Abstract

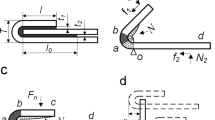

Numerical simulation of the roller hemming process is studied in this approach. Combined hardening is used for steel panel BSUFD roller hemming. Meshes are produced based on the deformation state of the panel. Tools are set up for flanging, pre-hemming, and final hemming. Roll-in/out results are obtained through a simulation and an experiment to verify the accuracy of the numerical model. Fracture is likely to occur in the bending area, while wrinkle may be found in the flanging area. The evolution of the load on the roller is found to be different over the process. Roller hemming could be accepted as a kind of plane strain bending deformation process.

Similar content being viewed by others

References

Hishida Y, Sato Y (1986) Analysis of hemming processes by the finite element method for improving hemming quality. Proceedings of the 14th Biannual Congress of IDDRG, April 21–23, Koln, Germany

Huang Y, Chien K (2002) Influence of cone semi-angle on the formability limitation of the hole-flanging process. Int J Adv Manuf Technol 19:597–606

Huang Y (2007) An elasto-plastic finite element analysis of the sheet metal stretch flanging process. Int J Adv Manuf Technol 34:641–618

Cao C (2009) Flange forming with combined blanking and extrusion process on sheet metals by FEM and experiments. Int J Adv Manuf Technol 45:234–244

Livatyali H, Muderrisoglu A, Ahmetoglu M, Akgeman N, Kinzel G, Altan T (2000) Improvement of hem quality by optimizing flanging and pre-hemming operations using computer aided die design. J Mater Process Technol 98:41–52

Livatyali H, Wu H, Altan T (2002) Prediction and elimination of springback in straight flanging using computer-aided design methods. Part 2. FEM predictions and tool design. J Mater Process Technol 120:348–354

Livatyali H, Larris S (2004) Experimental investigation on forming defects in flat surface-convex edge hemming: roll, recoil and warp. J Mater Process Technol 153–154:913–919

Zhang G, Hao H, Wu X, Hu S (2000) An experimental investigation of curved surface-straight edge forming. J Manuf Process 2–4:241–246

Muderrisoglu A, Murata M, Ahmetoglu M, Kinzel G, Altan T (1996) Bending, flanging and hemming of aluminum sheet—an experimental study. J Mater Process Technol 59:10–17

Lin G, Li J, Hu S, Cai W (2007) A computational response surface study of three-dimensional aluminum hemming using solid-to-shell mapping. Trans ASME 12:360–368

Thuillier S, Maout N, Manach P, Debois D (2008) Numerical simulation of the roll hemming process. J Mater Process Technol 98:226–233

Yoon Y, Shin D, Kim D, Kwak H, Ryu Y, Han B (2007) The study of roller hemming process via finite element analysis and experimental investigations. SAE International 2007-01-3737, August 2007

Le Maout N, Thuillier S, Manach P (2010) Classical and roll-hemming processes of pre-strained metallic sheets. Exp Mech 50:1087–1097. doi:10.1007/s11340-009-9297-7

Livermore Software Technology Corporation (2009) LS-PrePost roller hemming application tutorial manual, version 2.4

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, X., Zhao, Y., Huang, S. et al. Numerical analysis of the roller hemming process. Int J Adv Manuf Technol 62, 543–550 (2012). https://doi.org/10.1007/s00170-011-3822-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3822-4