Abstract

Food loss and waste is a major issue affecting food security, environmental pollution, producer profitability, consumer prices, and climate change. About 1.3 billion tons of food products are yearly lost globally, with China producing approximately 20 million tons of soybean dregs annually. Here, we review food and agricultural byproducts with emphasis on the strategies to convert this waste into valuable materials. Byproducts can be used for animal and plant nutrition, biogas production, food, extraction of oils and bioactive substances, and production of vinegar, wine, edible coatings and organic fertilizers. For instance, bioactive compounds represent approximately 8–20% of apple pomace, 5–17% of orange peel, 10–25% of grape seeds, 3–15% of pomegranate peel, and 2–13% of date palm seeds. Similarly, the pharmaceutical industry uses approximately 6.5% of the total output of gelatin derived from fish bones and animal skin. Animals fed with pomegranate peel and olive pomace improved the concentration of deoxyribonucleic acid and protein, the litter size, the milk yield, and nest characteristics. Biogas production amounts to 57.1% using soybean residue, 53.7% using papaya peel, and 49.1% using sugarcane bagasse.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

One-third of the food that was initially intended for human consumption is lost or wasted annually in the production and supply chain, amounting to approximately 1.3 billion tons globally. A significant amount of food wasted and lost suggests that the food system is inefficient, which is detrimental to food security, the environment, producer profits, consumer prices, and climate change. Recent consumer demand for more eco-friendly products has increased awareness of the need to utilize the food industry’s waste products in ways that could benefit the economy and reduce their pollution-causing effects (Orozco et al. 2023; Yang et al. 2022). Due to greenhouse gas emissions, climate change is characterized as a change in climate patterns (Osman et al. 2023; Osman et al. 2021). Global warming has been primarily attributed to greenhouse gas emissions, which cause the earth’s atmosphere to trap heat. The primary sources of these emissions are human activity and natural processes. Natural systems include forest fires, earthquakes, oceans, permafrost, wetlands, mud volcanoes, and volcanoes, while human activities primarily involve energy generation, industrial activities, and those associated with forestry, land use, and land-use change (Fawzy et al. 2020; Osman et al. 2021).

Burning or disposing of food wastes in a manner that increases heat emissions is one of the human activities that exacerbate the climate change crisis (Fawzy et al. 2020). Consequently, the topic of by-product utilization is crucial considering the current pro-environmental and eco-friendly tendencies, as well as the numerous international laws in place. In addition, from a technological standpoint, incorporating these materials into existing production processes may increase final product value or reduce production costs (Orozco et al. 2023; Yang et al. 2022). Furthermore, from an economic perspective, the circular economy concept encourages appropriate strategies for managing and valorizing these by-products to reduce pollution and promote sustainable bio-economy growth among industries, as well as the design and emergence of new revenue streams (Gómez et al. 2021). Consequently, several options exist for overcoming or reducing the potentially negative environmental effects of food or food agro-industrial by-products, including the extraction of oil and bioactive compounds, the production of vinegar, edible coatings, cosmetics, animal feed, biogas, and organic fertilizers, among others (Fig. 1) (Peng et al. 2023; Rashwan et al. 2023; Schieber et al. 2001; Toldrá et al. 2021).

Applications for food and agricultural by-products. Among the food applications of food and agricultural by-products are the extraction of oil and bioactive compounds, the production of vinegar and wine, and the production of edible coatings. Food and agricultural by-products can be utilized to produce biofertilizer, biogas slurry, biochar, and bottom ash. Food and agricultural by-products can be used to produce animal supplements and silage. It is possible to produce cosmetics, pharmaceuticals, and chemicals by recycling both food and agricultural by-products. Food and agricultural by-products are extensively used to generate renewable energy, such as biogas

Therefore, this review aims to describe critically and comprehensively the most significant routes for converting food agro-industrial by-products into valuable products. Consequently, this review has the potential to be a significant contribution to multiple fields, such as food production, pharmaceuticals, agriculture, animal nutrition, and biogas production. Consequently, the novelty and advancements of our review are the discussions of the best routes to convert food and agricultural by-products into valuable and economically viable products that can mitigate their negative effects on food security, the environment, producer profits, and consumer prices, as well as their contribution to climate change.

By-products sources

Throughout the many stages of food production, the agro-food business produces thousands of tons of “wastes”. These “wastes” are typically made up of skins, peels, seeds, leaves, and other inedible fractions that are thrown away because they have little nutritional value, contain dangerous compounds, or have insufficient sensory qualities. The vast volumes that are produced yearly and their high-water activity, which encourages microbial proliferation, are the main causes of serious environmental concerns (Čolović et al. 2019; Uyeh et al. 2021). The Food and Agriculture Organization of the United Nations reports that 1.3 billion tons of food are lost or wasted each year worldwide (FAO 2011).

Most of these by-products come through the processing of cereals, fruits, vegetables, meat, fish, and eggs, as shown in Fig. 2 (Čolović et al. 2019; Ondarza and Tricarico 2021a, b; Jayathilakan et al. 2012; Luithui et al. 2019; Rashwan et al. 2021; Raamsdonk et al. 2023). Therefore, recycling these by-products or wastes into valuable products can overcome the potential environmental concerns that result from these wastes. Many valuable products can be produced from human-inedible agricultural and agro-industrial by-products, such as oil, vinegar, extraction of bioactive compounds, edible coatings, cosmetics, animal feed, biogas, organic fertilizers, and others (Peng et al. 2023; Schieber et al. 2001; Tawfik et al. 2022; Toldrá et al. 2021).

Potential sources of food processing by-products and wastes. The processing of fruit can generate numerous by-products, including apple pomace, grape pomace, fruit peels, and fruit seeds, among others. Vegetable processing by-products include tomato pomace, peels, seed, onion, and garlic peels, among others. Most cereal by-products consist of wheat bran and germ, rice polish and germ, soybean meal, and quinoa bran. Sugar cane bagasse, sugar cane molasses, sugar cane tops, sugar beet pomace, and sugar beet tops are the by-products of sugar production. Several by-products, including bones, skin, blood, fat, and eggshells, can result from processing meat, fish, and eggs

To summarize, there are many sources of food and agricultural by-products, such as by-products of cereals, fruits, vegetables, meat, fish, and egg processing, where around 1.3 billion tons of food products are lost worldwide every year. About 20 million tons of soybean dregs in China are produced yearly.

Potential applications of by-products

Food production applications

In recent years, with the increasing concern about health and environmental protection, the by-products of edible plants have gradually become the most important resource in food production. These by-products can not only cost food processing but also pollute and waste resources. However, although these by-products have great potential to be used in food production, there are still many challenges and limitations in actual production. This section aims to discuss the current situation of the application of edible plant by-products in food production, the existing problems, and the future direction to provide a valuable reference for related research. Figure 3 shows the classification of potential applications using by-products of edible plants.

Potential applications of edible plants by-products. It consists primarily of five applications: oil and vinegar production, bioactive compounds, food additives, and edible coatings. Peels, seeds, fruits, and flowers are the primary sources of raw materials for this production among edible plants. With the aid of relevant industrial extraction technologies, various valuable new products can be obtained by utilizing these by-products in their natural state or after proper pretreatment. Mechanical pressing, supercritical fluid extraction, ultrasonic-assisted extraction, microwave-assisted extraction, ionic liquid extraction, and microbial fermentation extraction are the primary extraction methods used in these applications

Oil production

Today, which emphasizes sustainable development and environmental protection, the production of oil from the by-products of edible plants is a topic of great interest. Traditional methods of producing oil usually use many chemical processes, which not only pollute the environment but also have low resource utilization. In contrast, the rational use of edible plant by-products can not only reduce waste in the production process but also improve the efficiency and quality of oil production, thus achieving the goal of sustainable development. This section presents the status and future trends of research on the application of edible plant by-products in edible oil production from three aspects: types of by-products, oil production processes, and production effects. The parts with high oil content are the by-products of edible plants, seeds, fruits, and flowers. These oils can be extracted by mechanical pressing or solvent extraction (Kishikawa et al. 2015). However, these adversely affect human health because they need to use a lot of solvents and energy and produce a lot of waste and pollutants (Hanif et al. 2019). To overcome these problems, many researchers began to explore new ways to produce oil.

