Abstract

Transition metal dichalcogenides (TMDs), transition metal carbides (TMCs), and transition metal oxides (TMOs) have been widely investigated for electrocatalytic applications owing to their abundant active sites, high stability, good conductivity, and various other fascinating properties. Therefore, the synthesis of composites of TMDs, TMCs, and TMOs is a new avenue for the preparation of efficient electrocatalysts. Herein, we propose a novel low-cost and facile method to prepare TMD–TMC–TMO nano-hollow spheres (WS2–WC–WO3 NH) as an efficient catalyst for the hydrogen evolution reaction (HER). The crystallinity, morphology, chemical bonding, and composition of the composite material were comprehensively investigated using X-ray diffraction, Raman spectroscopy, field emission scanning electron microscopy, and X-ray photoelectron spectroscopy. The results confirmed the successful synthesis of the WS2–WC–WO3 NH spheres. Interestingly, the presence of nitrogen significantly enhanced the electrical conductivity of the hybrid material, facilitating electron transfer during the catalytic process. As a result, the WS2–WC–WO3 NH hybrid exhibited better HER performance than the pure WS2 nanoflowers, which can be attributed to the synergistic effect of the W–S, W–C, and W–O bonding in the composite. Remarkably, the Tafel slope of the WS2–WC–WO3 NH spheres was 59 mV dec−1, which is significantly lower than that of the pure WS2 NFs (82 mV dec−1). The results also confirmed the unprecedented stability and superior electrocatalytic performance of the WS2–WC–WO3 NH spheres toward the HER, which opens new avenues for the preparation of low-cost and highly effective materials for energy conversion and storage applications.

Similar content being viewed by others

1 Introduction

Over the past few decades, the over-exploitation of natural resources, such as oil, coal, and fossil gas, has been a critical challenge to humankind [1]. The consequences of the over-use of fossil fuels, including green gas emissions and global warming, have caused a severe threat to the environment and our lives [2, 3]. Therefore, scientists all over the world have endeavored to develop novel environmentally friendly and facile processes for synthesizing materials suitable for energy storage and conversion applications. Hydrogen is considered as the most efficient fuel [4,5,6]. The use of hydrogen gas in new technologies has increased significantly because it offers various advantages, such as poison-free gas emission and a simple and scalable production process [7, 8], which involves the application of an electric potential on electrodes in water to split it into oxygen and hydrogen. However, enhancing the efficiency of the water splitting process is a major challenge. In conventional techniques, scarce and noble materials, including platinum (Pt) and palladium (Pd), are frequently employed to produce hydrogen gas [9,10,11]. However, the scarcity, high cost, and poor stability of these noble materials limit their application for the production of hydrogen gas [12]. Therefore, earth-abundant metals have been extensively investigated as catalysts for the hydrogen evolution reaction (HER) [13,14,15].

Transition metals have partially filled d-orbitals, and hence exhibit unique mechanical and chemical properties, which have been extensively investigated [16, 17]. Interestingly, transition metal dichalcogenide (TMD) materials exhibit impressive electrocatalytic efficiency [18,19,20] owing to their abundant active sites, earth-abundance, and excellent stability in acidic or basic media [21]. An electrocatalyst should exhibit good conductivity improve the performance of the process [22]. However, the intrinsic conductivity of TMD materials is highly dependent on their morphology, structure, and chemical bonding. TMD materials exhibit poor intrinsic conductivity, which restricts their use in many electrochemical applications [23]. Recently, MoS2 and WS2 prepared using various techniques and procedures have been widely investigated for HER applications [24,25,26,27]. The different morphologies of WS2, such as nanosheets, nanoflowers (NFs), nanoparticles, nanotubes, and nano-hollow (NH), obtained using different synthesis methods showed different catalytic activities toward hydrogen generation. Nevertheless, the efficiency of these materials still needs to be improved to realize their industrial applications. Transition metal oxides (TMOs) also show various advantages, such as high intrinsic catalytic activity and a variety of desirable physical and chemical properties. The synergistic effect of WS2 and WO3 on the HER performance of their composite material has been investigated in detail [28, 29]. At the edge of the art, a new approach to improve the electrocatalytic performance of WS2 is to combine it with a transition metal carbide (TMC) material, such as WC or MoC [30, 31]. Transition metal carbides (TMCs) show high metallic conductivity and ceramic properties, including chemical durability, high hardness, and high melting point. Recently, TMC materials have been widely used in electrochemical applications owing to their high surface area, excellent electronic conductivity, hydrophilicity, and high chemical and mechanical durability [32, 33].

Herein, we propose a novel strategy to prepare WS2–WC–WO3 NH composite materials (WS2–WC–WO3 NH). For comparison, WS2 NFs were also synthesized by slightly modifying the procedure used for synthesizing the WS2–WC–WO3 NH spheres. The morphologies, structures, and chemical bonding of both the WS2–WC–WO3 NH spheres and WS2 NFs were investigated various techniques such as X-ray diffraction (XRD), Raman spectroscopy, field emission scanning electron microscopy (FE-SEM), and X-ray photoelectron spectroscopy (XPS), respectively. The results confirmed the successful preparation of the hybrid NH spheres of WS2, WC, and WO3. Interestingly, nitrogen was also detected in the hybrid NH spheres because it was doped in-situ into the hollow composite during the synthesis process. The high HER activity of the hybrid composite can be attributed the presence of WC, WO3, and nitrogen in it. Nitrogen doping significantly increased the electrical conductivity of the composite. Moreover, the synergistic effect of W–S, W–C, and W–O bonding improved the electrocatalytic performance of the WS2–WC–WO3 NH hybrid. Furthermore, the HER electrocatalytic performances of both the WS2 NFs and WS2–WC–WO3 NH spheres were carefully evaluated using a normal three-electrode system. The results showed that the WS2–WC–WO3 NH composite is a promising material for next-generation catalysts, which can be employed in energy conversion and storage applications.

