Abstract

The composite system of stone columns reinforced soil overlaid by granular mattress (GM) has been given more attention as a hybrid improvement technique. This work presents 3D finite element analyses using PLAXIS 3D software for a composite system of floating stone columns group constructed in a deep soft clay deposit in Port-Said in Egypt. The limited area of loading was investigated in conjunction with the system key parameters, i.e., length, diameter, and the GM main properties. Results validated the effectiveness of the GM in settlement reduction and system behavior enhancement. The GM thickness results in considerable settlement reduction up to value of 1.5d where d is the stone column diameter. The thickness increase can be an economical substitution instead of increasing stone column length where a new factor named “Mattress improvement factor: Ƞgm” is defined to represent the occurring improvement due to GM existence. Results also show notable reduction of settlement with increasing the length to a limiting value of L = 1.8B where B is the footing width.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The soft clay distinctive features of low bearing capacity and high compressibility have always formed a challenge in geotechnical practice. To overcome this, soil improvement techniques are being developed over time, where stone columns system has proved its credibility through multiple projects and experiments. Several studies have been conducted to provide better understanding of the system starting from [1] to current pioneer research, e.g., [2,3,4,5]. Stone columns can be constructed as end-bearing or floating columns. The behaviour of end-bearing columns is widely investigated through analytical or numerical methods, in contrast to the floating behaviour. Deeper understanding of the floating stone columns behaviour is yet to be generalized. In addition, literature shows limited studies that consider the three-dimensional behaviour of stone-column groups instead of the simplification by “unit-cell” concept, e.g., [4, 6,7,8]and [3]. The external columns usually lack the lateral confinement provided to inner ones by the surrounding columns [9], so this effect shall be considered in analysis and design for the probability of differential settlement. Considerable work has been done to study limited area loading cases like [10, 11] and [12].

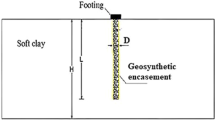

In 1981 [13] referred to a further improvement method by the placing of a sand blanket with 30 cm minimum thickness over the composite system.to function as an upper drainage layer and stress distributer for the structure loads on the composite system [14]. Agreed with the granular mattress importance and moreover they attributed its contribution to forcing the columns bulge into deeper layers where the overburden pressure is larger, hence leading to a larger ultimate capacity of the pile. They recommended a thickness that would reach 1 m of sand, gravel, or crushed stone. Starting the twenties, many studies have arisen [15]. Established a simple theoretical technique to predict the deformation behaviour of uniformly loaded soft ground reinforced by granular columns with granular mat on top. They came to the conclusion that having a granular mattress reduces the stress concentration factor towards the top of the pile, normalised displacements, and the percentage load borne by the granular pile at the top, as well as interface shear stresses [16]. Developed a mechanical model to predict the behaviour of a multilayer geosynthetic-reinforced granular fill soft soil with stone columns inclusions. Results showed the contribution of the developed system in total and differential settlement reduction. Moreover, they concluded that adding geosynthetic reinforcement layer to the stone column reinforced soft soil decreases the nonlinearity in the behaviour of the soft soil. Later, [17] have extended the study to multi-layer reinforcement system. Results have showed that geosynthetic reinforcements help the stress transfer process and cause further reduction of stress on the soft soil with time. In comparison between single and multi-layers cases, observations showed that when soft soil is enhanced with stone columns, the multilayer reinforcement system is less efficient in reducing total settlement than single layer reinforcement since the total settlement is reduced significantly by the stone column itself. Also, the differential settling is somewhat reduced due to the use of several geosynthetic layers compared to single layer. As experimental studies in this topic were limited, laboratory model experiments on single-stone columns were performed by [18] to investigate the influence of reinforcement diameter and thickness of reinforced and unreinforced sand beds on settlement response, bearing capacity, and stone column bulging. Their study resulted in considerable conclusions concerning the significant improvement in load carrying capacity and settlement reduction due to geogrid inclusion as reinforcing element in the sand bed. The probable first numerical analysis in this filed may be attributed to [19] where they validated a series of small-scale laboratory tests through three-dimensional finite element analyses using ABACUS software. They provided a valuable insight into acknowledging a more depth view in the context of stone columns system unreinforced and reinforced granular mattress. Yet, further research need to be conducted for comprehensive understanding of this hybrid system. The current paper presents a new three-dimensional finite element analysis using PLAXIS 3D (V.2013) software to study the behaviour of a composite system of floating stone columns group overlaid by GM. The term granular mattress (GM) is adopted herein to refer to the layer overlying the stone columns.

