Abstract

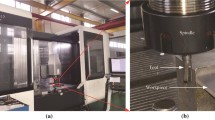

This paper is mainly focused on generating a high quality surface on tungsten carbide by micro polycrystalline diamond (PCD) milling tool. Micro milling tools made of PCD are developed. In order to machine tungsten carbide more precisely and more efficiently, systematic experimental procedures have been carried out. The influence of cutting parameters, including axial depth of cutting (a p ) and feed per tooth (f z ), on the achievable surface quality are studied under one-factor variation experimental design. Further tests are also conducted to monitor surface roughness as a function of the machining time. Mirror quality surfaces, with surface roughness Ra around 40 nm are obtained on the machined samples, which could be used as an example of the application of the process in specific fields, such as superior surface finishing.

Similar content being viewed by others

References

Kurlov AS, Gusev AI (2013) Tungsten carbides: structure, properties and application in hard metals. Springer, London

Dornfeld D, Min S, Takeuchi Y (2006) Recent advances in mechanical micromachining. CIRP Ann Manuf Technol 55:745–768

Chae J, Park SS, Freiheit T (2006) Investigation of micro-cutting operations. Int J Mach Tools Manuf 46:313–332

Cheng X, Wang Z, Nakamoto K, Yamazaki K (2010) A study on the micro tooling for micro/nano milling. Int J Adv Manuf Technol 53:523–533

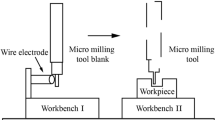

Cheng X, Wang Z, Nakamoto K, Yamazaki K (2010) Design and development of PCD micro straight edge end mills for micro/nano machining of hard and brittle materials. J Mech Sci Technol 24: 2261–2268

Yan J, Uchida K, Yoshihara N, Kuriyagawa T (2009) Fabrication of micro end mills by wire EDM and some micro cutting tests. J Micromech Microeng. doi:10.1088/0960-1317/19/2/025004

Suzuki H, Okadaa M, Fujiic K, Matsuid S, Yamagata Y (2013) Development of micro milling tool made of single crystalline diamond for ceramic cutting. CIRP Ann Manuf Technol 62:59–62

Suzuki H, Moriwaki T, Yamamoto Y, Goto Y (2007) Precision cutting of aspherical ceramic molds with micro PCD milling tool. Ann CIRP 56:131–134

Cheng X, Wang ZG, Nakamoto K, Yamazaki K (2009) Design and development of a micro polycrystalline diamond ball end mill for micro/nano freeform machining of hard and brittle materials. J Micromech Microeng. doi:10.1088/0960-1317/19/11/115022

Nakamoto K, Katahira K, Ohmori H, Yamazaki K, Aoyama T (2012) A study on the quality of micro-machined surfaces on tungsten carbide generated by PCD micro end-milling. CIRP Ann Manuf Technol 61:567–570

Bifano TG, Dow TA, Scattergood RO (1991) Ductile-regime grinding—a new technology for machining brittle materials. J Eng Ind T Asme 113:184–189

Zhong ZW (2003) Ductile or partial ductile mode machining of brittle materials. Int J Adv Manuf Technol 21:579–585

Liu K, Li XP, Rahmana M, Liu XD (2003) CBN tool wear in ductile cutting of tungsten carbide. Wear 255:1344–1351

Liu K, Li X, Rahman M, Neo K, Liu X (2007) A study of the effect of tool cutting edge radius on ductile cutting of silicon wafers. Int J Adv Manuf Technol 32:631–637

Gao C, Zhan Z, Wang S, He N, Li L (2013) Research on WEDM process optimization for PCD micro milling tool. Procedia CIRP 6:209–214

Zhan Z, Li L, He N, Shrestha R (2014) An experimental study on grinding parameters for manufacturing PCD micro-milling tool. Int J Adv Manuf Technol. doi:10.1007/s00170-014-5969-2

Dornfeld DA, Kim JS, Dechow H, Hewson J, Chen LJ (1999) Drilling burr formation in titanium alloy, Ti-6AI-4 V. CIRP Ann—Manuf Technol 48:73–76

Lee K, Dornfeld DA (2005) Micro-burr formation and minimization through process control. Precis Eng 29:246–252

Filiz S, Conley CM, Wasserman MB, Ozdoganlar OB (2007) An experimental investigation of micro-machinability of copper 101 using tungsten carbide micro-endmills. Inter J Mach Tools Manuf 47:1088–1100

Cao Z, He N, Li L (2008) Development of micro milling machine and analysis of the mechanics characteristics of micro milling cutter. China Mech Eng 19:2223–2226

Bian R, Ferraris E, He N, Reynaerts D (2014) Process investigation on meso-scale hard milling of ZrO2 by diamond coated tools. Precis Eng 38:82–91

Bissacco G, Hansen HN, Slunsky J (2008) Modelling the cutting edge radius size effect for force prediction in micro milling. Ann CIRP 57:113–116

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhan, Z., He, N., Li, L. et al. Precision milling of tungsten carbide with micro PCD milling tool. Int J Adv Manuf Technol 77, 2095–2103 (2015). https://doi.org/10.1007/s00170-014-6632-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6632-7