Abstract

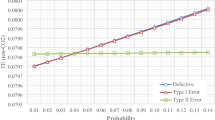

To ensure all products as perfect, inspection is essential, even though it is not possible to inspect all products after producing them like some special type products as plastic joint for the water pipe. In this direction, this paper develops an inventory model with lot inspection policy. With the help of lot inspection, all products need not to be verified still the retailer can decide the quality of products during inspection. If retailer founds products as imperfect quality, the products are sent back to supplier. As it is lot inspection, mis-clarification errors (Type-I error and Type-II error) are introduced to model the problem. Two possible cases are discussed for sending back products as defective lots are immediately withdrawn from the system and send back to supplier with retailer’s payment and for second case, retailer sends defective products during receiving next lot from supplier with supplier’s investment, like in food industry or in hygiene product industry. The model is solved analytically and results indicate that optimal order size and sample size are intrinsically linked and maximize the total profit. Numerical examples, graphical representations, and sensitivity analysis are given to illustrate the model. The results suggest that sending defective products maintaining the first case is the more profitable than the second case.

Similar content being viewed by others

Abbreviations

- y :

-

Order quantity size (units)

- n :

-

Number of items inspected per lot (integer)

- \(c_{l}\) :

-

Unit inspection cost ($/unit)

- \(c_{U}\) :

-

Lot purchase cost ($/lot)

- \(c_{a}\) :

-

Cost of falsely accepting a defective lot ($/lot)

- \(c_{r}\) :

-

Cost of falsely rejecting a non-defective lot ($/lot)

- D :

-

Demand rate (units/year)

- h :

-

Holding cost of a good quality item ($/unit/year)

- \(h_{d}\) :

-

Holding cost of a defective item kept in inventory (for the second subcase model) ($/unit/year)

- K :

-

Ordering cost ($/order)

- \({\mathrm {K}}_{d}\) :

-

Transport cost of defective lots back to supplier (for the first subcase model) ($)

- L :

-

Number of items per lot

- \(m_{1}\) :

-

Random variable representing the Type I error

- \(m_{2}\) :

-

Random variable representing the Type II error

- P :

-

Unit selling price ($/unit)

- \({\uprho }\) :

-

Fraction of defective lots supplied

- X :

-

Screening rate (units/year)

- E[.]:

-

Expected value of a random variable

- \(t_{l}\) :

-

Time to screen a shipment (years) \(=\frac{y}{X}\)

- \({{\mathrm {HC}}}_{n}\) :

-

Holding costs of the subcase n

- \({\mathrm {IC}}\) :

-

Inspection costs

- IEC:

-

Inspection error costs

- \({{\mathrm {PC}}}_{n}\) :

-

Purchase costs of the subcase n

- \({{\mathrm {TP}}}_{n}\) :

-

Total profit of the subcase n

- \({\mathrm {T}}_{0}\) :

-

Cycle time (years)

- \(y^{*}\) :

-

Optimal order quantity size (units)

References

Al-Salamah, M. (2011). Economic order quantity with imperfect quality, destructive testing acceptance sampling, and inspection errors. Advances in Management & Applied Economics, 1(2), 59–75.

Andriolo, A., Battini, D., Grubbström, R. W., & Persona, A. (2014). A century of evolution from Harris’s basic lot size model: Survey and research agenda. International Journal of Production Economics, 155, 16–38.

Cárdenas-Barrón, L. E. (2000). Observation on: “Economic production quantity model for items with imperfect quality.” [Int. J. Production Economics 64 59–64]. International Journal of Production Economics, 67(2), 201.

Cárdenas-Barrón, L. E., Chung, K. J., & Treviño-Garza, G. (2014). Celebrating a century of the economic order quantity model in honor of Ford Whitman Harris. International Journal of Production Economics, 155, 1–7.

Cárdenas-Barrón, L. E., Treviño-Garza, G., Taleizadeh, A. A., & Pandian, V. (2015). Determining replenishment lot size and shipment policy for an EPQ inventory model with delivery and rework. Mathematical Problems in Engineering, 1–8, Article ID, 595498.

Chan, W. M., Ibrahim, R. N., & Lochert, P. B. (2003). A new EPQ model: Integrating lower pricing, rework and reject situations. Production Planning & Control, 14(7), 588–595.

De, S. K., & Sana, S. S. (2013). Backlogging EOQ model for promotional effort and selling price sensitive demand—An intuitionist fuzzy approach. Annals of Operations Research. doi:10.1007/s10479-013-1476-3.

Goyal, S. K., & Cárdenas-Barrón, L. E. (2002). Note on: Economic production quantity model for items with imperfect quality—a practical approach. International Journal of Production Economics, 77(1), 85–87.

Harris, F. W. (1913). How many parts to make at once. Factory the Magazine of Management, 10, 135–136.

Hsu, L. F. (2012a). A note on ”An economic order quantity (EOQ) for items with imperfect quality and inspection errors”. International Journal of Industrial Engineering Computations, 3(4), 695–702.

Hsu, L. F. (2012b). Erratum to ”An economic order quantity (EOQ) for items with imperfect quality and inspection errors” [Int. J. Prod. Econ. 133, 113–118]. International Journal of Production Economics, 136(1), 253.

