Abstract

Background

Lead-containing glass wastes from crystal factories have environmentally harmful problems. In the current work, the reduction and the feasibility of recycling of such waste through the preparation of glass in the ternary system containing wastes—silica'sand—soda-lime-silica glass, were investigated in different ceramic or composite materials.

Results

The ceramic samples are characterized by crystallization of kilchoanite (Ca3Si2O7) in addition to mixed Ce oxides [i.e., CeO2 and Ce2O3] in Pb-containing waste alone. In the other ceramic samples containing the three constituents, low quartz, tridymite, cristobalite, and wollastonite were developed. The microstructures of the later ceramics show scattered needles and interlocked ones spread in glassy matrix. The density, porosity, and compression strength values of ceramic samples were between 0.392 and 2.743 g/cc, 9.33% and 30.19%, and between 10.26 and 83.25 KN/mm2, respectively. However, sintered Pb glass-containing wastes have the highest porosity, lowest density, and compression strength. The leachability of Pb in ceramic samples, according to the standard method by ASTM-D3987 (American Standard for Testing Materials, 2012), was between 0.025 and 0.007 mg/L which is lower than the legal value (5 mg/L).

Conclusion

The present product can be used in insulation, cladding brick, and as refractory (up to 900 °C) for the samples containing the three constituents.

Similar content being viewed by others

Introduction

Heavy metals in industrial wastes are considered dangerous and anti-environment materials. Therefore, the need for stabilization/solidification of industrial wastes into useful materials or keeping it in inert condition is a great challenge.

Waste glass was attractive to either keep the industrial wastes or produce new useful materials. Cathode ray tube glass (CRTs) of television sets, which has become limited in use, contains lead oxide up to 20–25 wt.% and is considered environmentally dangerous. CRT glass powder was successfully treated with nitrilotriacetic acid (C6H9NO6) chelating agents; the product was used as a supplementary cementing material or as a fine aggregate in cementations mortars (Bursi et al. 2017).

However, some CRT glass can be used in jewelry, crystal, or radio shielding glasses (Singh et al. 2016). Other treatment of CRTs with nitric acid was employed, and the product as fine aggregate was used in cement mortar (Ling and Poon 2013). Some researcher extract Pb from CRT glass up to 99% by ethylene diaminetetraacetic acid disodium salt (Na2EDTA) (Sasai et al. 2008). Lead fuming slag (has high ratio of CaO, SiO2, FeO, and Al2O3) can be used with raw materials in glass-ceramics with good properties for construction purposes (Ponsota et al. 2015). Also, addition of waste glass to lead fuming wastes can lower the melting temperature and reduce the heat-treatment (Yoon et al. 2013; Pan et al. 2018).

The pre-work in wastes of Pb-crystal glass factories is rare. In Egypt, Elkersh (2014) found that the addition of SiC increased the foam porosity and reduced density, compression strength, and thermal conductivity. Also, he found that addition of granite reduced the foam porosity and increased the bulk density, compression strength, and thermal conductivity. Reuse of crystal glass wastes by re-melting process into saleable products was done in Germany and such product may have pebble or streaks but its cost is clearly lower than the cost for waste disposal (Klaus-Peter Martinek 1999). Heat treatments of crystal glass wastes gave emotional design that can be reused in coatings for exterior walls or interior vertical coverings, furniture, and equipment which allow light to pass through (Fernando Miguel Marques 2015)

The present work deals with the developed ceramic material, through the system: waste of Pb-crystal glass, silica'sand, and soda-lime-silica glass, with study of some characterization and properties. The developed ceramic materials can be used in insulation and building constructions.

Methods

The starting materials in this work include Pb-containing wastes, silica, and soda-lime-silica glass cullet (SLSG). The chemical analysis of the starting materials was mentioned in Table 1. The batch of the samples was selected through the triangle of the main three constituents at each peak (Fig. 1). The well-mixed batches were casted into discs (about 1/2 in. in diameter) using uniaxial pressure at 20 KN/mm2. All discs were dried at 180 °C.

The chemical analysis of the Pb-containing waste and the sintered samples were carried out using X-ray fluorescence (WDXRF, Rh tube, PANalytical). The developed crystalline phases in sintered samples were identified by x-ray diffractometer (XRD; X-ray diffractometer model BRUKER Axs, D8ADVANCE, Germany). Scanning electron microscope (SEM/EDX, model FEJ quanta 250 Fei-Holland) was used on the fresh fracture surface of the sintered sample etched by 1%HF-1% HNO3.

The compression stress was performed using a universal testing machine. The density of the sintered samples was performed using sensitive balance for weight measuring and digital calipers for dimensions measuring to calculate size.

