Abstract

Domestic waste combustion in central heating furnaces is illegal in many countries, including Poland, but unfortunately still occurs. These activities have a negative influence on the environment and human health. The local nature of this process makes it difficult to effectively counteract this phenomenon. Information campaigns about the impact of domestic waste combustion in central heating furnaces, especially the impact on human health, are necessary, but undertaking parallel control activities is much more important. To control activity, support is necessary to develop a suitable method to confirm domestic waste combustion in central heating furnaces. In the present preliminary study, we have investigated two methods. The first method is indirect, it is based on the analytical pyrolysis of organic residues in ash and provides direct information on the type of plastic subjected to combustion. The second method is based on the principal component analysis (PCA) of polycyclic aromatic hydrocarbon (PAH) concentrations in ash samples. Special attention was paid to sixteen PAHs: naphthalene, acenaphthene, acenaphthylene, fluorene, anthracene, phenanthrene, fluoranthene, pyrene, chrysene, benzo(a)anthracene, benzo(a)pyrene, benzo(e)pyrene, benzo(b+k)fluoranthene, dibenzo(a,h)anthracene+ indeno(1,2,3-cd)pyrene, benzo(g,h,i)perylene, and perylene.

Similar content being viewed by others

Introduction

The combustion and co-combustion of domestic waste with solid fossil fuels in individual central heating furnaces leads to large quantities of atmospheric pollutants. This problem has a local and intermittent nature and, for this reason, is difficult to detect and properly locate. Incomplete combustion in central heating furnaces leads to the formation of soot and fine dust particles (particulate matter, PM); carbon monoxide; volatile organic compounds (VOCs), such as benzene, toluene and polycyclic aromatic hydrocarbons (PAHs), e.g., benzo(a)pyrene [1]; and polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDDs/PCDFs).

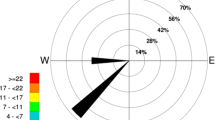

The total atmospheric emission of PAHs and PCDDs/PCDFs coming exclusively from combustion processes excluding industrial processes in Poland was estimated at 86.8% and 49.9%, respectively, in 2012 [2]. Surveys conducted in 2009–2012 [2] showed that on average, over 45% of respondents in the study area admitted to waste combustion in central heating furnaces. The most frequently mentioned types of waste were furnace waste—bottom ash (FW), multilayer barrier packaging, plastic bags, polyethylene terephthalate (PET) and other plastic packaging. In addition to the mentioned wastes, in one individual heating device, worn-out shoes, used tires, polyurethane foam and even poly(vinyl) chloride (PVC) waste were also burned. The average percentages of individual types of waste (in the studied area) relative to the total waste used by polluters who burn waste in individual heating devices are presented in Fig. 1.

The average percentages of combustion cases for individual types of waste [3]

More than 95% of respondents admitted to burning waste in the form of newspapers. On average, 50% of respondents admitted to, at least once, burning waste containing plastics, including PET and low-density polyethylene (LDPE). Respectively, 39, 24 and 23% of respondents burned fabrics, varnished wood (lacquered wood) and diapers. Less than 10% of respondents burned polystyrene (PS), polyurethane foam (PU), rubber waste (including waste tires) and PVC.

As mentioned above, waste combustion and co-combustion in individual heating devices have a negative impact on environmental and human health, and most importantly, such behaviour is illegal. The only direct and completely certain way to confirm the illicit combustion of waste in an individual heating device would be to catch a person committing an offence “hot-handed”. This solution is impossible, which is why indirect methods consisting of analysing the status quo via citizens’ reports and routine/follow-up inspections by services authorized to do so are used to confirm illicit combustion.

These indirect methods need to prove (with a greater or lesser probability, depending on the method) that the physicochemical properties of collected samples of, e.g., exhaust, soot or ash, deviate from those of samples derived from the combustion of pure fuel (biomass, hard coal or lignite). These methods include the following:

-

visual exhaust assessment,

-

exhaust gas analysis,

-

soot analysis, and

-

ash analysis.

