Abstract

Various researches on the recycling and reuse of potential wastes have accelerated. Industrial waste glass from the production and use of many products is one of the main sources of environmental pollution, because only 30% is reused globally. In this study, as an alternative fluxing component in the compositions of stoneware ceramic bodies, industrial soda-lime-silica glass wastes (GW) were utilized as partial and total replacing of sodium feldspar and potassium feldspar in the starting batches. New body recipes were composed by adding glass waste to the standard body composition consisting of quartz, kaolin, clay, Na-feldspar, and K-feldspar. Glass wastes were processed by grinding and sieving and further characterized by using hot-stage microscope, X-ray diffraction (XRD), and particle size analyzer. Designed clay body compositions were fired according to a special heat treatment cycle and characterized in terms of thermal, physical, mechanical, and microstructural behavior using a spectrophotometer, differential thermal analyses, hot-stage microscopy, XRD, scanning electron microscope, strength instrument, and energy dispersive X-ray spectroscopy.

Similar content being viewed by others

References

Rivera, J.F., et al.: Novel use of waste glass powder: production of geopolymeric tiles. Adv. Powder Technol. (2018). https://doi.org/10.1016/j.apt.2018.09.023

Rao, M.N., Sultana, R., Kota, S.H.: Solid and Hazardous Waste Management, Science and Engineering, 1st Edition, 344 pages, p. 2. Butterworth-Heinemann, Elsevier, Oxford (2016)

Aukour, F.J.: Feasibility study of manufacturing concrete eco-blocks using marble sludge powder as raw materials. Sustain. J. Dev. Plan. IV. 2, 845–852 (2009)

Coldiron, C.A.: Sculpture and Design with Recycled Glass, 208 pages, p. 14. Schiffer Publishing Ltd., Atglen (2011)

Johnson, G.: 1000 Ideas for Creative Reuse: remake, restyle, recycle, renew, 320 pages, p. 9. Quarry Books, Quayside (2009)

NIIR Board of Consultants & Engineers: The Complete Book on Glass and Ceramics Technology, 624 pages, page 2. Asia Pacific Business Press Inc., Delhi (2005)

Varshneya, A.K.: Fundamentals of Inorganic Glasses, New York State College of Ceramics. Alfred University, New York and Academic Press, Inc., Boston (1994)

Pulker, H., Pulker, H.K.: Coatings on Glass, 466 pages, p. 1. Elsevier Science, Amsterdam (1999)

Le Bourhis, E.: Glass: Mechanics and Technology, 416 pages, p. 1. Wiley-VCH, Weinheim (2014)

Shelby, J. E.: Introduction to Glass Science and Technology, 291 pages, page 3. Royal Society of Chemistry, Cambridge (2005)

Haldimann, M., Luible, A., Overend, M.: Structural Use of Glass, 215 pages, p. 4-5. IABSE, Zürich (2008)

Ismail, Z.Z., AL-Hashmi, E.A.: Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Manag. 29(2), 655–659 (2009)

Shayan, A., Xu, A.: Value-added utilization of waste glass in concrete. Cem. Concr. Res. 34, 81–89 (2004)

Sobolev, A.V., et al.: The amount of recycled crust in sources of mantle-derived melts. Sci. Express. 316, 412–417 (2006)

Malisch, W.R., Day, D.E.: Use of Domestic Waste Glass for Urban Paving: Summary report, 46 pages. National Environment Research Center (1975). https://nepis.epa.gov/Exe/ZyPDF.cgi/20014PZV.PDF?Dockey=20014PZV.PDF. Accessed 23 Oct 2018

Dhir, R.K., Limbachiya, M.C., Dyer, T.D.: Recycling and Reuse of Glass Cullet. Thomas Telford Ltd., London (2001)

Biçici, P.: The use of Elazığ - Uslu pottery clay in ceramic body, glaze and engobe, Anadolu University, Graduate School of Science, Ceramic Engineering Program, Master of Science Thesis, (2010)

Silva, R.V.: The role of glass waste in the production of ceramic-based products and other applications: a review. J. Clean. Prod. 167, 346–364 (2017)

Pinheiro, B.C.A., Holanda, J.N.F.: Reuse of solid petroleum waste in the manufacture of porcelain stoneware tile. J. Environ. Manag. 118, 205–210 (2013)

Abidin, S. Z. et al.: Proceedings of the 2nd international colloquium of art and design education research (i-CADER). https://doi.org/10.1007/978-981-10-0237-3_14. (2015)

Hummel, R.E.: Understanding Materials Science: History · Properties · Applications, p. 15. Springer Science & Business Media (2013). https://doi.org/10.1007/b137957

