Abstract

The adsorption efficiency of Pb(II) and Cd(II) from aqueous solutions on m-phenylenediamine-modified Amberlite XAD-4 resin was investigated. The effects of pH, adsorbent amount, initial metal concentration, eluent type and volume and flow rate on the retention of the metal ions have been studied on column studies. The optimum parameters were determined as pH 5, concentration 10 mg/L, stirring time 30 min and 0.2 g adsorbent amount and flow rate 2.5 mL/min for a quantitative adsorption. Sorption data were interpreted in terms of Langmuir and Freundlich equations, and both models were found to be fully appropriate. Each column can be used up to 10 sequential analyses without considerable change. The results indicate high metal adsorption capacity and satisfactory recovery of Pb(II) and Cd(II).

Similar content being viewed by others

Introduction

If industrial wastewater is discharged without environmentally friendly and effective treatment methods, it contains a large amount of heavy metals which may cause harm to public health and the environment. The most common and harmful ones are Hg, As, Cr, Pb, Ni, Cd, Cu and so on. In wastewater treatment systems, it is very significant to remove heavy metals from aqueous solutions and to recover precious metals. They can easily spread to the atmosphere, soil and water environment and are highly toxic. Heavy metal sources in wastewater are very high levels. The types and content of heavy metals vary depending on the type of production. Heavy metals spread to the environment from different activities of the mining, metallurgy, electronics, chemical production, pesticides, paints, leather and pharmaceutical industries (Yu et al. 2015; Farokhi et al. 2018; Ahmad et al. 2019; Chauhan et al. 2019). Heavy metals can produce toxic reactions in natural waters, even if they are in very low amounts about 0.1–0.3 mg/L. The negative effects of heavy metals affect living life by creating biological accumulation in the food chain as well as ecosystems (Alkorta et al. 2004; Lyer et al. 2005; Kavand et al. 2016). In order to protect natural resources, environment and human life, these wastewaters must be treated before it is spread to the environment (Safarzadeh et al. 2007). Chemical precipitation, adsorption, ion exchange, solvent extraction, membrane filtration, reverse osmosis and electrical coagulation techniques are used to removal and recovery of heavy metals and other pollutants from wastewater (Lundstrom et al. 2016; De Gisi et al. 2016; Xu et al. 2016; Dong et al. 2017; Yusuff et al. 2018; Yavuz and Ogutveren 2018; Bashir et al. 2019). Since adsorption is an effective, low-cost and environmentally friendly method, it is one of the most preferred processes of removing heavy metals and organic pollutants. However, adsorption capacity, selectivity, equilibrium time and recovery depend on the properties of the absorbent materials. Thus, recently researches about applications of new materials such as nano-adsorbents and modified sorbents are focused on adsorption of heavy metals from aqueous solutions (Yang et al. 2015; Jin et al. 2017; Batouti et al. 2017; Saha et al. 2017; Bhatti et al. 2017a, b; Azadegan et al. 2019; Somu et al. 2019).

Solid-phase extraction (SPE) method is very effective method for separation and preconcentration of heavy metals. This method has important advantages such as easy applicability, fast and economical, high enrichment factor, low adsorbent usage and environmentally friendly. Different SPE materials have been tried in the previous studies and obtained very good results for separation and preconcentration of heavy metal ions (Kocaoba and Arisoy 2011; Islam et al. 2012; Alothman et al. 2015; Islam et al. 2015; Ahmad et al. 2017; Aksoy et al. 2018; Baytak et al. 2018a, b; Hymavathi and Prabhakar 2019). Amberlite XAD resins are quite used for the development of various chelating materials to be used for preconcentration as they have good physical and chemical properties such as purity, porosity, high surface area and resistance (Islam et al. 2011; Kalal et al. 2012; Ahmad et al. 2015; Khalil et al. 2016; Javed et al. 2018; Kumar et al. 2019; Jamil et al. 2020).

In this study, m-phenylenediamine-modified Amberlite XAD-4 resin was used for the removal of Pb(II) and Cd(II) from aqueous solutions using the solid-phase extraction method by optimizing various parameters.

Experimental

Materials

Pb(NO3)2, CdCl2.H2O, HCl, NaOH (Merck, Germany) were used as analytical grade standard substances. Pb(II) and Cd(II) solutions (1000 mg/L) were used as AAS standards (Fluka Chemicals). In the studies, metal solutions were prepared by diluting them properly with Milli-Q water from stock solutions. Amberlite XAD-4 resin was obtained from Sigma-Aldrich (surface area of 725 m2/g, pore diameter of 4 nm, particle size of 20–60 mesh). 4 M HCl was used to remove organic and inorganic impurities in Amberlite XAD-4 that may have remained during the preparation of the resin. m-Phenylenediamine-modified Amberlite XAD-4 resin was used as adsorbent in this study. m-Phenylenediamine is a substance that can easily form chelates with metallic ions on the surface of the resin. 0.2 g was taken from m-phenylenediamine-modified Amberlite XAD-4 resin and filled into a glass column of 10 mm inner diameter and 200 mm length. Before using the columns in studies, first 1 mol/L HCl solution, then Milli-Q water until pH neutral, then ethanol–water (1:1) mixture and at last Milli-Q water passed through the column for cleaning and conditioning steps. The experiments were performed by connecting a peristaltic pump to the system and passing the metal solution through a column in downstream mode.

