Abstract

Leather, a by-product of the meat industry, has unique strength, elasticity, water vapor permeability, resistance to abrasion, durability, and longevity. In the background of ISO 15115:2019, the authenticity of leather has become a subject matter of concern. There is a need to distinguish leather (animal origin) from other leather-like materials derived from fossil fuel (PU, faux leather, etc.) and agro-product-driven vegan materials, which are also sold in the market as leather. For this purpose, this work relies on the signature FTIR bands of collagen (the skin-making protein) as a starting point to distinguish between animal origin and rest. A detailed investigation of all types of materials used in lifestyle products has been carried out to assess the boundary lines of this hypothesis. It is reasonably concluded that the signature Amide I, II, and III bands of collagen occurring at 1600, 1500, and 1200 cm−1 could serve as the first line to distinguish against all materials other than nylon and in the case of nylon, and the Amide A band at 3200 cm−1, forms the basis for differentiation from nylon. In essence, the FTIR spectra can be used as a robust, easy and unambiguous technique to distinguish leather from leather-like materials currently available on the market.

Graphical Abstract

Similar content being viewed by others

1 Introduction

Lifestyle products such as footwear, apparel, bags etc., are predominantly made of leather and polymeric materials such as Polyurethane (PU), Polyvinyl chloride (PVC) etc. Leather, which is a byproduct of the meat industry, has unique strength, elasticity, water vapour permeability, resistance to abrasion, high durability and longevity. A comparative assessment of the properties of leather vis-à-vis polymeric materials has been presented by Meyer et al., [1]. As leather has a niche over synthetic materials, some polymeric materials are also known as artificial leather, regenerated leather, faux leather, leatherette, etc [2]. The ISO 15115:2019 describes leather as skin or hide that has its original fibrous structure more or less intact, after having been tanned and with hair or wool removed, and a surface coating or layer if applied is not thicker than 0.15 mm [3].

In the background of the ISO 15115:2019 standard, the authenticity of leather (natural) has become a subject matter of concern. Practitioners of the trade suggest that the smell of leather was different from that of the synthetics. Researchers have quantified the smell using Gas Chromatography-Mass Spectroscopy (GC–MS) and other techniques [4]. Literature does suggest the identification of animal sources as a technique to identify leather and techniques ranging from microscopic observation [5] to Polymerase chain reaction (PCR) have been suggested. Microscopic evaluation of the leather surface is challenged when the grain surface of the leather is removed for certain types of leathers or in the case of chamois leathers (a particular type of oil-tanned leather) [6]. Archaeologists have employed Enzyme-Linked Immuno Sorbent Assay (ELISA), where anti-collagen-I antibody recognized the collagen present [7] and ZooMS [8]. In a High-Performance Liquid Chromatography- Mass Spectroscopy (LC–MS) based technique, the presence or absence of marker peptides was used to identify the species [9]. However, this method requires the removal of chromium (used in tanning) and trypsin digestion [10]. By extracting DNA from the leather and using a panel of ultra-specific primers that target mitochondrial DNA fragments, species origin of leather could be identified [6, 11]. This method has limitations such as potential damage to DNA fragments during leather processing and researchers have used techniques such as mitochondrial DNA [12, 13] analysis via DNA polymerase chain reaction [14] and hyperspectral imaging combined with chemometrics for the identification of leather. In this method, the spectral curves of leather differed from the regenerated leather and other polymeric materials in the number, position and depth of characteristic peaks associated with intact fibres of animal origin [15]. The spectral features possibly arise from the collagen, the major protein in the skin and on this background, a pyrolysis GC–MS of leather results in diketodipyrrole and 2,5-diketopiperazines, which is the main component of the collagen as well [16]. A laser-induced breakdown spectroscopy (LIBS) provides for typical signatures associated with tanning agents, dyes, pigments, and polymers [17]. The THz absorption coefficient and refractive index of collagen is different from that of PVC or PU and thus a terahertz transmission spectroscopy could be ideally employed for differentiating between leather and leather-like materials [18]. The Thermogravimetric(TG) of collagen-based materials indicate that the peaks associated are different between recently manufactured and patrimonial leather [19].

While species identification through markers associated with collagen has been detailed, there are also microscopic techniques that have used hair follicle patterns for the identification of skin species and thus leather [20]. By processing Scanning Electron Microscopy (SEM) images of the grain surface of the leather, the number of hair pores, pore density, size, shape and type, and inter-pore distance can be calculated. These values are unique for a given type of animal skin [21, 22].