2 Experimental details

2.1 Chemical materials

Ammonium meta-tungstate (AMT, (NH4)6H2W12O40) and thioacetamide (TAT, C2H5CS, 99%) were purchased from Sigma-Aldrich. Deionized (DI) water was purchased from Millipore Milli-Q system. Absolute ethanol (EtOH, C2H5OH) was obtained from Alfa Aesar. All the materials were used as received without further purification.

2.2 Synthesis of the WS2–WC–WO3 NH sphere composite

The WS2–WC–WO3 NH sphere composite was synthesized using a conventional solvothermal technique. First, 4 g of TAT was dissolved in 20 mL EtOH by stirring at room temperature for 30 min. Then, 4 g of AMT was added to the solution and stirred continuously for another 30 min. The prepared solution was then transferred to a Teflon autoclave for 24 h at 280 °C. The autoclave was then cooled to room temperature. The resulting product was collected and washed with DI water and EtOH three times through centrifugation. Finally, the product was placed in a furnace and dried at 100 °C for 12 h to obtain the WS2–WC–WO3 NH composite. Finally, the product was dispersed in DI water by sonication and used for further measurements.

2.3 Synthesis of the WS2 NFs

The WS2 NFs were synthesized by slightly modifying the procedure used for the synthesis of the WS2–WC–WO3 NH sphere composite. First, 4 g of TAT was dissolved in 20 mL DI water under stirring at room temperature for 30 min. To the resulting mixture, 4 g of AMT was added and the mixture was stirred continuously for another 30 min. The reaction mixture was then transferred to a Teflon autoclave for 24 h at 200 °C. The autoclave was then cooled to room temperature. The product was collected and washed with DI water and EtOH three times through centrifugation. Then, the product was placed in a furnace and dried at 100 °C for 12 h to obtain the WS2 NFs. Finally, the product was dispersed in DI water by sonication for further measurements.

2.4 Materials characterization

The crystalline structures of the as-synthesized WS2 NFs and WS2–WC–WO3 NH spheres were analyzed using XRD (D8-Advance/Bruker-AXS). The morphology, size, and shape of the synthesized WS2 NFs and WS2–WC–WO3 NH spheres were analyzed using FE-SEM (SIGMA/Carl Zeiss). Raman spectroscopy (Lab RAM HR, Horiba Jobin Yvon) was performed to investigate the chemical bonding and structure of the materials. The chemical compositions of the WS2 NFs and WS2–WC–WO3 NH spheres were examined using XPS (Thermo Fisher Scientific, K-Alpha, USA) at a base pressure of 1 × 10–5 mbar and 300 K with monochromatic Mg Kα radiation (1250 eV) and a constant pass energy of 50 eV.

2.5 Electrochemical measurements

The HER performances of the as-prepared WS2 NFs and WS2–WC–WO3 NH spheres were carefully evaluated using a three-electrode system in a standard 0.5 M H2SO4 solution. A carbon rod electrode and a saturated calomel electrode were used as the auxiliary and reference electrodes, respectively. A glassy carbon electrode (GCE) with a diameter of 3 mm was coated with the active material to form the working electrode. The active material was prepared by mixing 2 mg of each sample into 1 mL of DI water and 80 µL of Nafion (5%) as the stabilizer, followed by sonication for 30 min to form a homogeneous ink. Then, the homogeneous ink was deposited on the surface of the GCE and dried at 80 °C for 30 min. Linear sweep voltammetry (LSV) was performed at a scan rate of 5 mV s−1. To determine the double layer capacitances (Cdl) of the samples, the measurements were performed from 0 to 0.2 V at various scan rates of 5, 10, 20, 30, 40, and 50 mV s−1. Electrochemical impedance spectroscopy (EIS) measurements were performed at a potential of -0.33 V vs. RHE over a frequency range of 100 kHz–0.1 Hz. All the potentials were referenced to the reversible hydrogen electrode (RHE) using the Nernst equation: ERHE = ESCE + EoSCE + 0.059 pH.

3 Results and discussion

The XRD patterns of the WS2–WC–WO3 NH spheres and WS2 NFs were obtained to analyze their structures and crystallinity. Figure 1 shows the XRD patterns of the as-prepared WS2 NFs and WS2–WC–WO3 NH spheres. The XRD pattern of the WS2 NFs showed peaks corresponding to the hexagonal phase of WS2 (JCPDS Card No. No. 08-0237) [34,35,36]. The XRD pattern of the WS2–WC–WO3 NH spheres showed numerous sharp peaks, indicating the complex growth of different elements. The peaks corresponding to WS2, WC, and WO3 could be clearly observed, indicating the coexistence of WS2, WC, and WO3 in the composite. This confirms the successful synthesis of the composites of WS2, WC, and WO3. The sharp peaks of WS2, which also appeared in the XRD pattern of the WS2–WC–WO3 NH spheres, were located at approximately 2θ = 14.5°, 29°, 35.5°, and 60°. The peaks located at approximately 2θ = 30.5°, 35.5°, 47°, 63°, 66°, and 71.5° indicate the presence of WC. This is consistent with the results reported previously [37]. The peak observed at 2θ = 43.5° can be attributed to the WC1-x structure [38]. The peaks corresponding to WO3 were observed at approximately 2θ = 15°, 17°, 38°, 51°, and 53°. The results confirmed the existence of the orthorhombic structure of WO3 in the composite [39, 40]. The XRD pattern of the WS2 NFs did not show any peak corresponding to WC or WO3, confirming the successful preparation of pure WS2. The coexistence of WS2, WC, and WO3 in the WS2–WC–WO3 NH sphere composite can be attributed to the higher reaction temperature used in the synthesis process than that used in the case of WS2 NFs. The higher reaction temperature caused the replacement of S elements by C or O elements in the material.