Hsu, J. T., & Hsu, L. F. (2013a). An EOQ model with imperfect quality items, inspection errors, shortage backordering, and sales returns. International Journal of Production Economics, 143(1), 162–170.

Hsu, J. T., & Hsu, L. F. (2013b). Two EPQ models with imperfect production processes, inspection errors, planned backorders, and sales returns. Computers & Industrial Engineering, 64(1), 389–402.

Hsu, W. K., & Yu, H. F. (2011). Economic order quality model with immediate return for defective items. ICIC Express Letters, 5(7), 2215–2220.

Huang, C. K. (2002). An integrated vendor–buyer cooperative inventory model for items with imperfect quality. Production Planning and Control, 13(4), 355–361.

Jaber, M. Y., Zanoni, S., & Zavanella, L. E. (2014). Economic order quantity models for imperfect items with buy and repair options. Internation Journal Production Economics, 155, 126–131.

Jaggi, C. K., Tiwari, S., & Goel, S. K. (2016). Credit financing in economic ordering policies for non-instantaneous deteriorating items with price dependent demand and two storage facilities. Annals of Operations Research. doi:10.1007/s10479-016-2179-3.

Khan, M., Jaber, M. Y., & Ahmad, A.-R. (2014). An integrated supply chain model with errors in quality inspection and learning in production. Omega, 42(1), 16–24.

Khan, M., Jaber, M. Y., & Bonney, M. (2011a). An economic order quantity (EOQ) for items with imperfect quality and inspection errors. International Journal of Production Economics, 133(1), 113–118.

Khan, M., Jaber, M. Y., Guiffrida, A. L., & Zolfaghari, S. (2011b). A review of the extensions of a modified EOQ model for imperfect quality items. International Journal of Production Economics, 132(1), 1–12.

Lashgari, M., Taleizadeh, A. A., & Ahmadi, A. (2015). Partial up-stream advanced payment and partial down-stream delayed payment in a three-level supply chain. Annals of Operations Research. doi:10.1007/s10479-015-2100-5.

Mishra, U., Cárdenas-Barrón, L. E., Tiwari, S., & Treviño-Garza, G. (2017). An inventory model under price and stock dependent demand for controllable deterioration rate with shortages and preservation technology investment. Annals of Operations Research. doi:10.1007/s10479-017-2419-1.

Moussawi-Haidar, L., Salameh, M., & Nasr, W. (2013). An instataneous replenishment model under the effect of a sampling policy for defective items. Applied Mathematical Modeling, 37(3), 719–727.

Papachristos, S., & Konstantaras, I. (2006). Economic ordering quantity models for items with imperfect quality. International Journal of Production Economics, 100(1), 148–154.

Porteus, E. L. (1986). Optimal lot sizing, process quality improvement and setup cost reduction. Operations Research, 34(1), 137–144.

Raouf, A., Jain, J. K., & Sathe, P. T. (1983). A cost-minimization model for multicharacteristic component inspection. IIE Transactions, 15, 187–194.

Rezaei, J. (2005). Economic order quantity model with backorder for imperfect quality items. In Proceedings of International Engineering Management Conference on IEEE (pp. 11–13, 466–470).

Rosenblatt, M. J., & Lee, L. (1986). Economic production cycles with imperfect production processes. IEEE Transactions, 18(1), 48–55.

Roy, A., Sana, S. S., & Chaudhuri, K. (2015). Optimal Pricing of competing retailers under uncertain demand—a two layer supply chain model. Annals of Operations Research. doi:10.1007/s10479-015-1996-0.

Salameh, M. K., & Jaber, M. Y. (2000). Economic production quantity model for items with imperfect quality. International Journal of Production Economics, 64(1–3), 59–64.

Sarkar, B. (2013). A production-inventory model with probabilistic deterioration in two-echelon supply chain management. Applied Mathematical Modelling, 37(5), 3138–3151.

Sarkar, B. (2016). Supply chain coordination with variable backorder, inspections, and discount policy for fixed lifetime products. Mathematical Problem in Engineering, 2016, 6318737.

Sarkar, B., Cárdenas-Barrón, L. E., Sarkar, M., & Singgih, M. L. (2014). An economic production quantity model with random defective rate, rework process and backorders for a single stage production system. Journal of Manufacturing Systems, 33(3), 423–435.

Sarkar, B., Chaudhuri, K., & Moon, I. (2015a). Manufacturing setup cost reduction and quality improvement for the distribution free continuous-review inventory model with a service level. Journal of Manufacturing Systems, 34, 74–82.

Sarkar, B., Ganguly, B., Sarkar, M., & Pareek, S. (2016). Effect of variable transportation and carbon emission in a three-echelon supply chain model. Transportation Research Part E: Logistics and Transportation Review, 91, 112–128.

Sarkar, B., & Moon, I. (2014). Improved quality, setup cost reduction, and variable backorder costs in an imperfect production process. International Journal of Production Economic, 155, 204–213.