From the literature, it can be concluded that the signature pattern of collagen can be employed as a tool to distinguish between leather (animal origin) and synthetic leather-like materials. Such a technique without having to go into the detailing of the animal origin is likely to be facile as well. Fourier transform infrared—Attenuated Total Reflectance spectroscopy (FTIR-ATR) has been employed as a tool for the characterization of protein samples, as each protein has specific IR features that are used to evaluate secondary structure, fibrillation, denaturation etc. [23]. A detailed assessment of FTIR bands of collagen-based materials used in wound healing, skin substitutes, aged skin, collagen-based drug delivery vehicles, scaffolds etc., has been reviewed in detail [24]. One of the drawbacks associated with the method is that the Amide I band for collagen fibres and that of nylon 6 displays a maximal band centred at 1631–1632 cm−1 [25].

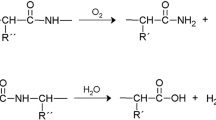

The Amide I (C=O stretching mode of peptide bond) and Amide II (N–H stretching mode of peptide bond) located around 1670–1620 F and 1570–1530 cm−1, respectively are typical IR signals which are related to the secondary structure of collagen [26]. It has been reported that each type of collagen could be distinguished through a combination of four spectral intervals, viz., stretching (C=O) absorption of Amide I (1700–1600 cm−1), the 1480–1350 cm−1 bands associated with bending (CH2), and bending (CH3), the 1300–1180 cm−1 bands associated with stretching (C–N), and bending (N–H) absorptions of Amide III, and stretching (C–O) and stretching (C–O–C) absorptions of carbohydrate moieties (1100–1005 cm−1) [27].

In light of the above literature, a methodology for the identification of leather as defined under ISO 15115:2019 needs to be developed so that consumers of lifestyle products can distinguish between leather and leather-like materials. The background of this paper is the hypothesis that the signature FTIR bands of collagen could serve as a good starting point to distinguish between the materials in a non-destructive manner. To assess the boundary lines of this hypothesis, a detailed FTIR investigation of all types of materials used in lifestyle materials was assessed, leading to a standard operating protocol for FTIR-based identification of leather.

2 Experimental section

2.1 Materials

Polystyrene film of molecular weight 104.1 g/mol was procured from Sigma Aldrich and was used as standard. Type I Collagen of molecular weight 250–300 kDa was obtained from Sigma-Aldrich and Hide powder was procured from BLC Leather Technology Centre Ltd UK. 330 samples of materials used in lifestyle products available in the market were kind gifts from the manufacturers of these products or were sourced from finished leather manufacturers or major leather fairs. These 330 leather samples (Table 1) were based on cow, buff, sheep and goat species. We had different types of finishing in these 330 samples like suede, aniline, foil coated, PU coated, pigmented, embossed, nubuck and wax coated etc. The 250 leather-like polymeric material (Table 2) was collected at the Hong Kong International Home Textiles Fair held in 2017.

2.2 Preparation of samples for FTIR

Wherever a surface coating existed in any of the 330 leather samples studied, the surface coating was scraped off using fine-macro grit emery paper to eliminate any surface material interference. Though the measurements can also be carried out using a handheld FTIR, for the present work, the samples were cut to 3 mm × 3 mm using a fine knife and the surface was cleaned by blowing air using a hair dryer. Type I collagen in the form of a film was prepared using earlier reported procedures [28]. The 250 leather-like polymeric materials were studied as such.

2.3 Fourier transform infrared spectroscopy—Attenuated total reflectance (FTIR- ATR)

ATR-FTIR spectra were collected for the prepared samples at 20 °C and 40% relative humidity by coupling an ATR (Model- Single-reflection ATR, JASCO Co., Tokyo, Japan) to an FTIR—4700 model spectrometers (JASCO Co., Tokyo, Japan). The samples were mounted on the ATR crystal (The crystal used is Zinc Selenide (ZnSe). ZnSe has a Refractive Index of 2.4, a long wavelength cut off 525, a Depth of penetration in microns@1000 cm−1 of 2.0 and a working pH range of 5–9), and the data was collected at a resolution of 4 cm−1, employing 40 scans in the wavelength range of 4000–600 cm−1. Data was collected in percentage transmittance (%T) mode. The FTIR-ATR instrument performance was verified using Polystyrene film.