Project overview

The studied area is located in Port-Said in Egypt where a deep deposit of soft clay extends to 44 m depth—Fig. 1a. The project requires the construction of 35 m x 15 m raft foundation with 34 kPa load intensity. Due to the expected high consolidation settlement (≈ 600 mm according to the site properties), the designers proposed the employment of stone-columns system with diameter 1 m, length 15 m, and spacing 2.2 m with the configuration shown in Fig. 1b that represents area replacement ratio of 39%, The system is further overlaid by GM to allow for better stress distribution, different thickness values for the GM are investigated in the present study.

Finite element modelling

Model geometry and meshing

The finite element code PLAXIS 3D was used to run a three-dimensional analysis—Fig. 2—representing only quarter of the system geometry considering the double symmetry about X-axis and Y- axis. The reference case was set to the proposed design parameters of a diameter of 1 m, length of 15 m, and spacing of 2.2 m without GM to compare the effect of its presence and its thickness variation. Model dimensions were selected such that the boundary conditions don’t affect the calculation results. This was initially performed based on the rules of thumb given by [20]. For the current case, the vertical boundaries were set to the largest distance of 3B or 2L after the loading area of interest (where B is the raft width and L is the column length). The horizontal bottom boundary was taken larger than 2B where B is the footing width. A sensitivity analysis of dimensions was accomplished to investigate the boundaries effect. No interface elements were used between the soil and stone columns considering full contact between the stone aggregates and the surrounding clay due to high compaction during installation as early presented in [21,22,23], while interface elements were used between the raft footing and soil to allow for strength reduction due to slipping and gapping. The raft was modelled as a plate element representing the flexible nature of the wide area of loading. The plate had thickness (dplate) of 0.6 m and elasticity modulus (E) of 2.1e7 kPa. The working load of 34 kPa was assigned as a uniform surface load through the PLAXIS interface options. The medium-coarse mesh option was selected initially with local refinement at the zones expected to have high stresses or deformations using 10-node tetrahedral elements. After the mesh sensitivity analysis, the final mesh was composed of 120966 elements and 171752 nodes.

Material modelling

The site test report offered the soil characteristics based on a detailed investigation through CPTs, SPTs and borehole tests. The report presents a detailed analysis of the soil parameters obtained from the field and laboratory tests, in addition to the various correlations used based on literature. Figures 3, 4, 5 present an overview of the geotechnical data of the site. The Soft Soil (SS) model [24] available by PLAXIS software was selected to simulate the high compressibility of the soft clay layer which was validated against the theoretical classic 1D consolidation solution in [25] given in Eq. 1. Figure 6 shows the consolidation values with depth using the SS model and the theoretical solution.

a Variation of the liquid limit, plastic limit and plasticity index for the executed BHs, b undrained shear strength versus depth based on CPTs, c undrained deformation modulus versus depth based on undrained shear strength from CPTs, and d variation of OCR versus depth as concluded from CPTu (Site soil report)

where: \(\delta\) c = settlement due to consolidation; Cc = compression index; eo = initial void ratio; H = height of the compressible soil; σzf = final vertical stress; σz0 = initial vertical stress.

The SS model is mainly defined by modified compression index (λ*) and recompression index (κ*) which are calculated automatically by the software using the inputs of reported compression, recompression indexes and the void ratio (Cc, Cs & e) based on Eqs. 2, 3.

The lateral earth pressure coefficient in the clay layer was raised above its original value of Ko to a value of 1.5 as a technique to consider the installation effect of stone piles as reported by many authors, e.g., [5, 9, 26,27,28,29,30,–31].

The Mohr -Coulomb (MC) model was used for all the granular materials with cohesion set to value 0.1 to avoid numerical errors; the sand properties were obtained based on the soil report, while the stone properties were adopted based on literature as given in Table 1 representing common range of values used for design. All materials were modelled as drained materials representing the long-term condition of loading. The total model parameters are given in Table 2.

