Abstract

In this paper, we start from the study on the packaging efficiency of the phosphor-converted white LED via a new way to measure and calculate the blue light from the blue die to the encapsulation lens. Then we try to estimate the limit of luminous efficacy of a pcW-LED with Type VII structure. In the calculation, with the EQE of 81% of the blue die and Stokes loss, we obtain the optimal limit of luminous efficacy. The largest one reaches 300 lm/W, and occurs for green-white light with CCT from 4000K to 5000K. More practical limit is calculated in considering phosphor quantum loss and geometry loss, and the practical limit of luminous for CRI around 60 is around 210 lm/W, and for CRI larger than 80 is around 175 lm/W. Luminous efficacy will be sacrificed to obtain higher CRI. In order to know the real optical flux on the illuminated target, we introduce the optical utilization factor (OUF). Three application cases are discussed. The OUFs for light bulb, automotive head lamp, and street light are 90%, 60% and 45%, respectively. In considering human factors, it is interesting to find that a light source with lower luminous efficacy can perform higher illumination luminous efficacy (ILE). Therefore it is important to use ILE rather than LE when a light source is practically applied to lighting.

Similar content being viewed by others

Background

Phosphor-converted white LED (abbreviated as pcW-LED) is a solid-state light source which emits white light based on a blue die covered by yellow or green-red phosphor [1]-[9]. Such a light source has been intensively applied to general lighting owing to its advantages, including high energy efficiency, fast response, acceptable color rendering, and low cost [10],[11]. The property in high luminous efficacy enables pcW-LEDs to replace most light sources in general lighting and even in special lighting. The use of high-efficiency pcW-LEDs becomes one of the important topics in global energy saving. With no doubt, a pcW-LED could save energy due to the light emission mechanism in a semiconductor with p-n junctions. A well design with a suitable substrate such as low-cost sapphire makes a pcW-LED to perform luminous efficacy as high as 150 lm/W operated at 1 watt [12]. Furthermore, a high quality GaN template could even rise the internal quantum efficiency (IQE) as high as 88% or potentially even higher [13],[14]. Also, well-developed chip process and die shaping could effectively increase the light extraction efficiency (LEE) to a level of 90% [15]-[18]. Combination of the IQE and LEE, the state-of-the-art external quantum efficiency (EQE) of a blue die for a pcW-LED could reach as high as 80%. However, it is lack of detailed analysis for packaging efficiency (PkE) to decide the limit of luminous efficacy of a pcW-LED with a certain spectrum.

In this paper, we present a study of PkE for several kinds of pcW-LEDs to figure out the possible limit of PkE. Then, we further consider the photopic spectral luminous efficiency function of human eye on pcW-LEDs according to the specific spectrum. In corporation with the state-of-the-art EQE, we study and discuss the potentially reachable luminous efficacy of a pcW-LED with different color performance.

Methods

Definition of packaging efficiency

The PkE is a ratio between the emitted light power of a pcW-LED and the blue light power escaping to the packaging volume from the blue die. The efficiency is defined in Eq. (1).

where P wo and P bi are the power of the white light emitted by the pcW-LED and the power of the blue light inside the packaging volume, respectively, as shown Figure 1. According to the definition in Eq. (1), we could summarize three kinds of power loss in the packaging level. The first is phosphor quantum loss, which is caused by limit quantum efficiency of a phosphor material in down-conversion emission. The second is called Stokes loss [19], which is caused by down conversion of the re-emitted photons pumped by blue photons, and the loss relates to the spectral distribution of the white light. The third is called geometry loss, which contains all possible absorptions in surfaces or materials other than the phosphor. To simplify the explanation, we combine the first two losses into a new one, which is so-called phosphor loss in this paper. Thus, the total power in the packaging level can be categorized into four different outcomes as described in Eq. (2).

where P bo and P yo are the measured power of the blue light and the re-emitted (yellow) light, respectively; P pl and P gl are the power of phosphor loss and of the geometry loss, respectively. Here, the total loss, including the phosphor loss and the geometry loss, in the packaging level is called packaging loss (PkL).

In calculating the PkE in a real pcW-LED, we have to measure the power of white light outside the pcW-LED and the power of the blue light from the blue die to the packaging volume. In a pcW-LED, the blue die will be covered by phosphor mixed with the encapsulation material such as silicone [20]. The blue light in the packaging is different from that emitted by a bare blue die to the air since the light extraction of the blue die changes. Generally, the LEE could increase in such a condition, because the light escaping cone in the blue die becomes larger owing to the increase of the refractive index outside the die. However, it could be possible to reduce the LEE if the major LEE comes from effective surface texture [15]-[18]. Eventually, it is difficult to measure the power of the blue light inside the packaging volume directly. To solve the problem, we propose a way with measuring the power of the bare blue die and a calibration factor to calculate the power of the blue light inside the packaging volume. The whole process can be illustrated as following.