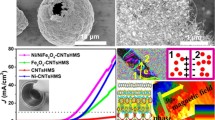

The morphologies of the WS2–WC–WO3 NH spheres and WS2 NFs were carefully observed using FE-SEM, as shown in Fig. 2. The FE-SEM images of the WS2–WC–WO3 NH spheres and WS2 NFs were obtained at various magnifications to clearly observe their sizes, shapes, and morphologies. Figure 2a and c show the SEM images of the highly uniform WS2 NFs at different scales. The thickness of the NFs ranged from 10 to 20 nm, and the distance between them was approximately 50–150 nm. In contrast, the FE-SEM images of the WS2–WC–WO3 composite showed hollow nanospheres. As can be observed from Fig. 2d–f, the diameter of these hollow nanospheres ranged from 300 to 700 nm, and the wall thickness was approximately 30–50 nm. The size of the WS2–WC–WO3 NH spheres was much smaller than that of the WS2 NH spheres reported in a previous study (300 nm–2 μm) [41]. This indicates that the active sites of the WS2–WC–WO3 NH spheres were significantly larger than those of the WS2 NFs. Interestingly, as can be observed from Fig. 2f, the surface of the WS2–WC–WO3 NH spheres was intensively and uniformly cracked. The hollow shape of the material might have been caused by the high synthesis temperature, which created high pressure inside the autoclave. The numerous cracks on the surface of the composite material can be attributed to the decomposition of TAT, in which NH3 and H2S gases were released during the sulfurization and carbonization of tungsten in AMT. This resulted in the formation of a hollow structure with numerous cracks on the surface. In addition, the nitrogen released from AMT was trapped in a hollow structure, which caused the in-situ nitrogen doping of the WS2–WC–WO3 NH composite. The EDS mapping of WS2–WC–WO3 NH composite were conducted. The EDS data of WS2–WC–WO3 NH composite was showed in the Additional file 1: Figure S1. The data confirms the well-define spatial elemental distribution for W, S, O, C, N atoms which were 35.24%, 25.32%, 19.53%, 19.41% and 0.45%, respectively. The presence of nitrogen was also detected using XPS. The empty space inside the spheres and the vast cracks on their surface contributed to the excellent electrocatalytic performance of the WS2–WC–WO3 NH composite by creating a large number of active sites in it. The hollow structure of the material also improved its stability because it prevented the depletion of materials in the electrochemical process.

The chemical structures and bonding of the WS2–WC–WO3 NH spheres and WS2 NFs were further investigated by obtaining their Raman spectra in Fig. 3. The Raman spectrum of the WS2 NFs showed bands corresponding to the W–S bonds at 352 and 417 cm−1. These bonds were related to the weak van der Waals interlayer interactions affecting the intralayer bonding and lattice vibration of stacked layer crystallites [42, 43]. These bands belong to the E2g mode of the W + S movement in the x–y plane and the A1g mode of the S movement along the z-axis [44, 45]. The Raman spectrum of the WS2 NFs showed peaks corresponding to WO3 at 131.3, 180, 261.9, 695, and 805 cm−1, which resulted in the surface oxidation of WS2. The Raman spectrum of the WS2–WC–WO3 NH spheres showed two peaks corresponding to WS2 at approximately 352 and 417 cm−1. The Raman peaks corresponding to WO3 could be clearly observed at 131.3, 185, 261.9, 327, 695, and 805 cm−1. The sharp WO3 peak centered at 327 cm−1 marked the most significant difference between the Raman spectra of the two materials. This peak indicates the co-existence of WO3, WS2, and WC in the composite materials. The band at 695 cm−1 corresponds to the O–W–O stretching mode of WO3, while that at 805 cm−1 could be ascribed to the asymmetric stretching mode of oxygen bridge (O–W–O). These O–W–O bands existed because the composite exhibited basal plane orientations that were perpendicular to the substrate surface. The Raman spectrum of the WS2–WC–WO3 NH spheres showed broad bands at approximately 1393 and 1594 cm−1 corresponding to WC [38]. Interestingly, the Raman peaks corresponding to WC were observed at approximately 262, 329, 710.8, and 807.2 cm−1. These peak positions were quite overlapping as compared to those of WO3 [46].