Reference study case

With placing stone columns, the settlement value at the raft centre was reduced to 88.6 mm while it reached 124 mm at the raft corner, which represents a settlement reduction factor (β = Suntreated/Streated) that ranges from 4.8 to 6.18 which implies a settlement reduction ratio between 79 and 85%. The stress-settlement curve—Fig. 7—shows weaker response with smaller system stiffness at the raft corner, where the stiffness improvement factor (SIF = E50%untreated/E50%treated) is 13 and 9.1 for the centre point and corner respectively; noting that the secant stiffness at 50% of the design load, i.e., at 18 kPa is adopted for stiffness comparison and the stiffness values are normalized to the stiffness of the untreated case.

This inverse differential settlement where the corner settlement is higher than the centre can be attributed to the loss of lateral confinement of stone columns at the raft periphery, which shall be considered an important merit of modelling the full three-dimensional nature of the group compared to the unit cell concept that assumes equal settlement at different column locations within the loading area. The numerical values of centre and corner settlement are herein validated to the developed mechanical method by [32]. They applied the equivalent raft method used for pile groups settlement analysis to the stone columns group, where they calculated the settlement based on dividing the zone of interest into three sections: plastic zone of composite soil, elastic zone of composite soil, and elastic zone of the original soil below the columns tip as demonstrated in Fig. 8.

Settlement of homogenous subsoil stratum reinforced with floating stone columns (after [32])

Their developed Eq. 4 was used to calculate the centre and corner settlement of the current study case considering the composite stiffness (Ecomp) of the improved ground along the column’s length and the native soil stiffness for the zone below columns. The composite stiffness was calculated according to Eq. 5 [33]. The resulting composite stiffness value was used for settlement calculation below the raft centre, while it was reduced by 75% for the settlement calculation at raft corner in order to consider the lack of confinement within the vicinity of this zone. The analytical method of [32] gave settlement values of 72 mm and 100 mm at the centre and corner respectively, therefore the numerical results can be considered acceptable values.

where q = applied stress extending to elastic zone of thickness L1; Eeq = the modified composite stiffness at plastic zone; Ecomp = the composite stiffness of improved ground at the elastic zone; qi = the stress at the mid-layer of the elastic zone having a thickness of L2; qj = the stress at the mid-layer of soil between column toe and 3D.

where E eq = equivalent modulus of the composite foundation; Es = soil modulus; Ec = column modulus; as = area replacement ratio.

Both locations show transition from the elastic to the plastic zone with hardening behaviour. The settlement contours are presented in Fig. 9 where the whole system shows block settlement, i.e., the columns and the soil in between acts as a composite unit. The zone of influence extends to 27 m which approximately equals 2B where B is the footing width. Little differential settlement exists between columns and soil which can be attributed to the loading case which suggest an intermediate level between rigid and flexible loading.

Concerning lateral deformation behaviour, the deformed shape shown in Fig. 10a presents the bulging occurring up to depth 2d:4d with the maximum value at column depth of 1d. This agrees with different reported deformation behaviour through literature. Yet, bulging was observed more as we approach the raft edges which can be attributed again to the lack of confinement in this zone due to nonexistence of stone columns. Bulging zones implies plastic deformation in the stone columns that can be shown in Fig. 10b of deviatoric shear strains that presents failure sections in columns.

Parametric study details

A parametric study is conducted to investigate the effect of changing some of the system key parameters given in Table 3. L/d values were increased from 6 which is an average common value in literature, e.g., [34, 35, 36] with increasing until reaching a limiting value. The same thing was done with the values of (t/d). While the stone friction angle was varied as based on different reported values through literature as presented in Table 1.