3 Results and discussion

A tropocollagen is a structural unit of collagen, which is 300 nm long, and 1.5 nm in diameter. It has three polypeptide strands, that spontaneously self-assemble [29]. A collagen fibre results from the quarter-staggered array of tropocollagen molecules, which subsequently assemble into fibre bundles [30]. A collagen fibre, itself, is a bundle of collagen fibrils, characterized by a coiled structure. To prevent the microbial degradation of skin, the collagen fibres are crosslinked through a process called tanning whereby mechanical strength, thermal stability, and durability are achieved [31]. Consumer-desired properties such as softness, feel etc., are added to the tanned material through emulsified oils (fatliquors), water-soluble aromatics, phenol condensates (retans), polymeric resins etc.

As a non-invasive technique, FTIR-ATR has found enormous applications in understanding the molecular changes in the collagen secondary structure [32]. The challenge of employing the technique for leather is the interference bands likely to arise from the chemicals used in leather processing. Bands specific to lipids such as those around 2920 – 2850 cm−1, and those of vegetable tannins (1602–1604 cm−1) will be observed along with the signature bands of the protein [31].

3.1 Collagen film

To understand the differences likely to arise between leather and collagen, the IR spectrum of type I collagen film was studied in detail. The spectrum (Fig. 1a) is characterized by the presence of Amide I (mostly C=O stretching) absorption bands at 1638.2 cm−1, Amide II (C-N stretching and N–H bending) at 1538.9 cm−1, and a group of three weaker bands that indicate Amide III (C–N stretching and N–H bending); vibration modes centred at 1237.1 cm−1. Spectral bands at 804.1, 871.6, 950.7, and 1070.2 cm−1 are characteristic of carbohydrate (collagen proteoglycans) moieties (C–O stretching and C–O–C stretching). The spectral bands at 1389.4 and 1448.2 cm−1 are attributable to methylene (CH2 and CH3 bd; hereon named as aliphatic) absorptions [27]. The introduction of hydrogen bridges through collagen–water interactions bring about changes in the FTIR spectra of collagen. An increase in the intensity of Amide A and Amide B bands at 3296.7 cm−1 (OH/NH stretching) and 3071.0 cm−1 (N–H bd overtone) is observed, similar to those reported elsewhere [33].

3.2 Hide powder

The IR spectrum of hide powder (Fig. 1b), was compared with that of type I collagen film (Fig. 1a). The distinctive Amide bands I, II, III, Amide A, and Amide B were examined. For hide powder, the Amide I, Amide II and Amide III bands are observed at 1641.1, 1546.6, and 1238.0 cm−1 respectively and the Amide A and Amide B at 3293.8 and 3075.9 cm−1 respectively. The observations are indicative of the characteristic signature bands of collagen being present in the hide powder as well. It is interesting to note that the preparation of hide powder from bovine skin consists of mechanical and chemical operations including acetic acid treatment and such treatment does not change the signature bands of collagen.

3.3 Leather

The FTIR spectrum of the leather sample is shown in (Fig. 1c). The spectrum has a strong similarity to that of collagen (Fig. 1a). The Amide I, II, and III bands are observed at 1637.2, 1537.9, and 1225.5 cm−1 respectively and the Amide A and Amide B at 3271.6 and 3062.4 cm−1 respectively. A band observed at 1738.5 cm−1 can be attributed to the chemicals employed during the leather processing.

A gist of the observations on various bands observed for collagen, hide powder and leather is provided in Table 3. It is interesting to note that while the transmittance intensity of the Amide I and Amide II bands of collagen film and hide powder remained around 82.5 and 85% respectively, an above 95% decrease in the intensity was observed for leather. This reduction in the intensity of the Amide bands can be attributed to the leather chemicals that are crosslinked or coated on collagen fibres.

