Abstract

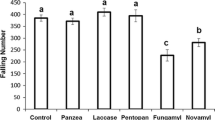

Composite wheat–cassava (WC) bread was recently proposed as a sustainable alternative to wheat bread. Nonetheless, using >20 % cassava flour on flour basis in bread baking has consistently been proven to impair the sensory quality. Selected enzymes: fungal alpha-amylase Fungamyl® 2500 SG (Fungamyl), maltogenic alpha-amylase Novamyl® 10000 BG (Novamyl), xylanase Panzea® BG (Panzea), lipase Lipopan® Xtra BG (Lipopan) and glucose oxidase Gluzyme® Mono 10000 BG (GOX) were tested for sensory improvement of the WC bread, investigating textural and structural changes. Wheat flour replacement with fermented cassava flour (Polvilho Azedo) at 30 % level resulted in bread of lower volume with chewier texture and smaller crumb pores. Fungamyl, Novamyl and Panzea enhanced loaf volume of wheat bread; however, they decreased volume and conferred stickiness when added to the WC bread. Lipopan increased loaf volume of the amylases- and xylanase-treated WC bread, but to a lower extent than that of its enzyme-free counterpart. No significant effects were observed when GOX was added to the WC bread. Sensory analysis showed softer texture and larger pore size, which were correlated to higher volume, for the two Lipopan-containing WC bread samples as compared to their enzyme-free counterpart.

Similar content being viewed by others

References

Godfray HCJ, Beddington JR, Crute IR, Haddad L, Lawrence D et al (2010) Food security: the challenge of feeding 9 billion people. Science 327(5967):812–818

Food Price Monitoring and Analysis Tool (FPMA) (2015) FAO—Food and Agriculture Organization of the United States. http://www.fao.org/giews/pricetool/. Source: Instituto de Economia Agrícola. http://www.iea.sp.gov.br/out/index.php. Accessed 06 July 2015

Begum R, Rakshit SK, Rahman SMM (2011) Protein fortification and use of cassava flour for bread formulation international. J Food Prop 14(1):185–198

Crabtree J, Kramer EC, Baldry J (1978) Technical note: the incorporation of fresh cassava into bread. J Food Technol 13(2):149–153

Jensen S, Skibsted LH, Kidmose U, Thybo AK (2015) Addition of cassava flours in bread-making: sensory and textural evaluation. Lwt Food Sci Technol 60(1):292–299

Nindjin C, Amani GN, Sindic M (2011) Effect of blend levels on composite wheat doughs performance made from yam and cassava native starches and bread quality. Carbohydr Polym 86(4):1637–1645

Eduardo M, Svanberg U, Oliveira J, Ahrné L (2013) Effect of cassava flour characteristics on properties of cassava–wheat–maize composite bread types. Int J Food Sci. Article ID 305407, 10 p

Eduardo M, Svanberg U, Ahrné L (2014) Effect of hydrocolloids and emulsifiers on baking quality of composite cassava–maize–wheat breads. Int J Food Sci. Article ID 479630, 9 p

Oladunmoye OO, Ojo A, Akinoso R, Akanbi CT (2010) Thermo-physical properties of composite bread dough with maize and cassava flours. Int J Food Sci Tech 45(3):587–593

Oladunmoye OO, Akinoso R, Olapade AA (2010) Evaluation of some physical-chemical properties of wheat, cassava, maize and cowpea flours for bread making. J Food Qual 33(6):693–708

Aryee FNA, Oduro I, Ellis WO, Afuakwa JJ (2006) The physicochemical properties of flour samples from the roots of 31 varieties of cassava. Food Control 17(11):916–922

Eriksson E, Koch K, Tortoe C, Akonor PT, Baidoo E (2014) Physicochemical, functional and pasting characteristics of three varieties of cassava in wheat composite flours. Br J Appl Sci Technol 4(11):1609–1621

Shittu TA, Aminu RA, Abulude EO (2009) Functional effects of xanthan gum on composite cassava–wheat dough and bread. Food Hydrocoll 23(8):2254–2260

Cauvain S, Young L (2006) Ingredients and their influences. In: Cauvain S, Young L (eds) Baked products, science, technology and practice. Blackwell Publishing, Oxford