Experimental procedure

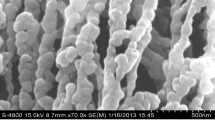

Preparation of modified Amberlite XAD-4 resin

5 g of Amberlite XAD-4 resin was taken, and 10 mL of conc. HNO3 and 25 mL of conc. H2SO4 were added and mixed in an oil bath at 60 °C for 1 h. This mixture was then poured into the ice–water mixture and the nitrated resin was filtered. It was washed with Milli-Q water until its pH was neutral, and then, 40 g SnCl2, 45 mL conc. HCl and 50 mL ethanol were added to this mixture and refluxed for another 12 h at 90 °C. It was then filtered and washed with Milli-Q water and 2 mol/L NaOH to obtain amino resin (R-NH2). 2 mol/L HCl was put in the medium and then washed with Milli-Q water to neutralize excess acid remaining in the medium. It was suspended in a mixture of approximately 350 mL ice–water. It was acidified with 1 mol/L HCl and titrated with 1 mol/L NaNO2 until a dark blue color was obtained with starch indicator. The resin was filtered, washed with ice–water mixture and reacted with 0.03 mol of m-phenylenediamine prepared in 30 mL of 2 mol/L HCl and stirred at 0 to 3 °C for 24 h. It was then filtered, washed twice with Milli-Q water and air-dried. The method used for preparation of modified XAD-4 resin (Kumar et al. 2000) is given in Fig. 1.

General procedure for sorption studies

Solid-phase extraction (SPE) was applied in a small column to preconcentration of heavy metals. Sample solutions containing Pb(II) and Cd(II) between 2.5 and 25 µg/100 mL were taken, and the pHs of the solutions were fixed to optimum value with HCl or NaOH solutions. The pH-adjusted samples were passed through the column by a peristaltic pump at the optimum flow rate.

After all samples were passed through the column, the retained metal ions were eluted from the column with a suitable solvent, and metal ion concentrations were determined with atomic absorption spectrometer (Analytical Jena-Nova 300).

Equilibrium experiments

0.5, 1, 1.5, 2, 3 g of modified Amberlite XAD-4 samples were weighed into Erlenmeyer flasks for equilibrium studies. It was contacted with solutions containing 200 mL Pb(II) and Cd(II) at 100 mg/L constant concentration values in a shaker at room temperature (20 ± 2 °C) for 5 days. The mixing speed was 250 rpm. The pH values in the beginning and equilibrium were measured with a pH meter.

The amount of metal adsorbed per unit adsorbent was calculated as;

where \(C_{0}\) and \(C_{e}\) are the initial and equilibrium concentrations (meq/L), \(m\) is the amount of the adsorbent (g), and \(V\) is the volume of the solution (L).

Sorption data have been interpreted in terms of Langmuir and Freundlich equations as described in the reference (Kocaoba 2007).

Results and discussion

In this study, the effects of some parameters such as pH, adsorbent amount, initial metal concentration, flow rate of sample solution, eluent type and volume, electrolytes and foreign ions on the recovery of metal ions were investigated. The results are given in Tables 1 and 2 and Figs. 2, 3, 4, and 5.

Equilibrium experiments were done, and sorption data were interpreted in terms of Langmuir and Freundlich equations. The isotherms were obtained and are presented in Figs. 6 and 7. Adsorption parameters of Langmuir and Freundlich isotherms, which show the retention of metal ions on modified Amberlite XAD-4, are given in Table 3.

Effect of pH

The solution pH is a factor that affects adsorption and should be considered. Therefore, the effect of pH on the preconcentration efficiency of metal ions was investigated with modified Amberlite XAD-4. Working pH range of sample solutions was chosen between 1 and 8 and adjusted to desired pH values with HCl and NaOH solutions.

The samples prepared at the appropriate pH were passed through the column at an optimum flow rate of 2.5 mL/min. The column was then washed by passing 1 M HCl. In these studies, it was observed that the amount of metal uptake in the column increased with increasing solution pH values. From the results given in Fig. 2, it is seen that there is a rapid increase up to its maximum level, pH 4–5.

As can be seen from the figure, there is a tendency to decrease in adsorption due to the possibility of metals precipitating at a pH higher than the optimum value. This is due to the competition of hydroxylated complexes of metals and metal ions (Yilmaz and Kartal 2012; Chowdhury et al. 2013; Khalil et al. 2016; Chauhan et al. 2019). Working at high pH values was not preferred because of the probability of precipitation of metal ions, and the optimum pH was chosen as 5 for both metals.

Effect of adsorbent amount

The samples of the modified Amberlite XAD-4 resin ranging from 0.05 to 0.4 g were studied to examine the effect of the amount of adsorbent. The results are given in Fig. 3. In this study, it was observed that the recovery of metals gradually increased in the amount of more than 0.1 g adsorbent, but reached the plateau in the amount of approximately 0.2 g adsorbent. Therefore, the amount of 0.2 g adsorbent was taken as the optimum value for all experiments.