The first mentioned method, visual exhaust assessment, is characterized by high technical feasibility and low cost but unfortunately is also highly subjective.

For this reason, visual exhaust assessment is far from unambiguous and cannot be used alone, for example, in court proceedings. Visual and organoleptic assessment, i.e., the determination of a specific chemical odour of exhaust gasses, which are often astringent, is the basis for the undertaking of authorized actions by approved services (municipal or other police) to control the furnace. The second method—the chemical analysis of exhaust gas—is highly objective and unequivocal and could be used to confirm waste combustion in an individual heater. Unfortunately, this method has some disadvantages, including low technical feasibility in the case of a gas sample collected directly from a chimney during combustion or co-combustion of waste. The second problem is collective chimney flues; no evidence would be able to indicate that a certain heating device connected to the chimney draft is the emitter. Moreover, there are no appropriate standards or limit values for this type of exhaust, and standards for waste combustion cannot be applied for this purpose.

The same situation applies in the potential use of the analysis of the chemical composition of soot. Soot, due to its physicochemical properties, can absorb pollutants in exhaust. Unfortunately, the composition of soot from collective chimney ducts does not allow a specific emitter to be identified. Additionally, there is no well-established knowledge that would enable determining the time of formation of individual soot layers that arise during the combustion of fuels. In this case, every analysis of collected soot samples would require an expert opinion.

Another factor in the detection of the illegal waste combustion process in central heating furnaces arises when applying the results of chemical analysis of ash collected from central heating furnaces. This method is the best, characterized by technical feasibility (there are no problems with the collection of FW from heating devices), the low cost required to perform physicochemical analysis, unambiguous results and the lack of legal contraindications.

A methodology to detect illegal combustion or co-combustion of waste in individual heating devices should be characterized by the following:

-

unequivocality,

-

technical feasibility,

-

low running costs, and.

-

compliance with applicable legal regulations.

A previous study conducted between 2012 and 2016 confirmed that it is possible to develop a classifier based on the physicochemical properties of fuel to determine the type and origin of the studied sample [4, 5].

Analysis of the chemical composition of FW (ash) by inductively coupled plasma-optical emission spectrometry (ICP-OES) can classify such waste and indicate whether the waste was obtained from the combustion of household and domestic wastes in an individual heating device. A methodology for detecting the illegal combustion and co-combustion of waste in personal heating devices was developed and has been implemented in territorial units of the Silesian district [6,7,8,9].

Classification analysis was carried out using the developed classification algorithm, consisting of a set of logical rules, to qualify the examined FW into one of three classes:

-

waste combustion in the individual furnace was excluded,

-

no waste combustion was identified in the individual furnace, or

-

waste combustion in the individual furnace was identified.

This classification algorithm is characterized by an accuracy of FW classification of not less than 97% for conditions where more than 10% m/m waste was burned as fuel [7].

We also attempted to improve our tool by utilizing two analytical methods. The first method is based on extraction with organic solvents and subsequent analysis by gas chromatography-mass spectrometry (GC–MS). The second method is based on pyrolytic gas chromatography-time-of-flight mass spectrometry (Pyro-GC-TOFMS). In both cases, mass spectrometers were utilized as detectors. Special attention was paid to sixteen PAHs: naphthene, acenaphthene, acenaphthylene, fluorene, anthracene, phenanthrene, fluoranthene, pyrene, chrysene, benzo(a)anthracene, benzo(a)pyrene, benzo(e)pyrene, benzo(b + k)fluoranthene, dibenzo(a,h)anthracene + indeno(1,2,3-cd)pyrene, benzo(g,h,i)perylene, and perylene.