Microbial fermentation is a new kind of microorganism that can transform the by-products of edible plants into oils and fats (Vargas et al. 2020). These micro-organisms include yeasts, bacteria, and fungi. Various types of oils and fats, such as triglyceride phospholipids and triglycerides, can be produced efficiently by microbial fermentation. These oils can be used in biodiesel, bio-lubricating oil, and biodegradable plastics (Yeboah et al. 2021). Another emerging technology is the use of supercritical fluid technology (Zhou et al. 2021). Supercritical fluids can extract oils and fats from edible plant by-products under high pressure and high temperature, which is more environmentally friendly and efficient than mechanical pressing or solvent extraction. Studies have shown that supercritical fluid extraction can achieve higher oil production in a shorter time while also generating wastes and pollutants (Ahangari et al. 2021; Uwineza and Waśkiewicz 2020). For example, Zuo et al. (2008) and Alvarez et al. (2019) found that the extraction rate of isoflavones from soybean oil by supercritical carbon dioxide could reach 87.3% while avoiding solvent residue and improving purity.

In addition, others are used to produce oil from edible plant by-products, such as ultrasonic-assisted extraction, microwave-assisted extraction, and ionic liquid extraction. They can achieve efficient extraction of target substances by accelerating intermolecular interaction. These effects on oil production are one of the important directions of biofuel production (Ullah et al. 2019). For example, Kostas et al. (2020) used ultrasonic-assisted extraction to extract oil from olive cake and found that the extraction rate increased by about 30% compared with solvent extraction. Hu et al. (2019) used a microwave-assisted extraction method to extract oil from Camellia oleifera seeds, and it was found that the oil yield was nearly 11% higher than that of extraction, and the waste yield was also increased to a certain extent. Figure 4 summarizes the main extraction methods used to produce oil from the edible plant by-products.

Primary techniques for extracting oil from by-products of edible plants. Mechanical pressing refers to the physical squeezing of edible plant by-products by a stationary mechanical device to extract the oil. Ultrasonic-assisted extraction, microwave-assisted extraction, and ionic liquid extraction all require the grinding of by-product raw materials into ash, followed by separating oil components using an ultrasonic probe, microwave reactor, or ionic liquid. Supercritical fluid extraction is the separation of oil from liquid or solid using fluid in a thermodynamic state with a temperature greater than the critical temperature and a pressure greater than the critical pressure. Using microorganisms, microbial fermentation extraction refers to the conversion of plant by-products into oils

In terms of research, peanuts are a common food crop, and their shells are as rich in oil as the fruit. Studies have shown that oil can be extracted from peanut shells by supercritical fluid extraction techniques, and these oils can be used to produce edible oils (Çelebi et al. 2022; Imran et al. 2022). In addition, by-products from edible plants such as olive pomace, coconut shells, and grape seeds are also widely used in oil production. For example, coconut oil can be extracted from coconut shells by mechanical pressing, which is rich in chain fatty acids that can promote fat metabolism in the body and are beneficial for maintaining good health (Osman 2019). Mechanical pressing and supercritical extraction methods can be used to obtain edible oils from grape seeds, which are rich in oleic acid and antioxidants that help maintain health and prevent cardiovascular disease (Souza et al. 2020; Martin et al. 2020). In addition, for some regional by-products of edible plants, such as the husks of Ephedra spp. and the kernels of dates, the production of oils from them can also meet the needs of the food industry (Guenaou et al. 2021; Liu et al. 2020).

In addition to the use of existing edible plant by-products for oil production, the possibility of using new edible plant by-product resources for oil production has also been demonstrated. For example, coffee bean residues, as a waste product of coffee bean use, are crushed, screened, and dehydrated, based on which oil can be extracted, usually by supercritical carbon dioxide extraction and supercritical methanol extraction, resulting in coffee oil with a strong coffee flavor and rich in beneficial components such as caffeine and tannins (Álvarez et al. 2021; Dong et al. 2021). These components make coffee oil potentially useful for a wide range of applications in everyday cooking and food processing. At the same time, the production of coffee oil from coffee bean by-products can also effectively reduce the waste of coffee beans and the associated environmental pollution problems.

In conclusion, using edible plant resources to produce oil is a kind of edible production and an important way of comprehensive utilization of plant resources. Tables 1 and 2, respectively, summarize the main edible plant resources that can be used in oil production at present, and the main methods for oil extraction from edible plant by-products. Microbial fermentation and supercritical fluid extraction are widely used in current research, and the utilization of new edible plants is also being explored and studied. However, in the future, more research is needed to optimize these and develop more efficient and environmentally friendly production technologies to promote oil production from the by-products of edible plants.

Vinegar production

Vinegar is a popular condiment and can be used in various dishes and drinks. Although most vinegar is made by alcoholic fermentation, the technology of producing vinegar from by-products of edible plants has attracted more and more attention in recent years (Prisacaru et al. 2021). This technology can not only utilize the waste of by-products but also produce high-quality vinegar. The by-products of edible plants are an important source of raw materials in vinegar production. Some widely used plant by-products include apple pomace, banana skin, peanut skin, and grape skin. These plant by-products have nutrients such as high fiber, sugar, protein, and minerals, which can be used for vinegar fermentation (Kandylis 2019). In addition, the production of these by-products is also very large. Effective use of these by-products can improve resource utilization efficiency and help protect the environment.

Nowadays, more and more researchers are beginning to pay attention to the technology of producing vinegar by-products of edible plants. For example, apple pomace is a by-product of apple processing, which is rich in pectin, cellulose, and other nutrients and can be used to produce vinegar. At present, apple pomace is proved that it could be used as a raw material for vinegar, among which a typically one is found by Du et al. (2019), who reported that vinegar prepared by apple pomace fermentation under the condition of controlling temperature and pH value could achieve not only high acid production and flavor score but also achieve significant production cost, which has a good application prospect (Guiné et al. 2021). Banana peel is also a common by-product of processing, which is rich in nutrients such as potassium and vitamin C and can also be used to produce vinegar. In recent years, the banana peel has also been reported as a by-product of edible plants that can be used for fermentation to prepare vinegar. At the same time, the preparation technology and product quality were also discussed (Prisacaru et al. 2021). For example, Hikal et al. (2022) reported that vinegar with higher yield and taste could be continuously fermented using banana peel as raw material.

Similarly, peanut peel is a by-product of peanut processing, which is rich in dietary fiber, polyphenols, and other nutrients, and has good edible and medicinal value. In recent years, some attempts have been made to prepare vinegar from peanut skin, and some progress has been made. For example, Quintana et al. (2021) found that vinegar with peanut peel and banana peel as raw materials could also achieve satisfactory yield and quality requirements. In addition, grape skin is a by-product of wine processing, which is rich in polyphenols, minerals, and other nutrients, so it can also be used to produce vinegar. Studies have shown that polyphenols rich in grape skins have good antioxidant and anticancer effects and can improve the nutritional value of vinegar (Caponio et al. 2022). In recent years, attention has been paid to the potential of using grape skins to produce high-quality vinegar. For example, Debajyoti and Kumar (2023) found that vinegar made from grape skins and wine residues could not only be commercialized but also have strong antioxidant activity under controlled fermentation conditions. In addition to the plant by-products described above, many other edible plant by-products can also be used to produce vinegar, such as grapefruit peel, persimmon residue, and papaya peel. These by-products also contain rich nutrients with utilization value (Gohil et al. 2022). At present, the related research is gradually deepening to explore the application of more edible plant by-products in vinegar production. Table 3 summarizes the by-product resources and characteristics of the main edible plants that can be used to produce vinegar at present, as well as the related representative research progress.

In summary, the production of vinegar from the by-products of edible plants has the following advantages: (1) Reducing the waste and using by-products to produce valuable food; (2) Improving the efficiency of resource utilization; (3) The vinegar produced has high quality and unique flavor and nutritional components. However, this technology also has some shortcomings, such as: (1) The collection and treatment of raw materials need to invest more manpower, material resources, and financial resources; (2) Production is relatively more complex and requires more technical and equipment support. In addition, as this technology is still in its initial stage, some technical problems remain to be solved, such as microbial contamination and stability in production (Kumari et al. 2022). In the future, with the continuous development of vinegar production technology from edible plant by-products, it can be predicted that it will become an important production and bring positive benefits in conservation and resource utilization (Boistean 2021). At the same time, it is also necessary to further improve and optimize the production and equipment of this technology to solve technical problems and improve production efficiency and product quality to meet markets’ demands. In addition, the promotion and publicity of this technology should be strengthened to promote consumers’ awareness and acceptance of this environmentally friendly, healthy, and high-quality food.