Effect of initial metal ion concentration

Standard stock solutions of Pb(II) and Cd(II) of 1000 mg/L were prepared from their salts using Milli-Q water. Figure 4 shows the effect of different initial metal concentrations on adsorption under optimized conditions such as 0.2 g adsorbent and 30 min stirring time. The studied Pb(II) and Cd(II) concentrations are between 5 and 100 mg/L. For both metals, the amount of adsorbed metal was found to be nearly constant over this concentration range. These results show that increasing the metal concentration does not have a significant effect on adsorption. Because the pores of the Amberlite XAD-4 resin fill more quickly with increasing metal concentration after a certain period of time, even if desorption will begin to occur instead of adsorption. Decrease in removal efficiency with increase in initial concentration can be explained in terms of active sites of the adsorbent, which becomes saturated at a certain concentration.

Heavy metal adsorption depends on different mechanisms such as adsorption and ion exchange. During the ion exchange process, metal ions can first pass either through the pores of resin or through the crystal lattice channels. Second, they can be replaced by cations such as sodium, magnesium and calcium, which are usually found in ion exchange resins. The diffusion phenomenon also occurs when the metal ions pass slowly or rapidly through the adsorbent pores. However, in cases where metal ions or hydrated metal ions cannot pass through smaller diameter pores, diffusion can be delayed. In this case, metal ion adsorption can be explained with ion exchange reactions in the Amberlite XAD-4 resin samples. The maximum adsorption efficiency was 99.50% for Pb(II) and 99.35% for Cd(II), respectively. It has been observed that the modified adsorbents used have more adsorption efficiency than many adsorbents used in other studies (Renu et al. 2017; Aksoy et al. 2018; Topuz et al. 2019; Shiri-Yekta 2020; Maksimov et al. 2021). In these experiments, the optimum concentration was selected as 20 mg/L.

Effect of flow rates of sample solutions

The flow rate of the sample solution affects the retention of the ions in the solution at the binding sites of the modified resin. Therefore, the effect of this parameter was examined by passing sample solutions through the column with a peristaltic pump under optimum conditions at determined flow rates of 1–7.5 mL/min. Flow rates slower than 1 mL/min were not preferred as it would significantly increase running time. However, at flow rates of more than 3 mL/min, retention percentages were reduced as the contact of the resin with metal ions could not be properly balanced. Metal ions not being able to come into contact with the resin sufficiently and the adsorbent reaching equilibrium more quickly are possible causes of this decrease. The optimum recovery of metal ions from chelating resins can be linked to different complex formation constants at different flow rates (Yilmaz and Kartal 2012; Tobias and Walas 2014; Ahmad et al. 2015; Trzonkowskaet al. 2017). As given in Fig. 5, the optimum flow rate for both metals was chosen as 2.5 mL/min.

Effect of type and volume of elution solutions

Regeneration of the adsorbent is a significant parameter for the reuse of the column in multiple adsorption–desorption cycles. Therefore, the concentration of acid solution used in the regeneration of metals retained in the column should be as low as possible, so as not to damage the resin. Also, the eluent volume should be as small as possible to achieve a higher preconcentration factor. 0.5 and 1 M HCl and HNO3 solutions were used for regeneration studies. 5, 10 and 15 mL were chosen as the elution volume. The results are given in Table 1. It was observed that 10 mL of 1 M HCl solution was sufficient for both metals examined.

Effect of the volume of sample solutions

The effect of changes in the volume of sample solution passed through the column on the recovery of Pb(II) and Cd(II) was investigated in order to determine an applicable sample volume or a minimum analyte concentration. For this purpose, 50, 100, 250, 500, 750 and 1000 mL volume solution containing 0.25, 0.10, 0.05, 0.033 and 0.025 µg/mL of Pb(II) and Cd(II) was passed through the column under the optimum conditions. It was found that both metal ions could be recovered quantitatively (≥ 95%) up to 250 mL of the sample solution. The results are given in Fig. 6. The recoveries for analytes decreased at the higher volumes. In this study, the elution volume was 10 mL, and therefore, the preconcentration factors were 25 for the analytes. These results show that Pb(II) and Cd(II) ions could be determined in low concentrations by the proposed method, which could not be determined directly by AAS.

Effect of column reuse

The column stability and reusability and various adsorption–elution cycles were performed, and changes in the recovery of metal ions were examined. Hence, Pb(II) and Cd(II) ions were adsorbed on a 0.2 g modified Amberlite XAD-4 resin at a concentration of 50 µg/mL, in a 50 mL solution volume, and then desorbed under optimal operating conditions. After 10 adsorption–desorption cycles, retention capacity did not change more than 2.0%. The SPE columns appeared relatively stable for up to 10 cycles.

Precision of the method

The optimum conditions were applied to investigate the accuracy of the method, and the sequential adsorption–elution cycles were performed with 50 µg Pb(II) and Cd(II). The precision of the method was evaluated as the relative standard deviations (RSD). In order to evaluate the precision of the determination of Pb(II) and Cd(II) ions, the studied procedure was repeated 5 times under optimum conditions mentioned above. The method precision is very good, and the recovery of analytes is quantitative (above 95%). The recoveries and RSD of Pb(II) and Cd(II) ions were found to be 97.5 ± 0.5 and 98.7 ± 0.3 at 95% confidence level, respectively.