The elemental compositions of the WS2 NFs and WS2–WC–WO3 NH spheres were further investigated by carrying out XPS measurements, as shown in Fig. 4. The wide XPS survey profiles of the WS2 NFs and WS2–WC–WO3 NH spheres are shown in Fig. 4a. As can be observed from the figure, the XPS profiles of both the WS2 NFs and WS2–WC–WO3 NH spheres showed nitrogen peaks, indicating that nitrogen was doped in-situ into the WS2 NFs and WS2–WC–WO3 NH spheres during the synthesis process. This is contrary to the results of a previous study, in which the nitrogen doping of the catalytic material was not observed [24]. The appearance of nitrogen was caused by the use of AMT as the precursor during the synthesis. The presence of nitrogen in the WS2–WC–WO3 NH composite significantly improved its conductivity and electrocatalytic performance [47]. The significant differences in the chemical composition and the W 4f binding energy levels of the WS2 NFs and WS2–WC–WO3 NH spheres can be clearly observed from Fig. 4b and c. As can be observed from Fig. 4b, the W 4f profile of the WS2–WC–WO3 NH spheres showed peaks corresponding to W–C, W–S, and W–O [48] because of the presence of WS2, WC, and WO3. The synergistic effect of these components improved the material characteristics, leading to a significant improvement in its HER performance as compared to that of the bare WS2 [49]. In Fig. 4c, The W 4f XPS profile of the WS2 NFs showed only the peaks corresponding to W–S and W–O, which originated from surface oxidation of WS2 (Fig. 4c). The peaks located at approximately 32 and 34.2 eV could be assigned to the W 4f7p/2 and W 4f5p/2 levels of the W–S bonds, while peaks located at 35.6 and 37.8 eV corresponded to the W 4f7/2 and W 4f5/2 levels of W–O bonding. The core-level XPS profiles of the WS2 NFs and WS2–WC–WO3 NH spheres are shown in Additional file 1: Figures S2 and S3, respectively. Both the samples showed high-resolution C 1 s and O 1 s peaks. However, in the XPS profiles of the WS2 NFs, the oxygen peaks were detected because of the surface oxidation of WS2, while the carbon peaks were attributed to the graphitic TAT used in the synthesis process. This is consistent with the XRD and Raman spectroscopy results. The S 2p, N 1 s, and O 1 s PS profiles of the WS2 NFs are shown in Additional file 1: Figure S2a–c. In contrast, the oxygen and carbon peaks in the XPS profile of the WS2–WC–WO3 NH spheres indicate the co-existence of WC and WO3. The co-existence of WC and WO3 in the WS2–WC–WO3 NH composite was also indicated by the XRD and Raman spectroscopy results. To understand the complex peaks of the other elements on the surface of the materials, the S 2p, N 1 s, O 1 s and C 1 s peaks of the WS2–WC–WO3 NH composite were deconvoluted, as shown in Additional file 1: Figure S3a–d. The S 2p peaks of the WS2 NFs and WS2–WC–WO3 NH spheres were also significantly different. The S 2p peak of the WS2–WC–WO3 NH composite could be deconvoluted into three main peaks located at approximately 161.9, 163.2, and 164.5 eV corresponding to the S 2p3/2 and S 2p1/2 orbitals of divalent sulfide ions and C–S=C bonding, respectively, as shown in Additional file 1: Figure S3a. In contrast, as shown in Additional file 1: Figure S2a the S 2p peak of the WS2 NFs could be deconvoluted into two main peaks centered at 161.6 and 163 eV corresponding to the S 2p3/2 and S 2p1/2 orbitals of divalent sulfide ions, respectively [50]. The N 1 s XPS peak of the WS2–WC–WO3 NH composite could be deconvoluted into two components centered at approximately 400.1 and 402.8 eV, corresponding to free nitrogen and hydrogen bonding amine, respectively (Additional file 1: Figure S3b) [51]. The O 1 s peak of the WS2–WC–WO3 NH composite could be deconvoluted into –O– and –OH peaks, which were attributed to surface contamination and O2- combined with W ions, respectively [52]. The C1s peak could be deconvoluted into several peaks, as shown in Additional file 1: Figure S3d. We focused on the two strongest peaks centered at approximately 284.8 and 286 eV corresponding to the sp2 and sp3 hybridization of the C–C or C–H bonds, respectively [53].

The HER performances of the WS2 NFs and WS2–WC–WO3 NH spheres were carefully investigated using a three-electrode system (Fig. 5). The HER performance of the WS2 NFs was highly consistent with that obtained in our previous study [41]. The Tafel slope, impedance, and double-layer capacitance of the WS2 NFs were approximately 82 mV dec−1, 95 Ω, and 0.08 mF cm−2, respectively. To drive a cathodic current density of − 10 mA cm−2, an overvoltage of − 352 mV was employed. The stability of WS2 NFs was tested for 1000 cycles, the polarization curves of tested samples was carried out. The HER performance of WS2 NFs after test (AT) was presented in Fig. 5. After stability test, the Tafel slope of WS2 NFs AT was increased from 82 mV dec−1 to 83.5 mV dec−1. The data indicates that WS2 NFs is quite stable in acid media for HER application with a negligible shift after stability test. We also investigated the HER performance of the WS2–WC–WO3 NH spheres before and after test (WS2–WC–WO3 NH (AT))-the stability test using cyclic voltammetry (1000 cycles), which was denoted as WS2–WC–WO3 NH (AT). The electrocatalytic activity of the WS2–WC–WO3 NH composite toward the HER was measured using a three-electrode system in a standard acidic medium of 0.5 M H2SO4. The stability the WS2–WC–WO3 NH composite was evaluated over the overpotential range of − 0.3 to − 0.5 V for 1000 cycles, as shown in Additional file 1: Figure S5b. Figure 5a shows the polarization curves of the WS2 NF, WS2–WC–WO3 NH, and WS2–WC–WO3 NH (AT) samples and a standard platinum electrode. After 1000 cycles, the overpotential of the WS2–WC–WO3 NH sample decreased slightly as compared to the initial value, indicating the outstanding durability of the sample. At the current density of − 10 mA cm−2, the overpotential of the WS2–WC–WO3 NH sample was − 0.312 mV, which is much better than that of the WS2 NFs (− 352 mV). Therefore, the WS2–WC–WO3 NH composite is a promising material for water dissociation as compared to the WS2 NFs. To further evaluate the HER performances of the WS2–WC–WO3 NH and WS2–WC–WO3 NH (AT) samples in acidic media, their Tafel slopes were plotted, as shown in Fig. 5b. The Tafel slopes of the WS2–WC–WO3 NH and WS2–WC–WO3 NH (AT) samples were 59 and 60 mV dec−1, respectively. This confirms that the stability of the WS2–WC–WO3 NH material was much better than that of the WS2 NFs (82 mV dec−1). Figure 5c shows the electronic properties of the materials before and after the cyclic voltammetry (CV) test. The equivalent circuit shown in the inset of Fig. 5c was composed of constant phase elements and charge-transfer resistances. The charge-transfer resistances included the wire connection (Rs), the resistance between the electrocatalysts and solution (R1), and the resistance between the electrocatalysts and GCE (R2). The fitting values are listed in Table 1. The connection showed a resistance of 6.44–6.47 Ω. More importantly, the charge transfer resistance of the WS2–WC–WO3 NH composite was approximately 22.94 Ω, indicating that the electron conduction on the surface of the hollow composite was better than that of the pure WS2 NFs (94.36 Ω). This means that the conductivity of the WS2–WC–WO3 NH composite was much higher than that of the WS2 NFs. The double-layer capacitance (Cdl) of the WS2–WC–WO3 NH composite and WS2 NFs was calculated via CV scanning at different scan rates of 5, 10, 20, 30, 40, and 50 mV s−1. The CV curves were obtained within the potential window of 0–0.2 V, where no Faradaic current was observed. The CV scans of the WS2 NF and WS2–WC–WO3NH samples at various scan rates are shown in Additional file 1: Figures S4a and S5a, respectively. Figure 5d shows that the Cdl of the WS2–WC–WO3 NH and WS2 NF samples were approximately 11.8 mF cm−2 and 0.084 mF cm−2, respectively. The higher Cdl of the WS2–WC–WO3 NH composite can be attributed to its hollow sphere structure, owing to which it had a larger active surface and was robust to surface depletion during the electrochemical process. Additional file 1: Table S1 presents this work results and previous data. It indicates that WS2–WC–WO3 NH is a prominent catalyst material which could be applied for HER application.