Effect of column length (L/d)

For the current load level at 30 kPa, reducing the column length leads to settlement increase and stiffness reduction—Fig. 11—with the weakest case for of L/d = 6. The settlement reduction factor (β) in Fig. 12 shows high rate of increase from L/d = 6 to L./d = 8 of 36%, then shows less linear increase around 20% with length increase until the length effect diminishes when moving from L/d = 20 to L/d = 25. The change in settlement percent compared to the reference case at the applied stress 30 kPa (ηL) is also presented in Fig. 13. Results indicates wide variation from the lowest value of L/d = 6 to the reference case value L/d = 15, while further increase in the L/d value shows insignificant change. The current results show continuous contribution of the columns length to improvement degree exceeding the values around 6d which is commonly reported through literature to be the critical length of stone columns. When the column length is normalized to the footing width—Fig. 14, the critical length can be limited to a value around 1.7:1.8 B where B is the footing width. This may indicate that the system improvement is related to the footing dimensions and loading area rather that the stone column diameter, which agrees with [37] recommendation to relate the optimum length to the footing dimensions rather than the diameter for more realistic representation of the loading zone conditions. The SIF curve in Fig. 15 represents average 1.2 folds of the SIF values with length increase although not showing a uniform trend.

Effect of stones friction angle (φ)

The stones friction angle has significant effect on the system behaviour as presented in Fig. 16. The settlement reduction factor—Fig. 17—decreased with an average rate 35% for changing the friction angle with 5° with an approximately linear relationship. The SIF in Fig. 18 indicated an average reduction of 50% of the SIF values. The change in settlement percent compared to the reference case (ηφ) reached 60% and 133% increase for the friction angle values of 40° and 35° respectively which implies the high importance of compaction degree to the overall system enhancement. Concerning the differential settlement; the corner settlement was still higher than at centre but changing the friction angle did not show observed change as the values ranged between 37 and 42 for the three cases which may indicate the ineffectiveness of its value for differential settlement control. The lateral deformation behaviour was similar for all the friction angle cases, where bulging was observed to depth 4d of the stone pile length with its maximum value at 1d depth at the outer columns. The maximum X- direction values were 0.05 m, 0.04 m, and 0.03 m for ϕ = 35°, 40°, and 45° respectively, while the maximum Y-direction values were 0.048 m, 0.040 m, and 0.029 m for ϕ = 35°, 40°, and 45° respectively with the maximum values occurring at the perimeter columns due to partial confinement.

Effect of granular mattress thickness (t/d)

The placing of granular mattress with thickness t = 0.25d over the composite soil—Fig. 19—results in noticeable improvement in settlement reduction and stiffness increase. The system total settlement was reduced by 42% at both raft centre and corner for using thickness 0.25d and further reduction of 28% when using t = 0.5d, additional thickness increase results in less improvement until no further noticeable increase as can be seen in Fig. 20.

A new factor (ηgm) is defined—Eq. 6—representing the improvement of the overall system due to the placing of granular mattress over the stone columns, compared to the case where only stone columns are used (i.e., ref. case where t/d = 0). The factor is referred to as “Mattress improvement factor: ηgm”, and its values are presented in Fig. 21. The values indicate reaching an optimum value of thickness about 1.5d.

where, St0: System settlement with stone columns only, i.e., tgm = 0.

Sti: System settlement for and (i) value of the granular mattress thickness.

A similar discussions are reported through literature concerning the system of rigid inclusions overlaid by load transfer platform (LTP) where the increasing of the LTP enhances the overall system performance due to the arching effect, e.g. [38, 39] and [40].

The inverse differential settlement is still noticed with lower granular mattress thickness until reaching a specific value where the normal behavior appears as the centre settlement value slightly exceeds the corner settlement value as presented in Fig. 22 where the system becomes more rigid, and the thickness increase adds more stabilization to the edge columns. Generally, the overall differential settlement showed significant reduction with thickness increase leading to uniform distribution of stresses which is illustrated in Fig. 23. The SIF values showed relatively lower improvement—Fig. 24—for increasing thickness, yet the behaviour turned stiffer and more linear with the yield zone pushed further with thickness existence and increase to t = 0.5d, then the SIF values show less increase rate.

The lateral deformation was observed to be reduced with placing the granular mattress with further thickness increase as can be illustrated from the shading contours of X-direction and Y-direction in Figs. 25 and 26 respectively. Starting from t = 0.25d, the lateral deformation showed bulging shape up to the depth around 4D with the maximum bulge values at the edge columns. Transition to t = 1d and with thickness further increase, the lateral deformation showed different behaviour as bending of stone columns was observed with outward lateral movement in + X -direction and + Y- direction at the columns tip in conjunction with the common bulging shape, this behaviour was observed marginally at the outer columns.