Extraction of bioactive compounds

Bioactive compounds refer to chemical substances with specific biological activities and pharmacological effects. These compounds can come from different sources, such as plants, animals, and microorganisms. The activities and pharmacological effects of bioactive compounds include but are not limited to antioxidant, anti-inflammatory, antibacterial, anti-tumor, and lowering blood pressure and blood sugar. These compounds can be used in producing and researching industries such as medicines, health products, and foods (Cruz et al. 2022; Rashwan et al. 2022). There are different kinds and contents of bioactive compounds in the by-products of edible plants, such as peel, seed coat, seed shell, and leaf. The extraction of bioactive compounds includes water extraction, alcohol extraction, supercritical fluid extraction, microwave-assisted extraction, and ultrasonic extraction (Parra et al. 2021; Patra et al. 2022).

Water extraction is a kind of extraction with the characteristics of simple, environmental protection, and low cost, which is widely used in the extraction of natural products. Water extraction usually involves the steps of mixing raw materials with water and submerging them under high temperature or high pressure to extract, concentrate and separate the target compounds. However, some limitations of water extraction include low extraction efficiency, long extraction time, and easy decomposition (Fan and Gao 2022). Alcohol extraction is widely used in the extraction of natural products, which has the advantages of high extraction efficiency, fast extraction speed, and low extraction temperature. Organic solvents such as ethanol and methanol are often used as extractants, and different technical parameters and operating conditions are adopted to achieve the extraction and separation of target compounds. However, some disadvantages of alcohol extraction include that it is easy to lead to residues of extractant and may produce toxic products (Lefebvre et al. 2021).

In contrast, supercritical fluid extraction is efficient based on physical and chemical characteristics. It uses high pressure and temperature conditions to change the solvent into a supercritical state and has the advantages of high efficiency, environmental protection, fast speed, and little residue. This kind of supercritical solvent are usually non-polar substances such as carbon dioxide, methane, and propane, and the control of operation parameters and extraction conditions greatly influences the extraction effect. For example, Muangrat and Jirarattanarangsri (2020) proved that operating parameters and extraction conditions could control the extraction efficiency by using supercritical carbon dioxide to extract γ-linolenic acid from Camellia oleifera’s seed oil. However, it also has some limitations, including high equipment cost and high technical requirements (Gallego et al. 2019; Molino et al. 2020). In addition, microwave-assisted extraction is also a fast and efficient extraction, which has the advantages of accelerating extraction speed and improving extraction efficiency and solvent dosage. This is often done by heating the sample together with the solvent under a microwave field to rapidly dissolve the target compound in the solvent. For example, Boli et al. (2022) extracted the total phenols from olive leaves by microwave-assisted extraction, which was found to increase the extraction speed by an average of 1.5 times and also reduce the amount of solvent. However, some disadvantages of microwave-assisted extraction include the need for high-pressure reaction vessels to be heated easily (Wen et al. 2020). Table 4 summarizes the main advantages and limitations of current use for extracting bioactive compounds from by-products of edible plants.

At present, the use of by-products of edible plants to extract bioactive compounds is under investigation with an upward trend, which mainly focuses on improving extraction efficiency, the purity of compounds, and extraction costs. Through continuous research, researchers have found many effective extracts and successfully applied them to extract different bioactive compounds. For example, Peanparkdee and Iwamoto (2019) used ultrasonic-assisted extraction technology to extract polyphenols from rice straws and evaluated their antioxidant activity in the study of rice residues. The results showed that ultrasonic-assisted extraction was effective, and the antioxidant activity of polyphenols was higher. Pokkanta et al. (2022) also extracted polyphenols from rice husks by ultrasonic-assisted extraction and verified their protective effect on vascular endothelial cells by experiments. It is indicated that rice residue is a potential bioactive compound resource that can be extracted effectively by a series of related technologies.

In addition, tea residues were also considered as a potential source of bioactive compounds. In China, Shang et al. (2023) extracted flavonoids from tea trees’ flowers using microwave-assisted extraction technology, which proves that it has antioxidant and antibacterial activities. While in Indonesia, Djuardi et al. (2020) extracted tea polyphenols from tea dregs and proved them to have anti-inflammatory and antioxidant activities through experiments. Meanwhile, grape residue has been extensively studied, with researchers focusing on polyphenolic compounds. According to reports, Averilla et al. (2019) extracted resveratrol from grape skin using ultrasonic-assisted extraction technology and proved its antioxidant and anti-diabetic effects through experiments. At the same time, An et al. (2023) extracted proanthocyanidins from grape seeds and demonstrated that it could help to promote the proliferation of cancer cells and promoting tumor cell apoptosis.

It is also interesting to note that the olive tree (Olea europaea), one of the most widely cultivated fruit trees in the Mediterranean, is a potential source of bioactive compounds in addition to providing edible olive fruit (Abdallah et al. 2023). Olive trees are usually pruned in winter, and the branches, after pruning, contain many polyphenols and flavonoids. It is reported that olive pruning extract has significant antioxidant, antibacterial, and anti-inflammatory effects and low toxicity (Khwaldia et al. 2022). Esmeeta et al. (2022) investigated the inhibitory effect of olive pruning extract on human breast cancer cell lines and compared it with a chemotherapy drug (paclitaxel). The results showed that olive pruning extracts had the same anticancer effect as paclitaxel but had little effect on healthy cells. Calvano and Tamborrino (2022) compared olive pruning extract with green tea polyphenols and found that olive pruning extract had stronger antioxidant and anti-inflammatory effects. However, it is worth noting that the extraction of olive pruning is cumbersome, and the yield of the extract is low, which limits the possibility of large-scale production. In addition, the pruning and yield of olive trees are also affected by several factors, such as seasonal age and geographical location, which also bring some uncertainties to its application (González et al. 2022). Table 5 summarizes the main research progress of extracting bioactive compounds from by-products of edible plants in recent years.

In general, the advantages of extracting bioactive compounds from the by-products of edible plants are as follows: firstly, the by-products of edible plants can be fully utilized, which would not waste resources; Secondly, the extracted bioactive compounds can be used in the fields of medicine, health care products and food, and have high economic value and social value; Finally, using technologies such as supercritical fluid extraction can make the production more environmentally friendly by using organic solvents (Ramos et al. 2019). However, there are also some problems in this application, such as how to choose the extraction, improve the extraction efficiency, and ensure the purity of the extracted compounds, which need to be solved through continuous research and improvement (Khawli et al. 2020). It can be predicted that the public’s demand for bioactive compounds will increase with the improvement of people’s health awareness. Therefore, the use of extracting bioactive compounds from edible plant by-products can be used to reduce waste accumulation and landfilling costs. Valorization of these by-products could also encourage innovation, present business opportunities, and ultimately generate income from previously expensive waste material (Pandey 2019; Rashwan et al. 2023). At the same time, it is worth exploring more efficient and environmentally friendly extraction and continuing to find new bioactive compounds to provide better protection for human health and life.

Food additives

Food additives refer to chemical substances or products used to change food’s physical, chemical, biological, and nutritional characteristics, including preservatives, pigments, sweeteners, spices, sour agents, and stabilizers. The use of food additives can improve the taste, color, shelf life, safety, and other characteristics of food, to meet the needs and expectations of consumers (Williams and Phillips 2021). Rich bioactive substances such as polysaccharides, proteins, and phenolic compounds in the by-products of edible plants have certain nutritional and health care functions and can be applied to producing related food additives (Faustino et al. 2019; Rashwan et al. 2020). The extraction used in this application mainly includes water extraction, acid–base extraction, microwave-assisted extraction, and others. Among them, water extraction is one of the most commonly used extractions, which has the characteristics of simplicity, safety, and environmental protection; Acid–base extraction is suitable for extracting proteoglycan and other substances; Microwave-assisted extraction has the advantages of fast, high efficiency, and energy saving (Kumar et al. 2021; Xiang et al. 2022). At present, many studies on food additives produced from by-products of edible plants have been carried out all over the world, and abundant achievements have been made.