HER catalytic activities of the WS2 NF, WS2 NF(AT), WS2–WC–WO3 NH and WS2–WC–WO3 NH (AT) samples. a Polarization curves of the WS2 NF, WS2 NF(AT), WS2–WC–WO3 NH, and WS2–WC–WO3 NH (AT) samples and commercial Pt/C at a scan rate of 5 mV s−1, b Tafel plots of the WS2 NF, WS2 NF(AT), WS2–WC–WO3 NH, and WS2–WC–WO3 NH (AT) samples and standard Pt/C, c EIS results with the inset showing an equivalent circuit and d double-layer capacitances of the WS2 NF and WS2–WC–WO3 NH samples

Another important parameter affecting the electrochemical performance of a material is its electrochemical active surface area (ECSA). ECSA represents the area of an electrode material that is accessible to the solution for electron transfer or charge storage. The ECSA of an electrode can be calculated using the following equations [54, 55]:

where Cs is the capacitance per unit area of the smooth planar surface of the material. Here we used a general specific capacitance of Cs = 0.04 mF/cm2 in 0.5 M H2SO4. The Cdl values of the WS2–WC–WO3NH and WS2 NF samples were calculated to be 11.8 and 0.084 mF cm−2, respectively. By substituting the values of Cdl and Cs in Eq. (1), the ECSA values of the WS2–WC–WO3 NH and WS2 NF samples were calculated to be 295 and 2.1, respectively. These values indicate that the WS2–WC–WO3 NH composite showed better charge transfer or charge storage than the WS2 NFs.

The turnover frequency (TOF) of H2 is the number of H2 molecules generated per active site per unit time. The TOF of H2 produced by the WS2 NFs and WS2–WC–WO3 NH spheres was calculated using the following formula [56, 57].

where j is the current density (A cm− 2), A is the surface area of the working electrode (cm2), n is the number of moles of the catalyst loaded onto the working electrode, and F is the faraday constant (F = 96485.3329 C mol− 1). The TOFs of H2 production at η = −312 mV and − 352 mV (current density measured = 10 mA cm− 2) for the WS2 NF and WS2–WC–WO3 NH samples were 0.08 and 0.02 s− 1, respectively, and the corresponding results are shown in Additional file 1: Figures S4b and S5c.

Finally, the stability of the WS2–WC–WO3 NH spheres was also investigated by prolonged electrolysis at a constant overpotential of − 0.33 V. As can be observed from Fig. 6, the sample showed excellent stability in a 0.5 M H2SO4 solution for 50,000 s. The results indicate that the composite prepared in this study is a promising material for electrochemical applications.

4 Conclusions

In this study, we developed r a facile and low-cost procedure to prepare a novel composite of WS2 (TMD), WC (TMC), and WO3 (TMO) (WS2–WC–WO3 NH) using the conventional solvothermal technique. Interestingly, the hybrid material was doped in-situ with nitrogen. The electrochemical measurements of the WS2–WC–WO3NH composite were also carried out in an acidic medium to evaluate its electrocatalytic performance for the HER. The results indicated that the WS2–WC–WO3 NH composite exhibited extraordinary electrocatalytic properties as compared to the pure WS2 NFs. This improvement can be attributed to the presence of WC and WO3, which exhibited a synergistic effect with WS2 and endowed the composite with various advantages of TMC and TMO materials. Moreover, the nitrogen doping significantly increased the electrical conductivity of the hybrid material. The Tafel slopes of the WS2–WC–WO3 NH composite before and after the CV test (1000 cycles) were 59 and 60 mV dec−1, respectively. These results demonstrate the excellent performance and stability of the WS2–WC–WO3 NH catalyst for the HER. Therefore, the WS2–WC–WO3 NH composite prepared in this study is a promising alternative to expensive noble metal catalysts for the HER and other electrochemical applications.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Change history

19 October 2021

A Correction to this paper has been published: https://doi.org/10.1186/s40580-021-00284-5

Abbreviations

- NH:

-

Nano-hollow

- NF:

-

Nanoflower

- HER:

-

Hydrogen evolution reaction

- TMD:

