Abstract

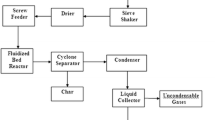

Extensive concentration has been given to the development of renewable energy due to imminent demand of fossil fuels and environmental concerns over global warming. Biomass materials are used since millennia for meeting myriad human needs including energy. In this study, the pyrolysis characteristics of cotton shell were investigated to evaluate their potential use as source of bio-oil. Flash pyrolysis of the cotton shell was carried out on an electrically heated fluidized bed reactor. The effects of operating parameters such as temperature, particle size and sweep gas flow rate were investigated. In this study, the maximum yield of pyrolysis bio-oil 51.25 wt% can be obtained under the operation temperature of 450 °C, 1 mm particle size at sweep gas flow rate of 1.75 m3/h. The liquid product was analyzed for physical, elemental and chemical composition using Fourier transform infra-red (FTIR) spectroscopy, gas chromatography (GC) and 1H NMR spectroscopy.

Similar content being viewed by others

References

Martin MA (2010) First generation biofuels compete. New Biotechnol 27:596–608

Naik SN, Goud VV, Rout PK, Dalai AK (2010) Production of first and second generation biofuels: a comprehensive review. Renew Sustain Energy Rev 14:578–597

Nurul Islam M, Nurul Islam M, Rafiqul Alam Beg M, Rofiqul Islam M (2005) Pyrolytic oil from fixed bed pyrolysis of municipal solid waste and its characterization. Renew Energy 30:413–420

Chen Yen-Chang, Pan Yung-Ning, Hsieh Kuo-Huang (2011) Process optimization of fast pyrolysis reactor for converting forestry wastes into bio-oil with the Taguchi method. Proced Environ Sci 10:1719–1725

Nurul Islam M, Zailani R, Ani FN (1999) Pyrolytic oil from fluidised bed pyrolysis of oil palm shell and its characterization. Renew Energy 17:73–84

Syamsiro M, Saptoadi H, Tambunan BH, Pambudi NA (2012) A preliminary study on use of cocoa pod husk as a renewable source of energy in Indonesia. Energy Sustain Dev 16:74–77

Park Y-K, Yoo ML, Lee HW, Park SH, Jung S-C, Park S-S, Kim S-C (2012) Effects of operation conditions on pyrolysis characteristics of agricultural residues. Renew Energy 42:125–130

Brammer JG, Lauer M, Bridgwater AV (2006) Opportunities for biomass-derived “Biooil” in European heat and power markets. Energy Policy 34:2871–2880

Meier D, Faix O (1999) State of the art of applied fast pyrolysis of lignocellulosic materials-a review. Bioresour Technol 68:71–77

Hamelinck CN, van Hooijdonk G, Faaij APC (2005) Ethanol from lignocellulosic biomass: techno-economic performance in short-, middle- and long-term. Biomass Bioenergy 28:384–410

Gani A, Naruse I (2007) Effect of cellulose and lignin content on pyrolysis and combustion characteristics for several types of biomass. Renew Energy 32:649–661

Raja SA, Kennedy ZR, Pillai BC, Lindon Robert Lee C (2010) Flash pyrolysis of jatropha oil cake in electrically heated fluidized bed reactor. Energy 35:2819–2823

Onay O, Kockar OM (2003) Slow fast and flash pyrolysis of rapeseed. Renew Energy 28:2417–2433

Park HJ, Park Y-K, Kim JS (2008) Influence of reaction condition and the char separation system on the production of bio-oil from radiata pine sawdust by fast pyrolysis. Fuel Process Technol 89:797–802

Chopra S, Jain AK (2007) A Review of fixed bed gasification systems for biomass. Agric Eng Int 5:1–23

Lv PM, Xiong ZH, Chang J, Wu CZ, Chen Y, Zhu JX (2004) An experimental study on biomass air-steam gasification in a fluidized bed. Bioresour Technol 95:95–101

Li XT, Grace R, Lim C, Watkinson AP, Chen HP, Kim JR (2004) Biomass gasification in a circulating fluidized bed. Biomass Bioenergy 26:171–193

FAO (2010). The Research Progress of Biomass Pyrolysis Processes; National Resource Management Environment Department: Available online: http://www.fao.org/docrep. Accessed 14 June 2010

Roy C, Blanchette D, Korving L, Yang J, De Caumia B (1997) Development of a novel vacuum pyrolysis reactor with improved heat transfer potential. In: Bridgewater AV, Boocock DGB (eds) Developments in thermochemical biomass conversion. Blackie Academic and Professional, London, pp 351–367

Wagenaar BM, Venderbosch RH, Carrasco J, Strenziok R, Van der Aa BJ (2001) Rotating cone bio-oil production and applications. In: Bridgewater AV (ed) Progress in thermochemical biomass conversion. Blackwell Science, Oxford, pp 1268–1280