As one of the important research areas of food additives, researchers in Europe have carried out a series of studies. For example, Patocka et al. (2020) reported on the extraction of apple pectin from apple peel and its application in the production of a food additive containing two to three times more dietary fiber than in apple pulp, which provided a new way for resource utilization of apple peel. Although the research results in Europe are abundant, there are still some shortcomings, such as the lack of diversity of research objects, which need to further expand the research scope and strengthen cooperation. While in North America, the research on food additives is also active, and many researchers have also explored the related application. For example, Dean (2020) reported that polyphenols were extracted from peanut peel and applied to meat products and found that they had good antioxidant and fresh-keeping effects. In addition, Nasir et al. (2022) researched extracting cellulose from mung bean hull and found that it can be used as an emulsifier and stabilizer with wide application prospects. However, the research results in North America also have shortcomings, such as the lack of systematicness and comprehensiveness, which is needed to further expand the research scope and strengthen cooperation.

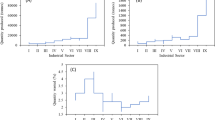

In addition, Asia, which is also rich in edible plants, is another important research area for producing food additives from by-products of edible plants. In Asia, many related by-products have been used to produce food additives, such as soybean dregs, red jujube dregs, and medlar dregs. These by-products not only come from a wide range of sources but also have high yields, so they have potential commercial value (Jiang et al. 2021; Rashwan et al. 2020). For example, soybean dregs are a common by-product of edible plants in China and Japan. About 20 million tons of soybean dregs in China are produced yearly. At present, researchers have used it to produce a variety of food additives such as soybean dregs polysaccharides, cellulose, and protein. These additives can be used in many food fields, such as beverages, dairy products, bread, and cakes (Kamble and Rani 2020; Zhou et al. 2019). Besides soybean dregs, jujube dregs and medlar dregs are also potential by-product resources. Researchers have found that they are rich in polysaccharides, flavonoids, and phenolic acids, which can be used to produce healthy foods, functional foods, and nutritional supplements. At present, there have been reports on the production of polysaccharide phenolic acid and other food additives from jujube dregs and medlar dregs (Chen et al. 2023; Farahani et al. 2022). Table 6 and Fig. 5 summarize the recent reports on the main research achievements in producing food additives from by-products of edible plants.

Research for food additives produced from edible plant by-products. As food additives, stabilizers and emulsifiers can be derived from polysaccharides in yogurt waste and cellulose in mung bean shells. Apple peel pectin is utilized in the production of dietary fiber, a type of bioactive food additive. Food additives derived from polysaccharides, cellulose, and protein in soybean dregs and polyphenols in peanut peel can be used to enhance the flavor of baked goods and the freshness of meat, respectively. The polysaccharides, flavonoids, and phenolic acids in jujube residue and medlar residue can be used to produce food additives with health benefits

On the other hand, some new by-products of edible plants have also aroused the interest and concern of scholars. Coffee grounds, for example, are by-products generated from coffee beans, which are usually regarded as wastes, but still contain various bioactive substances such as alkaloids and triterpenoids (Franca and Oliveira 2022). Therefore, researchers began to pay attention to the potential of coffee grounds as food additives. Gonçalves et al. (2019) evaluated polyphenols extracted from coffee grounds and applied them to the oxidative stability of whey protein isolate. The results showed that coffee grounds polyphenols could significantly improve the oxidative stability of whey protein isolate and its antioxidant capacity was equivalent to that of catechol, a commonly used synthetic antioxidant. Chatzimitakos et al. (2023) extracted polyphenols from coffee grounds and applied them to bread making. The results showed that polyphenols from coffee grounds could significantly improve bread’s antioxidant capacity without affecting bread’s texture and sensory quality. However, coffee grounds will be affected by different factors, such as the acidity of coffee preparation and polyphenol composition, so the application of coffee grounds as food additives needs more research (Bondam et al. 2022).

In addition, the cortex of fruits rich in many nutrients is usually regarded as waste. However, nutrients such as dietary fiber and vitamins contained in fruit peels have important physiological functions and antioxidant properties (Suri et al. 2022). For example, grape skin polyphenols can significantly improve the oxidative stability of fresh meat products without affecting the sensory properties of meat quality, so it is considered as a very potential food additive. Szmechtyk et al. (2021) found that adding it to fresh beef could prolong its shelf life (about 20 h) and improve its antioxidant and antibacterial properties. Sridhar and Charles (2021) have shown that it can be used to replace synthetic antioxidants to produce healthier and safer foods. In addition, Amorim et al. (2019) reported that polyphenols in grape skin can be used to produce cakes, bread, and other foods rich in antioxidants to enhance their nutritional value. Although some substances in grape skins have wide application prospects in the field of food additives, there are still some challenges and limitations. First, the high cost of mass production limits its wide application in the food industry. Secondly, grape skin’s safety and toxicological characteristics should be further studied to ensure its safe application in food. In addition, it is necessary to further study the interaction between grape skin polyphenols and other food components to better control their effects on food (Andrade et al. 2019).

From the above research results, it could be seen that Europe, North America, and Asia, which are rich in edible plant resources, are also important regions for extracting food additives from the by-products of such plants. It is worth noting that although results show that extracting food additives from by-products of edible plants is potential, there are also some challenges and limitations (Ueda et al. 2022). First, the composition and properties of by-products of different plants may vary greatly, so it is necessary to study each by-product in detail to determine the extraction and suitable application fields. Secondly, because the extraction of food additives from by-products is still in the exploratory stage, there may be some technical problems in the extraction, such as low yield and high cost. In addition, some by-products of edible plants may need special treatment to extract effective food additives, making the extraction complicated and costly (Andrade et al. 2023). In addition, although this application is regarded as environmentally friendly and feasible, there may be some limitations in practice. For example, extraction may consume a lot of water and energy and also produce some wastes and pollutants, which may have a certain impact (Aparicio 2021). Therefore, it is necessary to consider these feasibility problems when applying this method to actual production.

In general, extracting food additives from the by-products of edible plants is a promising way. It can make use of these by-products resources to avoid waste and pollution, and at the same time, provide more sustainable and healthy choices for the food industry. However, more research and work are still needed to overcome the technical challenges and limitations of applying this method to practical production.

Edible coatings production

Edible coatings are a chemical widely used in food packaging and food processing. Its purpose is to protect the quality of food, prolong the shelf life of food and improve the appearance of food. Edible coatings need to comply with relevant hygiene and regulations to ensure that they are harmless to human health. In recent years, the by-products of edible plants have been rich in various beneficial compounds, such as polysaccharides, proteins, and phenolic pigments, and they are used to produce and prepare food-grade coatings (Suhag et al. 2020). At present, many edible coatings can be extracted from edible plant by-products. For example, acid, base, or enzyme are used for extraction, or modern technologies such as supercritical fluid extraction, ultrasonic extraction, and microwave-assisted extraction are used for extraction (Yong and Liu 2021). In terms of application, researchers have successfully extracted edible coatings from various edible plant by-products, which have good application prospects in food packaging and processing.

In this status, León et al. (2018) used mango by-products (peels and seeds) to form a biodegradable food-grade coating with good permeability antioxidant properties, and better hydrophobicity. Experimentally, fresh peaches coated with this coating were found to produce significantly less ethylene and carbon dioxide and consume less oxygen compared to uncoated peaches. Jodhani and Nataraj (2021) prepared a food-grade coating by using extracts from aloe vera gel and lemon peel and tested it for physicochemical and biological properties. The results showed that bananas with this coating showed less weight loss and good hardness, no serious deterioration, and great preservation of biomolecules such as sugars, organic acids, and ascorbic acid in them; at the same time, without refrigeration, the shelf life of the bananas was extended by 9 days compared to the control group, thus gaining considerable acceptance in the market. Deepika et al. (2022) explored the application of technology using grape vines as feedstock. They also prepared a new type of edible paint by extracting ingredients such as cellulose and tannins. The research results show that the coating exhibits good stability and processability at different temperatures and has good water and oil repellency. Table 7 summarizes the main research progress in producing edible coatings from edible plant by-products in recent years.