Effect of electrolytes and foreign ions

The interference effect on the adsorption of other elements that can be found in the same environment was examined. The effects of some salts and ions such as KI, KBr, NaCl, Na3PO4, Na2SO4, NaNO3, Mg(II) and Ca(II) on the adsorption of Pb(II) and Cd(II) were examined. The concentration range of interfering ions was between 0.5 and 10 μg/mL. Tolerance limits were determined with ± 5% relative standard error and are given in Table 2. Cations and organic substances are ubiquitous in water. H+ and other cations can also compete with Pb(II) and Cd(II) with available sorption sites. This may reduce the adsorption ability of the adsorbent used. However, as can be seen from the results obtained, it was understood that the presence of Na+, K+, Mg2+ and Ca2+ ions had little effect on the adsorption of heavy metals.

These results show that when working with natural samples, these ions that can be found in water do not interact with the metals selected under the experimental conditions used at normal concentration levels. According to the results obtained, it shows that the preconcentration method performed in this study can be easily applied to natural water samples containing ions that may be interfere at tolerable levels given in Table 2.

Adsorption isotherm models

In this study, two important and widely studied Langmuir and Freundlich isotherm models were selected. The results are given in Figs. 7 and 8. Langmuir and Freundlich isotherm parameters are given in Table 3. Langmuir and Freundlich isotherm models were applied to examine the amount of metal ions adsorbed onto modified Amberlite XAD-4. Sorption data have been interpreted in terms of Langmuir and Freundlich equations as described in the reference (Kocaoba 2007).

Langmuir and Freundlich isotherm parameters and constants for the adsorption of Pb(II) and Cd(II) ions on modified Amberlite XAD-4 were calculated from the experimental equilibrium data, and the results are summarized in Table 3 with regression coefficients. The calculated regression coefficients (R2) were compared to determine the most suitable isotherm model. The calculated regression coefficients given in Table 3 clearly indicate that both Langmuir and Freundlich isotherm models provided good relationship to the experimental equilibrium data for the adsorption of heavy metal ions on modified Amberlite XAD-4. As can be seen in Fig. 7, log \(Q_{e}\) versus log \(C_{e}\) curves give straight lines according to the Freundlich isotherm equation. Both \(K_{f}\) and n are empirical constants, being indicative of the extent of adsorption and the degree of nonlinearity between solution and concentration, respectively. For favorable adsorption, 0 < n < 1. Since the degree of favorability increases as n approaches zero, all samples show a very high affinity for studying heavy metals.

The adsorption intensity given by the Freundlich coefficient, n, is < 1 in all cases, the values lying between 0.006 and 0.021. A greater value of the intercept \(K_{f}\) indicates a higher capacity for adsorption than a smaller value. The Freundlich adsorption capacity (\(K_{f}\)) lies between 0.0282 and 0.0315.

In order to ascertain whether the adsorption is chemisorptive in nature with chemical forces binding Pb(II) and Cd(II) ions to the surface of the modified Amberlite XAD-4, the experimental data were also tested with respect to Langmuir isotherm. As shown in Fig. 8 from the linear relation between \({{C_{e} } \mathord{\left/ {\vphantom {{C_{e} } {Q_{e} }}} \right. \kern-\nulldelimiterspace} {Q_{e} }}\) and \(C_{e}\), the adsorption equilibrium constant b and maximum adsorption capacity \(Q_{0}\) of adsorbents were calculated and these are also shown in Table 3. The adsorption isotherm of Pb(II) and Cd(II) exhibits Langmuir behavior, which indicates a monolayer adsorption.

The plots have good linearity in both cases (Freundlich plots, R = 0.9774–0.9895, Langmuir plots, R = 0.9962–0.9980) at room temperature. The values of the adsorption coefficients computed from these plots are given in Table 3. The values of the adsorption coefficients indicate the favorable nature of adsorption of Pb(II) and Cd(II) on the modified Amberlite XAD-4. The Langmuir monolayer adsorption capacity, \(Q_{0},\) is between 0.2647 and 0.6553 mequiv/g. The Langmuir equilibrium coefficient, b, has values of 0.0052–0.0080. The separation factor, \(R_{L}\), with values of 0.8620–0.9058, also supports favorable adsorption of the metal ions on the modified Amberlite XAD-4. Strong adsorbate–adsorbent interactions are suggested by the values of the adsorption coefficients. Also, some other studies showed that Freundlich and Langmuir isotherms correspond well with the experimental results of some heavy metals (Chung et al. 2015; Hoque et al. 2015; Bhatti et al. 2017a, b; Boudaoud et al. 2020; Kocaoba 2020; Santana et al. 2021).

Comparisons of the advantages of modified Amberlite XAD-4 resin with other sorbents

The main focus of extensive research on chelating resins is the preparation of functionalized polymers that can provide more flexible working conditions together with good stability, selectivity, high concentration ability, high capacity of metal ions and a simple operation synthesized a chelating resin Amberlite XAD-4 with different substances like 8-hydroxyquinoline, o-aminobenzoic acid, 2,3-dihydroxy-naphthalene, ammonium pyrrolidinedithiocarbamate, some Schiff bases, succinic acid, maleic acid, salicylic acid, biomass, etc. (Metilda et al. 2005; Islam et al. 2012; Li et al. 2013; Ahmad et al. 2015; Saffarionpour et al. 2016; Aksoy et al. 2018; Baytak et al. 2018a, b; Ozdemir et al. 2021). The m-phenylenediamine-modified Amberlite XAD-4 resin exhibits a good preconcentration factor and the sorption capacity and recovery for metal ions compared with several known chelating resins (Bag et al. 1999; Alan et al. 2007; Dalman et al. 2007; Duran et al. 2007; Tajodini and Moghimi 2010; Marahel et al. 2011; Bagheri et al. 2012; Islam et al. 2013; Zhou et al. 2014; Cetinkaya and Aydın 2017; Topuz and Yakut 2020; Elbadawy et al. 2021; Zawierucha et al. 2022).

