Abstract

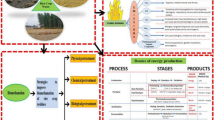

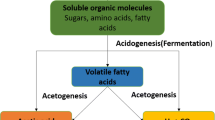

Even though technologically we have advanced many folds, the dreadful practices of eco-asphyxiating the sanctity of a clean air parcel are widely prevalent in our country. Among the famous agrarian economies of the world, India and China are one of the largest generators of agro-waste with a non-streamlined infrastructure for agro-waste management. Of late, reports of smog in the Northern regions of India were in trend owing to farmers’ open burning of paddy straw in Haryana and Punjab. These emissions account for more than 29% of PM 2.5 emissions which, along with other sources, are one of the major contributors to bad health. This also adds to the escalating greenhouse gas emissions (GHG), which messes up the global climate balance. In light of the latest COP26, where all the developed and developing nations are hoarding toward carbon neutrality, a discussion on the existing eco-depleting activities is necessary. The paper, therefore, strives to understand the direct causes of why the farmers are adopting these practices and briefly outlines the current rice straw (RS)-based biogas plants that have been commissioned by the Indian government and explore the lab-scale interventions done on rice straw valorization, and tries to suggest a sustainable solution for agro-waste management and climate change mitigation.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Abdel Daiem MM, Said N, Negm AM (2018) Potential energy from residual biomass of rice straw and sewage sludge in Egypt. Procedia Manufacturing 22:818–825. https://doi.org/10.1016/j.promfg.2018.03.116

Barua VB, Kalamdhad AS (2019) Biogas production from water hyacinth in a novel anaerobic digester: a continuous study. Process Saf Environ Prot 127:82–89. https://doi.org/10.1016/j.psep.2019.05.007

Baruah J, Nath BK, Sharma R, Kumar S, Deka RC, Baruah DC, Kalita E (2018) Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front Energy Res 6(DEC). Frontiers Media, S.A. https://doi.org/10.3389/fenrg.2018.00141

Bhattacharyya P, Bisen J, Bhaduri D, Priyadarsini S, Munda S, Chakraborti M, Adak T, Panneerselvam P, Mukherjee AK, Swain SL, Dash PK., Padhy SR, Nayak AK, Pathak H, Arora S, Nimbrayan P (2021) Turn the wheel from waste to wealth: Economic and environmental gain of sustainable rice straw management practices over field burning in reference to India. Sci Total Environ 775. Elsevier B.V. https://doi.org/10.1016/j.scitotenv.2021.145896

Chandra R, Takeuchi H, Hasegawa T (2012) Hydrothermal pretreatment of rice straw biomass: a potential and promising method for enhanced methane production. Appl Energy 94:129–140. https://doi.org/10.1016/j.apenergy.2012.01.027

Chandra R, Trivedi A, Jha B, Verma RA, Vijay KV (2017). Energy generation from Paddy Straw. Akshay Urja

Darwin D, Cheng JJ, Liu ZM, Gontupil J, Kwon OS (2014) Anaerobic Co-Digestion of rice straw and digested swine manure with different total solid concentration for methane production. Int J Agric Biol Eng 7(6):79–90. https://doi.org/10.3965/j.ijabe.20140706.01

Ghosh N (2020) Punjab cabinet approves IOCL's proposal to set up compressed biogas plant. Hindustan Times. Retrieved January 15, 2023, fromhttps://www.hindustantimes.com/chandigarh/punjab-cabinet-approves-iocl-s-proposal-to-set-up-compressed-biogas-plant/story-28Ib0NDOhLFore5xuyNIlJ.html

Goodman BA (2020) Utilization of waste straw and husks from rice production: a review. J Bioresour Bioprod 5(3):143–162. KeAi Communications Co. https://doi.org/10.1016/j.jobab.2020.07.001

Gupta A (2022) Biomass sector in India – problems and challenges. BioEnergy Consultant. Retrieved January 14 (2023)

Jha B (2022, April 28) Haryana: power crisis forces more blackouts, 2nd in a week. The Times of India.https://timesofindia.indiatimes.com/city/gurgaon/haryana-power-crisis-forces-more-blackouts-2nd-in-a-week/articleshow/91137518.cms

Kainthola J (2019) Enhancement of biogas production from rice straw by co-digestion and pretreatment techniques

Li D, Liu S, Mi L, Li Z, Yuan Y, Yan Z, Liu X (2015) Effects of feedstock ratio and organic loading rate on the anaerobic mesophilic co-digestion of rice straw and cow manure. Biores Technol 189:319–326. https://doi.org/10.1016/j.biortech.2015.04.033

Mandavgane SA, Chakravarty I (2021) Inoculant for rapid biodegradation of agricultural waste and method of use (Patent No. 360956). The Patent office, Government of India

Meng L, Xie L, Kinh CT, Suenaga T, Hori T, Riya S, Terada A, Hosomi M (2018) Influence of feedstock-to-inoculum ratio on performance and microbial community succession during solid-state thermophilic anaerobic co-digestion of pig urine and rice straw. Biores Technol 252:127–133. https://doi.org/10.1016/j.biortech.2017.12.099

Metcalf & Eddy (2003) Wastewater engineering : treatment and reuse. Fourth edition/revised by George Tchobanoglous, Franklin L. Burton, H. David Stensel. Boston : McGraw-Hill, [2003] ©2003.https://search.library.wisc.edu/catalog/999935704402121

Mirmohamadsadeghi S, Karimi K (2020) Recovery of silica from rice straw and husk. In Current developments in biotechnology and bioengineering: resource recovery from wastes. Elsevier, pp 411–433. https://doi.org/10.1016/B978-0-444-64321-6.00021-5