Materials and Method

For our study, a series of ash samples from pure hard coal and municipal waste, such as textiles, waste furniture wood and waste plastics, were prepared. Next, we prepared samples of ashes by combusting several types of municipal waste, such as textiles, waste furniture wood and waste plastics, with hard coal, coke and two different types of biomass (oak wood and straw), in individual heating devices with powers of up to 25 kW. All samples were obtained during co-combustion at a mass ratio of 90% solid fuel and 10% waste. Next, the ash was homogenized by grinding and sieving (0.02 mm) to prepare analytical samples.

Two analytical approaches were then utilized:

-

qualitative and quantitative analysis of PAH concentration by extraction with organic solvents and subsequent GC analysis of the extract, and

-

qualitative analysis of the organic residues in ash by Pyro-GC-TOFMS.

PAH Analysis

1 g of ash sample was extracted with acetone (10 ml) and dichloromethane (10 ml). Extractions were conducted by using an ASE350 accelerated solvent extractor (Dionex). The extract was concentrated to 1 ml by evaporation of the solvent under reduced pressure. Prior to chromatographic analysis, an internal standard was added: triphenylmethane and 9,10-diphenyl anthracene in toluene. PAH concentrations were determined with a FOCUS gas chromatograph (Thermo-Scientific) coupled with a DSQ II quadrupole mass spectrometer (Thermo-Scientific). Mass spectrometer: range 45–354 m/z, data collection rate 4 Hz, emission current 70 eV. Carrier: helium at 1 ml/min. Split-splitless injector: split ratio 1:10, liner: glass liner packed with quartz wool. Column: Rxi-5 ms, 30 m × 0.25 mm × 0.25 μm. Temperature program: 0–5 min, 50 °C; 5–28 min, 10 °C/min to 280 °C; 28–60 min, 280 °C. Injector temperature: 280 °C.

Organic Residue Analysis

Analyses were conducted by using a Pegasus 4D (LECO) equipped with a thermo desorption unit (TDU, Gerstel), pyrolysis module (Pyro, Gerstel) and cooled injection system (CIS-4, Gerstel). Pegasus 4D is a comprehensive two-dimensional GC-TOFMS system. For the purpose of this study, the instrument was switched to one-dimensional mode.

A 5 mg sample of ash was placed in a quartz tube reactor, which was then inserted into the pyrolysis module. The sample was heated to 700 °C at a rate of 5 °C/s and kept at that temperature for 10 min. All vapours were transferred to the CIS-4 (Gerstel) and kept at − 150 °C (cooled with liquid nitrogen).

After the pyrolysis step, GC analysis started. The CIS was heated to 280 °C at a rate of 110 °C/min and kept at that temperature for 15 min. Mass spectrometer: range 45–650 m/z, data collection rate 10 Hz, emission current 70 eV. Carrier: helium at 1 ml/min. Injector: split ratio 1:15, liner: glass liner packed with quartz wool. Column: Rxi-5 ms, 27 m × 0.25 mm × 0.25 μm. Temperature program: 0–2 min, 50 °C; 2–25 min, 10 °C/min to 280 °C; 25–40 min, 280 °C. The quartz reactor with the ash sample remained in the pyrolysis module during the whole GC run.

Principal Component Analysis

In the present study, we applied principal component analysis (PCA) to analyse the data set of PAH concentrations in the selected solid FW. All calculations were conducted using MATLAB [10] software. PCA is a very efficient tool for analysing multidimensional data. This method can be used to reduce the data dimensions and create new transformed variables (principal components, PCs). In PCA, the eigenvalues and eigenvectors are calculated based on the covariance matrix of the original variables [11, 12]. The new variables (PCs) are linear combinations of the original variables, and in many cases, a specific physical or chemical interpretation can be described by the PCs [13, 14].