-

Transition metal dichalcogenide

- TMO:

-

Transition metal oxide

- TMC:

-

Transition metal carbide

- FE-SEM:

-

Field emission scanning electron microscopy

- XRD:

-

X-ray diffraction

- XPS:

-

X-ray photoelectron spectroscopy

- CV:

-

Cyclic voltammetry

- EIS:

-

Electrochemical impedance spectroscopy

- AMT:

-

Ammonium meta-tungstate

- TAT:

-

Thioacetamide

- DI:

-

De-ionized

- GCE:

-

Glassy carbon electrode

- LSV:

-

Linear sweep voltammetry

- RHE:

-

Reference hydrogen electrode

- ECSA:

-

Electrochemical active surface area

- TOF:

-

Turnover frequency

References

M.L. Khandekar, T. Murty, P. Chittibabu, The global warming debate: a review of the state of science. Pure Appl. Geophys. 162, 1557–1586 (2005)

W. Bach, Fossil fuel resources and their impacts on environment and climate. Int. J. Hydrogen Energy. 6, 185–201 (1981)

J. Bebbington, T. Schneider, L. Stevenson, A. Fox, Fossil fuel reserves and resources reporting and unburnable carbon: investigating conflicting accounts. Crit. Perspect. Account. 66, 102083 (2020)

J.O. Abe, A. Popoola, E. Ajenifuja, O. Popoola, Hydrogen energy, economy and storage: review and recommendation. Int. J. Hydrogen Energy. 44, 15072–15086 (2019)

C. Acar, I. Dincer, Review and evaluation of hydrogen production options for better environment. J. Clean. Prod. 218, 835–849 (2019)

I. Staffell, D. Scamman, A.V. Abad, P. Balcombe, P.E. Dodds, P. Ekins, N. Shah, K.R. Ward, The role of hydrogen and fuel cells in the global energy system. Energy Environ Sci. 12, 463–491 (2019)

T. He, P. Pachfule, H. Wu, Q. Xu, P. Chen, Hydrogen carriers. Nat. Rev. Mater. 1, 1–17 (2016)

M. Navlani-García, K. Mori, Y. Kuwahara, H. Yamashita, Recent strategies targeting efficient hydrogen production from chemical hydrogen storage materials over carbon-supported catalysts. NPG Asia Mater. 10, 277–292 (2018)

C. Li, J.B. Baek, Recent advances in noble metal (Pt, Ru, and Ir)-based electrocatalysts for efficient hydrogen evolution reaction. ACS Omega. 5, 31–40 (2019)

J. Fan, K. Qi, L. Zhang, H. Zhang, S. Yu, X. Cui, Engineering Pt/Pd interfacial electronic structures for highly efficient hydrogen evolution and alcohol oxidation. ACS Appl. Mater. Interfaces. 9, 18008–18014 (2017)

S. Sarkar, S.C. Peter, An overview on Pd-based electrocatalysts for the hydrogen evolution reaction. Inorg Chem Front. 5, 2060–2080 (2018)

X. Ren, Q. Lv, L. Liu, B. Liu, Y. Wang, A. Liu, G. Wu, Current progress of Pt and Pt-based electrocatalysts used for fuel cells. Sustain. Energy Fuels. 4, 15–30 (2020)

T. Shan-Shan, W. Xue-Jing, L. Qing-Chuan, Xiao-Jun, Progress on electrocatalysts of hydrogen evolution reaction based on carbon fiber materials. Chin. J. Anal. Chem. 44, 1447–1457 (2016)

Y. Wu, H. He, Electrodeposited nickel–iron–carbon–molybdenum film as efficient bifunctional electrocatalyst for overall water splitting in alkaline solution. Int. J. Hydrogen Energy. 44, 1336–1344 (2019)

A. Borgschulte, O. Sambalova, R. Delmelle, S. Jenatsch, R. Hany, F. Nüesch, Hydrogen reduction of molybdenum oxide at room temperature. Sci. Rep. 7, 1–9 (2017)

J. Kim, M. Kim, C.Y. Seo, J. Ryu, T. Ryu, H.-J. Hong, D. Shin, Y.J. Suh, Effects of Al, V, Cr, Mn, Ni, Nb, Mo, and W Addition to BCC-Fe on its elastic properties and hardness for a biomass boiler: First principles approaches. Korean J Metals Mater. 57, 374–380 (2019)

M.J. Kim, S.H. Bak, J. Hahn, S.J. Kim, D.B. Lee, High-temperature oxidation of Fe-12Cr-0.3 C-4Mn-(13-15)Cu composite alloys. Korean J. Metals Mater. 57, 575–581 (2019)

K. Zhu, C. Li, Z. Jing, X. Liu, Y. He, X. Lv, Y. Wang, K. Liu, Two-dimensional transition-metal dichalcogenides for electrochemical hydrogen evolution reaction. FlatChem. 18, 100140 (2019)

X. Chia, M. Pumera, Characteristics and performance of two-dimensional materials for electrocatalysis. Nat. Catal. 1, 909–921 (2018)

D.R. Cummins, U. Martinez, A. Sherehiy, R. Kappera, A. Martinez-Garcia, R.K. Schulze, J. Jasinski, J. Zhang, R.K. Gupta, J. Lou, Efficient hydrogen evolution in transition metal dichalcogenides via a simple one-step hydrazine reaction. Nat. Commun. 7, 1–10 (2016)

W. Choi, N. Choudhary, G.H. Han, J. Park, D. Akinwande, Y.H. Lee, Recent development of two-dimensional transition metal dichalcogenides and their applications. Mater. Today. 20, 116–130 (2017)

H. Schmidt, F. Giustiniano, G. Eda, Electronic transport properties of transition metal dichalcogenide field-effect devices: surface and interface effects. Chem. Soc. Rev. 44, 7715–7736 (2015)