Combined analysis for stone column length and GM thickness

For further generalization of the current results of stone columns length and GM thickness, additional analyses were conducted according to Table 4 where multiple column length values were solved in conjunction with the GM thickness change through a combined analysis for three stone column diameter values of 1 m, 1.25 m, and 1.5 m.

Marginal improvement in the system behaviour is observed for increasing the length from 6 to 8d specially for the cases of t/d = 0 and noticing that the system yield appears clearer in the low length values for all the cases of t/d = 0 and 0.5. Further improvement is observed for length increase in all the studied cases as can be presented through the β values presented in Fig. 27 that shows relatively linear pattern for settlement reduction.

For diameter 1 m—Fig. 28, the settlement values showed notable reduction with placing a granular mattress of different thickness, with stiffness increase of the whole system that approaches linear behaviour with thickness increase. Settlement value reached around 80% of the original value with no granular mattress. Improvement rate when moving from the zero-thickness case to the case of 0.5d thickness reached 48%, 65% and 73% for the cases of L/d = 6,8 and 10 respectively, while the improvement rate decreased with moving towards larger thickness compared to the case of 0.5d.

The same improvement was observed for the case of 1.25 m diameter—Fig. 29, where the settlement was reduced to 41% of the zero-thickness case for L/d = 6, 39%, 38%, and 35% for L/d = 8,10, and 15 respectively. The pattern is extended to the case of diameter 1.5 m as presented in Fig. 30, where placing 0.5d thick mattress reduced settlement to 42% of the zero-thickness case for L/d = 6. Moving from zero-thickness to t/d = 1.5 caused settlement reduction to 39%, 41%, and 39% for L/d = 8, 10 and 15 respectively. In general, the system stiffness showed notable increase that approaches linear behaviour, indicating moving beyond the yield limit of the system. Figure 31 summarizes the variation of β values with different t/d values, where approximately linear patterns are apparent for all cases with an average β value of 15. Placing of the granular mattress and further increase in thickness also showed notable reduction in the differential settlement values up to t = 0.5d as presented in Fig. 32 where further thickness increase does not yield much improvement. The mattress thickness factor ηgm in Fig. 33 gives an average 70% improvement in settlement compared to the zero-thickness case.

Conclusions

The present paper has discussed the 3D FE analysis of a proposed design for large floating stone columns group supporting a raft over soft clay. A parametric study was conducted to varying some key parameters to investigate their effect. The main findings can be concluded as:

-

1.

Modelling the complete three-dimensional nature of the large stone pile groups instead of modelling the unit cell concept aids to determine the differential settlement values at different points, which can be more representative of the actual field conditions.

-

2.

Lateral deformation of outer columns was more dominant than internal ones due to lack of confinement that affected the whole system deformation for all cases of different pile length.

-

3.

Increasing the stone pile length resulted in continuous contribution to settlement improvement exceeding the values around (6d) which is commonly reported through literature to be the critical length and reaching up to (20d). The critical stone pile length can be limited to about (1.7 B) where (B) is the footing width.

-

4.

The optimum granular mattress thickness can be limited to a value of (1.5d) where (d) is the column diameter as further values increase results in small improvement rate.

-

5.

A new factor was introduced namely: “Mattress improvement factor: ηgm”, which represents the improvement of the overall system due to the placing of granular mattress over the stone columns compared to the case where only stone columns are used, it has showed that the increase of granular mattress thickness resulted in settlement reduction of an average 65% of the zero-thickness case settlement.