3.4 Leather-like materials

FTIR spectrum of polymeric materials that are employed in leather-like materials with that of collagen is presented in Fig. 2. The polymers found in leather-like materials are polypropene (PP), polyethylene (PE), ethylene vinyl acetate (EVA), polyurethane (PU), polyvinyl chloride (PVC) and polyester (PES). Alternatives to conventional leather are frequently referred to as artificial leather and have been utilized as materials for decades. The best way to characterize these synthetic leathers is as laminates or composite materials. In this case, a textile fabric—such as a polyester woven fabric—is coated with a polymer, such as one made of PVC or PU or PP or PE or EVA. The best way to characterize it is as a product of two distinct industries: the textile and chemical industries. However, there are also issues with the use of PVC materials. None of these compounds had bands that were even closer to signature Amide I and II bands of collagen. Leather-like material composed of PP made from monomer propylene via a chain-growth polymerization process having a molecular formula (C3H6) n had bands at 2950, and 2870 cm−1, arising from the asymmetrical and symmetrical stretching of CH3, 2920 and 2840 cm−1 corresponds to asymmetrical and symmetrical stretching of CH2 respectively. Symmetric in-plane C–H (–CH3 bending) at 1455 cm−1 and a shoulder at 1358 cm−1, shown in Fig. 2a further confirms that the leather-like material is composed of PP. The absence of a band associated with C=O stretching frequency at 1600 cm.−1 which is the Amide I peak in leather is a confirmatory evidence to distinguish from leather. [34]

Leather-like materials are predominantly composed of Polyethylene (Fig. 2b). Polyethylene refers to a group of thermoplastic homopolymers made up of molecular chains consisting of multiple repeating ethane (C2H4) n The IR spectrum of PE exhibits 2919 cm−1 as the asymmetrical stretching of CH2, 2850 cm−1 symmetrical stretching of CH2, 1375 cm−1 as the symmetrical bending of C-CH3 and 720 cm−1 as the rocking of C–CH2. PE IR spectrum does not exhibit a spectral band at 1600 cm−1 which is attributable to the C=O stretching frequency of the Amide I group and can be easily distinguished from the FTIR spectrum of collagen. [35]. Similarly, EVA-based leather-like materials have an FTIR spectrum (Fig. 2c), Ethylene–vinyl acetate (EVA), also known as poly (ethylene–vinyl acetate), is a copolymer of ethylene and vinyl acetate (CH2-CH2 nCH2-CH-COOCH3)m. In IR spectrum 2920, and 2852 cm−1, arising from the asymmetrical and symmetrical stretching of CH3 respectively. The 1739 cm−1 corresponds to the C = O stretching of carboxylates. 1372 cm−1 symmetrical bending of C–CH3 and 720 cm−1 to rocking of C–CH3. For EVA-based materials, the prominent bands of Amide A and Amide B at 3271.6 and 3062.4 cm−1 respectively and the Amide I band at 1600 cm.−1 is absent and thus can be differentiated from that of leather. [36]

One of the prominent polymers that is found in leather-like materials is PU. Polyurethanes (PUs) are a class of segmented copolymers composed of soft and hard segments. The soft segment is usually a polyether or polyester polyol while the hard segment is composed of a diisocyanate and chain extender with a common repeating unit of (R-NH-COO) n. The FTIR spectrum (Fig. 2d) of such materials is not quite different from that of leather. In the IR spectrum of PU, the band at 1734 cm−1 is associated with the C=O stretching frequency of the carboxylate group which does not match with the Amide I peak at 1600 cm-1 of leather. Thus differentiating PU from that of leather [37]. Furthermore, with this IR spectrum, an ether-based PU can be differentiated from ester-based PU (Fig. 3). Ether-based PU has a strong C–O–C stretch between 1250 and 1050 cm−1, these stretching frequencies are absent in ester-based PU. PVC-based materials also do not exhibit any bands at 3320 cm−1 (–OH/NH stretching) and 3020 cm−1 (N–H bd overtone) (Fig. 2e) which is very prominently present in the FTIR spectrum of collagen. The prominent peaks at 850 cm−1 in the FTIR spectrum of PVC correspond to the C–Cl stretching [38]. The 1735 cm−1 peak in the PVC IR –spectrum is attributed to the carboxylate group of plasticisers that are generally used to increase their flexibility, transparency, durability, and longevity [39]. These plasticisers are generally esters of phthalic acid. The FTIR spectrum of polyester (PES) based leather-like material is shown in Fig. 2f. This spectrum too doesn’t show any bands at 3320 cm−1 (–OH/NH stretching), 3020 cm−1 (N–H bd overtone), and the C=O stretching frequency at 1734 cm−1, is that of the carboxylate group [40].