The first is to measure the power of the bare blue die (P bb ) after die bonding and wire bonding on the submount. The second is to cover the blue die by using an encapsulation lens with an appropriate material as shown in Figure 2 and measure the blue light outside the blue emitter. In general, the power of the blue emitter is larger than the power of the bare blue die. But the power of the blue light outside the packaging volume is smaller than the power of the blue light inside the packaging volume owing to Fresnel loss of the boundary between the lens and the air. To figure out the Fresnel loss, in the last process we have to apply Monte Carlo ray tracing to simulate the power distribution of the blue emitter and calculate the power ratio of the Fresnel loss (R F ) [21]. The blue light power inside the packaging volume can be calculated according to Eq. (3).

where R bob is the power ratio between the blue light outside the packaging volume and the bare blue die. For example, a packaging structure with a silicone dome lens covered on a blue die (EZ700 by Cree), the calculated power ratio of the Fresnel loss is around 1.4%, and the measured R bob is 1.270. Therefore, in such geometry, the blue light power inside the packaging volume is written in Eq. (4).

It is noted that the gain coefficient in Eq. (4) will be changed when a blue die with a different light extraction approach is used. The result with Eq. (4) is then applied to the evaluation of PkE in Eq. (1).

Packaging efficiency in experiment and simulation

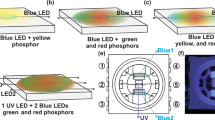

The study of the PkE is aimed to figure out the potentially highest efficiency so that people knows which the improvement space is for the current pcW-LEDs. In this study, several typical packaging structures are applied. Figure 3 shows three kinds of structures (numbered Type I to Type III) and the corresponding remote-phosphor types (numbered Type IV to Type VI) [22]-[24], which moves the phosphor layer (volume) away from the blue die to reduce the temperature and die absorption. Type VII is an alternative type of Type II, with phosphor conformal coating on the blue die [25]. The diameter of the encapsulation lens is 6 mm in all types. The blue dies are selected with a name of EZ700 by CREE with a peak wavelength of 450 nm. The corresponding samples in the experiment are shown in Figure 4. The injection current is controlled at 20 mA, while the measurement is done with thermal equilibrium even when the heat generation is small. Yellow YAG phosphor with a diameter range centering at 6 μ m and 15 μ m are used to achieve white light incorporated with a blue die in the experiment while Green YAG and Red Nitride phosphors are used in the simulation. The normalized emission spectra of the used phosphor are shown in Figure 5.

Samples of the pcW-LED corresponding to Figure 3 . (a) Type I, dome shape (b) Type II, molding (c) Type III, cup shape (d) Type IV, remote dome (e) Type V, remote molding (f) Type VI, remote cup (g) Type VII, conformal coating.

The measurement of the PkE follows the procedure addressed above and P bi is calculated with Eq. (4). The correlated color temperature (CCT) of all the samples is controlled at 6500K ±500K. The measurement of the PkE for the seven kinds of pcW-LED is shown in Figure 6. The relatively higher PkE is found in Types I, IV and VII, i.e., the phosphor dome structure with/without remote design, and the conformal coating. The measured highest PkE reaches 63%. The lower PkE can be found in Type III and Type VI because there is an additional reflective cup absorbing lights, the PkE is reduced.

The limit PkE can be analyzed through examining the PkL budget through simulation with Monte Carlo ray tracing incorporated with the precise phosphor model that we developed [26]-[33]. The practical PkL mainly comes from the geometry loss including the absorption in the bottom layer of the board and the absorption in the active layer of the blue die. To make fair comparison, we adjust the phosphor concentration and thickness to achieve similar particle number of the phosphor so that the CCT is controlled at 6500K ±100K. In the simulation, the reflectivity of the bottom layers is changed from 70% to 90%, and the absorption coefficient of the active layer is changed from 200 cm −1 to 1000 cm −1. The simulation result of the PkL is shown in Figure 7, where we can find that the geometry loss plays an important role in PkE. The lowest PkL is found around 27% in Type IV, which is 8% larger than the phosphor loss of 19% at 6500K in the presented case, where that the Stokes loss takes away around 15% of power. It means that we could achieve PkE of 73% with the packaging structure of Types IV with the reflectivity of the bottom layer as high as 90% and the absorption coefficient of the active layer as low as 200 cm −1. This could be regarded as a practical limit of PkE with a specific phosphor.