Results and Discussion

The first method for determining whether an ash sample originated from the combustion of domestic wastes was based on a direct search for organic residues in ash samples that would indicate the combustion of plastic wastes. For this study, we prepared three samples of ash by combustion of 10% plastic and 90% coal in individual heating devices with powers of up to 25 kW. The first two experiments were conducted with PET bottles and PS chips. The third experiment used mixed domestic wastes (mainly LDPE). Prior to further analysis, the ash samples were milled and homogenized. Then, the ash samples were subjected to analytical pyrolysis. GC analysis revealed that products of the thermal decomposition of non-combusted plastic were still present in the ash (Figs. 2, 3 and 4). These products provide information not only about the combustion of illegal substances but also about the type of burned material.

The total ion chromatograms of the coal and PET ash samples obtained from pyrolysis are presented in Fig. 2, and the molecular structures of the pyrolysis fragments are listed in Table 1; these structures were confirmed by running a search program in a mass spectrometry database. In the pyrolysis fragments of the studied sample, characteristic peaks attributed mainly to benzoic acid and monoethylene phthalate appeared at 12.20 and 17.46 min, respectively, implying that the test sample contains unburned PET residues; this result has been confirmed by similar studies in this area [15, 16].

The total ion chromatogram for the second studied ash sample, obtained by co-combustion of coal and PS waste, is presented in Fig. 3, and the molecular structures of the pyrolysis fragments are listed in Table 2. In this case, the most intensive peak, attributed mainly to styrene, appears at 7.10 min. This contaminant concentration in the ash implies that the test sample contains unburned PS residue [17].

The last studied ash sample was obtained by co-combustion of coal and mixed domestic wastes (mainly LDPE). The total ion chromatogram is presented in Fig. 4a, b, and the molecular structures of the pyrolysis fragments are listed in Table 3. In this case, the most intensive peak corresponds to n-alkanes and n-alk-1-enes, which do not occur in such amounts and varieties in ash samples from coal combustion. This contaminant concentration in the ash implies that the test sample contains unburned polyolefin residues [17]. The remaining peaks, attributed to benzene and phenol derivatives, are due to thermal decomposition of phenolic resins.

The first method for determining whether an ash sample originates from the combustion of domestic wastes was based on the analysis of PAH content.

Selected samples of ashes obtained from individual heating devices with powers of up to 25 kW and by incineration in a laboratory muffle furnace were subjected to PAH analysis by GC after extraction. The results of this analysis are presented in Table 4. Samples marked as coal ash, textile ash, textile ash #2 and furniture ash were obtained by incineration in a laboratory muffle furnace. Samples marked as FW from coal, FW from coal and textile, FW from coal and textile #2, and FW from coal and furniture waste were obtained from individual heating devices with powers of up to 25 kW. There are significant differences between the concentrations of PAHs in samples obtained by the two different means. Primary comparative data analysis does not resolve whether it is possible to determine (based on PAH analysis) whether a tested FW comes from combustion of clean fuel (hard coal or biomass) or from the co-combustion of fuel and municipal waste. Here, analytical data were used for PCA analysis, and the results are presented graphically in Fig. 5.

PCA analysis correctly divided the tested group into two classes depending on the preparation method: ash samples obtained by waste and fuel co-combustion in an individual heating device with a power of up to 25 kW (marked in orange) and ash samples obtained by waste and fuel incineration under laboratory conditions (marked in red). These differences depended on the time, temperature and stability conditions. In the case of ash sample incineration under laboratory conditions, the temperature was uniform and stable, and the residual time was always the same. For ash samples obtained from individual heating devices with a power of up to 25 kW, the conditions were more varied. The residual time of ash in the heating zone strongly depended on the air stream supplied to the furnace, and the temperature situation was similar. Therefore, these two types of ash sample were very different from a chemical point of view, and thus PCA was used.

The test samples were divided into two groups with respect to the main component (PC 1). The concentrations of all tested analytes yielded positive values of PC 1 (proportionally), which means that the FW samples contain lower amounts of PAHs than the samples obtained by incineration under laboratory conditions.