B. Chen, G. Sun, J. Wang, G. Liu, C. Tan, Y. Chen, H. Cheng, J. Chen, Q. Ma, L. Huang, Transition metal dichalcogenide/multi-walled carbon nanotube-based fibers as flexible electrodes for electrocatalytic hydrogen evolution. Chem. Commun. 56, 5131–5134 (2020)

T.P. Nguyen, S.Y. Kim, T.H. Lee, H.W. Jang, Q. Van Le, I.T. Kim, Facile synthesis of W2C@WS2 alloy nanoflowers and their hydrogen generation performance. Appl. Surf. Sci. 504, 144389 (2020)

A. Hasani, T.P. Nguyen, M. Tekalgne, Q. Van Le, K.S. Choi, T.H. Lee, T.J. Park, H.W. Jang, S.Y. Kim, The role of metal dopants in WS2 nanoflowers in enhancing the hydrogen evolution reaction. Appl. Catal. A General. 567, 73–79 (2018)

X. Liu, L. Liu, Y. Wu, Y. Wang, J. Yang, Z. Wang, Rosette-like MoS2 nanoflowers as highly active and stable electrodes for hydrogen evolution reactions and supercapacitors. RSC Adv. 9, 13820–13828 (2019)

X. Ren, F. Yang, R. Chen, P. Ren, Y. Wang, Improvement of HER activity for MoS2: insight into the effect and mechanism of phosphorus post-doping. New J. Chem. 44, 1493–1499 (2020)

X. Shang, Y. Rao, S.S. Lu, B. Dong, L.M. Zhang, X.H. Liu, X. Li, Y.R. Liu, Y.M. Chai, C.G. Liu, Novel WS2/WO3 heterostructured nanosheets as efficient electrocatalyst for hydrogen evolution reaction. Mater. Chem. Phys. 197, 123–128 (2017)

N. Lee, J. Kwak, J.H. Kwak, S.-M. Jung, J. Kim, A. Giri, K. Thiyagarajan, Y.T. Kim, S. Jung, J.K. Kim, Microwave-assisted evolution of WO3 and WS2/WO3 hierarchical nanotrees. J. Mater. Chem. A. 8, 9654–9660 (2020)

M. Shi, Z. Jiang, B. Mei, Y. Li, F. Sun, H. Yu, Y. Xu, Tuning the hydrogen evolution performance of 2D tungsten disulfide by interfacial engineering. J. Mater. Chem. A. 9, 7059–7067 (2021)

P. Yan, Y. Wu, X. Wei, X. Zhu, W. Su, Preparation of robust hydrogen evolution reaction electrocatalyst WC/C by molten salt. Nanomaterials. 10, 1621 (2020)

J. Huang, W. Hong, J. Li, B. Wang, W. Liu, High-performance tungsten carbide electrocatalysts for the hydrogen evolution reaction. Sustain. Energy. Fuels. 4, 1078–1083 (2020)

C. Liu, D. Zhou, J. Zhou, Z. Xie, Y. Xia, Synthesis and characterization of tungsten carbide and application to electrocatalytic hydrogen evolution. RSC Adv. 6, 76307–76311 (2016)

X. Zhang, H. Tan, Z. Fan, M. Ge, X. Ye, M. Xue, Synthesis and electrochemical performance of ultrathin WS2 nanosheets. Chalcogenide Letters. 14, (2017)

X. Zhang, H. Xu, J. Wang, X. Ye, W. Lei, M. Xue, H. Tang, C. Li, Synthesis of ultrathin WS2 nanosheets and their tribological properties as lubricant additives. Nanoscale Res Lett. 11, 1–9 (2016)

Y. Zhu, W. Hsu, H. Terrones, N. Grobert, B. Chang, M. Terrones, B. Wei, H. Kroto, D. Walton, C. Boothroyd, Morphology, structure and growth of WS2 nanotubes. J. Mater. Chem. 10, 2570–2577 (2000)

M. Shi, L. Kang, Y. Jiang, Microwave-assisted synthesis of mesoporous tungsten carbide/carbon for fuel cell applications. Catal. Lett. 144, 278–284 (2014)

A. Pawbake, R. Waykar, A. Jadhavar, R. Kulkarni, V. Waman, A. Date, D. Late, H. Pathan, S. Jadkar, Wide band gap and conducting tungsten carbide (WC) thin films prepared by hot wire chemical vapor deposition (HW-CVD) method. Mater. Lett. 183, 315–317 (2016)

R. Balzer, V. Drago, W.H. Schreiner, L.F. Probst, Synthesis and structure-activity relationship of a WO3 catalyst for the total oxidation of BTX. J. Brazil. Chem. Soc. 25, 2026–2031 (2014)

A.V. Kadam, S.B. Patil, Polyaniline globules as a catalyst for WO3 nanoparticles for supercapacitor application. Mater. Res. Express. 5, 085036 (2018)

T.P. Nguyen, D.L.T. Nguyen, V.H. Nguyen, T.H. Le, Q.V. Ly, D.V.N. Vo, Q.V. Nguyen, H.S. Le, H.W. Jang, S.Y. Kim, Facile synthesis of WS2 hollow spheres and their hydrogen evolution reaction performance. Appl. Surf. Sci. 505, 144574 (2020)

G. Frey, R. Tenne, M. Matthews, M. Dresselhaus, G. Dresselhaus, Optical properties of MS2 (M = Mo, W) inorganic fullerenelike and nanotube material optical absorption and resonance Raman measurements. J. Mater. Res. 13, 2412–2417 (1998)

