Abstract

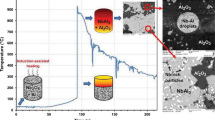

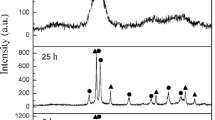

Fe-Al intermetallic/TiC-Al2O3 ceramic composites were successfully prepared by self-propagating high-temperature synthesis (SHS) from natural ilmenite, aluminium and carbon as the raw materials. The effects of carbon sources, preheating time and heat treatment temperature on synthesis process and products were investigated in detail, and the reaction process of the FeTiO3-Al-C system was also discussed. It is shown that the temperature and velocity of the combustion wave are higher when graphite is used as the carbon source, which can reflect the effect of the carbon source structure on the combustion synthesis; Prolonging the preheating time or heat treatment temperature is beneficial to the formation of the ordered intermetallics; The temperature and velocity of the combustion wave are improved, but the disordered alloys are difficult to eliminate with the preheating time prolonged. The compound powders mainly containing ordered Fe3Al intermetallic can be prepared through heat treatment at 750 °C.

Similar content being viewed by others

References

Schicker S, Garcia D E, Bruhn J, et al. Reaction Processing of Al2O3 Composites Containing Iron and Iron Aluminides[J]. J. Am. Ceram. Soc., 1997, 80(9):2294–2300

Subramanian R, Schneibel J H, Alexander K B, et al. Iron Aluminide-titanium Carbide Composites by Pressureless Melt Infiltration-microstructure and Mechanical Properties[J]. Scripta Materialia, 1996, 35(5):583–588

GAO Mingxia, PAN Yi, Oliveira F J, et al. The Formation of Core-rim Structures in Fe40Al/(TiC-TiN-WC) Cermets Produced by Pressureless Melt Infiltration[J]. Materials Science and Engineering, 2004, A371:277–282

Subramanian R, Schneibel J H. FeAl-TiC and FeAl-WC Composites-melt Infiltration Processing, Microstructure and Mechanical Properties[J]. Materials Science and Engineering, 1998, A244: 103–112

GONG Hongyu, YIN Yansheng, WANG Xin, et al. Fabrication and Microstructure of in situ Toughened Al2O3/Fe3Al[J]. Materials Research Bulletin, 2004, 39: 513–521

YIN Yansheng, GONG Hongyu, FAN Runhua, et al. Preparation and Mechanical Properties of Fe3Al/Al2O3 Nano/Micro-Composite[J]. Trans. Nonferrous Met. Soc. China, 2003, 13(6): 1376–1380

LIU Xiaofeng, LIU Yong, HUANG Baiyun, et al. Fabrication of FeAl/TiC Composites Through Reactive Hot Pressing[J]. J. Cent. South. Univ. Technol., 2004, 11(4): 343–347

Schicker S, Garcia D E, Bruhn J, et al. Reaction Synthesized A12O3-based Intermetallic Composites[J]. Acta Materials, 1998, 46(7): 2485–2492

ZOU Zhengguang, YIN Chuanqiang, WU Yi, et al. Fabrication of Fe-Al Intermetallic/ TiC-Al2O3 Ceramic Composites from Ilmenite by Reaction Sintering[J]. Key Engineering Materials, 2007, 336–338:1501–1503

SHI Yuxiang, NI Junjie, XIE Zhaode. Mechanical Milling Characteristics of (Fe-Al)/Al2O3 Composite Nano-sized Powders[J]. Engineering Journal of Wuhan University, 2004, 37(2): 29–32

Subramanian R, McKamey C G, Schneibel J H, et al. Iron Aluminide-Al2O3 Composites by in situ Displacement Reactions: Processing and Mechanical Properties[J]. Mater. Sci. Engineering, 1998, A254: 119–128

WU Yi, YIN Chuanqiang, ZOU Zhengguang, et al. Research on Al2O3-TiC/Fe-Al Composite by SHS[J]. Journal of Materials Engineering, 2005, 7: 3–6

N J Welham, P E Willis. Formation of TiN/TiC-Fe Composites from Ilmenite (FeTiO3) Concentrate[J]. Metall. & Mater. Trans. B., 1998, (29B):1077–1083

WU Yi, YIN Chuanqiang, LI Xiaomin, et al. Thermodynamics on FeTiO3-Al-C System and Preparation of Al2O3-TiC/Fe Composite by Ilmentie[J]. J. Chin. Ceram. Soc., 2005, 33(9): 1173–1178

Welham N J. Mechanochemical Reaction between Ilmenite (FeTiO3) and Aluminium[J]. Journal of Alloys and Compounds, 1998, 270: 228–236

Choi Y, Rhee S W. Reaction of TiO2-Al-C in the Combustion Synthesis of TiC-Al2O3 Composite[J]. J. Am. Ceram. Soc., 1995, 78(4): 986–992

ZHANG Yonggang, HAN Yafang, CHEN Guoliang, et al. Ordered Structural Intermetallics[M]. Beijing: National Defence Industry Press, 2001

ZOU Zhengguang. Study on Process and Mechanism of Self-propagating High Temperature Synthesis of TiC/Fe and Its Application[D]. Wuhan: Wuhan University of Technology, 1998

ZHANG Yujun, LI Aiju, LI Chunsheng, et al. Preparation of Fe-Al Intermetallic Compounds Powder[J]. Acta Mater. Compos. Sin., 1999, 16(4): 40–43

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Natural Science Fundation of Guangxi Province(No. 0575104), the Guangxi Education Department Key Fund (No. 2003-22), the Guangxi Fund of New Century Qualified Scholars(No. 2002210) and the National Science Foundation (No. 50672016)

Rights and permissions

About this article

Cite this article

Zou, Z., Wu, Y., Yin, C. et al. Preparation of Fe-Al intermetallic / TiC-Al2O3 ceramic composites from ilmenite by SHS. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 22, 706–709 (2007). https://doi.org/10.1007/s11595-006-4706-6

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11595-006-4706-6