Application of method to real samples

Using this method, determination of Pb(II) and Cd(II) ions in tap water was achieved by the standard addition method. The procedure for the preconcentration was carried out by taking proper volume of sample solutions fixed to optimum pH. When the results given in Table 4 are examined, it is understood that the proposed method is feasible to water analyses at 95% confidence level. Pb(II) and Cd(II) concentrations in the samples were determined with less than 5% relative error in all samples. The results obtained indicate that this recommended method is very suitable for the determination of heavy metals in tap water and other water and wastewater streams.

Conclusions

The results from this study show that the modified Amberlite XAD-4 resin can be effectively used for the preconcentration of heavy metals. As a novel chelating resin, the m-phenylenediamine-modified XAD-4 resin showed high adsorption selectivity for Pb(II) and Cd(II) ions. Using this proposed method, analytes in sample solutions can be directly preconcentrated. Another important advantage is that this preconcentration technique is cheap. 0.2 g of adsorbent is just required, and the resin can be regenerated and used repeatedly. The optimum pH value for the studied metals was 5, and the optimum flow rate was 2.5 mL/min. Different volumes of HNO3 and HCl solutions were tried to find the appropriate solvent and amount in recovering metal ions retained in the column.10 mL of 1 mol/L HCl solution was found sufficient for both metals. It has been observed that both metal ions can be recovered quantitatively (95%) up to a volume of 250 mL sample solution.

With this process, it was shown that analytes showed better retention, better repeatability of experiments and multiple column application (approximately 10 studies). The matrix effects of other ions that may be present in the environment have also been shown to be reasonably tolerated.

The method is relatively fast and effective for the preconcentration of metal ions at trace levels. It can also be concluded that the use of m-phenylenediamine-modified Amberlite XAD-4 resin as an adsorbent may be an alternative for the treatment of liquid wastes that contain heavy metals. Moreover, the rapid uptake allows to consider carrying out the sorption of heavy metals on column filled with this adsorbent because the contact time between the metal solution and the adsorbent is generally short in this process.

As a result, the studied method has very good performance in terms of simplicity, precision, selectivity, accuracy and column stability.

Availability of data

Research data have been provided in the manuscript.

Abbreviations

- AAS:

-

Atomic absorption spectrometer

- SPE:

-

Solid-phase extraction

- RSD:

-

Relative standard deviations

References

Ahmad A, Siddique JA, Laskar MA, Kumar R, Mohd-Setapar SH, Khatoon A, Shiekh RA. New generation Amberlite XAD resin for the removal of metal ions: a review. J Environ Sci. 2015;31:104–23.

Ahmad H, Ahmad A, Islam SS. Magnetic Fe3O4@poly (methacrylic acid) particles for selective preconcentration of trace arsenic species. Microchim Acta. 2017;184:2007–14.

Ahmad H, Cai C, Liu C. Separation and preconcentration of Pb(II) and Cd(II) from aqueous samples using hyperbranched polyethyleneimine-functionalized graphene oxide immobilized polystyrene spherical adsorbents. Microchem J. 2019;145:833–42.

Aksoy E, Elçi SG, Siyal AN, Elçi L. Chromium speciation using an aminated amberlite XAD-4 resin column combined with microsample injection-flame atomic absorption spectrometry. Acta Chim Slov. 2018;65:512–20.

Alan M, Kara D, Fisher A. Preconcentration of heavy metals and matrix elimination using silica gel chemically modified with 2,3-dihydroxybenzaldehyde. Sep Sci Technol. 2007;42:879–95.

Alkorta I, Allica JH, Becerril JM, Amezaga I, Albizu I, Garbisu C. Recent findings on the phytoremediation of soils contaminated with environmentally toxic heavy metals and metalloids such as zinc, cadmium, lead, and arsenic. Rev Environ Sci Biotechnol. 2004;3:71–90.

Alothman ZA, Yilmaz E, Habila M, Soylak M. Solid phase extraction of metal ions in environmental samples on 1-(2-pyridylazo)-2-naphtholimpregnated activated carbon cloth. Ecotoxicol Environ Saf. 2015;112:74–9.

Azadegan F, Bidhendi ME, Badiei A. Removal of Hg(II) ions from aqueous environment with the use of modified LUS-1 as new nanostructured adsorbent. Int J Environ Res. 2019;13:557–69.

Bag H, Turker AR, Lale A. Determination of trace metals in geological samples by atomic absorption spectrophotometry after preconcentration by Aspergillus niger immobilized on sepiolite. Anal Sci. 1999;15:1251–6.

Bagheri H, Afkhami A, Saber-Tehrani M, Khoshsafar H. Preparation and characterization of magnetic nanocomposite of Schiff base/silica/magnetite as a preconcentration phase for the trace determination of heavy metal ions in water, food and biological samples using atomic absorption spectrometry. Talanta. 2012;97:87–95.