References

Hughes JM, Withers NJ (1974) Reinforcing of soft cohesive soils with stone columns. Gr Eng. https://doi.org/10.1016/0148-9062(74)90643-3

Castro J (2011) Consolidation and deformation around stone columns: numerical evaluation of analytical solutions. Comput Geotech 38(3):354–362. https://doi.org/10.1016/j.compgeo.2010.12.006

Ng KS, Tan SA (2015) Stress transfer mechanism in 2D and 3D unit cell models for stone column improved ground. Int J Geosynth Gr Eng 1(1):1–9. https://doi.org/10.1007/s40891-014-0003-1

Sexton BG, McCabe BA, Castro J (2014) Appraising stone column settlement prediction methods using finite element analyses. Acta Geotech 9(6):993–1011. https://doi.org/10.1007/s11440-013-0260-5

Ellouze S, Bouassida M, Bensalem Z, Znaidi MN (2016) Numerical analysis of the installation effects on the behaviour of soft clay improved by stone columns. Geomech Geoeng 12(2):73–85

Elsawy M, Lesny K, & Richwien W (2009) Behavior of ordinary and encased stone columns studied by FEM analysis. Proceedings of the 17th international conference on soil mechanics and geotechnical engineering: (Volumes 1, 2, 3 and 4) (pp. 2350–2353). IOS Press.

Fayed AL, Sorour TM, & Shehata HF (2017) Study of the behavior of floating stone columns in soft clay formations using numerical modeling. in international congress and exhibition “sustainable civil infrastructures: innovative infrastructure geotechnology” (pp. 236–251). Springer, Cham.

Muzammil SP, Varghese RM, Joseph J (2018) Numerical simulation of the response of geosynthetic encased stone columns under oil storage tank. Int J Geosynth Gr Eng 4(1):1–12

Shehata HF, Sorour TM, Fayed AL (2021) Effect of stone column installation on soft clay behavior. Int J Geotech Eng 15(5):530–542. https://doi.org/10.1080/19386362.2018.1478245

Killeen MM, McCabe BA (2014) Settlement performance of pad footings on soft clay supported by stone columns: a numerical study. Soils Found 54(4):760–776

Tan SA, Ng KS, Sun J (2014) Column group analyses for stone column reinforced foundation. Geotech Special Publ 233:597–608. https://doi.org/10.1061/9780784413265.048

McCabe BA, Killeen MM (2017) Small stone-column groups: mechanisms of deformation at serviceability limit state. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000700

Mitchell JK (1981) Soil improvement-state of the art report. In Proc., 11th Int. Conf. on SMFE (Vol. 4, pp. 509–565).

Barksdale RD, Bachus RC (1983) Design and construction of stone columns, vol I (No. FHWA/RD-83/026; SCEGIT-83–104). Turner-Fairbank Highway Research Center, McLean

Shahu JT, Madhav MR, Hayashi S (2000) Analysis of soft ground-granular pile-granular mat system. Comput Geotech 27(1):45–62

Deb K, Basudhar PK, Asce AM, Chandra S (2007) Generalized model for geosynthetic-reinforced granular fill-soft soil with stone columns. Int J Geomech 7(4):266–276

Deb K, Chandra S, Basudhar PK (2008) Response of multilayer geosynthetic-reinforced bed resting on soft soil with stone columns. Comput Geotech 35(3):323–330. https://doi.org/10.1016/j.compgeo.2007.08.004

Deb K, Samadhiya NK, Namdeo JB (2011) Laboratory model studies on unreinforced and geogrid-reinforced sand bed over stone column-improved soft clay. Geotext Geomembr 29(2):190–196. https://doi.org/10.1016/j.geotexmem.2010.06.004

Debnath P, Dey AK (2017) Bearing capacity of reinforced and unreinforced sand beds over stone columns in soft clay. Geosynth Int 24(6):575–589. https://doi.org/10.1680/jgein.17.00024

Lees A (2016) Geotechnical finite element analysis. ICE Publishing, London

Kirsch F (2006) Vibro stone column installation and its effect on ground improvement. In proceedings of the international conference on numerical modelling of construction processes in geotechnical engineering for urban environment (pp. 115–124).

Gäb M, Schweiger HF, Kamrat-Pietraszewska D, Karstunen M (2008) Numerical analysis of a floating stone column foundation using different constitutive models. In geotechnics of soft soils: focus on ground improvement. CRC Press, Boca Raton, (pp 149–154)

Shahu JT, Reddy YR (2011) Clayey soil reinforced with stone column group: model tests and analyses. J Geotech Geoenviron Eng 137(12):1265–1274

Brinkgreve RBJ (1994) Geomaterial models and numerical analysis of softening. TU Delft University.