Another important noteworthy feature is the absence of spectral bands attributable to Amide I, Amide II and Amide III in the FTIR spectra of the above leather-like materials. Many of these materials are composites that carry nylon along with them. Nylon is a polyamide having Amide I, II and III bands Fig. 4. The distinguishing features between nylon and collagen (leather) call for a closer analysis of the FTIR spectra. The spectrum of nylon is devoid of the O–H stretching band. Further, the N–H stretching band is observed as a sharp band at 3320 cm−1, while the same for leather is slightly broader due to the presence of water, which exists hydrogen bonded with O–H and N–H groups (Magnified images in Fig. 1a and Fig. 4). This observation is similar to that observed elsewhere for nylon 6, which is a model polyamide and having steeper branches and one shoulder–though there were absorption bands centred around 1631–1632 cm−1 [41].

3.5 Confirmatory analysis

Having established the presence of signatory bands of collagen in the leather and the absence of the same in leather-like materials, including nylon, the methodology was evaluated for its robustness in a range of leathers that were tanned using chromium (III), vegetable tannins, aldehydes, and oil. These tanned skin/hides were further treated with various aromatic and polymeric materials (employed as fillers—known as retan) and emulsified natural and synthetic oils (known as fatliquor). In the case of leathers that were coated with a polymeric surface coating containing pigments, the finished film had to be removed using an emery paper before analysis. The method was found to be robust and could easily distinguish leather from leather-like materials.

4 Conclusion

FTIR has been established as a facile technique for the identification of leather from non-leather or leather-like materials through the signature bands of collagen, viz., Amide I, II, III, and A&B. Leather-like materials based on various polymers could easily be distinguished from leather. In the case of nylon, a closer examination and distinction is based on the nature of the Amide A- band at 3320 cm−1. Through analysis of over 300 samples, the technique has been established as one with significantly low false positives/ negatives. The present study was able to establish a reliable means of distinguishing all types of polymeric materials that resemble leather from authentic leather. The findings are indicative of the significance of the research in the field of material science and its impact on the manufacturing industry. By providing a means of accurately differentiating between leather-like polymeric materials and genuine leather, the study offers valuable insights for manufacturers, retailers, and consumers alike. This groundbreaking study has the power to revolutionize the leather industry. By accurately distinguishing between all types of leather-like polymeric materials and authentic leather, it ensures that consumers receive exactly what they are paying for. With this study, you can trust that you are getting the real deal, every time.

Availability of data and materials

All data from this study are presented in the paper.

Abbreviations

- PU:

-

Polyurethane

- PVC:

-

Polyvinyl chloride

- PP:

-

Polypropene

- PE:

-

Polyethylene

- EVA:

-

Ethylene-vinyl acetate

- PES:

-

Polyester

- GC-MS:

-

Gas Chromatography-Mass Spectroscopy

- PCR:

-

Polymerase chain reaction

- ELISA:

-

Enzyme-Linked Immuno Sorbent Assay

- LC-MS:

-

High-Performance Liquid Chromatography- Mass Spectroscopy

- LIBS:

-

Laser-induced breakdown spectroscopy

- TG:

-

Thermogravimetric

- SEM:

-

Scanning Electron Microscopy

- FTIR-ATR:

-

Fourier transform infrared—Attenuated Total Reflectance spectroscopy

References

Meyer M, Dietrich S, Schulz H, Mondschein A. Comparison of the technical performance of leather, artificial leather, and trendy alternatives. Coatings. 2021;11(2):226.

Chen Z, Deng J, Zhu Q, Wang H, Chen Y. A systematic review of machine-vision-based leather surface defect inspection. Electronics. 2022;11(15):2383.

International organization for standardization. Leather–vocabulary I. 2019.

Schroepfer M, Schulz H, Czerny M, Schieberle P, Iultcs, editors. The smell of leather. In: 30th congress of the international-union-of-leather-technologists-and-chemists-societies; 2009 Oct 11–14; Beijing, PEOPLES R CHINA2009.

Varghese A, Jain S, Prince AA, Jawahar M. Digital microscopic image sensing and processing for leather species identification. IEEE Sens J. 2020;20(17):10045–56.

Long AJ, Addy VL, Loftus R. Extraction of DNA from leather and applications to the supply chain. J Am Leather Chem Assoc. 2007;102(1):22–6.

Liu Y, Li Y, Chang RX, Zheng HL, Zhou Y, Li ML, et al. Species identification of ancient leather objects by the use of the enzyme-linked immunosorbent assay. Anal Methods. 2016;8(42):7689–95.