Bashir A, Malik LA, Ahad S, Manzoor T, Bhat MA, Dar GN, Pandith AH. Removal of heavy metal ions from aqueous system by ion-exchange and biosorption methods. Environ Chem Lett. 2019;17:729–54.

Batouti ME, Ahmed AMM, Ibrahim NA, Mohamed N. Adsorption of Co(II) on nanobentonite surface: kinetic and equilibrium studies. Indian J Chem Technol. 2017;24:461–70.

Baytak S, Channa AM, Çamuroğlu E. Mucor pusillus immobilized Amberlite XAD4 biocomposites for preconcentration of heavy metal ions by solid-phase extraction method. J Anal Sci Technol. 2018a;9:9.

Baytak S, Channa AM, Camuroğlu E. Mucor pusillus immobilized Amberlite XAD-4 biocomposites for preconcentration of heavy metal ions by solid-phase extraction method. J Anal Sci Technol. 2018b;9:1–6.

Bhatti AA, Memon S, Memon N, Bhatti AA, Solangi IB. Evaluation of chromium(VI) sorption efficiency of modified Amberlite XAD-4 resin. Arab J Chem. 2017a;10:1111–8.

Bhatti AA, Memon S, Memon N, Bhatti AA, Solangi IB. Evaluation of chromium(VI) sorption efficiency of modified Amberlite XAD-4 resin. Arab J Chem. 2017b;10:1111–8.

Boudaoud N, Miloudi H, Bouazza D, Adjdir M, Tayeb A, Fortuny A, Demey H, Sastre AM. Removal of zinc from aqueous solutions using lamellar double hydroxide materials impregnated with cyanex 272: characterization and sorption studies. Molecules. 2020;25:1263.

Cetinkaya E, Aydın A. A novel thiocarbohydrazide derivative for preconcentration of copper(II), nickel(II), lead(II), and cadmium(II) in water samples for flame atomic absorption spectrophotometry (FAAS). Desalin Water Treat. 2017;74:224–36.

Chauhan A, Islam A, Javed H, Kumar S. Facile fabrication of Amberlite XAD-16 with dipicolylamine for remediation of industrial wastewater containing lead and copper: Isotherm, kinetics, thermodynamics and selectivity studies. Microchem J. 2019;146:606–13.

Chowdhury DA, Ul Hoque MI, Fardous Z. Solid phase extraction of copper, cadmium and lead using Amberlite XAD-4 resin functionalized with 2-hydroxybenzaldehyde thiosemicarbazone and its application on green tea leaves. Jordan J Chem. 2013;8:90–102.

Chung HK, Kim WH, Park J, Cho J, Jeong TY, Park PK. Application of Langmuir and Freundlich isotherms to predict adsorbate removal efficiency or required amount of adsorbent. J Ind Eng Chem. 2015;28:241–6.

Dalman O, Bulut VN, Degirmencioglu I, Tufekci M. Preconcentration of trace elements on Amberlite XAD-4 resin functionalised with 1,2-bis (o-aminophenylthio) ethane and their determination by FAAS in environmental samples. Turk J Chem. 2007;31:631–46.

De Gisi S, Lofrano G, Grassi M, Notarnicola M. Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: a review. Sustain Mater Technol. 2016;9:10–40.

Dong Y, Liu J, Sui M, Qu Y, Ambuchi JJ, Wang H, Feng Y. A combined microbial desalination cell and electrodialysis system for copper-containing wastewater treatment and high-salinity-water desalination. J Hazard Mater. 2017;321:307–11.

Duran C, Senturk HB, Gundogdu A, Bulut VN, Elci L, Soylak M, Tufekci M, Uygur Y. Determination of some trace metals in environmental samples by flame AAS following solid phase extraction with Amberlite XAD-2000 resin after complexing with 8-hydroxyquinoline. Chin J Chem. 2007;25:196–202.

Elbadawy HA, Abdel-Salam AH, Khalil TE. The impact of an Amberlite XAD-16-based chelating resin for the removal of aqueous Cd(II) and Pb(II) ions. Microchem J. 2021;165:106097.

Farokhi M, Parvareh A, Moraveji MK. Performance of ceria/iron oxide nano-composites based on chitosan as an effective adsorbent for removal of Cr(VI) and Co(II) ions from aqueous systems. Environ Sci Pollut Res. 2018;25:27059–73.

Hoque MI, Chowdhury DA, Holze R, Chowdhury AN, Azam MS. Modification of Amberlite XAD-4 resin with 1,8-diaminonaphthalene for solid phase extraction of copper, cadmium and lead, and its application to determination of these metals in dairy cow’s milk. J Environ Chem Eng. 2015;3:831–42.

Hymavathi D, Prabhakar G. Modeling of cobalt and lead adsorption by Ficus benghalenesis L. in a fixed bed column. Chem Eng Commun. 2019;206:1264–72.

Islam A, Laskar MA, Ahmad A. The efficiency of Amberlite XAD-4 resin loaded with 1-(2-pyridylazo)-2-naphthol in preconcentration and separation of some toxic metal ions by flame atomic absorption spectrometry. Environ Monit Assess. 2011;175:201–12.

