111–1117

Pönni R, Vuorinen T, Kontturi E (2012) Proposed nano-scale coalescence of cellulose in chemical pulp fibers during technical treatments. BioResources 7(4):6077–6108

Pönni R, Kontturi E, Vuorinen T (2013) Accessibility of cellulose: structural changes and their reversibility in aqueous media. Carbohydr Polym 93:424–429

Rahkamo L, Siika-aho M, Viikari L, Leppänen T, Buchert J (1998) Effects of cellulases and hemicellulase on the alkaline solubility of dissolving pulps. Holzforschung 52:630–634

Sandgren M, Shaw A, Ropp TH, Wu S, Bott R, Cameron AD, Ståhlberg J, Mitchinson C, Jones TA (2001) The X-ray crystal structure of the trichoderma reesei family 12 Endoglucanase 3, Cel12A, at 1.9 AÊ Resolution. J Mol Biol 308:295–310

Simons F (1950) A stain for use in the microscopy of beaten fibers. Tappi 33(7):312–314

Sixta H (2006) Pulp properties and applications in handbook of pulp. In: Sixta H (ed), Wiley-VHC GmbH &Co KGaA, Weinheim pp 1009–1067

Sjöström E (1993) Wood chemistry, fundamentals and applications, 2nd edn. Academic Press, Ink, San Diego

Stone JE, Scallan AM (1967) The effect of component removal upon the porous structure of the cell wall of wood II. Swelling in water and the fiber saturation point. Tappi J 50(10):496–501

Suurnäkki A, Li TQ, Buchert J, Tenkanen M, Viikari L, Vuorinen T, Ödberg L (1997) Effects of enzymatic removal of xylan and glucomannan on the pore size distribution of kraft fibres. Holzforschung 51:27–33

Vehviläinen M, Kamppuri T, Rom M, Janicki J, Ciechańska D, Grönqvist S, Siika-aho M, Elg Christoffersson K, Nousiainen P (2008) Effect of wet spinning parameters on the properties of novel cellulosic fibres. Cellulose 15(5):671–680

Vehviläinen M, Nousiainen P, Kamppuri T, Järventausta M (2009) A method for dissolving cellulose and a cellulosic product obtained from a solution comprising dissoved cellulose. WO 2009/135875 A1

Wang X, Maloney TC, Paulapuro H (2003) Internal fibrillation in never-dried and once-dried chemical pulps. Appita J 56:455–459

Wang X, Paulapuro H, Maloney TC (2005) Chemical pulp refining for optimum combination of dewatering and tensile strength. Nord Pulp Pap Res J 20:442–447

Wang X, Maloney TC, Paulapuro H (2007) Fibre fibrillation and its impact on sheet properties. Pap Puu 89:148–151

Yu X, Minor JL, Atalla R (1995) Mechanism of action of Simons’ stain. Tappi J 78(6):175–180

Acknowledgments

The project was partially financed by FIBIC/The National Technology Agency (TEKES). The technical assistance of Maija Järventausta, Leena Nolvi, Mariitta Svanberg, Eila Turunen and Nina Vihersola is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grönqvist, S., Hakala, T.K., Kamppuri, T. et al. Fibre porosity development of dissolving pulp during mechanical and enzymatic processing. Cellulose 21, 3667–3676 (2014). https://doi.org/10.1007/s10570-014-0352-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0352-x