Abstract

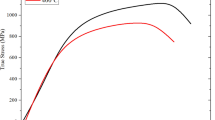

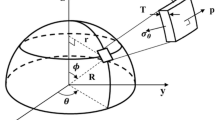

The incremental updated Lagrangian elasto-plastic finite element method (FEM) was employed in this study to analyse the stretch flanging of circular plates with a pre-determined smaller hole at the centre of the sheet metal. An extended r min technique was employed such that each incremental step size is determined not only by the yielding of an element Gaussian point, but also by the change in the boundary condition along the tool-sheet interface. The experimental results, using a low-carbon (BA-CQ2) sheet plate with a thickness of 1.0 mm, have been obtained and compared with the corresponding theoretical results. It was found that the flange thickness does not always decrease monotonically from the die shoulder to the flange edge. Reducing the punch diameter and increasing the flange height significantly reduced the flange thickness. Web width does not influence the thickness distribution of the flange. The tendency of flange thickness to thin decreases as punch diameter increases. The reduction of thickness at the die shoulder depends on the die shoulder radius. Simulation results of punch load of stretch flanging, the deformed geometry, and the distribution of thickness are compared with experimental data and found to satisfactorily agree.

Similar content being viewed by others

References

Takuda H, Hatta N (1998) Numerical analysis of formability of a commercially pure zirconium sheet in some sheet forming process. Mater Sci Eng A242:15–21

Kumagai T, Saiki H, Meng Y (1999) Hole flanging with ironing of two-ply thick sheet metals. J Mater Process Technol 89–90:51–57

Takuda H, Mori K, Fujimoto H, Hatta N (1999) Prediction of forming limit in bore-expanding of sheet metals using ductile fracture criterion. J Mater Process Technol 92–93:433–438

Leu D (1996) Finite-element simulation of hole-flanging process of circular sheets of anisotropic materials. Int J Mech Sci 38:917–933

Takuda H, Kikuchi S, Hatta N (1998) Formability of a commercially pure zirconium sheet. J Mater Process Technol 84:117–121

Leu D, Chen T, Huang Y (1999) Influence of punch shapes on the collar-drawing process of sheet metal. J Mater Process Technol 88:134–146

Huang Y, Chien K (2001) The formability limitation of the hole-flanging process. J Mater Process Technol 117:43–51

Asnafi N (1999) On stretch and shrink flanging of sheet aluminum by fluid forming. J Mater Process Technol 96:198–214

Hyun DI, Oak SM, Kang SS, Moon YH (2002) Estimation of hole flangeability for high strength steel plates. J Mater Process Technol 110–131:9–13

Yamada Y, Yoshimura N, Sakurai T (1968) Plastic stress-strain matrix and its application for the solution of elastic-plastic problems by the finite-element method. Int J Mech Sci 10:343–354

McMeeking R, Rice J (1975) Finite element formulations for problems of large elastic-plastic deformation. Int J Solids Struct 11:601–606

Yamada Y (1980) Plasticity and visco-elasticity. Baifukan, Japan

Belytschko T, Ong SJ, Liu WK, Kennedy M (1984) Hourglass control in linear and nonlinear problems. Comput Methods Appl Mech Eng 43:251–276

Liu WK, Ong JS-J, Uras RA (1985) Finite element stabilization matrices - a unification approach. Comput Methods Appl Mech Eng 53:13–46

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, YM. An elasto-plastic finite element analysis of the sheet metal stretch flanging process. Int J Adv Manuf Technol 34, 641–648 (2007). https://doi.org/10.1007/s00170-007-0958-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-0958-3