Abstract

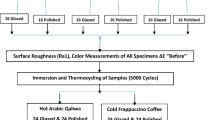

To evaluate the effect of two different additive manufacturing technologies on the color stability, surface roughness and biaxial flexural strength of interim restorative materials after thermal aging. Disk-shaped specimens were manufactured via two types of vat polymerization methods [Stereo-lithography (SLA) and digital light processing (DLP)] and milling technology (n = 16). CIELab color coordinates and surface roughness were measured before and after thermal cycling. Then biaxial flexural strength tests were performed using a universal testing machine. The data were analyzed by Kruskal–Wallis, one-way ANOVA, and Tamhane and Tukey HSD tests (α < 0.05). There was no significant difference among ΔE values of all study groups (p = 0.191). The milled group showed a higher initial surface roughness value (p < 0.05), while there was no significant difference among the other groups after aging (p = 0.213). DLP had significantly lower flexural strength values than SLA and Milled (p = 0.000). After aging, SLA and DLP were similar to milling method, in terms of color stability and surface roughness. However, milling had an adverse effect on the initial surface roughness. The SLA and milled groups had better mechanical properties than the DLP group.

Similar content being viewed by others

Data availability

All data included in this study are available upon request by contact with the corresponding author.

References

Abad-Coronel C, Carrera E, Mena Cordova N, Fajardo JI, Aliaga P. Comparative analysis of fracture resistance between CAD/CAM materials for interim fixed prosthesis. Materials (Basel). 2021;14:7791.

Nasiry Khanlar L, Revilla-León M, Barmak AB, Ikeda M, Alsandi Q, Tagami J, Zandinejad A. Surface roughness and shear bond strength to composite resin of additively manufactured interim restorative material with different printing orientations. J Prosthet Dent. 2021. https://doi.org/10.1016/j.prosdent.2021.08.010.

Akay C, Tanis MC, Gulverdiyeva M. Coloration of provisional restoration materials: a comparison of the effects of mouth rinses and green tea. Eur Oral Res. 2018;52:20–6.

Benli M, Eker-Gumus B, Kahraman Y, Huck O, Ozcan M. Can polylactic acid be a CAD/CAM material for provisional crown restorations in terms of fit and fracture strength? Dent Mater J. 2021;40:772–80.

Sadid-Zadeh R, Zirkel C, Makwoka S, Li R. Fracture strength of interim CAD/CAM and conventional partial fixed dental prostheses. J Prosthodont. 2021;30:720–4.

Myagmar G, Lee JH, Ahn JS, et al. Wear of 3D printed and CAD/CAM milled interim resin materials after chewing simulation. J Adv Prosthodont. 2021;13:144–51.

Jeong KW, Kim SH. Influence of surface treatments and repair materials on the shear bond strength of CAD/CAM provisional restorations. J Adv Prosthodont. 2019;11:95–104.

Karaokutan I, Sayin G, Kara O. In vitro study of fracture strength of provisional crown materials. J Adv Prosthodont. 2015;7:27–31.

Park JM, Jeon J, Koak JY, Kim SK, Heo SJ. Dimensional accuracy and surface characteristics of 3D-printed dental casts. J Prosthet Dent. 2021;126:427–37.

Unkovskiy A, Schmidt F, Beuer F, Li P, Spintzyk S, Kraemer FP. Stereolithography vs. direct light processing for rapid manufacturing of complete denture bases: an in vitro accuracy analysis. J Clin Med. 2021;10:1070.

Methani MM, Revilla-Leon M, Zandinejad A. The potential of additive manufacturing technologies and their processing parameters for the fabrication of all-ceramic crowns: a review. J Esthet Restor Dent. 2020;32:182–92.

Lee WS, Lee DH, Lee KB. Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system. J Adv Prosthodont. 2017;9:265–70.

Zimmermann M, Ender A, Egli G, Ozcan M, Mehl A. Fracture load of CAD/CAM-fabricated and 3D-printed composite crowns as a function of material thickness. Clin Oral Investig. 2019;23:2777–84.