Islam A, Ahmad A, Laskar MA. Preparation, characterization of a novel chelating resin functionalized with o-hydroxybenzamide and its application for preconcentration of trace metal ions. Clean: Soil, Air, Water. 2012;40:54–65.

Islam A, Laskar MA, Ahmad A. Preconcentration of metal ions through chelation on a synthesized resin containing O, O donor atoms for quantitative analysis of environmental and biological samples. Environ Monit Assess. 2013;185:2691–704.

Islam A, Ahmad A, Laskar MA. Flame atomic absorption spectrometric determination of trace metal ions in environmental and biological samples after preconcentration on a newly developed Amberlite XAD-16 chelating resin containing p-aminobenzene sulfonic acid. J AOAC Int. 2015;98:165–75.

Jamil W, Memon Z, Memon SQ, Samon MK, Taha M, Khan KM. Environmental friendly synthetic modification of Amberlite XAD-2 resin for the removal of highly toxic hexavalent chromium from water. Acta Chim Slov. 2020;67:260–9.

Javed H, Islam A, Chauhan A, Kumar S, Kumar S. Efficacy of engineered GO Amberlite XAD-16 picolylamine sorbent for the trace determination of Pb(II) and Cu(II) in fishes by solid phase extraction column coupled with inductively coupled plasma optical emission spectrometry. Sci Rep. 2018;8:1–11.

Jin XC, Xiang ZY, Liu QG, Chen Y, Lu FC. Polyethyleneimine-bacterial cellulose bioadsorbent for effective removal of copper and lead ions from aqueous solution. Biores Technol. 2017;244:844–9.

Kalal HS, Panahi HA, Hoveidi H, Taghiof M, Menderjani MT. Synthesis and application of Amberlite XAD-4 functionalized with alizarin red-S for preconcentration and adsorption of rhodium(III). Iran J Environ Health Sci Eng. 2012;9:1–9.

Kavand M, Soleimani M, Kaghazchi T, Asasian N. Competitive separation of lead, cadmium, and nickel from aqueous solutions using activated carbon: response surface modeling, equilibrium, and thermodynamic studies. Chem Eng Commun. 2016;203:123–35.

Khalil TE, El-Dissouky A, Rizk S. Equilibrium and kinetic studies on Pb2+, Cd2+, Cu2+ and Ni2+ adsorption from aqueous solution by resin 2,2’–(Ethylenedithio) diethanol immobilized Amberlite XAD-16 (EDTDE-AXAD-16) with chlorosulphonic acid. J Mol Liq. 2016;219:533–46.

Kocaoba S. Comparison of Amberlite IR 120 and dolomite’s performances for removal of heavy metals. J Hazard Mater. 2007;147:488–96.

Kocaoba S. Adsorption of Fe(II) and Fe(III) from aqueous solution by using sepiolite: speciation studies with MINEQL+ computer program. Sep Sci Technol. 2020;55:896–906.

Kocaoba S, Arısoy M. The use of white rot fungi (Pleurotus ostreatus) immobilized on Amberlite XAD-4 as a new biosorbent in trace metal determination. Biores Technol. 2011;102:8035–9.

Kumar M, Rathore DPS, Singh AK. Amberlite XAD-2 functionalized with o aminophenol: synthesis and applications as extractant for copper(ii), cobalt(ii), cadmium(ii), nickel(II), zinc(ii) and lead(II). Talanta. 2000;51:1187–96.

Kumar S, Islam A, Ahmad H, Zaidi N. Graphene oxide supported on amberlite resin for the analytical method development for enhanced column preconcentration/sensitive flame atomic absorption spectrometric determination of toxic metal ions in environmental samples. Ind Eng Chem Res. 2019;58:8309–16.

Li C, Xu M, Sun X, Han S, Wu X, Liu YN, Huang J, Deng S. Chemical modification of Amberlite XAD-4 by carbonyl groups for phenol adsorption from wastewater. Chem Eng J. 2013;229:20–6.

Lundstrom M, Liipo J, Taskinen P, Aroma J. Copper precipitation during leaching of various copper sulfide concentrates with cupric chloride in acidic solutions. Hydrometallurgy. 2016;166:136–42.

Lyer A, Mody K, Jha BK. Biosorption of heavy metals by a marine bacterium. Mar Pollut. 2005;50:175–9.

Maksimov AF, Kutyrev GA, Zhukovaa AA, Kudryashova DA, Kutyreva MP. New adsorbent based on zeolite modified with hyperbranched polyesterpolybenzoylthiocarbamate. Russ Chem Bull. 2021;70:672–6.

Marahel F, Ghaedi M, Montazerozohori M, Biyareh MN, Kokhdan SN, Soylak M. Solid-phase extraction and determination of trace amount of some metal ions on Duolite XAD 761 modified with a new Schiff base as chelating agent in some food samples. Food Chem Toxicol. 2011;49:208–14.

Metilda P, Sanghamitra K, Gladis JM, Naidu GRK, Prasada TR. Amberlite XAD-4 functionalized with succinic acid for the solid phase extractive preconcentration and separation of uranium(VI). Talanta. 2005;65:192–200.

Ozdemir S, Kılınç E, Acer O, Soylak M. Simultaneous preconcentrations of Cu(II), Ni(II), and Pb(II) by SPE using E profundum loaded onto Amberlite XAD-4. Microchem J. 2021;171:106758.