Sarkar, B., & Saren, S. (2016). Product inspection policy for an imperfect production system with inspection errors and warranty cost. European Journal of Operational Research, 248(1), 263–271.

Sarkar, B., Saren, S., & Cárdenas-Barrón, L. E. (2015b). An inventory model with trade-credit policy and variable deterioration for fixed lifetime products. Annals of Operations Research, 229(1), 677–702.

Sarkar, M., Lee, Y. H. (2017). Optimum pricing strategy for complementary products with stochastic reservation price in a supply chain model. Journal of Industrial and Management Optimization, 13(2), Article in press. doi:10.3934/jimo.2017007.

Skouri, K., Konstantaras, I., Lagodimos, A. G., & Papachristos, S. (2014). An EOQ model with backorders and rejection of defective supply batches. International Journal of Production Economics, 155, 148–154.

Skouri, K., Konstantaras, I., Manna, S. K., & Chaudhuri, K. S. (2011). Inventory models with ramp type demand rate, time dependent deterioration rate, unit production cost and shortages. Annals of Operations Research. doi:10.1007/s10479-011-0984-2.

Tai, A. H. (2015). An EOQ model for imperfect quality items with multiple quality characteristic screening and shortage backordering. European Journal of Industrial Engineering, 9(2), 261–276.

Taleizadeh, A. A., Kalantari, S. S., & Cárdenas-Barrón, L. E. (2016a). Pricing and lot sizing for an EPQ inventory model with rework and multiple shipments. TOP, 24(1), 143–155.

Taleizadeh, A. A., Sari Khanbaglo, M. P., & Cárdenas-Barrón, L. E. (2016b). An EOQ inventory model with partial backordering and reparation of imperfect products. International Journal of Production Economics, 182, 418–434.

Tayyab, M., & Sarkar, B. (2016). Optimal batch quantity in a cleaner multi-stage lean production system with random defective rate. Journal of Cleaner Production, 139, 922–934.

Wang, W. T., Wee, H. M., Cheng, Y. L., Wen, C. L., & Cárdenas-Barrón, L. E. (2015). EOQ model for imperfect quality items with partial backorders and screening constraint. European Journal of Industrial Engineering, 9(6), 744–773.

Yu, H. F., Hsu, W. K., & Chang, W. J. (2012). EOQ model where a portion of the defectives can be used as perfect quality. International Journal of Systems Science, 43(9), 1689–1698.

Yu, H. F., Hsu, W. K., & Huang, Y. X. (2013). The integrated policy with immediate return for defective items. Journal of Industrial and Production Engineering, 30(4), 230–237.

Acknowledgements

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (Project Number: 2017R1D1A1B03033846).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

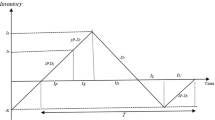

To determine holdings costs, we split the total area in two parts like in the Fig. 8 and express each area separately. The screening time could be expressed as \({ t}_{l}=\frac{yL}{X}\).

The blue area is expressed as

The yellow area is expressed as a single triangle

Appendix 2

Proof of \(\left| \frac{\delta ^{2}{{\mathrm {TP}}}_{1}\left( y,n \right) }{{\delta n}^{2}} \right| >\left| \frac{\delta ^{2}{{\mathrm {TP}}}_{1}\left( y,n \right) }{\delta n\delta y} \right| \)

To demonstrate the second condition, it is necessary to prove that

In order to prove this step, some previous mathematical operations are required. Let’s first assume some obvious considerations and numerical range estimations as:

-

1.

\(0 \ll \left( L-n \right) \ll y\)

-

2.

\({\mathrm {E}}\left[ {\uprho } \right] \approx 0\) and \({\mathrm {E[\uprho }}_{e}] \approx 0\), but strictly positive and therefore \(\left( {\mathrm {1-E}}\left[ {\uprho }_{e} \right] \right) \approx 1\)

-

3.

For \(E\left[ m_{2} \right] \) and \(E\left[ m_{1} \right] \) strictly positive tending to zero.

and with simplifications

As it can be stated that \(\frac{2\left( \mathrm {K+}{\mathrm {K}}_{d} \right) D}{y\left( L-n \right) ^{3}}>\frac{\left( \mathrm {K+}{\mathrm {K}}_{d} \right) D}{y^{2}\left( L-n \right) ^{2}}\) for \(\left( L-n \right) \ll y\), the inequality becomes

The first term of the inequality is always positive and the second term of the inequality is always negative as it is supposed that \(\left( L-n \right) \ll y\) and therefore \({\mathrm {L}}\ll y\). The inequality is therefore true and the statement \(\left| \frac{\delta {{\mathrm {TPU}}}_{1}(y,n)}{\delta n\delta n} \right| >\left| \frac{\delta {{\mathrm {TPU}}}_{1}(y,n)}{\delta n\delta y} \right| \) is verified. \(\square \)

Rights and permissions

About this article

Cite this article

Cheikhrouhou, N., Sarkar, B., Ganguly, B. et al. Optimization of sample size and order size in an inventory model with quality inspection and return of defective items. Ann Oper Res 271, 445–467 (2018). https://doi.org/10.1007/s10479-017-2511-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-017-2511-6