Henderson JY, Korioth TVP, Tantbirojn D, Versluis A. Failure load of milled, 3D-printed, and conventional chairside-dispensed interim 3-unit fixed dental prostheses. J Prosthet Dent. 2022;127:275e1-375.

Schweiger J, Edelhoff D, Guth JF. 3D printing in digital prosthetic dentistry: an overview of recent developments in additive manufacturing. J Clin Med. 2021;10:2010.

Revilla-Leon M, Ozcan M. Additive manufacturing technologies used for processing polymers: current status and potential application in prosthetic dentistry. J Prosthodont. 2019;28:146–58.

Hata K, Ikeda H, Nagamatsu Y, Masaki C, Hosokawa R, Shimizu H. Development of dental poly(methyl methacrylate)-based resin for stereolithography additive manufacturing. Polymers (Basel). 2021;13:4435.

Zhang ZC, Li PL, Chu FT, Shen G. Influence of the three-dimensional printing technique and printing layer thickness on model accuracy. J Orofac Orthop. 2019;80:194–204.

You SG, You SM, Kang SY, Bae SY, Kim JH. Evaluation of the adaptation of complete denture metal bases fabricated with dental CAD-CAM systems: an in vitro study. J Prosthet Dent. 2021;125:479–85.

Nam NE, Shin SH, Lim JH, Shim JS, Kim JE. Effects of artificial tooth brushing and hydrothermal aging on the mechanical properties and color stability of dental 3d printed and CAD/CAM materials. Materials (Basel). 2021;14:6207.

Tasin S, Ismatullaev A. Comparative evaluation of the effect of thermocycling on the mechanical properties of conventionally polymerized, CAD-CAM milled, and 3D-printed interim materials. J Prosthet Dent. 2022;127:173e1-273.

Yao Q, Morton D, Eckert GJ, Lin WS. The effect of surface treatments on the color stability of CAD-CAM interim fixed dental prostheses. J Prosthet Dent. 2021;126:248–53.

Lee EH, Ahn JS, Lim YJ, Kwon HB, Kim MJ. Effect of layer thickness and printing orientation on the color stability and stainability of a 3D-printed resin material. J Prosthet Dent. 2022;127:784e1–7.

Lee EH, Ahn JS, Lim YJ, Kwon HB, Kim MJ. Effect of post-curing time on the color stability and related properties of a tooth-colored 3D-printed resin material. J Mech Behav Biomed Mater. 2022;126:104993.

Tasin S, Ismatullaev A, Usumez A. Comparison of surface roughness and color stainability of 3-dimensionally printed interim prosthodontic material with conventionally fabricated and CAD-CAM milled materials. J Prosthet Dent. 2021;S0022–3913:00075–85.

Song SY, Shin YH, Lee JY, Shin SW. Color stability of provisional restorative materials with different fabrication methods. J Adv Prosthodont. 2020;12:259–64.

Revilla-Leon M, Umorin M, Ozcan M, Piedra-Cascon W. Color dimensions of additive manufactured interim restorative dental material. J Prosthet Dent. 2020;123:754–60.

Kim D, Shim JS, Lee D, Shin SH, Nam NE, Park KH, Shim JS, Kim JE. Effects of post-curing time on the mechanical and color properties of three-dimensional printed crown and bridge materials. Polymers (Basel). 2020;12:2762.

Aldahian N, Khan R, Mustafa M, Vohra F, Alrahlah A. Influence of conventional, CAD-CAM, and 3D printing fabrication techniques on the marginal integrity and surface roughness and wear of interim crowns. Appl Sci. 2021;11:8964.

Shim JS, Kim JE, Jeong SH, Choi YJ, Ryu JJ. Printing accuracy, mechanical properties, surface characteristics, and microbial adhesion of 3D-printed resins with various printing orientations. J Prosthet Dent. 2020;124:468–75.

Al-Qahtani AS, Tulbah HI, Binhasan M, Abbasi MS, Ahmed N, Shabib S, Farooq I, Aldahian N, Nisar SS, Tanveer SA, Vohra F, Abduljabbar T. Surface properties of polymer resins fabricated with subtractive and additive manufacturing techniques. Polymers (Basel). 2021;13:4077.