In conclusion, using edible plant by-products to produce food-grade coatings has many advantages. First, the discharge of this kind of waste meets the requirements of protection and feasibility; Secondly, the coating made of natural substances is harmless to human health; In addition, plant by-products are rich in nutrients, which can also improve the nutritional value of food. However, there are still some challenges in the current research, such as high costs and unstable processes (Basumatary et al. 2022). In the future, it is necessary to further explore economical production and conduct more in-depth research on the safety and stability of these coatings.

Cosmetics, pharmaceuticals, and chemicals applications

Cosmetic, pharmaceutical, and chemical applications could be new trends to reuse by-products (Crini et al. 2019). For instance, a variety of substances, such as plasminogen, fibrinogen, fibrinolysin, serotonin, kalikreninsa, and immunoglobulins, are separated from the blood that represents as a by-product resulting from slaughterhouses (Young and Lawrie 1974). Besides, many blood products are utilized in the laboratory as nutrients for tissue culture media, an essential component of blood agar, and peptones for microbiological usage (Kurbanoglu and Kurbanoglu 2004). Furthermore, inedible fat can be used to produce cosmetics, whereas creams, lotions, and bath treatments made from fats are used on the hands and body. Plasticizers, lubricants, and softeners can all be made from rendered fats and used to polymerize rubber and plastic (Toldrá et al. 2021).

Moreover, the pharmaceutical business uses around 6.5% of the overall output of gelatin, which can be derived from the bones and skin of fish and animals. In which, most of the gelatin is used to make the outer shell of capsules. Besides, gelatin can be used to produce medicated tablets and pastilles as a binding and compounding agent, which is considered a key component of protective ointments such as zinc gelatin for treating ulcerated varicose veins. Whipping gelatin into a foam, treating it with formaldehyde, and drying it result in a sterile sponge that is used in surgery as well as to directly implant a drug or antibiotic into a specific area (Jayathilakan et al. 2012). Additionally, the bioactive substances found in olive by-products have an intriguing mineral composition, significant antioxidant activity (particularly for oleuropein), and a distinctive fatty acid profile. Thus, olive by-products can be used in the field of skincare products and cosmetics, as those bioactive compounds can fulfill a real cosmetic function and activity (Rodrigues et al. 2015).

By-products of cork also can be repurposed as promising ingredients in topical products that may be used in a variety of pharmaceutical and cosmetic applications, such as the prevention of skin aging and skin depigmentation activity, or as a supplement in the treatment of acne and inflammatory skin processes (Carriço et al. 2018). A day cream with enhanced benefits and sun protection features was created using cocoa husk extracts with significant antioxidant and antiradical activity (Gajić et al. 2023). The extracts in this study were distinguished by their high concentrations of total proteins (10–27%), total phenols (37–45 mg of gallic acid equivalents/gram), and total flavonoids (14–21 mg of rutin equivalents/gram). Moreover, the potassium, sodium, and calcium mineral concentrations were 41–60, 0.8–1.2, and 2.5–5.9 mg/100 g, respectively. Total antioxidant activity was between 14 and 20 mg of ascorbic acid equivalents per 100 g of dry weight, while antiradical activity against 2,2-Diphenyl-1-picrylhydrazyl and 2,2’-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) radicals had the half maximal inhibitory concentration values of 11–13 and 7–9 g/mL, respectively. To demonstrate the safety of the newly developed product based on subcritical water extracts of the cocoa hull, the prepared facial cream was examined concerning fundamental quality characteristics for cosmetic products (Gajić et al. 2023).

To summarize, the pharmaceutical business uses around 6.5% of the overall output of gelatin, which can be derived from the bones and skin of fish and animals. Besides, olive by-products can be used in the field of skincare products and cosmetics, as those bioactive compounds can fulfill a real cosmetic function and activity. Moreover, a day cream with enhanced benefits and sun protection features was created using cocoa husk extracts with significant antioxidant and antiradical activity.

Animal nutrition application

Ruminant animals can transform nutrients from by-products and forages that are indigestible to humans into food that humans can eat. In which these animals can digest fibrous forages and feeds because of the bacteria in their rumen, which are not used by people or animals with monogastric stomachs like pigs. Thus, feeding animals’ by-products are the greatest way to turn these wastes into valuable products and lessen environmental problems (Ondarza and Tricarico 2021a, b; Raamsdonk et al. 2023). For instance, canola and soybean meals (80% of the bean) are often used as the main source of protein in dairy diets after producing canola and soybean oil for human consumption. Besides, around half of the corn grain used to make ethanol or human food is left over for animal feed (Ondarza and Tricarico 2021a, b).

As a potential prebiotic supplement for hens, lignin from sugarcane bagasse was added at 1% (weight/weight) to commercial chicken feed and studied in two feed forms: mash and pellets (Fangueiro et al. 2023). Regarding the physical characteristics of the pellets, lignin increased the cohesiveness of the pellets, indicating a higher resistance to breakout, and lignin reduces the propensity of the pellets for microbiological contamination. In terms of prebiotic potential, mash feed containing lignin promoted the growth of Bifidobacterium more than mash feed without lignin or lignin-containing pellet feed (Fangueiro et al. 2023). Furthermore, in the complete diets of growing ram lambs, the authors used sweet sorghum bagasse that was processed into an expander extruded. They discovered that feeding sweet sorghum bagasse processed significantly increased the average daily gain of ram lambs. Furthermore, feed conversion efficiency (kilogram/kilogram gain) and cost Rupees per kilogram live weight gain were higher in sweet sorghum bagasse processed-fed lambs than in pre-slaughter weight (Kumari et al. 2023).

Another study examined the effects of sugarcane bagasse as the sole source of roughage on the digestibility, composition, and production of milk in breastfeeding buffaloes and microbial protein. According to the findings, adding sugarcane bagasse to rations enhanced in vitro dry matter digestion and organic matter digestion degradability compared to the control. With improved ruminal fundamentals, the complete substitution of barley straw with sugarcane bagasse 40% greatly raised the nutritional digestibility coefficient. Compared to control buffaloes, buffaloes given 40% sugarcane bagasse had higher milk component yields, 4% fat-corrected milk and plasma proteins, and lower plasma creatinine and cholesterol (Abd El-Mola and Elnesr 2022). The effects of supplementing pomegranate peel and olive pomace on rabbit doe reproductive and oxidative state were investigated. Compared to the control, feeding animals a diet containing 4.5% pomegranate peel significantly increased the serum levels of gonadotropic hormones and oestradiol-17 two hours after mating, on the 20th day of lactation, and after weaning. It also significantly increased progesterone levels at mid-pregnancy and prolactin on the 10th day of lactation. The results also showed that animals fed with pomegranate peel at a 4.5% concentration and a blend of pomegranate peel and olive pomace showed substantial improvements in total deoxyribonucleic acid, protein concentration, litter size, milk yield, and nest characteristics (Bakeer et al. 2022).

To summarize, following the production of canola and soybean oil for human use, canola, and soybean meals (80% of the bean) are frequently employed as the main source of protein in dairy diets. Furthermore, around half of the corn grain used to manufacture ethanol or human food is left behind for animal feed. Adding sugarcane bagasse to meals improved in vitro dry matter digestion and organic matter digestion degradability.

Plant nutrition application

Currently, increased efforts are being placed on processing locally available agro-industrial by-products and transforming them into value-added products that can contribute to the sustainability of agroecosystems (Jiang et al. 2021). Several studies have proposed various low-cost bioenergy by-products (such as biochar, bottom ash, and biogas slurry) as a good solution for soil remediation and a useful source of plant nutrition (Fig. 6) (Ehaliotis et al. 2005; Sattar et al. 2023).