Brandt LØ, Mannering U. Taxonomic identification of Danish Viking age shoes and skin objects by ZooMS (Zooarchaeology by mass spectrometry). J Proteom. 2021;16(231):104038.

Kumazawa Y, Hattori S, Taga Y. Semi-nondestructive certification of crocodilian leather by LC–MS detection of collagen marker peptides. Anal Chem. 2019;91(3):1796–800.

Kumazawa Y, Taga Y, Iwai K, Koyama Y. A rapid and simple LC–MS method using collagen marker peptides for identification of the animal source of leather. J Agric Food Chem. 2016;64(30):6051–7.

Merheb M, Vaiedelich S, Maniguet T, Hanni C. DNA for species identification in leather: fraud detection and endangered species protection. Res J Biotechnol. 2015;10(9):65–8.

Merheb M, Vaiedelich S, Maniguet T, Hanni C. Mitochondrial DNA, restoring Beethovens music. Mitochondrial DNA Part A. 2016;27(1):355–9.

Pavithra N, Aishwarya AB, Pravin AS, Sundar VJ, Gnanamani A. Exploring DNA diversity in leathers: an approach on identification of origin. J Am Leather Chem Assoc. 2021;116(1):22–9.

Zhang X, Lange S. Leather species identification via mitochondrial DNA polymerase chain reaction. J Am Leather Chem Assoc. 2019;114(7):265–70.

Hou QJ, Jin XK, Qiu YJ, Zhou ZY, Zhang HF, Jiang JJ, et al. Spectral characterization and identification of natural and regenerated leather based on hyperspectral imaging system. Coatings. 2023;13(2):450.

Kurata S, Ichikawa K. Identification of small bits of natural leather by pyrolysis gas chromatography/mass spectrometry. Bunseki Kagaku. 2008;57(7):563–9.

Gilon N, Soyer M, Redon M, Fauvet P. Separation of leather, synthetic leather and polymers using handheld laser-induced breakdown spectroscopy. Sensors. 2023;23(5):2648.

Long S, Zhang H, Song ZY, Yan SH, Cui HL. Spectroscopic studies on the natural leather and artificial leather in terahertz band. Spectrosc Spectr Anal. 2019;39(4):1030–5.

Budrugeac P, Miu L, Popescu C, Wortmann FJ. Identification of collagen-based materials that are supports of cultural and historical objects. J Therm Anal Calorim. 2004;77(3):975–85.

Dohshi S, Okumura A, Shiozaki H. Development of quantitative estimation of hair follicle patterns for leather surface by point pattern analysis. J Soc Leather Technol Chem. 2013;97(1):1–4.

Jawahar M, Vani K, Babu NKC. Leather species identification based on surface morphological characteristics using image analysis technique. J Am Leather Chem Assoc. 2016;111(8):308–14.

Wagner M, Bailey DG. Structure of bovine skin and hair root—a scanning electron microscope investigation. J Am Leather Chem Assoc. 1999;94(10):378–83.

Bettini S, Bonfrate V, Syrgiannis Z, Sannino A, Salvatore L, Madaghiele M, et al. Biocompatible collagen paramagnetic scaffold for controlled drug release. Biomacromol. 2015;16(9):2599–608.

Riaz T, Zeeshan R, Zarif F, Ilyas K, Muhammad N, Safi SZ, et al. FTIR analysis of natural and synthetic collagen. Appl Spectrosc Rev. 2018;53(9):703–46.

Vidal BD, Mello MLS. Collagen type I amide I band infrared spectroscopy. Micron. 2011;42(3):283–9.

Goormaghtigh E, Ruysschaert J-M, Raussens V. Evaluation of the information content in infrared spectra for protein secondary structure determination. Biophys J. 2006;90(8):2946–57.

Belbachir K, Noreen R, Gouspillou G, Petibois C. Collagen types analysis and differentiation by FTIR spectroscopy. Anal Bioanal Chem. 2009;395(3):829–37.

Terzi A, Storelli E, Bettini S, Sibillano T, Altamura D, Salvatore L, et al. Effects of processing on structural, mechanical and biological properties of collagen-based substrates for regenerative medicine. Sci Rep. 2018;8(1):1429.

Parvizi J, Kim GK. Chapter 53—Collagen. In: Parvizi J, Kim GK, editors. High yield orthopaedics. Philadelphia: W.B. Saunders; 2010. p. 107–9.