Miguel ÂSM, Lobo BWP, da Costa Figueiredo ÉV, Dellamora-Ortiz GM, Martins-Meyer TS (2013) Enzymes in bakery: current and future trends. INTECH Open Access Publisher

Goesaert H, Slade L, Levine H, Delcour JA (2009) Amylases and bread firming—an integrated view. J Cereal Sci 50(3):345–352

Courtin CM, Delcour JA (2001) Relative activity of endoxylanases towards water-extractable and water-unextractable arabinoxylan. J Cereal Sci 33(3):301–312

AACC method 10-05.01 guidelines for measurement of volume by rapeseed displacement, 2010

AACC method 74-09.01 measurement of bread firmness by universal testing machine, 2008

Bourne M (2002) Food texture and viscosity. Concept and measurement. Food science and Technology, 2nd edn., International seriesElsevier Science Imprint, San Diego

ASTM (1986) Physical requirements guidelines for sensory evaluation laboratories. American Society for Testing Materials, Philadelphia

Defloor I, Nys M, Delcour JA (1993) Wheat starch, cassava starch, and cassava flour impairment of the breadmaking potential of wheat flour. Cereal Chem 70(5):526

Goesaert H, Brijs K, Veraverbeke WS, Courtin CM, Gebruers K et al (2005) Wheat flour constituents: how they impact bread quality, and how to impact their functionality. Trends Food Sci Tech 16(1–3):12–30

Synowiecki J (2007) The Use of Starch Processing Enzymes in the Food Industry. In: Polaina J, MacCabe AP (eds) Industrial enzymes. Structure, function and applications. Springer, Dordrecht, pp 19–34

Collar C, Martinez JC, Andreu P, Armero E (2000) Effects of enzyme associations on bread dough performance. A response surface analysis [Efectos de las asociaciones enzimáticas sobre la calidad funcional de masas panarias. Análisis de superficies de respuesta]. Food Sci Technol Int 6(3):217–226

Martínez-Anaya MA, Jiménez T (1997) Rheological properties of enzyme supplemented doughs. J Texture Stud 28(5):569–583

Van Der Maarel MJ, Van Der Veen B, Uitdehaag JC, Leemhuis H, Dijkhuizen L (2002) Properties and applications of starch-converting enzymes of the α-amylase family. J Biotechnol 94(2):137–155

Gerits LR, Pareyt B, Delcour JA (2014) A lipase based approach for studying the role of wheat lipids in bread making. Food Chem 156:190–196

Bonet A, Rosell CM, Caballero PA, Gómez M, Pérez-Munuera I et al (2006) Glucose oxidase effect on dough rheology and bread quality: a study from macroscopic to molecular level. Food Chem 99(2):408–415

Acknowledgments

This research is part of the bilateral Brazilian/Danish Food Science Research Program “BEAM - Bread and Meat for the Future” supported by the Danish Research Council for Strategic Research (Grant 11-116064) and by São Paulo Research Foundation FAPESP (Fundaҫão de Amparo à Pesquisa do Estado de São Paulo, Grant 2011/51555-7). The authors would like to thank Birgitte Foged for technical assistance with baking and instrumental analysis and Nina Eggers for technical assistance with sensory analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with Ethics Requirements

The research is exclusively funded by the Danish Research Council for Strategic Research (Grant 11-116064) and by São Paulo Research Foundation FAPESP (Fundaҫão de Amparo à Pesquisa do Estado de São Paulo, Grant 2011/51555-7). Hence, the authors Luca Serventi, Sidsel Jensen, Leif H. Skibsted and Ulla Kidmose declare that they have no conflict of interest. Sensory evaluation of breads was performed as a part of the present study using a trained sensory panel. Prior to the sensory evaluation, informed consent was obtained from each assessor in the sensory panel. In addition, the sensory panel was only presented to breads with ingredients of food grade.

Rights and permissions

About this article

Cite this article

Serventi, L., Jensen, S., Skibsted, L.H. et al. Addition of enzymes to improve sensory quality of composite wheat–cassava bread. Eur Food Res Technol 242, 1245–1252 (2016). https://doi.org/10.1007/s00217-015-2628-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-015-2628-2