Zakin, R.: Ceramics: Mastering the Craft, 256 pages, p. 30. Krause Publications, Wisconsin (2001)

Hopper, R.: The Ceramic Spectrum: A Simplified Approach to Glaze & Color Development, 225 pages, p. 25. Chilton Book Co., Radnor (1984)

Correia, L., et al.: Using experiments design to model linear firing shrinkage of triaxial ceramic bodies. Mater. Sci. Forum. 498–499, 430–435 (2005)

Márquez, J.M., Rincón, J.M., Romero, M.: Effect of firing temperature on sintering of porcelain stoneware tiles. Ceram. Int. 34, 1867–1873 (2008). https://doi.org/10.1016/j.ceramint.2007.06.006

Espe, W.: Silicates: Materials of High Vacuum Technology, 684 pages, p. 589. Elsevier, Burlington (2013)

Galvão, A.C.P., et al.: Characterization of waste of soda-lime glass generated from lapping process to reuse as filler in composite materials as thermal insulation. Cerâmica. 61, 367–373 (2015)

Sallam, E.M.H., Chaklader, A.C.D.: Sintering characteristics of porcelain. Ceramurg. Int. 4(4), 151–161 (1985)

Bondioli, F., Ferrari, A.M., Romagroli, M.: The effect of sintering conditions on linear shrinkage in porcelainized stoneware tiles as studied in a two level full factorial design. Int. Ceram. 56(2), 108–110 (2006)

Hamisi, H., et al.: Influence of firing temperature on physical properties of same clay and pugu kaolin for ceramic tiles application. Int. J. Mater. Sci. Appl. 3(5), 143–146 (2014)

Islam, S., et al.: Effect of soda lime silica glass waste on the basic properties of clay aggregate. Int. J. Sci. Eng. Res. 7(4), 149–153 (2016)

Agnew, N.: Conservation of ancient sites on the Silk Road. In: Proceedings of an International Conference on the Conservation of Grotto Sites GCI Proceedings. Getty Publications, Los Angeles (1997)

Cubas, G.B., et al.: The effect of investment materials on the color of feldspathic ceramics. Eur. J. Dent. 5(4), 433–440 (2011)

Pontikes, Y.: Thermal behaviour of clays for traditional ceramics with soda-lime-silica waste glass admixture. J. Eur. Ceram. Soc. 27(2–3), 1657–1663 (2007)

Gualtier, A.F.: Thermal behavior of the raw materials forming porcelain stoneware mixtures by combined optical and ın situ x-ray dilatometry. J. Am. Ceram. Soc. 90(4), 1222–1231 (2007)

Venturelli, C.: Thermal expansion study of a β-eucryptite-based glass-ceramic by means of the optical dilatometry. Ceram. Forum Int. 83(9), E67–E70 (2006)

Gungor, F.: Investigation into the Soft Porcelain Production by a Lesser Energy Consumption. Anadolu University Graduate School of Sciences Ceramics Engineering Program, PhD Thesis, p. 25 (2012). https://www.academia.edu/16474446/Fazilet_g%C3%BCng%C3%B6r_tez. Accessed 10 Oct 2018

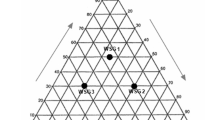

Osborn, E. F., Muan, A.: System CaO–Al2O3–SiO2; composite, Phase equilibrium diagrams of oxide systems, Plate 1, Am. Ceram. Soc., Edward Orton, Jr., Ceramic Foundation, Fig. 00630, revised and redrawn, Colombus, Ohio (1960)

Carter, C.B., Norton, M.G.: Ceramic materials science and engineering, p. 129. Springer Science & Business Media, New York (2013)

Haccuria, E., et al.: Selected phase equilibria studies in the Al2O3-CaO-SiO2 system. J. Am. Ceram. Soc. 99, 691–704 (2016). https://doi.org/10.1111/jace.13991

Acchar, W., Dultra, E.J.V.: Theoretical analysis of crystalline phases. In: Ceramic materials from coffee bagasse ash waste. Springer Briefs in Applied Sciences and Technology. Springer, Cham (2015)

Bloomfield, L.: Techno file: phase and eutectics, Ceramics Monthly, April, 80–81 (2017). https://ceramicartsnetwork.org/ceramics-monthly/ceramic-glaze-recipes/glaze-chemistry/phase-and-eutectics/

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yeşilay, S. Production of stoneware clay bodies by using industrial soda-lime-silica glass waste. J Aust Ceram Soc 55, 747–758 (2019). https://doi.org/10.1007/s41779-018-0286-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-018-0286-0