Daane S, Toth BA. Chapter 17—Keloids and hypertrophic scars. In: Weinzweig J, editor. Plastic surgery secrets plus. 2nd ed. Philadelphia: Mosby; 2010. p. 120–2.

Vyskočilová G, Carşote C, Ševčík R, Badea E. Burial-induced deterioration in leather: a FTIR-ATR, DSC, TG/DTG, MHT and SEM study. Herit Sci. 2022;10(1):7.

Glassford SE, Byrne B, Kazarian SG. Recent applications of ATR FTIR spectroscopy and imaging to proteins. Biochimica et Biophysica Acta—Proteins and Proteomics. 2013;1834(12):2849–58.

Susi H, Ard JS, Carroll RJ. The infrared spectrum and water binding of collagen as a function of relative humidity. Biopolymers. 1971;10(9):1597–604.

Fang J, Zhang L, Sutton D, Wang X, Lin T. Needleless melt-electrospinning of polypropylene nanofibres. J Nanomater. 2012;1(2012):1–9.

D’Amelia RP, Gentile S, Nirode WF, Huang L. Quantitative analysis of blends and copolymers of polyvinyl acetate (PVAc) using Fourier transform infrared spectroscopy (FTIR) and elemental analysis (EA). World J Chem Educ. 2016;4:25–31.

Adelnia H, Bidsorkhi HC, Ismail AF, Matsuura T. Gas permeability and permselectivity properties of ethylene vinyl acetate/sepiolite mixed matrix membranes. Sep Purif Technol. 2015;146:351–7.

Asefnejad A, Khorasani MT, Behnamghader A, Farsadzadeh B, Bonakdar S. Manufacturing of biodegradable polyurethane scaffolds based on polycaprolactone using a phase separation method: physical properties and in vitro assay. Int J Nanomed. 2011;6:2375–84.

Pandey M, Joshi GM, Mukherjee A, Thomas P. Electrical properties and thermal degradation of poly(vinyl chloride)/polyvinylidene fluoride/ZnO polymer nanocomposites. Polym Int. 2016;65(9):1098–106.

Borlandelli CM, Mahltig B. Leather types and fiber-based leather alternatives-an overview on selected materials, properties, microscopy, electron dispersive spectroscopy eds and infrared spectroscopy. Ann Textile Eng Fashion Technol. 2022;1(1):1001.

Partini M, Pantani R. FTIR analysis of hydrolysis in aliphatic polyesters. Polym Degrad Stab. 2007;92(8):1491–7.

de Campos VB, Mello MLS. Collagen type I amide I band infrared spectroscopy. Micron. 2011;42(3):283–9.

Acknowledgements

We acknowledge that CSIR-Central Leather Research Institute for its financial support for this research work. CLRI communication number: 1900.

Funding

We thank CSIR-CLRI for funding this work under CSIR-Central Leather Research Institute OLP-2318.

Author information

Authors and Affiliations

Contributions

PN: Conceptualization, Methodology, Validation, and Writing—Original Draft, Data Curation, Software KJS: Visualization, Investigation, Supervision, Writing—Review & Editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

We confirm that this manuscript did not involve the use of animals or humans in the study; therefore, this is not applicable.

Consent for publication

I, Sreeram Kalarical Janardhanan, assertively grant Springer Open the exclusive right to publish, reproduce, distribute, transmit, publicly display, and publicly perform, including the abstract, in whole or in part, in any medium and format, throughout the world, in all languages, for the full term of copyright protection and any extensions or renewals thereof. I confirm that I have the full legal authority to grant this permission and that I have not assigned, pledged, or encumbered my rights in the work before. Additionally, I acknowledge that I have obtained all necessary permissions from any third parties whose work may be included in my work. I strongly agree to indemnify and hold Springer Open harmless from any claims, demands, or losses arising out of or in connection with the publication of my work. I hereby assert and certify that I am the author of the work and that I have not infringed on the copyright or other intellectual property rights of any third party. I declare that no animals or humans are used in this study. I have carefully read and fully understood this Consent to Publish and hereby assert that I agree to its terms.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. All authors declare that there are no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Narayanan, P., Janardhanan, S.K. An approach towards identification of leather from leather-like polymeric material using FTIR-ATR technique. Collagen & Leather 6, 1 (2024). https://doi.org/10.1186/s42825-023-00145-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42825-023-00145-3