Abstract

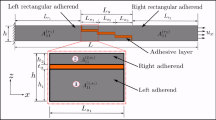

Skin/stiffener debonding has been a longstanding concern for the users of stiffened composite panels in long-term service. Z-pinning technology is an emerging solution to reinforce the composite assembly joints. This work experimentally characterizes the progressive debonding of Z-pinned skin/stiffener interface with the skin under static bend loading. The three-stage failure process is identified as: flange edge debonding, pin/laminate debonding, and ultimate structural failure. Three different distribution patterns were compared in terms of the static debonding properties revealed the affirmative fact that locating pins in high normal stress regions, that is close to the flange edges in skin/stiffener structures, is more beneficial to utilize the full potential of Z-pinning reinforcement. The unit strip FE model was developed and demonstrated effective to analysis the effect of Z-pin distribution on the ultimate debond load. On the other hand, the evolution of fatigue cracks at Z-pinned skin/flange interface was investigated with a series of displacement-controlled fatigue bending tests and microscopic observations. Results show that Z-pinning postpones crack initiations at low displacement levels, and the remarkable crack-arresting function of pins enables the structure a prolonged fatigue life. However, pins become less effective when the maximum displacement exceeds the crack initiation level due to gradually pullout of pins.

Similar content being viewed by others

References

Partridge, I.K., Yasaee, M., Allegri, G., Lander, J.K.: Damage-tolerant composite structures by Z-pinning. In: Qinghua, Q., Jianqiao, Y. (eds.) Toughening Mechanisms in Composite Materials, pp. 161–189. Elsevier, Cambridge (2015)

Lander, J.K.: Designing with Z-Pins: Locally Reinforced Composite Structures. PhD Dissertation, Cranfield University (2009)

Mouritz, A.P.: Review of z-pinned composite laminates. Compos Part a-Appl S. 38(12), 2383–2397 (2007)

Javier, T.V., Bruno, C., Jean-Jacques, B., Nicolas, S.: Multi-level analysis of low-cost Z-pinned composite joints part 2 joint behaviour. Compos. A: Appl. Sci. Manuf. 42(12), 2082–2092 (2011)

Heimbs, S., Nogueira, A.C., Hombergsmeier, E., May, M., Wolfrum, J.: Failure behaviour of composite T-joints with novel metallic arrow-pin reinforcement. Compos. Struct. 110, 16–28 (2014)

Cartié, D.D.R., Troulis, M., Partridge, I.K.: Delamination of Z-pinned carbon fibre reinforced laminates. Compos. Sci. Technol. 66(6), 855–861 (2006)

Zhang, X., Hounslow, L., Grassi, M.: Improvement of low-velocity impact and compression-after-impact performance by z-fibre pinning. Compos. Sci. Technol. 66(15), 2785–2794 (2006)

Pingkarawat, K., Mouritz, A.P.: Improving the mode I delamination fatigue resistance of composites using Z-pins. Compos. Sci. Technol. 92, 70–76 (2014)

Pegorin, F., Pingkarawat, K., Daynes, S., Mouritz, A.P.: Mode II interlaminar fatigue properties of z-pinned carbon fibre reinforced epoxy composites. Compos. A: Appl. Sci. Manuf. 67, 8–15 (2014)

Chang, P., Mouritz, A.P., Cox, B.N.: Properties and failure mechanisms of pinned composite lap joints in monotonic and cyclic tension. Compos. Sci. Technol. 66(13), 2163–2176 (2006)

Allegri, G., Zhang, X.: On the delamination and debond suppression in structural joints by Z-fibre pinning. Compos Part a-Appl S. 38(4), 1107–1115 (2007)

Koh, T.M., Feih, S., Mouritz, A.P.: Experimental determination of the structural properties and strengthening mechanisms of z-pinned composite T-joints. Compos. Struct. 93(9), 2222–2230 (2011)

Park, Y.B., Lee, B.H., Kweon, J.H., Choi, J.H., Choi, I.H.: The strength of composite bonded T-joints transversely reinforced by carbon pins. Compos. Struct. 94(2), 625–634 (2012)

Koh, T.M.: Improvement the Mechanical Properties of Aerospace Carbon Fiber Epoxy Joints by Z-Pinning. PhD Dissertation, RMIT University (2012)

Koh, T.M., Feih, S., Mouritz, A.P.: Strengthening mechanics of thin and thick composite T-joints reinforced with z-pins. Compos. A: Appl. Sci. Manuf. 43(8), 1308–1317 (2012)

Yasaee, M., Lander, J.K., Allegri, G., Hallett, S.R.: Experimental characterisation of mixed mode traction–displacement relationships for a single carbon composite Z-pin. Compos. Sci. Technol. 94, 123–131 (2014)