Bioenergy by-products such as biochar, bottom ash, and biogas slurry play a significant role in promoting soil remediation and plant nutrition. The incorporation of these by-products into the soil can result in numerous advantages. First, they can increase the soil’s organic carbon (OC), phosphorus (P), nitrogen (N), calcium (Ca), sulfur (S), potassium (K), aluminum (Al), and iron (Fe) levels. Second, they can enhance soil water retention and aggregation, as well as neutralize soil pH, ultimately enhancing soil quality. In addition, bioenergy by-products can stimulate plant growth by promoting root development and boosting chlorophyll fluorescence, photosynthesis, chlorophyll pigments, biomass accumulation, and leaf area. These advantages can lead to improved plant health and yield, ultimately benefiting agricultural practices and the sustainability of ecosystems

Biochar, a solid carbonaceous material produced by pyrolysis (less than 700 °C), is a carbon-rich and stable organic material (Kim et al. 2018; Pandey et al. 2020). Biochar application can increase long-term soil carbon storage (Keith et al. 2011), reduce soil acidity (Wang et al. 2014), improve soil water-holding capacity (Li et al. 2019), and increase crop yields (Hu et al. 2021), especially in nutrient-poor soils (Xie et al. 2013). It also has the potential to neutralize soil pH ands serve as a source of essential nutrients and a soil conditioner to improve overall soil health (Wang et al. 2023). Due to its liming potential and nutrient-rich characteristics, bottom ash can also be used as a soil amendment to offset soil nutrient deficiencies and thus boost plant development (Vassilev et al. 2013). The combined application of biochar and ash has been shown to improve soil physicochemical properties and increase soil fertility (Sattar et al. 2023). Biochar and ash exhibit increased chemical activity toward inorganic and organic compounds in the soil environment, highlighting their potential application in the remediation of chemically degraded soils (Laird et al. 2010).

Biogas slurry, on the other hand, is a liquid by-product formed from the anaerobic digestion of organic wastes such as crop straw, animal manure, and municipal waste (Chen et al. 2022). Biogas slurry can be used to promote resource conservation, soil health improvement, and climate change mitigation by reducing intensive mineral fertilizers use (Haefele et al. 2011). The use of biogas slurry as a soil amendment improves soil fertility by reducing soil erosion, improving water infiltration and nutrient cycling, and mediating air permeability (Whitman et al. 2011). The alkaline nature of biogas slurry (pH higher than 7.5) helps to reduce soil acidity when applied to acidic soils (Zhang et al. 2010). Thus, the incorporation of biochar, ash, and biogas slurry into the soil has the potential to alter soil acidity and neutralize soil pH, which would improve root growth and increase photosynthetic and photochemical activities, leading to higher plant growth and yield (Fig. 6) (Sattar et al. 2023).

Furthermore, several other by-products have recently been evaluated as sources of plant nutrition. Phosphogypsum, a by-product of fertilizer production from phosphate rock, has been suggested as an amendment to improve soil health and increase crop yields due to its rich content of key elements such as phosphorus, calcium, and sulfur (Hanafi et al. 2021). Recent studies have highlighted the potential of manufacturing organic fertilizer from soy whey, a nutrient-rich by-product produced during tofu processing, as an enriched nitrogen resource for plant growth (Chua and Liu 2019; Dai et al. 2021). This, in turn, could contribute to the win–win effect of sustainable production for both the soy products industry and plant nutrition (Dai et al. 2023). Lignocellulosic plant residues have been shown to have a positive effect on soil fertility and plant growth (Alokika et al. 2022). Excreted coffee grounds have also been suggested as an organic soil amendment leading to improved soil fertility, increased soil microbial diversity, improved structural stability of soil aggregates, improved water-holding capacity, and reduced bulk density (Mata et al. 2022).

When added to soils, mining by-products can be a source of multiple nutrients essential to plant growth (Ramos et al. 2020). This practice could be a cost-effective solution for providing nutrients while providing a value-added option for the sustainable disposal of rock mining by-products (Medeiros et al. 2021). Another feature is that agro-industrial by-products can be slowly composted to produce xenobiotic-free and nutrient-rich composts (Ehaliotis et al. 2005). If no turning occurs, the thermophilic stages of composting can continue for weeks, releasing heat into the environment (Tiquia et al. 2002). This heat could instead warm shallow-rooted plant roots (Ehaliotis et al. 2005). For instance, the application of agro-industrial by-products from the olive mill (leaves and pomace) warmed the rhizosphere of cucumber plants during an extended in situ composting process conducted beneath the plants’ root systems (Ehaliotis et al. 2005).

To summarize, the initial research results indicate the possibility of producing organic fertilizers from agro-industrial by-products, which can be a viable alternative to chemical fertilizers. Furthermore, the bioenergy by-products offer positive attributes that make them suitable for improving soil health and promoting plant growth. In this regard, we advocate further research to assess the economic and social viability of locally manufacturing these by-products as soil amendments.

Biogas production application

Biogas is a mixed gas produced by microbial decomposition of biomass under anaerobic conditions. Its main components are methane (50–75%) and carbon dioxide (25–50%), and it also contains a small amount of hydrogen, nitrogen, oxygen, and hydrogen sulfide. Biogas is a kind of renewable energy that is widely used in power generation, heating, and fuel fields (Abanades et al. 2022). In biogas production, the by-products of edible plants can replace biomass as raw materials, which not only can discharge pollutants but also can produce renewable energy. Figure 7 summarizes the production process of biogas and generates the advantages and disadvantages of utilizing biogas resources.

Advantages and disadvantages of biogas resources as well as the biogas production method. First, animal husbandry, plant, and food residues are gathered in a stationary container for anaerobic fermentation. Subsequently, fermented biogas resources will be stored in another container and converted into electricity and heat energy for human consumption as needed. The advantages of biogas resources include environmental friendliness, low cost, and a reduced greenhouse effect. However, biogas resources have disadvantages such as a small scale, few technological advancements, the presence of pollutants, and its inapplicability to densely populated areas

In this process, the by-products of edible plants usually need to be pretreated, such as crushing, adding water, and heating. The treated by-products can be mixed with water, and then the biogas digester passes through the corresponding biogas generation. Currently, two main production methods are used in the application: anaerobic fermentation and bio-methanation. In anaerobic fermentation, by-products of edible plants are first added to anaerobic reactors and then produced by a series of microbial metabolic reactions. In bio-methanation, the by-products of edible plants are first converted into reaction raw materials, and then bio-methanation reactions are carried out to produce biogas (Kasinath et al. 2021; Obaideen et al. 2022).

In recent years, researchers in many countries have been exploring the application of by-products of edible plants in biogas production. Szilágyi et al. (2021) found that by-products from tomato processing (tomato peels and pomace) can be good symbiotic substrates with maize straw for biogas production in continuous anaerobic fermentation. Similarly, Muenmee and Prasertboonyai (2021) investigated the potential of different types of fruit waste (durian shells, dragon fruit peels, and pineapple peels) in combination with other food waste to produce biogas in a series of experiments. It was found that co-fermentation of durian shells and food waste increased methane production and reduced start-up time compared to conventional single food waste fermentation. In addition, Narendra et al. (2021) investigated the potential of mixing Durva grass, common in rural India, with mango peel to produce biogas and experimentally demonstrated that a specific combination (10% mango peel + 50% Durva grass + 10% livestock residue + 30% water) resulted in 8.5 cubic meters of biogas and 72.3% methane yield, which is of good energy utilization value.

On the other hand, several new edible plant by-products have also proved to be useful for biogas production. One noteworthy application is the use of coffee bean residues for biogas production, which are generally discarded as waste after use but can be a very promising but almost unexplored substrate for biogas production. Vanyan et al. (2022) obtained high biogas yields under anaerobic and weakly alkaline conditions (pH approximately 7.5) by combining coffee bean residues with alcoholic waste in their study. In addition, Lotisa et al. (2022) investigated the ability to produce biogas from soya bean residue, papaya peel, and sugar cane bagasse in batch experiments and analyzed the methane production from biogas produced from different feedstocks using gas chromatography. The results showed that biogas produced from soya bean residue, papaya peel and sugarcane bagasse had good production efficiency with methane yields of 57.1, 53.7, and 49.1% respectively. According to the research results, using the by-products of edible plants as raw materials for biogas production has a series of advantages: (1) Possibility: the by-products of edible plants are renewable resources that can replace fossil energy; (2) Environmental protection: Using it as biogas raw material can discharge pollutants and have a positive effect on protection; (3) Economy: compared with the use of new raw materials such as biomass energy, the production cost can be reduced, and the economic benefit can be improved. However, at the same time, its use inevitably has some disadvantages, such as high treatment costs and the need to solve the problems of odor and waste treatment (Petrovič et al. 2022; Scano et al. 2021). Generally, in the future, with the output of edible plant by-products, the application of edible plant by-products as biogas raw materials will expand gradually. At the same time, the related technology and equipment will be continuously upgraded to improve the efficiency and economy of biogas production. In addition, some research on new power generation technologies using biogas is also underway, which will further promote the application of edible plant by-products in biogas production (Valenti and Porto 2019).