To clarify, PCA analysis was conducted only for samples belonging to the first class—ash samples obtained in individual heating devices with powers of up to 25 kW. The results of the second analysis are presented in Fig. 6.

In addition, we performed a second PCA analysis, but only for the set of ash samples selected by the previous analysis. This analysis clearly shows that PAH analysis can be used to indicate that an ash sample collected during the inspection of individual heating devices with powers of up to 25 kW resulted from the co-combustion of solid fuels and household waste. Positive values of PC1, PC2 and PC3 strongly corelated with acenaphthene, acenaphthylene, fluorene and benzo(a)anthracene concentrations higher than those in the ash of pure hard coal. The first three molecules are PAHs composed of three rings, including two aromatic rings. Positive values of PC1 with simultaneous negative values of PC2 and PC3 correspond to PAHs consisting of only aromatic rings, which were found in higher concentrations than in the ash from pure hard coal.

As shown in Fig. 6 the negative values of all three PCs strongly corresponded to ash samples from pure hard coal due to the significantly lower concentrations of the studied PAHs. For benzo(b + k)fluoranthene, benzo(e)pyrene, benzo(e)pyrene and the total PAH concentrations, the values were very similar in the studied ash samples.

Conclusions

In this preliminary study, we presented two analytical approaches for determining illegal waste combustion in heating devices. The first method is based on analytical pyrolysis and requires a GC coupled with an analytical pyrolyser. This method was superior to the second method because it can not only detect the combustion of plastic wastes, but also provides some information about the type of plastic that was burned.

The second method was based on ash sample extraction and subsequent analysis of PAHs with GC–MS.

This method could be more widely applied than the first method because it utilizes standard analytical equipment. However, our research showed that this method is not sufficiently accurate. This method appeared to be highly sensitive to the combustion conditions. Incineration in a laboratory muffle furnace resulted in ash that contained significantly higher concentrations of PAHs than ash obtained from individual heating devices with powers of up to 25 kW. Therefore, future studies are needed to improve this method.

References

Szewczyńska M, Dobrzyńska E, Pośniak M (2009) Niekontrolowane spalanie odpadów-zagrożenia dla środowiska i człowieka. CIOP-PIB, Warszawa (In Polish)

KOBIZE (2014) Krajowy bilans emisji SO2, NOx, CO, NH3, NMLZO, pyłów, metali ciężkich i TZO za lata 2011–2012 w układzie klasyfikacji SNAP—Raport syntetyczny. (Raport in Polish)

Oleniacz R, Bacik B, Spiszak M (2014) Niekontrolowane spalanie odpadów i pozostałości roślinnych na terenach wiejskich—przykład inwentaryzacji źródeł emisji i oceny wpływu na jakość powietrza—[Uncontrolled burning of waste and plant residues in rural areas—an example of inventory of emission sources and assessment of the impact on air quality]. Inżynieria i ochrona powietrza. Wrocław. Oficyna Wydawnicza Politechniki Wrocławskiej. 314–323. ISBN: 978-83-7493-839-6

Sajdak M (2015) Verification of origin of the material obtained from thermal biomass conversion—new methods. In: papers of the 23rd European biomass conference and exhibition, At Vienna, 1483–1487. https://doi.org/10.5071/23rdeubce2015-4av.1.21

Sajdak M (2017) Development and validation of new methods for identification of bio-char as an alternative solid bio-fuel for power generation. Fuel Process Technol 167(1):229–240. https://doi.org/10.1016/j.fuproc.2017.06.031

Sajdak M, Sobolewski A (2018) Koncepcja metodyki wykrywania nielegalnego spalania i współspalania odpadów w indywidualnych urządzeniach grzewczych. Niska emisja—węgiel tak. smog nie. 117–129. Katowice. Główny Instytut Górnictwa. ISBN 978-83-65503-15-2