Characteristics of Pb-containing waste

Crystal glass (may be called lead glass) is a variety of potash glass with replacement of lead (PbO: 18–40% by weight) for calcium. The addition of lead oxide in glass batch lead to the brilliance and sparkling effect in crystal glass; therefore, it is desirable in decorative and architecture purposes (Benvenuto 2015 )

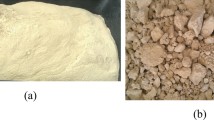

In the crystal glass factory, after grinding and polishing of crystal glass, considerable amount of wastes are generated which are collected in water as sludge of Pb-containing waste. Three sludge batches were collected from local crystal glass factory in Egypt. The collected sludge were mixed and pulverized to less than 0.038 mm in grain size, according to the ISO2859-1 method.

The leaching of lead from the tested sample was carried out according to the ASTM D3987 (2012) method “Standard Practice for Shake Extraction of Solid Waste with Water”. A sample of 70 g of the sludge along with 1400 ml of distilled water was added in 2-l container leaving adequate headspace for mixing at 29 rpm speed according to the standard, and the sample was agitated for 18 h. The leached lead ratio from the solution was determined using Spectrophotometer (Genway 6300-spectrophotometer—UV single beam). In the representative sludge sample, the leaching content of Pb was found 7.53 mg/L. The determined lead ratio in the sludge sample was higher than the legal one (5 mg/L, Table 2). Therefore, the present Pb-solid waste is considered hazardous based on US legislations. Table 2 shows the average content of Pb in mg/L after leaching in water for the three samples.

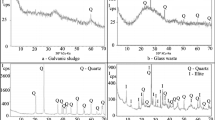

The x-ray diffraction of the dried Pb-containing waste showed a mixture of crystalline CeO2 (ICDD card 81-0792) and Ce2O3 (ICDD card 87-0484) with clear amorphous hump between 2Θ 20 and 30 (Fig. 2). The later results showed the used material in polishing the crystal glass (i.e., CeO2 and Ce2O3 ) and with the abraded crystal glass.

Results

The chemical analysis of the sintered Pb-containing waste W0 sample at 900 °C/2 h shows ~ 20% of PbO (Table 3). For the composite WSG1, WSG2, and WSG3 samples, sintered at 900 °C/2 h and within Pb-containing wastes, silica'sand, and sod-lime-silica glass system, the Pb-content was between 6 and 12% PbO (Table 3).

The x-ray diffraction analysis of W0, WSG1, WSG2, and WSG3 samples sintered at 900 °C/2 h is shown in Fig. 2. In W0 sample of Pb-containing waste, kilchoanite (ICDD card 85-1048, Ca3Si2O7) was developed in addition to two valences oxides of cerium oxide (CeO2, Ce2O3). In the case of WSG1, WSG2, and WSG3 sintered samples containing admixed Pb-containing wastes—silica'sand and sod-lime-silica glass, low quartz was the main phase with cristobalite (ICDD card 82-1403, SiO2) and wollastonite in WSG1. In the case of WSG2 and WSG3 of low Pb-containing waste, tridymite (ICDD card 88-535, SiO2) appeared in addition to the major low quartz with the wollastonite (ICDD card 76-0186, CaSiO3).

The SEM micrographs of the present W0, WSG1, WSG2, and WSG3 samples sintered at 900 °C/2 h show large clear pores in the W0 sample which decrease in size and content in direction of low soda-lime-silica glass (Fig. 3). In high-magnification photographs, interlocked needles in glassy matrix are clear in W0 samples and appear also in WSG1 and WSG3 samples (Fig. 3). In the WSG2 sample, the needles are impregnated in glassy matrix and appear as rods spread in different directions (Fig. 3).The EDX microanalysis of W0 and WSG2 of the needle- and rod-like crystals show the presence some predominant elements and very little ones (Fig. 4 and Table 4). However, in the W0 sample, both CeO2 and Ce2O3 were developed in addition to Ca silicate kilchoanite [Ca6(SiO4)(Si3O10)]. On the other hand, wollastonite (CaSiO3) and silica minerals (SiO2) were developed in WSG2.

The values of density, compression strength, and porosity of W0, WSG1, WSG2, and WSG3 samples sintered at 900 °C/2 h are shown in Table 5. Although the W0 sample has high PbO ratio, its density was very low (0.392 g/cc) due to its high porosity (~ 30%). The density of WSG1, WSG2, and WSG3 samples, containing three constituents, were 2.509, 2.732, and 2.743 g/cc, respectively. In general, the increasing of the density values follows the increase of soda-lime-silica glass content concomitant with the decrease in porosity. Also, the compression strength increased from 10.26 KN/mm2 in the W0 sample to 83.25 KN/mm2 in the WSG3 sample of the highest soda-lime-silica glass ratio (Table 4).

The leachability of Pb ratio in the sintered samples, according to the route mentioned in ASTM D3987 (2012), is given in Table 6. All the resulted values were lower than the legal value given by ASTM D3987 route (2012).

