Abstract

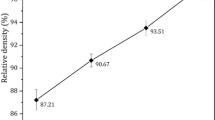

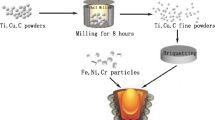

FeAl/TiC composites were fabricated by reactive hot pressing blended elemental powders. The TiC content was varied from 50% to 80% (volume fraction) and the aluminum content in the binder phase was changed from 40% to 50% (mole fraction). The effects of these compositional changes on the densification process and mechanical properties were studied. The results show that with the increase of TiC content, densities of the composites decrease due to insufficient particle rearrangement aided by dissolution — reprecipitation reaction during hot pressing. Closely related with their porosities and defect amount, the hardness and bend strength of the composites show peak values, attaining the highest values with TiC content being 70% and 60%, respectively. Increasing the aluminum content is beneficial to the densification process. But the hardness and bend strength of the composites are reduced to some extent due to the formation of excessive oxides and thermal vacancies.

Similar content being viewed by others

References

Stoloff N S. Iron aluminides: present status and future prospects[J]. Material Science and Engineering A, 1998, 258(1/2): 1–14.

Liu C T, George E P, Maziasz P J, et al. Recent advances in B2 iron aluminide alloys: deformation, fracture and alloy design[J]. Material Science and Engineering A, 1998, 258(1/2): 84–98.

Misra A K. Identification of thermodynamically stable ceramic reinforcement materials for iron aluminide matrices[J]. Metall Trans A, 1990, 21A(2): 441–448.

Inoue M, Suganuma K, Nichara K. Mechanical properties of aluminide matrix composites fabricated by reactive hot-pressing in several environments[J]. Intermetallics, 2000, 8(10): 1035–1042.

Deevi S C, Sikka V K. Nickel and iron aluminides: an overview on properties, processing and applications [J]. Intermetallics, 1996, 4(5): 357–375.

Inoue M, Suganuma K. Mechanical behavior of reactively hot-pressed FeAl matrix composites with carbide particles at elevated temperatures[J]. Journal of Materials Science Letters, 2002, 21(9): 699–701.

Schneibel J H, Carmichael C A, Subramanian R. Liquid-phase sintered iron aluminide composites[J]. Intermetallics, 1997, 5(1): 61–67.

Subramanian R, Schneibel J H. FeAl-TiC and FeAl-WC composites-melt infiltration processing, microstructure and mechanical properties[J]. Materials Science and Engineering A, 1998, 244(1): 103–112.

Subramanian R, Schneibel J H. The ductile-brittle size transition of iron aluminide ligaments in an FeAl/TiC composite[J]. Acta Mater, 1998, 46(13): 4733–4739.

Inoue M, Suganuma K, Niihara K. Fracture properties at ambient temperatures of iron aluminides fabricated by reactive hot-pressing[J]. Scripta Mater, 1998, 39(10): 1477–1482.

Subramanian R, Schneibel J H. Processing iron-aluminide composite containing carbides or borides[J]. JOM, 1997, 49(8): 50–54.

Inoue M, Nagao H. Fracture mechanism of FeAl matrix composites with discontinuous ceramic reinforcements[J]. Materials Science and Engineering A, 1999, 265(1/2): 240–245.

LIU Yong, LIU Feng-xiao, HUANG Bai-yun, et al. Improving densification and mechanical properties of FeAl/TiC composites by addition of Ni[J]. Journal of Materials Science and Technology, 2003, 19(1): 73–76.

Inoue M, Nagao H. Fracture properties of Fe40%Al matrix composites reinforced with ceramic particles and fibers[J]. Materials Science and Engineering A, 1998, 258(1/2): 298–305.

Helena S, Maria K W, Birger K. The role of oxygen in powder processing of FeAl[J]. Intermetallics, 2003, 11(5): 475–482.

Krasnowskia M, Witekb A, Kulika T. The FeAl-30% TiC nanocomposite produced by mechanical alloying and hot-pressing consolidation [J]. Intermetallics, 2002, 10(4): 371–376.

Morris M A, George O, Merris D G. Vacancies, vacancy aggregates and hardening in FeAl[J]. Materials Science and Engineering A, 1998, 258(1/2): 99–107.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (96JJY2009) supported by the Natural Science Foundation of Hunan Province

Rights and permissions

About this article

Cite this article

Liu, Fx., Liu, Y., Huang, By. et al. Fabrication of FeAl/TiC composites through reactive hot pressing. J Cent. South Univ. Technol. 11, 343–347 (2004). https://doi.org/10.1007/s11771-004-0071-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-004-0071-9