Abstract

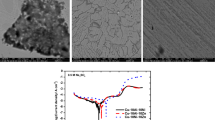

The influence of the addition of HCl on the corrosion behavior of low-alloy steel containing copper and antimony was investigated using electrochemical (potentiodynamic and potentiostatic polarization tests, and electrochemical impedance spectroscopy) and weight loss tests in a 1.6M H2SO4 solution with different concentrations of hydrochloric acid (0.00, 0.08, 0.15 and 0.20 M HCl) at 60 °C. The result showed that the corrosion rate decreased with increasing HCl by the formation of protective layers. SEM, EDS and XPS examinations of the corroded surfaces after the immersion test indicated that the corrosion production layer formed in the solution containing HCl was highly comprised of metallic Cu, Cu chloride and metallic (Fe, Cu, Sb) compounds. The corrosion resistance was improved by the Cu-enriched layer, in which chloride ions are an accelerator for cupric ion reduction during copper deposition. Furthermore, cuprous and antimonious chloride species are complex salts for cuprous ions adsorbed on the surface during copper deposition.

Similar content being viewed by others

References

D. P. Le, W. S. Ji, and J. G. Kim, Corros. Sci. 50, 1195 (2008).

S.-A. Park, J.-G. Kim, B.-H. Lee, and J.-B. Yoon, Korean J. Met. Mater. 52, 837 (2014).

S. A. Park, S. H. Lee, and J. G. Kim, Met. Mater. Int. 18, 957 (2012).

M. J. Kim, S. H. Lee, J. G. Kim, and J. B. Yoon, Corrosion 66, 1250051 (2010).

S. A. Park, W. S. Ji, and J. G. Kim, Int. J. Electrochem. Sci. 8, 7498 (2013).

S. A. Park, J. G. Kim, and J. B. Yoon, Corrosion 70, 196 (2014).

J. Okamoto, A. Usami, A. Soeno, H. Mimura, and T. Ishitsuka, Nippon Steel Tech. Rep. 90, 98 (2004).

J. Okamoto, A. Usami, and H. Mimura, Nippon Steel Tech. Rep. 87, 46 (2003).

A. Usami, M. Okushima, S. Sakamoto, S. Nishimura, T. Kusunoki, and K. Kojima, Nippon Steel Tech. Rep. 90, 25 (2004).

D. A. Jones, Principles and Prevention of Corrosion, 2nd ed., pp.31–148, Prentice Hall, New Jersey (1996).

T. V. Shibaeva, V. K. Laurinavichyute, G. A. Tsirlina, A. M. Arsenkin, and K. V. Grigorovich, Corros. Sci. 80, 299 (2014).

B. Lin, R. Hu, C. Ye, Y. Li, and C. Lin, Electrochim. Acta 55, 6542 (2010).

W. S. Li and J. L. Luo, Corros. Sci. 44, 1695 (2002).

B. Jegdic, D. M. Drazic, and J. P. Popic, Corros. Sci. 50, 1235 (2008).

L. Vracar and D. M. Drazic, J. Electrochem. Soc. 110, 703 (1963).

V. J. Drazic, D. M. Drazic, and V. Jevtic, J. Serb. Chem. Soc. 52, 711 (1987).

ASTM G 1-90, Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens, pp.16–23, Annual Book of ASTM Standards, ASTM, West Conshohocken, PA (2002).

ASTM G 31-72, Standard Practice for Laboratory Immersion Corrosion Testing of Metals, pp.101–108, Annual Book of ASTM Standards, ASTM, West Conshohocken, PA (2002).

M. I. Barrena, J. M. Gómez de Salazar, J. M. Vázquez, I. García-Cano, and J. M. Guilemany, Met. Mater. Int. 20, 613 (2014).

N. D. Nam, D. Y. Lee, J. G. Kim, and N. J. Park, Met. Mater. Int. 20, 469 (2014).

S. H. Lee, W. K. Oh, and J. G. Kim, Prog. Org. Coat. 76, 778 (2013).

M. Gojic, Corros. Sci. 43, 919 (2013).

B. G. Ateya, B. E. El-Anadouli, and M. El-Nizmay, Corros. Sci. 24, 509 (1984).

B. Dus and Z. Szklarska-Smialowska, Corrosion 25, 69 (1969).

A. Frignani, M. Tassinari, and G. Trabanelli, Electrochim. Acta 34, 1259 (1989).

G. A. Zhang and Y. F. Cheng, Corros. Sci. 51, 87 (2009).

Macdonald, J. Electrochem. Soc. 125, 2062 (1978).

X. Guo, H. Imaizumi, and K. Katoh, J. Electroanal. Chem. 383, 99 (1995).

K. H. Kim, S. H. Lee, N. D. Nam, and J. G. Kim, Corros. Sci. 53, 3576 (2011).

J. H. Hong, S. H. Lee, J. G. Kim, and J. B. Yoon, Corros. Sci. 32, 174 (2012).

F. Farelas, M. Galicia, B. Brown, S. Nesic, and H. Castaneda, Corros. Sci. 52, 509 (2010).

G. Moretti, F. Guidi, and G. Grion, Corros. Sci. 46, 387 (2004).

Marcel Pourbaix, Atlas of Electrochemical Equilibria in Aqueous Solution, pp.307–392, NACE, Houston (1974).

W. P. Dow and H. S. Huang, J. Electrochem. Soc. 152, C67 (2005).

W. P. Dow, H. S. Huang, M. Y. Yen, and H. H. Chen, J. Electrochem. Soc. 152, C77 (2005).

D. M. Soares, S. Wasle, K. G. Weil, and K. Doblhofer, J. Electroanal. Chem. 532, 353 (2002).

D. P. Barkey and F. Oberholtzer, Q. Wu, J. Electrochem. Soc. 145, 590 (1998).

M. Tan and J. N. Harb, J. Electrochem. Soc. 150, C420 (2003).

D. Stoychev and C. Tsvetanov, J. Appl. Electrochem. 26, 741 (1996).

T. Kekeri and M. Isshiki, J. Appl. Electrochem. 27, 982 (1997).

H. P. Lee, K. Nobe, and A. J. Pearlstein, J. Electrochem. Soc. 132, 1031 (1985).

A. J. Pearlstein, H. P. Lee, and K. Nobe, J. Electrochem. Soc. 132, 2159 (1985).

T. P. Moffat, J. E. Bonevich, W. H. Huber, A. Stanishevsky, and D. R. Kelly, J. Electrochem. Soc. 147, 4524 (2000).

H. K. Lin and X. Wu, Metall. Mater. Trans. B 27B, 157 (1996).

H. K. Lin, X. Wu, and P. D. Rao, J. Appl. Electrochem. 24, 758 (1994).

Y. S. Choi, J. J. Shim, and J. G. Kim, J. Alloys Compd. 391, 162 (2005).

A. L. Pitman, M. Pourbaix, and N. de Zoubov, J. Electrochem. Soc. 104, 594 (1957).

N. D. Nam and J. G. Kim, Corros. Sci. 52, 14 (2010).

R. F. North and M. J. Pryor, Corros. Sci. 9, 509 (1969).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, SA., Kim, SH., Yoo, YH. et al. Effect of chloride ions on the corrosion behavior of low-alloy steel containing copper and antimony in sulfuric acid solution. Met. Mater. Int. 21, 470–478 (2015). https://doi.org/10.1007/s12540-015-4421-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-4421-y