Terzaghi K, Peck RB, Mesri G (1967) Soil mechanics in engineering practice. John Wiley & Sons, New York

Ammari KA, Ph D, Clarke BG, Ph D, Eng C (2018) Effect of vibro stone-column installation on the performance of reinforced soil. J Geotech Geoenviron Eng 144(9):1–10. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001914

Camelo CYS (2016) Three-dimensional numerical analysis of test embankment on geosynthetic-encased stone columns (Doctoral dissertation, Universidade Federal do Rio de Janeiro). https://doi.org/10.13140/RG.2.1.5090.0887

Castro J, Karstunen M (2010) Numerical simulations of stone column installation. Can Geotech J 47(10):1127–1138

Elshazly H, Hafez D, & Mossaad M (2006) Back-calculating vibro-installation stresses in stone-column-reinforced soils. Proceedings of the institution of civil engineers-ground improvement. 10(2), 47-53.

Bouassida M, Ellouze S, & Debats JM (2008) Parametric study of improved soft clay due to installation of a group of stone columns. In International Conference on Numerical Computation in Geotechnical Engineering NUCGE (Vol. 8).

Kirsch F (2008) Evaluation of ground improvement by groups of vibro stone columns using field measurements and numerical analysis. In proc. of the 2nd Int. Workshop on the geotechnics of soft soils, Glasgow (pp. 241–248).

Ng KS, Tan SA (2015) Settlement prediction of stone column group. Int J Geosynth Gr Engin. https://doi.org/10.1007/s40891-015-0034-2

Han J (2015) Principles and practice of ground improvement. John Wiley & Sons, New York

Malarvizhi SN, Ilamparuthi K (2007) Comparative study on the behaviour of encased stone column and conventional stone column. Soils Found 47(5):873–885

McKelvey D (2002) The performance of vibro stone column reinforced foundations in deep soft ground. [PhD thesis, Queen’s University of Belfast]

Najjar SS, Sadek S, Maakaroun T (2010) Effect of sand columns on the undrained load response of soft clays. J Geotech Geoenviron Eng 136(9):1263–1277

Castro J, Miranda M, Da Costa A, Cañizal J, & Sagaseta C (2019) Critical length of stone columns. In proc. 17th Eur. conf. soil mechanics and geotechnical engineering (pp. 1–6).

Dong Y, Zheng J, Zhang J (2011) Analysis of flow and failure mechanism of cushion in rigid pile composite foundation. Adv Mater Res 168–170:1491–1495. https://doi.org/10.4028/www.scientific.net/AMR.168-170.1491

IREX (2012) Recommendations for the design, construction and control of rigid inclusion ground improvements. Presses des Pont, Paris

Bohn C (2016) Serviceability and safety in the design of rigid inclusions and combined pile-raft foundations Cécilia Bohn.

Nazari Afshar J, Ghazavi M (2012) Experimental studies on bearing capacity of geosynthetic reinforced stone columns. Arab J Sci Eng 39(3):1559–1571

Al-Ani W, & Wanatowski D (2017) Settlement analysis of floating stone columns. In Numerical modeling of construction processes in geotechnical engineering for urban environment: proceedings of the 19th international conference on soil mechanics and geotechnical engineering, Seoul.

Ambily AP, Gandhi SR (2007) Behavior of stone columns based on experimental and FEM analysis. J Geotech Geoenviron Eng 133(4):405–415

Andreou P, Papadopoulos V (2014) Factors affecting the settlement estimation of stone column reinforced soils. Geotech Geol Eng 32(5):1175–1185

Choobbasti AJ, Pichka H (2014) Improvement of soft clay using installation of geosynthetic-encased stone columns: numerical study. Arab J Geosci 7(2):597–607

El-Garhy B, Maraie M, Youssef AF (2011) Behavior of model footings resting on soft clay reinforced by floating granular piles: experimental study. Int J Geotech Eng 5(4):415–424

Fattah MY, Majeed QG (2012) Finite element analysis of Geogrid encased stone columns. Geotech Geol Eng 30(4):713–726

Fattah MY, Al-Neami MA, Al-Suhaily AS (2017) Estimation of bearing capacity of floating group of stone columns. Eng Sci Technol Int J 20(3):1166–1172

Hasan M, Samadhiya NK (2016) Experimental and numerical analysis of geosynthetic-reinforced floating granular piles in soft clays. Int J Geosynth Gr Eng 2(3):1–13

Castro J, & Sagaseta C (2009) Field instrumentation of an embankment on stone columns. In proceedings of the 17th international conference on soil mechanics and geotechnical engineering (Volumes 1, 2, 3 and 4) (pp. 1865–1868). IOS Press.