In conclusion, by-products from edible plants have a wide range of promising applications in biogas production. However, there are differences in the biodegradability, gas production, and quality of by-products from various edible plants (Ravindran et al. 2022). Therefore, in practical applications, the by-products of different edible plants need to be analyzed and screened to select the appropriate by-products and suitable treatment methods to maximize biogas production and quality. In addition, there are some advantages and disadvantages of edible plant by-products in biogas production at the same time, and future research should give sufficient consideration and attention to these aspects and try to propose more effective treatment options.

Conclusion

The utilization of food and agricultural by-products is an important subject to discuss, given the current pro-environmental and pro-ecological trends, as well as the diverse legal regulations around the globe. Every year, one-third of the food intended for human consumption is lost or wasted during production and distribution. Significant food loss and waste are indicative of an inefficient food system, which negatively affects food security, the environment, producer profitability, consumer pricing, and climate change. Approximately 1.3 billion tons of food are lost annually on a global scale, and China alone produces 20 million tons of soybean dregs annually. Consequently, a variety of applications can be utilized to address the issue of food and agricultural by-products. These applications include food production, pharmaceuticals, animal nutrition, plant nutrition, and energy production (biogas). In food applications, the by-products of food and agriculture can be recycled for the extraction of oil and bioactive compounds, which can be used as food additives, as well as the production of vinegar, wine, and edible coatings. Among the food applications, the extraction of bioactive compounds is considered the best option for recycling food and agriculture by-products, where the bioactive compounds represent approximately 8–20% of apple pomace, 5–17% of orange peel, 10–25% of grape seeds, 3–15% of pomegranate peel, and 2–13% of date palm seeds. Moreover, the pharmaceutical business uses around 6.5% of the overall output of gelatin, which can be derived from the bones and skin of fish and animals. Besides, animals fed with pomegranate peel at a 4.5% concentration and a blend of pomegranate peel and olive pomace showed substantial improvements in total deoxyribonucleic acid, protein concentration, litter size, milk yield, and nest characteristics. Additionally, the initial research results indicate the possibility of producing organic fertilizers from agro-industrial by-products, which can be a viable alternative to chemical fertilizers. Besides, biogas produced from soybean residue, papaya peel, and sugarcane bagasse had good production efficiency with methane yields. Therefore, this work can pique the interest of scientists and industry professionals.

References

Abanades S et al (2022) A critical review of biogas production and usage with legislations framework across the globe. Int J Environ Sci Technol 19:3377–3400. https://doi.org/10.1007/s13762-021-03301-6

Abd El-Mola AA, Elnesr SS (2022) Influence of sugarcane bagasse on in vitro degradability, rumen characteristics, nutrients digestibility, blood parameters and milk production of lactating buffaloes. Anim Biotechnol 17:1–9. https://doi.org/10.1080/10495398.2022.2149546

Abdallah M et al (2023) Useful bioactive compounds from olive tree by-products (Leaves, Branches, Fruits). In: Ramawat KG, Mérillon J-M, Arora J (eds) Agricultural waste: environmental impact, useful metabolites and energy production. Springer Nature Singapore, Singapore, pp 331–358. https://doi.org/10.1007/978-981-19-8774-8_13

Ahangari H et al (2021) Supercritical fluid extraction of seed oils—a short review of current trends. Trends Food Sci Technol 111:249–260. https://doi.org/10.1016/j.tifs.2021.02.066

Alokika et al. (2022) Utilization of lignocellulosic plant residues for compost formation and its role in improving soil fertility. Pedosphere https://doi.org/10.1016/j.pedsph.2022.11.008

Alvarez MV et al (2019) Valorization of an agroindustrial soybean residue by supercritical fluid extraction of phytochemical compounds. J Supercrit Fluids 143:90–96. https://doi.org/10.1016/j.supflu.2018.07.012

Álvarez P et al (2021) Supercritical CO2-ethanol extraction of oil from green coffee beans: optimization conditions and bioactive compound identification. J Food Sci Technol 58:4514–4523. https://doi.org/10.1007/s13197-020-04933-1

Amorim FL et al (2019) Grape peel (Syrah var.) jam as a polyphenol-enriched functional food ingredient. Food Sci Nutr 7:1584–1594. https://doi.org/10.1002/fsn3.981

An Q et al (2023) Prospects for proanthocyanidins from grape seed: extraction technologies and diverse bioactivity. Food Rev Intl 39:349–368. https://doi.org/10.1080/87559129.2021.1906699

Andrade MA et al (2019) Pomegranate and grape by-products and their active compounds: are they a valuable source for food applications? Trends Food Sci Technol 86:68–84. https://doi.org/10.1016/j.tifs.2019.02.010

Andrade MA et al (2023) Citrus by-products: valuable source of bioactive compounds for food applications. Antioxidants 12:38. https://doi.org/10.3390/antiox12010038

Aparicio I (2021) Chapter 19 - Plant-based by-products. In: Galanakis CM (ed) Food Waste Recovery, 2nd edn. Academic Press, San Diego, pp 367–397. https://doi.org/10.1016/B978-0-12-820563-1.00022-6

Apekshita S et al (2021) Functional uses of peanut (Arachis hypogaea L.) Seed storage proteins. In: Jose Carlos J-L (ed) Grain and Seed Proteins Functionality. IntechOpen, Rijeka. https://doi.org/10.5772/intechopen.96871

Averilla JN et al (2019) Improved extraction of resveratrol and antioxidants from grape peel using heat and enzymatic treatments. J Sci Food Agric 99:4043–4053. https://doi.org/10.1002/jsfa.9632

Bakeer M et al (2022) Effects of pomegranate peel and olive pomace supplementation on reproduction and oxidative status of rabbit doe. J Anim Physiol Anim Nutr 106:655–663. https://doi.org/10.1111/jpn.13617

Basumatary IB et al (2022) Edible films and coatings. Biopolymer-based food packaging. Wiley, UK, pp 445–475. https://doi.org/10.1002/9781119702313.ch14

Boistean A (2021) Aspects of vinegars production and marketing in Moldova. J Social Sci 4:128–138. https://doi.org/10.52326/jss.utm.2021.4(2).13

Boli E et al (2022) Recovery of bioactive extracts from olive leaves using conventional and microwave-assisted extraction with classical and deep eutectic solvents. Separations 9:255. https://doi.org/10.3390/separations9090255

Bondam AF et al (2022) Phenolic compounds from coffee by-products: extraction and application in the food and pharmaceutical industries. Trends Food Sci Technol 123:172–186. https://doi.org/10.1016/j.tifs.2022.03.013

Calvano CD, Tamborrino A (2022) Valorization of olive by-products: innovative strategies for their production. Treat Charact Foods 11:768. https://doi.org/10.3390/foods11060768

Caponio GR et al (2022) Nutraceuticals: focus on anti-inflammatory, anti-cancer, antioxidant properties in gastrointestinal tract. Antioxidants 11:1274. https://doi.org/10.3390/antiox11071274

Carriço C et al (2018) Converting cork by-products to ecofriendly cork bioactive ingredients: novel pharmaceutical and cosmetics applications. Ind Crops Prod 125:72–84. https://doi.org/10.1016/j.indcrop.2018.08.092

Çelebi H et al (2022) A beneficial bio-waste with a zero-waste approach: peanut shell. Biol Life Sci Forum 20:8. https://doi.org/10.3390/IECBM2022-13381

Chatzimitakos T et al (2023) optimized isolation procedure for the extraction of bioactive compounds from spent coffee grounds. Appl Sci 13:2819. https://doi.org/10.3390/app13052819

Chen S et al (2022) Substituting urea with biogas slurry and hydrothermal carbonization aqueous product could decrease NH3 volatilization and increase soil DOM in wheat growth cycle. Environ Res 214:113997. https://doi.org/10.1016/j.envres.2022.113997

Chen K et al (2023) New process of goji fermented wine: effect of goji residue degradation to generate norisoprenoid aroma compounds. Food Sci Technol 43:e126522. https://doi.org/10.1590/fst.126522

Chua J-Y, Liu S-Q (2019) Soy whey: more than just wastewater from tofu and soy protein isolate industry. Trends Food Sci Technol 91:24–32. https://doi.org/10.1016/j.tifs.2019.06.016