Renu, Agarwal M, Singh K. Heavy metal removal from wastewater using various adsorbents: a review. J Water Reuse Desalin. 2017;7:387–419.

Safarzadeh MS, Bafghi MS, Moradkhani D, Ilkhchi MO. A review on hydrometallurgical extraction and recovery of cadmium from various resources. Miner Eng. 2007;20:211–20.

Saffarionpour S, Sevillano DM, Van der Wielena LAM, Noordman TR, Brouwer E, Ottensa M. Selective adsorption of flavor-active components on hydrophobic resins. J Chromatogr A. 2016;1476:25–34.

Saha GC, Hoque MIU, Miah MM, Holze R, Chowdhury DA, Khandaker S, Chowdhury S. Biosorptive removal of lead from aqueous solutions onto Taro (Colocasiaesculenta (L.) Schott) as a low cost bioadsorbent: characterization, equilibria, kinetics and biosorption-mechanism studies. J Environ Chem Eng. 2017;5:2151–262.

Santana AH, Araujo JAS, Bento AMS, Santos AR, Santos LG, Gomes HO, Costa JGM, Menezes JMC, Coutinho HDM, Filho FJP, Teixeira RNP. Copper and lead ion removal from wastewater using fava d’anta fodder (Dimorphandra gardneriana Tulasne). Environ Geochem Health. 2021;43:1583–97.

Shiri-Yekta Z. Removal of Th(IV) ion from wastewater using a proper Schiff base impregnated onto Amberlite XAD-4. Part Sci Technol. 2020;38:494–504.

Somu P, Kannan U, Paul S. Biomolecule functionalized magnetite nanoparticles efficiently adsorb and remove heavy metals from contaminated water. J Chem Technol Biotechnol. 2019;94:2009–22.

Tajodini N, Moghimi A. Simultaneous preconcentration of cadmium(II) and lead(II) in water samples using resin amberlite XAD-2 functionalized with nitroso R salt and determination with atomic absorption spectrometry. Asian J Chem. 2010;22:3349–61.

Tobiasz A, Walas S. Solid-phase-extraction procedures for atomic spectrometry determination of copper. Trends Anal Chem. 2014;62:106–22.

Topuz B, Yakut SM. Preconcentration and separation of Mn(II) from environmental water samples on N, N-bis (Salicylidene) Cyclohexanediamine functionalized Amberlite XAD-4 resin and its spectrophotometric assessment. J Water Chem Technol. 2020;42:45–53.

Topuz B, Kabadayi F, Solmaz A. A novel method for the simultaneous determination of Pb (II), Cd (II) and Zn (II) in environmental water samples. Int J Environ Anal Chem. 2019;99:641–52.

Trzonkowska L, Lesniewska B, Zylkiewicz BG. Studies on the effect of functional monomer and porogen on the properties of ion imprinted polymers based on Cr(III)-1,10-phenanthroline complex designed for selective removal of Cr(III) ions. React Funct Polym. 2017;117:131–9.

Xu YC, Wang ZX, Cheng XQ, Xiao YC, Shao L. Positively charged nanofiltration membranes via economically mussel-substance-simulated co-deposition for textile wastewater treatment. Chem Eng J. 2016;303:555–60.

Yang W, Yu Z, Pan B, Lv L, Zhang W. Simultaneous organic/inorganic removal from water using a new nanocomposite adsorbent: a case study of p-nitrophenol and phosphate. Chem Eng J. 2015;268:399–407.

Yavuz Y, Ogutveren UB. Treatment of industrial estate wastewater by the application of electrocoagulation process using iron electrodes. J Environ Manag. 2018;207:151–8.

Yilmaz V, Kartal S. Determination of some trace metals by FAAS after solid phase extraction with Amberlite XAD-1180/TAN chelating resin. Anal Sci. 2012;28:515–21.

Yu C, Li H, Jia X, Chen B, Li Q, Zhang J. Heavy metal flows in multi-resource utilization of high-alumina coal fly ash: a substance flow analysis. Clean Technol Environ Policy. 2015;17:757–66.

Yusuff AS, Gbadamosi AO, Lala MA, Ngochindo JF. Synthesis and characterization of anthill-eggshell composite adsorbent for removal of hexavalent chromium from aqueous solution. Environ Sci Pollut Res. 2018;25:19143–54.

Zawierucha I, Zajac AN, Girek T, Lagiewka J, Ciesielski W, Pawlowska B, Biczak R. Arsenic(V) removal from water by resin impregnated with cyclodextrin ligand. Processes. 2022;10:253.

Zhou Q, Xing A, Zhao K. Simultaneous determination of nickel, cobalt and mercury ions in water samples by solid phase extraction using multiwalled carbon nanotubes as adsorbent after chelating with sodiumdiethyldithio carbamate prior to high performance liquid chromatography. J Chromatogr A. 2014;1360:76–81.

Acknowledgements

Not applicable.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

SK designed the study and directed all experiments and wrote the manuscript. The experiments were carried out by herself. Author read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The author states that there is no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kocaoba, S. Determination of some heavy metals from aqueous solutions using modified Amberlite XAD-4 resin by selective solid-phase extraction. J Anal Sci Technol 13, 15 (2022). https://doi.org/10.1186/s40543-022-00324-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40543-022-00324-7