Bianchi, F., Koh, T.M., Zhang, X., Partridge, I.K., Mouritz, A.P.: Finite element modelling of z-pinned composite T-joints. Compos. Sci. Technol. 73, 48–56 (2012)

Zhang, X.Y., Hoa, S.V., Li, Y., Xiao, J., Tan, Y.: Effect of Z-pinning on fatigue crack propagation in composite skin stiffener structures. J. Compos. Mater. (2017). doi:10.1177/0021998317710708

Mouritz, A.P.: Structural properties of z-pinned carbon-epoxy T-joints in hot-wet environment. J. Compos. Mater. 48(23), 2905–2914 (2013)

Mouritz, A.P.: Environmental durability of z-pinned carbon fibre-epoxy laminate exposed to water. Compos. Sci. Technol. 72(13), 1568–1574 (2012)

Chang, P., Mouritz, A.P., Cox, B.N.: Elevated temperature properties of pinned composite lap joints. J. Compos. Mater. 42(8), 741–769 (2008)

Chang, P., Mouritz, A.P., Cox, B.N.: Properties and failure mechanisms of z-pinned laminates in monotonic and cyclic tension. Compos. A: Appl. Sci. Manuf. 37(10), 1501–1513 (2006)

Minguet, P.J., O' Brien, T. K.: Analysis of test methods for charaterizing skin/stringer debonding failures in reinforced composite panels In: Composite Materials: Testing and Design: Twelfth Volume. pp. 105–124. ASTM International, (1996)

Krueger, R., Paris, I.L., O'Brien, T.K., Minguet, P.J.: Fatigue life methodology for bonded composite skin/stringer configurations. J. Compos. Technol. Res. 24(2), 56–79 (2002)

Dubé, M., Hubert, P., Yousefpour, A., Denault, J.: Fatigue failure characterisation of resistance-welded thermoplastic composites. Int. J. Fatigue. 31(4), 719–725 (2009)

Bertolini, J., Castanie, B., Barrau, J.J., Navarro, J.P.: Multi-level experimental and numerical analysis of composite stiffener debonding. Part 1: non-specific specimen level. Compos. Struct. 90(4), 381–391 (2009)

Krueger, R., Cvitkovich, M.K., O'Brien, T.K., Minguet, P.J.: Testing and analysis of composite skin/stringer debonding under multi-axial loading. J. Compos. Mater. 34(15), 1263–1300 (2000)

Mouritz, A.P.: Compression properties of z-pinned composite laminates. Compos. Sci. Technol. 67(15–16), 3110–3120 (2007)

Dai, S.C., Yan, W.Y., Liu, H.Y., Mai, Y.W.: Experimental study on z-pin bridging law by pullout test. Compos. Sci. Technol. 64(16), 2451–2457 (2004)

Gornet, L., Ijaz, H., Cartie, D.D.R.: Inelastic interface damage modeling with friction effects: application to Z-pinning reinforcement in carbon fiber epoxy matrix laminates. J. Compos. Mater. 44(17), 2067–2081 (2010)

Akhlaque-E-Rasul, S.M.: Compressive Response of Tapered Curved Composite Plates. PhD thesis, Concordia University (2010)

Barbero, E.J.: Finite Element Analysis of Composite Materials Using Abaqus™. CRC press, Boca Raton (2013)

ASTM D5528-13 Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites, ASTM International, West Conshohocken, PA (2013). doi:10.1520/D5528

ASTM D7905/D7905M-14 Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites, ASTM International, West Conshohocken, PA (2014). doi:10.1520/D7905_D7905M-14

Pegorin, F., Pingkarawat, K., Mouritz, A.P.: Comparative study of the mode I and mode II delamination fatigue properties of z-pinned aircraft composites. Mater. Des. 65, 139–146 (2015)

Warzok, F., Allegri, G., Gude, M., Hallett, S.R.: Experimental characterisation of fatigue damage in single Z-pins. Compos. A: Appl. Sci. Manuf. 91, 461–471 (2016)

Acknowledgements

The work was funded by the Aeronautical Science Foundation of China (grant number 2015ZE52049) and China Scholarship Council. Also appreciation goes to the colleagues from Concordia Center for Composites, Concordia University, for technical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Zhang, X., Li, Y., Van Hoa, S. et al. Investigation into Z-Pin Reinforced Composite Skin/Stiffener Debond under Monotonic and Cyclic Bending. Appl Compos Mater 25, 203–219 (2018). https://doi.org/10.1007/s10443-017-9640-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-017-9640-6