Abstract

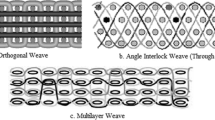

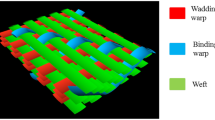

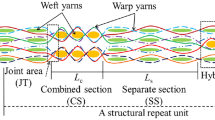

Bullet penetration resistance is investigated in on use of 3d orthogonal structures for soft armor application which may have positive outcomes with a combination of high-performance yarn in a particular direction. 3d fabric structures have a promising architecture, to develop a soft armor system due to its good mould-ability and its interaction characteristic with the yarns. 3d orthogonal fabric was manufactured on hand-loom; four different variants of the fabrics were woven with the same fabric architecture with different types of yarn in different directions. The research investigated the performance of a single 3d orthogonal fabric of 8 layers and a double 3d orthogonal fabric of a total 16 layers in different variant combinations as per the NIJ standard 101.06 level II-A. The performance of double 3d orthogonal fabric for maximum combinations was optimum to prevent the penetration of the bullet at a velocity as per NIJ std 101.06 level II-A. Besides, the single 3d orthogonal fabric of 8 layers did not perform in preventing the bullet penetration at a higher velocity. The design strategy of combining the 3d fabric variants is implemented to check the ballistic performance of the combined 3d fabric variants when the number of layers of a single 3d fabric is not able to prevent perforation by the projectile. It was observed that 100% kevlar double 3d orthogonal fabric had a lower energy absorption limit due to lesser areal density and lower modulus of the yarns in the fabric structure affecting the energy dissipation of the projectile on the impact. However in comparison to hybrid composite double 3d orthogonal fabric (3dof), with ultra-high molecular weight polyethylene in the z-direction of the second layer of double fabric, improves the energy dissipation capability due to good energy absorption capability of yarn with higher modulus. The back face signature (bfs) values for all the non-penetrated combined double 3d orthogonal fabric combinations were lesser than the standard requirement of 44 mm. The results of the testing show the bfs values were inversely proportional to the areal density of the 3d orthogonal fabrics.

Similar content being viewed by others

Data and code availability

Data mentioned in the Tables 1–9 are obtained from actual experimental analysis and evaluation. Data is available only on request after the patent is granted to the author. The data involved in this research work are under submission process for a patent as ‘New 3D woven structure in soft body armor development’.

References

Abtew, M.A., Boussu, F., Bruniaux, P., Loghin, C., Cristian, I.: Ballistic impact mechanisms—a review on textiles and fibre-reinforced composites impact responses. Compos. Struct. 223, 110966 (2019). https://doi.org/10.1016/j.compstruct.2019.110966

NIJ Standard-0101.06. Ballistic Resistance of Personal Body Armor. NIJ Stand 2008:89.

Yang, D., Chen, X., Sun, D., Zhang, S., Yi, C., Gong, X., et al.: Ballistic performance of angle-interlock woven fabrics. J. Text. Inst. 108, 586–596 (2017). https://doi.org/10.1080/00405000.2016.1176622

Bilisik, K., Karaduman, N.S., Bilisik, E., Bilisik, H.E.: Three-dimensional fully interlaced woven preforms for composites. Text. Res. J. (2013). https://doi.org/10.1177/0040517513487791

Sun, D., Chen, X.: 13 - Three-dimensional textiles for protective clothing. In: Advances in 3D textiles, Woodhead Publishing, 341–360 (2015). https://doi.org/10.1016/B978-1-78242-214-3.00013-9

Cunniff, P.M.: A semiempirical model for the ballistic impact performance of textile-based personnel armor. Text. Res. J. 66, 45–58 (1996). https://doi.org/10.1177/004051759606600107

Wang, Y., Chen, X., Young, R., Kinloch, I.: Finite element analysis of effect of inter-yarn friction on ballistic impact response of woven fabrics. Compos. Struct. 135, 8–16 (2016). https://doi.org/10.1016/j.compstruct.2015.08.099

Zahid, B., Chen, X.: Impact performance of single-piece continuously textile reinforced riot helmet shells. J. Compos. Mater. (2014). https://doi.org/10.1177/0021998313477173

Naik, N.K.: Analysis of woven fabric composites for ballistic protection. In: Chen, X. (ed.) Advanced fibrous composite materials for ballistic protection. Elsevier, Amsterdam (2016). https://doi.org/10.1016/B978-1-78242-461-1.00008-X

Bazhenov, S.: Dissipation of energy by bulletproof aramid fabric. J. Mater. Sci. 32, 4167–4173 (1997). https://doi.org/10.1023/A:1018674528993

Tripathi, L.: Modeling and simulation of impact behavior of 3d woven solid structure for ballistic application. J. Ind. Text. (2022). https://doi.org/10.1177/1528083720980467

Bandaru, A.K., Sachan, Y., Ahmad, S., Alagirusamy, R., Bhatnagar, N.: On the mechanical response of 2D plain woven and 3d angle-interlock fabrics. Compos. Part B Eng. 118, 135–148 (2017). https://doi.org/10.1016/j.compositesb.2017.03.011

Hysoung aramid certificate of analysis 2000:7269

DSM UHMWPE technical property sheet.pdf

Acknowledgements

The authors would like to thank all the staff of the “Ballistic Research and Testing Centre at National Forensic Science University” In Gandhinagar involved in the ballistic impact tests. Authors would like to thank the management of Arvind Composites Ltd, Ahmedabad and SMPP Delhi for providing assistance in arranging the high-performance yarns for fabric weaving. We would like to thank Dr. Saurabh Kumar for his help during the ballistic tests and scanning of blunt trauma deformation in the backing material as well as Mr. G. M. Karkar for his help during the 3d weaving session. No funding was received from any authors for this research experimental activity.

Funding

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Not Applicable.

Consent for publication

Not Applicable.

Consent to participate

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Junare, N., Vakil, M. & Rajpurohit, A. Ballistic performance evaluation of 3-dimensional orthogonal composite soft armor systems. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01752-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01752-y