Information available on the website of the Self-government of the Silesian Voivodeship. https://powietrze.slaskie.pl/content/dokumenty-opracowane-razem-z-aktualizacja-programu-ochrony-powietrza. http://www.slaskie.pl/zalaczniki/2017/12/15/1513338526/1513338547.pdf (27-02-2018)

Uchwała zarządu nr 2541/228/V/2017 z dnia 28 listopada 2017 roku w sprawie: zatwierdzenia projektów dokumentów opracowanych wraz z Programem ochrony powietrza (In Polish)

Resolution No. V / 47/5/2017 Regional Council of the Silesian Voivodeship from December 18, 2017, regarding the adoption of the Air Protection Program for the area of the Śląskie Voivodeship aimed at achieving the levels of permissible substances in the air and the exposure concentration ceiling, Information available on the website of the Self-government of the Silesian Voivodeship: https://archiwum-bip.slaskie.pl/dokumenty/2017/12/22/1514455216.pdf (20-12-2018)

MATLAB R 2016a and Statistics Toolbox, The MathWorks, Inc. Natick, Massachusetts, United States

Fendt A, Streibel T, Sklorz M, Richte D, Dahmen N, Zimmermann R (2012) On-line process analysis of biomass flash pyrolysis gases enabled by soft photoionization mass spectrometry. Energy Fuels 26:701–711. https://doi.org/10.1021/ef2012613

Zuba D, Parczewski A (2008) Chemometria w analityce. Instytut Ekspertyz Sądowych, Krakow (ISBN 978-83-87425-88-3)

Giacomino A, Abollino O, Malandrino M, Mentasti E (2011) The role of chemometrics in single and sequential extraction assays: a review: part I. Extraction procedures. uni- and bivariate techniques and multivariate variable reduction techniques for pattern recognition. Anal Chim Acta 688:104–121. https://doi.org/10.1016/j.aca.2010.12.020

Giacomino A, Abollino O, Malandrino M, Mentasti E (2011) The role of chemomertics in single and sequential extraction assays: a reviev. Part II Cluster analysis, multiple linear regression, mixtere resolution, experimental desing and other techniques. Anal Chim Acta 688:122–139. https://doi.org/10.1016/j.aca.2010.12.028

Sovová K, Ferus M, Matulková I, Španěl P, Dryahina K, Dvořák O, Civiš S (2011) A study of thermal decomposition and combustion products of disposable polyethylene terephthalate (PET) plastic using high resolution fourier transform infrared spectroscopy, selected ion flow tube mass spectrometry and gas chromatography mass spectrometry. Mol Phys 106(9–10):1205–1214. https://doi.org/10.1080/00268970802077876

Brems A, Baeyens J, Vandecasteele C, Dewil R (2011) Polymeric cracking of waste polyethylene terephthalate to chemicals and energy. J Air Waste Manag Assoc 61(7):721–731. https://doi.org/10.3155/1047-3289.61.7.721

Kusch P (2017) Chapter 7—application of pyrolysis-gas chromatography/mass spectrometry (Py–GC/MS). Compr Anal Chem 75:169–207. https://doi.org/10.1016/j.chroma.2011.03.038 (Elsevier)

Acknowledgements

The result presented in this paper were obtained during the performance of a research project entitled “Development and improvement of analytical techniques for qualitative and quantitative assessment of liquid and gas fuels, industrial wastewater and chemical solutions used in carbon dioxide capture” (IChPW No 11.18.001), financed by the Ministry of Science and Higher Education (Poland).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that there are no conflicts of interest.

Ethical Approval

This article does not contain any experiments involving human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Published in the topical collection The 41st Symposium Chromatographic Methods of Investigating Organic Compounds with guest editor Michał Daszykowski.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Muzyka, R., Chrubasik, M., Pogoda, M. et al. Py–GC–MS and PCA Analysis Approach for the Detection of Illegal Waste Combustion Processes In Central Heating Furnaces. Chromatographia 82, 1101–1109 (2019). https://doi.org/10.1007/s10337-019-03747-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-019-03747-4