Castro J (2016) An analytical solution for the settlement of stone columns beneath rigid footings. Acta Geotech 11(2):309–324

Sexton BG, Killeen MM, & McCabe BA (2012) Appraisal of current settlement prediction methods applicable to vibro replacement design. BCRI 2012.

Murugesan S, Rajagopal K (2007) Model tests on geosynthetic-encased stone columns. Geosynth Int 14(6):346–354

Naseer S, Sarfraz Faiz M, Iqbal S, Jamil SM (2019) Laboratory and numerical based analysis of floating sand columns in clayey soil. Int J Geo-Eng 10(1):1–16

Ng KS, Tan SA (2014) Design and analyses of floating stone columns. Soils Found 54(3):478–487

Ong DEL, Sim YS, Leung CF (2018) Performance of field and numerical back-analysis of floating stone columns in soft clay considering the influence of dilatancy. Int J Geomech 18(10):04018135

Najjar S, Sadek S, & Bou Lattouf H (2013) The drained strength of soft clays with partially penetrating sand columns at different area replacement ratios. In 18th international conference on soil mechanics and geotechnical engineering (pp. 939–942).

Sadaoui O, Bahar R (2019) Field measurements and back calculations of settlements of structures founded on improved soft soils by stone columns. Eur J Environ Civ Eng 23(1):85–111

Serridge CJ, Sarsby RW (2008) A review of field trials investigating the performance of partial depth vibro stone columns in a deep soft clay deposit. In Proceedings of the 2nd International Workshop on the Geotechnics of Soft Soils-Focus on Ground Improvement (pp. 293–298)

Six V, Mroueh H, Shahrour I, Bouassida M (2012) Numerical analysis of elastoplastic behavior of stone column foundation. Geotech Geol Eng 30(4):813–825

Stacho J, & Sulovska M (2019) Laboratórne stanovenie pevnostných a deformačných.

Stacho J, Sulovska M (2019) Numerical analysis of soil improvement for a foundation of a factory using stone columns made of different types of coarse-grained materials. Periodica Polytechnica Civil Eng 63(3):795–803

Yoo C (2010) Performance of geosynthetic-encased stone columns in embankment construction: numerical investigation. J Geotech Geoenviron Eng 136(8):1148–1160

Zahmatkesh A, Choobbasti AJ (2012) Settlement evaluation of soft clay reinforced with stone columns using the equivalent secant modulus. Arab J Geosci 5(1):103–109

Mohtasham MR, Khodaparast M (2018) Investigation of the effect of dimensional characteristics of stone column on load-bearing capacity and consolidation time. Civil Eng J 4(6):1437–1446

Fathi E, Mohtasham R (2016) Numerical analysis of the reinforced stone column by geosynthetic on stability of embankment. In Proceedings of the World Congress on Civil, Structural, and Environmental Engineering (CSEE’16), Prague, Czech Republic–March (pp. 30–31)

Ghazavi M, Afshar JN (2013) Bearing capacity of geosynthetic encased stone columns. Geotextiles and Geomembranes 38:26–36

Kirsch F (2009) Evaluation of ground improvement by groups of vibro stone columns using field measurements and numerical analysis. Geotechnics of Soft Soils: Focus on Ground Improvement.

Acknowledgements

The authors would like to thank Faculty of Engineering -Mansoura University for their academic support and providing open sources for research and knowledge. They would like also to express their gratitude for each person who provided all hands of help along the path of this research.

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yasser, F., Altahrany, A. & Elmeligy, M. Numerical investigation of the settlement behavior of hybrid system of floating stone columns and granular mattress in soft clay soil. Geo-Engineering 13, 12 (2022). https://doi.org/10.1186/s40703-022-00177-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-022-00177-4