Nurun Nabi Md, Mustafizur Rahman Md, Shamim Akhter Md (2009) Biodiesel from cotton seed oil and its effect on engine performance and exhaust emissions. Appl Thermal Eng 29:2265–2270

Sensoz Sevgi, Demiral Ilknur, Gercel Hasan Ferdi (2006) Olive bagasse (Olea europea L.) Pyrolysis. Bioresour Technol 97:429–436

Haykiri-Acma H (2006) The role of particle size in the non-isothermal pyrolysis of hazelnut shell. J Anal Appl Pyrol 75:211–216

Natarajan E, Ganapathy Sundaram E (2009) Pyrolysis of rice husk in a fixed bed reactor. World Academy of Science. Eng Technol 56:504–508

Shen J, Wang X-S, Garcia-Perez M, Mourant D, Rhodes MJ, Li C-Z (2009) Effects of particle size on the fast pyrolysis of oil mallee woody biomass. Fuel 88:1810–1817

Demirbas Ayhan (2004) Effect of initial moisture content on the yields of oily products from pyrolysis of biomass. J Anal Appl Pyrol 71:803–815

Abnisa F, Wan Daud WMA, Husin WNW, Sahu JN (2011) Utilization possibilities of palm shell as a source of biomass energy in Malaysia by producing bio-oil in pyrolysis process. Biomass Bioenergy 35:1863–1872

Gercel HF (2002) The production and evaluation of bio oils from the pyrolysis of sunflower oil cake. Biomass Bioenergy 23(4):54–65

Jung S-H, Kang B-S, Kim J-S (2008) Production of bio-oil from rice straw and bamboo sawdust under various reaction conditions in a fast pyrolysis plant equipped with a fluidized bed and a char separation system. J Anal Appl Pyrol 82:240–247

Luo Z, Wang S, Liao Y, Cen K (2004) Mechanism study of cellulose rapid pyrolysis. Ind Eng Chem Res 43:5605–5610

Putun AE, Ozcan A, Putun E (1999) Pyrolysis of hazelnut shells in a fixed-bed tubular reactor: yields and structural analysis of bio-oil. J Anal Appl Pyrol 52:33–49

Kockar OM, Onay O, Putun AE, Putun E (2000) Fixed-bed pyrolysis of hazelnut shell: a study on mass transfer limitations on product yields and characterization of the pyrolysis oil. Energy Sources Part A 22:913–924

Onay O, Beis SH, Kockar OM (2001) Fast pyrolysis of rape seed in a well-swept fixed-bed reactor. J Anal Appl Pyrol 58–59:995–1007

Mani T, Murugan P, Abedi J, Mahinpey N (2010) Pyrolysis of wheat straw in a thermogravimetric analyser: effect of particle size and heating rate on devolatilization and estimation of global kinetics. Chem Eng Res Des 88:952–958

Miao X, Wu Q, Yang C (2004) Fast pyrolysis of micro algae to produce renewable fuels. J Anal Appl Pyrol 71:855–863

Zanzi R, Sjostrom K, Bjornbom E (2002) Rapid pyrolysis of agricultural residues at high temperature. Biomass Bioenergy 23:357–366

Luo Z, Wang S, Liao Y, Zhou J, Gu Y, Cen K (2004) Research on biomass fast pyrolysis for liquid fuel. Biomass Bioenergy 26:455–462

Solantausta Y, Nylund N-O, Westerholm M, Koljonen T, Oasmaa A (1993) Wood-Pyrolysis oil as fuel in a Diesel-Power Plant. Bioresour Technol 46:177–188

Ates F, Isikdag MA (2009) Influence of temperature and alumina catalyst on pyrolysis of corncob. Fuel 88:1991–1997

Treedet W, Suntivarakorn R (2011) Sugar cane trash pyrolysis for bio-oil production in a fluidized bed reactor. Bio energy Technology, World Renewable Energy Congress pp140–147

Capunitan JA, Capareda SC (2012) Assessing the potential for biofuel production of corn stover pyrolysis using a pressurized batch reactor. Fuel 95:563–572

Ates F, Isikdag MA (2008) Evaluation of the role of the pyrolysis temperature in straw biomass samples and characterization of the oils by GC/MS. Energy Fuels 22:1936–1943

Salehi E, Abedi J, Harding T (2009) Bio-oil from sawdust: pyrolysis of sawdust in a fixed-bed system. Energy Fuels 23:3767–3772

Acknowledgments

The authors would like to express their thanks to the School of Mechanical Sciences, Karunya University, Coimbatore, Tamil Nadu for their support that made this work possible by providing their facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Madhu, P., Kanagasabapathy, H. & Neethi Manickam, I. Cotton shell utilization as a source of biomass energy for bio-oil by flash pyrolysis on electrically heated fluidized bed reactor. J Mater Cycles Waste Manag 18, 146–155 (2016). https://doi.org/10.1007/s10163-014-0318-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-014-0318-y