Mothe S, Polisetty VR (2021) Review on anaerobic digestion of rice straw for biogas production. Environ Sci Pollut Res 28(19):24455–24469. https://doi.org/10.1007/s11356-020-08762-9

Moudgil M (2021) From pollution to power, what stops paddy straw from becoming the fuel of choice. Mongabay Series: Clean Energy.https://india.mongabay.com/2021/12/from-pollution-to-power-what-stops-paddy-straw-from-becoming-the-fuel-of-choice/

Mussoline W, Esposito G, Giordano A, Lens P (2013) The anaerobic digestion of rice straw: a review. Crit Rev Environ Sci Technol 43(9):895–915. https://doi.org/10.1080/10643389.2011.627018

Mustafa AM, Poulsen TG, Sheng K (2016) Fungal pretreatment of rice straw with Pleurotus ostreatus and Trichoderma reesei to enhance methane production under solid-state anaerobic digestion. Appl Energy 180:661–671. https://doi.org/10.1016/j.apenergy.2016.07.135

Negi S, Dhar H, Hussain A, Kumar S (2018) Biomethanation potential for co-digestion of municipal solid waste and rice straw: A batch study. Biores Technol 254:139–144. https://doi.org/10.1016/j.biortech.2018.01.070

Ngan NVC, Chan FMS, Nam TS, van Thao H, Maguyon-Detras MC, Hung DV, Cuong DM, van Hung N (2020) Anaerobic digestion of rice straw for biogas production. In: Sustainable rice straw management. Springer International Publishing, pp 65–92.https://doi.org/10.1007/978-3-030-32373-8_5

PEDA (2022) Waste to energy projects. Punjab Energy Development Agency (PEDA). Retrieved January 15, 2023, from https://www.peda.gov.in/waste-to-energy-projects

Paul Choudhury S, Panda S, Haq I, Kalamdhad AS (2022) Enhanced methane production and hydrocarbon removal from petroleum refinery sludge after Pseudomonas putida pretreatment and process scale-up. Biores Technol 343:126127. https://doi.org/10.1016/j.biortech.2021.126127

Paul Choudhury S, Panda S, Haq I, Kalamdhad AS (2022) Microbial pretreatment using Kosakonia oryziphila IH3 to enhance biogas production and hydrocarbon depletion from petroleum refinery sludge. Renewable Energy 194:1192–1203. https://doi.org/10.1016/j.renene.2022.05.167

Prasad RD, Raturi A (2021) Prospects of Sustainable Biomass-Based Power Generation in a Small Island Country. J Clean Prod 318.https://doi.org/10.1016/j.jclepro.2021.128519

Roy P, Kaur M (2015) Status and Problems of Paddy Straw Management in West Bengal. Int J Adv Agric Environ Eng 2(1). https://doi.org/10.15242/ijaaee.er1015204

Shen F, Li H, Wu X, Wang Y, Zhang Q (2018) Effect of organic loading rate on anaerobic co-digestion of rice straw and pig manure with or without biological pretreatment. Biores Technol 250:155–162. https://doi.org/10.1016/j.biortech.2017.11.037

Singh L, Brar BS (2021). A review on rice straw management strategies. Nat Environ Pollut Technol 20(4):1485–1493. Technoscience Publications. https://doi.org/10.46488/NEPT.2021.v20i04.010

Singh R, Srivastava M, Shukla A (2016) Environmental sustainability of bioethanol production from rice straw in India: a review. Renew Sustain Energy Rev 54:202–216. Elsevier Ltd. https://doi.org/10.1016/j.rser.2015.10.005

Song Z, Yang G, Guo Y, Zhang T (2012) Comparision of two chemical pretreatment of rice straw for biogas production by anaerobic digestion.

TNN (2019) In a first, Haryana gets straw-to-gas plant: Ludhiana News—Times of India. The Times of India. Retrieved January 15, 2023, from https://timesofindia.indiatimes.com/city/ludhiana/in-a-first-hry-gets-straw-to-gas-plant/articleshow/71679257.cms

TNN (2022) Asia's largest CBG plant operational in Sangrur: Chandigarh News—Times of India. The Times of India. Retrieved January 15, 2023, from https://timesofindia.indiatimes.com/city/chandigarh/asias-largest-cbg-plant-operational-in-sangrur/articleshow/93533223.cms

Xu N, Liu S, Xin F, Zhou J, Jia H, Xu J, Jiang M, Dong W (2019) Biomethane production from lignocellulose: biomass recalcitrance and its impacts on anaerobic digestion. Front Bioeng Biotechnol 7(AUG). https://doi.org/10.3389/fbioe.2019.00191

Zadgaonkar LA, Mandavgane SA (2020) Framework for calculating ecological footprint of process industries in local hectares using emergy and LCA approach. Clean Technol Environ Policy 22(10):2207–2221. https://doi.org/10.1007/s10098-020-01970-4

Zhou J, Yang J, Yu Q, Yong X, Xie X, Zhang L, Wei P, Jia H (2017) Different organic loading rates on the biogas production during the anaerobic digestion of rice straw: a pilot study. Biores Technol 244:865–871. https://doi.org/10.1016/j.biortech.2017.07.146

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Panda, S., Jain, M.S. (2024). A Review on Sustainable Rice Straw Management Through Anaerobic Digestion. In: Yadav, K.D., Jariwala, N.D., Kumar, A., Sinha, A. (eds) Recent Advances in Sustainable Waste Management Practices. SWMP 2023. Lecture Notes in Civil Engineering, vol 430. Springer, Singapore. https://doi.org/10.1007/978-981-99-4186-5_3

Download citation

DOI: https://doi.org/10.1007/978-981-99-4186-5_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-4185-8

Online ISBN: 978-981-99-4186-5

eBook Packages: EngineeringEngineering (R0)