S. Li, Z. Chen, W. Zhang, Dye-sensitized solar cells based on WS2 counter electrodes. Mater. Lett. 72, 22–24 (2012)

N.D. Boscher, C.J. Carmalt, I.P. Parkin, Atmospheric pressure chemical vapor deposition of WSe 2 thin films on glass—highly hydrophobic sticky surfaces. J. Mater. Chem. 16, 122–127 (2006)

J. de la Roche-Yepes, J.M. González, E. Restrepo-Parra, & H. Sánchez-Sthepa, Corrosion resistance and tribological behavior of WS2-Ti coatings by Ti cathode power changes in magnetron co-sputtering. Dyna. 85, 221–226 (2018)

Y. Yan, B. Xia, X. Qi, H. Wang, R. Xu, J.Y. Wang, H. Zhang, X. Wang, Nano-tungsten carbide decorated graphene as co-catalysts for enhanced hydrogen evolution on molybdenum disulfide. Chem. Commun. 49, 4884–4886 (2013)

G. Yan, C. Wu, H. Tan, X. Feng, L. Yan, H. Zang, Y. Li, N-Carbon coated P-W2C composite as efficient electrocatalyst for hydrogen evolution reactions over the whole pH range. J. Mater. Chem. A. 5, 765–772 (2017)

Q. He, L. Wang, K. Yin, S. Luo, Vertically aligned ultrathin 1T-WS2 nanosheets enhanced the electrocatalytic hydrogen evolution. Nanoscale Res. Lett. 13, 1–9 (2018)

P.V. Sarma, C.S. Tiwary, S. Radhakrishnan, P.M. Ajayan, M.M. Shaijumon, Oxygen incorporated WS2 nanoclusters with superior electrocatalytic properties for hydrogen evolution reaction. Nanoscale. 10, 9516–9524 (2018)

W. Yang, J. Wang, C. Si, Z. Peng, J. Frenzel, G. Eggeler, Z. Zhang, [001] preferentially-oriented 2D tungsten disulfide nanosheets as anode materials for superior lithium storage. J. Mater. Chem A. 3, 17811–17819 (2015)

M.A. Ahmed, A.A.A. Shaweesh, N.M. El-Ashgar, I.M. El-Nahhal, M.M. Chehimi, F. Babonneau, Synthesis and characterization of immobilized-polysiloxane monoamine-thiol triacetic acid and its diamine and triamine derivatives. J. Sol-Gel. Sci. Technol. 78, 660–672 (2016)

S. Li, Z. Yao, J. Zhou, R. Zhang, H. Shen, Fabrication and characterization of WO3 thin films on silicon surface by thermal evaporation. Mater. Lett. 195, 213–216 (2017)

S.-K. Jerng, D.S. Yu, J.H. Lee, C. Kim, S. Yoon, S.H. Chun, Graphitic carbon growth on crystalline and amorphous oxide substrates using molecular beam epitaxy. Nanoscale Res. Lett. 6, 1–6 (2011)

P. Connor, J. Schuch, B. Kaiser, W. Jaegermann, The determination of electrochemical active surface area and specific capacity revisited for the system MnOx as an oxygen evolution catalyst. Z. Phys. Chem. 234, 979–994 (2020)

J. Hu, B. Huang, C. Zhang, Z. Wang, Y. An, D. Zhou, H. Lin, M.K. Leung, S. Yang, Engineering stepped edge surface structures of MoS 2 sheet stacks to accelerate the hydrogen evolution reaction. Energy Environ. Sci. 10, 593–603 (2017)

M.A. Tekalgne, K. Van Nguyen, D.L.T. Nguyen, V.H. Nguyen, T.P. Nguyen, D.V.N. Vo, Q.T. Trinh, A. Hasani, H.H. Do, T.H. Lee, Hierarchical molybdenum disulfide on carbon nanotube–reduced graphene oxide composite paper as efficient catalysts for hydrogen evolution reaction. J. Alloys Compd. 823, 153897 (2020)

I.M. Mosa, S. Biswas, A.M. El-Sawy, V. Botu, C. Guild, W. Song, R. Ramprasad, J.F. Rusling, S.L. Suib, Tunable mesoporous manganese oxide for high performance oxygen reduction and evolution reactions. J. Mater. Chem. A. 4, 620–631 (2016)

Acknowledgements

Not applicable.

Funding

This research was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (2021R1A4A3027878, 2020H1D3A1A04081409).

Author information

Authors and Affiliations

Contributions

TVN and HHD prepared experiment and wrote the original manuscript. MT, SHH, JHC measured XRD, FE-SEM, Raman and XPS. QVL, TPN, DVD interpreted all the data of manuscript. SHA, SYK performed the data curation, overall review of the manuscript and funding acquisition. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Figure S1.

EDS map images of WS2-WC-WO3 NH spheres showing the spatial elemental distribution for W, S, O, C and N atoms. Figure S2. High-resolution (a) S 2p, (b) N 1s, and (c) O1s XPS profiles of the WS2 NFs. Figure S3. High-resolution (a) S 2p, (b) N 1s, (c) O1s, and (d) C1s XPS profiles of the WS2-WC-WO3 NH spheres. Figure S4. (a) CV curves and (b) TOF of the WS2 NFs. Figure S5. CV curves of the WS2-WC-WO3 NH composite at various scan rates (a) before and (b) after 1000 cycles and (c) TOF of the WS2-WC-WO3 NH composite. Table S1. Comparison of other electrocatalysts previously reported in HER.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Van Nguyen, T., Do, H.H., Tekalgne, M. et al. WS2–WC–WO3 nano-hollow spheres as an efficient and durable catalyst for hydrogen evolution reaction. Nano Convergence 8, 28 (2021). https://doi.org/10.1186/s40580-021-00278-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40580-021-00278-3