Scherer MD, Barmak BA, Ozcan M, Revilla-Leon M. Influence of postpolymerization methods and artificial aging procedures on the fracture resistance and flexural strength of a vat-polymerized interim dental material. J Prosthet Dent. 2021;S0022–3913:00099–108.

Bayarsaikhan E, Lim JH, Shin SH, Park KH, Park YB, Lee JH, Kim JE. Effects of postcuring temperature on the mechanical properties and biocompatibility of three-dimensional printed dental resin material. Polymers (Basel). 2021;13:1180.

Wesemann C, Spies BC, Sterzenbach G, Beuer F, Kohal R, Wemken G, Krügel M, Pieralli S. Polymers for conventional, subtractive, and additive manufacturing of occlusal devices differ in hardness and flexural properties but not in wear resistance. Dent Mater. 2021;37:432–42.

Atria PJ, Bordin D, Marti F, et al. 3D-printed resins for provisional dental restorations: comparison of mechanical and biological properties. J Esthet Restor Dent. 2022;34:804–15.

Mayer J, Reymus M, Wiedenmann F, Edelhoff D, Hickel R, Stawarczyk B. Temporary 3D printed fixed dental prosthesis materials: impact of post printing cleaning methods on degree of conversion as well as surface and mechanical properties. Int J Prosthodont. 2021;34:784–95.

Park SM, Park JM, Kim SK, Heo SJ, Koak JY. Flexural strength of 3D-printing resin materials for provisional fixed dental prostheses. Materials (Basel). 2020;13:3970.

Chen H, Cheng DH, Huang SC, Lin YM. Comparison of flexural properties and cytotoxicity of interim materials printed from mono-LCD and DLP 3D printers. J Prosthet Dent. 2021;126:703–8.

Derban P, Negrea R, Rominu M, Marsavina L. Influence of the printing angle and load direction on flexure strength in 3D printed materials for provisional dental restorations. Materials (Basel). 2021;14:3376.

Revilla-Leon M, Morillo JA, Att W, Ozcan M. Chemical composition, knoop hardness, surface roughness, and adhesion aspects of additively manufactured dental interim materials. J Prosthodont. 2021;30:698–705.

Seyidaliyeva A, Rues S, Evagorou Z, Hassel AJ, Rammelsberg P, Zenthöfer A. Color stability of polymer-infiltrated-ceramics compared with lithium disilicate ceramics and composite. J Esthet Restor Dent. 2020;32:43–50.

Karatas O, Gul P, Akgul N, Celik N, Gundogdu M, Duymus ZY, Seven N. Effect of staining and bleaching on the microhardness, surface roughness and color of different composite resins. Dent Med Probl. 2021;58:369–76.

Paravina RD, Ghinea R, Herrera LJ, Bona AD, Igiel C, Linninger M, Sakai M, Takahashi H, Tashkandi E, Perez MM. Color difference thresholds in dentistry. J Esthet Restor Dent. 2015;27:S1-9.

International Standards Organization. ISO6872:2015—dentistry—ceramic materials. Geneva: ISO/TC 106/SC 2 Prosthodontic materials; 2015. p. 6–15.

Bollen CM, Lambrechts P, Quirynen M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: a review of the literature. Dent Mater. 1997;13:258–69.

Unkovskiy A, Bui PH, Schille C, Geis-Gerstorfer J, Huettig F, Spintzyk S. Objects build orientation, positioning, and curing influence dimensional accuracy and flexural properties of stereolithographically printed resin. Dent Mater. 2018;34:e324–33.

Miura S, Shinya A, Ishida Y, Fujisawa M. Mechanical and surface properties of additive manufactured zirconia under the different building directions. J Prosthodont Res. 2022. https://doi.org/10.2186/jpr.JPR_D_22_00166.

Chu SJ, Trushkowsky RD, Paravina RD. Dental color matching instruments and systems. Review of clinical and research aspects. J Dent. 2010;38:e2-16.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest among the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Diken Türksayar, A.A., Baytur, S. Color stability, surface roughness and flexural strength of additively manufactured and milled interim restorative materials after aging. Odontology 111, 680–686 (2023). https://doi.org/10.1007/s10266-022-00778-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10266-022-00778-6