Čolović D et al (2019) Plant food by-products as feed: Characteristics, possibilities, environmental benefits, and negative sides. Food Rev Intl 35:363–389. https://doi.org/10.1080/87559129.2019.1573431

Crini N et al (2019) Applications of chitosan in food, pharmaceuticals, medicine, cosmetics, agriculture, textiles, pulp and paper, biotechnology, and environmental chemistry. Environ Chem Lett 17:1667–1692. https://doi.org/10.1007/s10311-019-00904-x

Cruz JMDA et al (2022) Ficus spp. fruits: bioactive compounds and chemical, biological and pharmacological properties. Food Res Int 152:110928. https://doi.org/10.1016/j.foodres.2021.110928

Dai Y et al (2021) Biotransformation of soy whey into a novel functional beverage by Cordyceps militaris SN-18. Food Product Process Nutrition 3:13. https://doi.org/10.1186/s43014-021-00054-0

Dai Y et al (2023) Tofu by-product soy whey substitutes urea: Reduced ammonia volatilization, enhanced soil fertility and improved fruit quality in cherry tomato production. Environ Res 226:115662. https://doi.org/10.1016/j.envres.2023.115662

Dean LL (2020) Extracts of peanut skins as a source of bioactive compounds: methodology and applications. Appl Sci 10:8546. https://doi.org/10.3390/app10238546

Debajyoti S, Prabir Kumar D (2023) Bioconversion of agricultural and food wastes to vinegar. In: Heena S, Priyanka Singh R (eds) Updates on Fermentation. IntechOpen, Rijeka. https://doi.org/10.5772/intechopen.109546

Deepika C et al (2022) Edible coatings and films from agricultural and marine food wastes. Biotechnology for Zero Waste. Wiley, Germany, pp 543–556. https://doi.org/10.1002/9783527832064.ch35

Djuardi AUP et al (2020) Emulsifying properties and antioxidant activity of soy protein isolate conjugated with tea polyphenol extracts. J Food Sci Technol 57:3591–3600. https://doi.org/10.1007/s13197-020-04391-9

Dong W et al (2021) Comparison of the effect of extraction methods on the quality of green coffee oil from Arabica coffee beans: lipid yield, fatty acid composition, bioactive components, and antioxidant activity. Ultrasonics Sonochem 74:105578. https://doi.org/10.1016/j.ultsonch.2021.105578

Du G et al (2019) Phenolic composition of apple products and by-products based on cold pressing technology. J Food Sci Technol 56:1389–1397. https://doi.org/10.1007/s13197-019-03614-y

Efenberger-Szmechtyk M et al (2021) Plant extracts rich in polyphenols: antibacterial agents and natural preservatives for meat and meat products. Crit Rev Food Sci Nutr 61:149–178. https://doi.org/10.1080/10408398.2020.1722060

Ehaliotis C et al (2005) Residues and by-products of olive-oil mills for root-zone heating and plant nutrition in organic vegetable production. Sci Hortic 106:293–308. https://doi.org/10.1016/j.scienta.2005.04.006

Esmeeta A et al (2022) Plant-derived bioactive compounds in colon cancer treatment: an updated review. Biomed Pharmacother 153:113384. https://doi.org/10.1016/j.biopha.2022.113384

Espínola F et al (2021) Processing effect and characterization of olive oils from spanish wild olive trees (Olea europaea var. sylvestris). Molecules 26:1304. https://doi.org/10.3390/molecules26051304

Fan R, Gao Y (2022) Maillard and hydrolytic reactions in subcritical water extraction of bioactive compounds from licorice. Molecules 27:6851. https://doi.org/10.3390/molecules27206851

Fangueiro JF et al (2023) Lignin from sugarcane bagasse as a prebiotic additive for poultry feed. Int J Biol Macromol 239:124262. https://doi.org/10.1016/j.ijbiomac.2023.124262

FAO. (2011) Food and agriculture organization of the united nations, global food losses and food waste-extent, causes and prevention. https://www.fao.org/3/i2697e/i2697e.pdf/Accessed

Farahani Z et al (2022) Modification of sodium alginate by octenyl succinic anhydride to fabricate beads for encapsulating jujube extract. Curr Res Food Sci 5:157–166. https://doi.org/10.1016/j.crfs.2021.11.014

Faustino M et al (2019) Agro-food byproducts as a new source of natural food additives. Molecules 24:1056. https://doi.org/10.3390/molecules24061056

Fawzy S et al (2020) Strategies for mitigation of climate change: a review. Environ Chem Lett 18:2069–2094. https://doi.org/10.1007/s10311-020-01059-w

Franca AS, Oliveira LS (2022) Potential uses of spent coffee grounds in the food industry. Foods 11:2064. https://doi.org/10.3390/foods11142064

Gajić J et al (2023) ESG approach in the valorization of cocoa (Theobroma cacao) by-products by subcritical water: application in the cosmetic industry. Sustain Chem Pharm 31:100908. https://doi.org/10.1016/j.scp.2022.100908

Gallego R et al (2019) Sub- and supercritical fluid extraction of bioactive compounds from plants, food-by-products, seaweeds and microalgae—an update. TrAC, Trends Anal Chem 116:198–213. https://doi.org/10.1016/j.trac.2019.04.030

Gohil K et al (2022) Production, cost analysis, and marketing of acetic acid (Vinegar). In: Amaresan N, Dharumadurai D, Cundell DR (eds) Industrial microbiology based entrepreneurship: making money from microbes. Springer Nature Singapore, Singapore, pp 93–115. https://doi.org/10.1007/978-981-19-6664-4_8

Gómez-García R et al (2021) Valorisation of food agro-industrial by-products: from the past to the present and perspectives. J Environ Manag 299:113571. https://doi.org/10.1016/j.jenvman.2021.113571

Gonçalves M et al (2019) Extraction, identification and quantification of polyphenols from spent coffee grounds by chromatographic methods and chemometric analyses. Waste Manage 96:15–24. https://doi.org/10.1016/j.wasman.2019.07.009

González MJ et al (2022) Wood waste from fruit trees: biomolecules and their applications in agri-food industry. Biomolecules 12:238. https://doi.org/10.3390/biom12020238

Guenaou I et al (2021) Bioactive compounds from ephedra fragilis: extraction optimization, chemical characterization, antioxidant and antiglycation activities. Molecules 26:5998. https://doi.org/10.3390/molecules26195998

Guiné RPF et al (2021) Apple fermented products: an overview of technology, properties health effects. Processes 9:223. https://doi.org/10.3390/pr9020223

Haefele SM et al (2011) Effects and fate of biochar from rice residues in rice-based systems. Field Crop Res 121:430–440. https://doi.org/10.1016/j.fcr.2011.01.014

Hanafi MM et al (2021) Valorization of rare earth processing byproducts for agriculture usage. Sci Rep 11:15234. https://doi.org/10.1038/s41598-021-93704-9

Hanif MA et al (2019) Essential oils. In: Malik S (ed) Essential oil research: trends in biosynthesis, analytics, industrial applications and biotechnological production. Springer International Publishing, Cham, pp 3–17. https://doi.org/10.1007/978-3-030-16546-8_1

Hikal WM et al (2022) Banana peels: a waste treasure for human being. Evid Based Complement Altern Med 2022:7616452. https://doi.org/10.1155/2022/7616452

Hu B et al (2019) A method for extracting oil from tea (Camelia sinensis) seed by microwave in combination with ultrasonic and evaluation of its quality. Ind Crops Prod 131:234–242. https://doi.org/10.1016/j.indcrop.2019.01.068

Hu Y et al (2021) After-effects of straw and straw-derived biochar application on crop growth, yield, and soil properties in wheat (Triticum aestivum L.) -maize (Zea mays L.) rotations: a four-year field experiment. Sci Total Environ 780:146560. https://doi.org/10.1016/j.scitotenv.2021.146560

Imran A et al (2022) Extraction, amino acid estimation, and characterization of bioactive constituents from peanut shell through eco-innovative techniques for food application. Int J Food Prop 25:2055–2065. https://doi.org/10.1080/10942912.2022.2119999

Jayathilakan K et al (2012) Utilization of byproducts and waste materials from meat, poultry and fish processing industries: a review. J Food Sci Technol 49:278–293. https://doi.org/10.1007/s13197-011-0290-7