Discussions

The present ceramic materials were produced after the sintering process of the three compositions. In crystallization, silica minerals, i.e., cristobalite and tridymite, were enhanced in the presence of alkali and alkaline earth. One can ask why Ca silicate mineral of kilchoanite and wollastonite appeared early at low temperature (i.e., at 900 °C). Actually, the presence of some elements in composition of crystal glass, such as La, Ce, and Zr, can act as a catalyst to enhance the crystallization of kilchoanite and wollastonite phases.

The density values of our samples, 2.509, 2.732, and 2.743 g/cc for W1, W2, and W3, respectively, follow the increase of soda-lime-silica glass content concomitant with the decrease in porosity. Also, the compression strength increase from 10.26 KN/mm2 in W0 sample to 83.25 KN/mm2 in WSG3 of the highest soda-lime-silica glass ratio.

In general, the leachability values of Pb ratio in the sintered samples were lower than the legal value given by ASTM D3987 route (2012). This means that lead was incorporated in the glassy state with very low mobility in case of leaching process.

Conclusion

Composite materials (like ceramic) were prepared from Pb glass-containing wastes—silica'sand and soda-lime-silica glass kilchoanite (Ca3Si2O7)—in addition to mixed Ce-oxides (Ce2O–Ce2O3) in sintered Pb glass containing wastes whereas low quartz, tridymite, cristobalite, and wollastonite were developed in the case of composites containing three constituents. The density, porosity, and compression strength values of ceramic samples were between 0.392 and 2.743 g/cc, 9.33% and 30.19%, and between 10.26 and 83.25 KN/mm2, respectively. The microstructure show scattered needles and interlocked needles embedded in glassy matrix. The chemical resistance according to the method given by the standard method by ASTM-D3987 (2012) was between 0.025 and 0.007 mg/L which is very low than the legal value (5 mg/L). From the later results, the present product can be used in insulation, in cladding brick, and as refractory (up to 900 °C) for the samples containing the three constituents.

Availability of data and materials

The authors declare that the data and material are available.

Change history

28 January 2020

After publication of the original article (Hamzawy et al. 2019), we were notified that.

References

ASTM D3987, Standard practice for shake extraction of solid waste with water. Active Standard ASTM D3987| Developed by Subcommittee: D34.01.04. Book of Standards Volume: 11.04 (2012).

Benvenuto MA (2015) Industrial chemistry: for advanced students. Walter de Gruyter GmbH & Co KG ISBN 9783110351705

Bursi E, Barbieri L, Lancellotti I, Saccani A, BignozziM (2017) Lead waste glasses management: chemical pretreatment for use in cementations composites. Waste Manag Res 35(9):958–966

Elkersh H (2014) Innovative cleaner production technique foam glass production from lead crystal glass sludge. MSc dissertation. The American University in Cairo AUC

Ling TC, Poon CS (2013) A comparative study of the feasible use of recycle beverage and CRT funnel glass as fine aggregate in cement mortar. J Cleaner Prod 29–30:46–52

Marques FM (2015) Recycled glass crystal an approach to emotional design. Procedia Manufacturing 3:5941–5946

Martinek K-P (1999) Recycling of typical waste of the glass industry by use of a melting furnace. NGF’s 50th anniversary meeting in Reykjavik, Iceland

Pan D’a, Li L, Wu Y, Liu T, Yu H (2018) Characteristics and properties of glass-ceramics using lead fuming slag. J Cleaner Prod 175(20):251–256

Ponsota I, Bernardo E, Bontempi E, Depero L, Detsch R, Chinnam RKA, Boccaccinic R (2015) Recycling of pre-stabilized municipal waste incinerator fly ash and soda-lime glass into sintered glass-ceramics. J Cleaner Prod 89(15):224–230

Sasai R, Kubo H, Kamiya M et al (2008) Material recycling process for spent lead glass using a mechano-chemical process and Na2EDTA reagent. Environ Sci Technol 42:4159–4164

Singh N, Wang J, Li J (2016) Waste cathode ray tube: an assessment of global demand for processing. Procedia Environ Sci 31:465–474

Yoon S-D, Lee J-U, Lee J-H, Yun Y-H, Yoon W-J (2013) Characterization of wollastonite glass-ceramics made from waste glass and coal fly ash. J. Mater. Sci. Technol. 29:149–153

Acknowledgments

The authors thank colleagues in Asfour factory of crystal glass for their help in collecting the samples and their help in using the available instruments in the factory.

Funding

This study was not funded by any source.

Author information

Authors and Affiliations

Contributions

All authors contributed in the practical work of this research. They also share in preparing the manuscript for publication. They approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The authors declare that the work is ethically approved.

Consent for publication

This work not accepted or published before.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: we were notified that 1. In table 3, the caption ‘n.d. not deleted’ should be replaced with ‘n.d. not detected'; 2. In table 5, repeated photos shouldn't be there.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Hamzawy, E.M.A., El-Sherbiny, S.I. & Saber, A.M. Trials of reuse the Pb-containing wastes of crystal glass factories into useable new materials. Bull Natl Res Cent 43, 191 (2019). https://doi.org/10.1186/s42269-019-0204-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42269-019-0204-9