Now we discuss the PkE induced by the phosphor. In the presented case, the YAG phosphor performs the quantum efficiency as high as 90% from the experimental measurement and it corresponds to 4% phosphor quantum loss in the simulation [24],[34],[35]. Therefore, there is more space to reduce geometry loss than to reduce phosphor loss. As well-known, the particle sizes of phosphors do effect the strength of the scattering according to the Mie theory. Tran et al. observed that the bigger the particle size is, the higher the phosphor concentration is required to achieve the light output of the same CCT. However, when the particle size becomes too large, the propagation in the horizontal direction of light is slightly changed and increases the geometry loss [36]. Furthermore, Yang et al. give a quantitative model to delineate the relation among the lumen output and the CCT of pcW-LEDs, the particle sizes of the phosphors, and the concentration of the phosphors. They find that there exists an optimal particle number for the balance between phosphor conversion and the Mie scattering [37]. In this work, only two typical particle sizes of 6 μ m and 15 μ m are taken into consideration for the particle size issue. An obvious example can be observed using another kind of yellow YAG phosphor with a diameter centering at 15 μ m. The simulation is shown in Figure 8, where the simulation parameters are the same with those in Figure 6 except the particle size is changed from 6 μ m to 15 μ m. It is found that all simulated PkE’s increase. The gain in PkE is from the decrease of geometry loss because the phosphor of the diameter of 15 μ m induces less backward scattering than that of 6 μ m [36]. The corresponding simulation shows that the geometry loss of the phosphor of the diameter at 15 μ m is 5∼7% less than that at 6 μ m for Types I to VI. Type VII is another story in geometry loss because the most geometry loss comes from absorption in the active layer. The reduced backward scattering by changing phosphor size makes a big benefit in reducing the absorption loss in the blue die. The simulation shows that the PkL can be reduced to 23% in Type VII. The corresponding experiment shows that the maximal measured PkE reaches 66%. In addition, the packaging efficiency is also a function of the defined CCT, which is related to the spectrum. Lower CCT of a pcW-LED means more transformation from the blue photon to yellow/green/red photon. Thus there could be more phosphor loss. It is noted that the geometry loss is also a function of the CCT. In a pcW-LED with lower CCT, the blue photons have more chances to hit the phosphor, so that more backward scattering occurs, making the geometry loss becomes heavy. Figure 9 shows a simulation of Type IV and Type VII for the phosphor size of 6 μ m and 15 μ m, respectively. The simulation shows that the more backward scattering with 6 μ m, the more geometry loss the both types of LED would suffer from. In the case of Type VII, the geometry loss is more sensitive in phosphor particle size than in the absorption coefficient of the active layer. Therefore, phosphor particle size of 15 μ m greatly benefits the packaging efficiency with much less geometry loss in both Types IV and VII, and so does other types. In the simulation, we can find that the lowest geometry loss occurs in Type VII when the particle size is 15 μ m and the absorption coefficient is 200 cm −1. The geometry loss is about 4% when the CCT is 6500K and increases to 5.6% when the CCT is 500K.

To summarize the PkE for the case using the yellow YAG phosphor and the CCT around 6500K, the ideal PkE is 85% when the Stokes loss is the only power loss in PkL. In the more practical case, we have to count the phosphor quantum loss, so the PkE drops to 81%. If a practical limit of geometry loss is counted, the PkE could reach 73% in Type IV for the phosphor with particle size of 6 μ m, and 77% in Type VII for the phosphor with particle size of 15 μ m. In the experiment, the measured highest PkEs are 63% and 66% respectively in the two cases, where the difference between the two cases is similar to the practical limit in simulation. To reach the limit of the PkE, how to reduce geometry loss is the point.

Results and discussion

Luminous efficacy

The PkE is a function of the CCT and both are affected by phosphors. Yellow phosphor is the simplest and most cost-effective way to perform white light with acceptable color rendering index (CRI) of around 70. To increase CRI up to 85 or above, two phosphors with yellow/green and red could be adopted; however, the PkE could drop due to more Stokes loss when more red lights are emitted. To achieve higher luminous efficacy of a pcW-LED, a possible way is to use green phosphor. Thus the PkL could be reduced owing to smaller Stokes loss. Another incentive is the luminous efficacy of radiation [38] becomes larger. We explore the luminous efficacy by utilizing the CIE 1924 photopic spectral luminous efficiency function [39], which describes the average spectral sensitivity of human visual perception of brightness. We choose three kinds of phosphor recipe for the study, which are including yellow YAG phosphor, green YAG phosphor, and yellow YAG phosphor with red Nitride phosphor. The peak wavelength of the blue die in the study is kept 450 nm. The obtained chromaticity of pcW-LEDs are shown in Figure 10. It is noted that the yellow and green phosphor make the chromaticity deviate off the Planckian locus of the black body radiation while still keep CCT constant. Therefore, we also adopt Δ u v for evaluating the distance between the obtained chromaticity and the ones on Planckian locus of the same CCT in CIE 1960 UCS diagram. The luminous efficacy of radiation versus Δ u v for diverse phosphor recipes of various CCTs is shown in Figure 11. Only when the Δ u v is less than 0.02, the light can be said to be white and of a meaningful CCT [39]. We find that when the chromaticity is within the maximal deviation range of Δ u v≤0.02, and the optimal luminous efficacy of radiation is only around 357 lm/W at CCT is 5872K. In contrast, beyond the criteria of 0.02, the luminous efficacy of radiation can reach as high as 466 lm/W at CCT is 4892K. However, the appearance of the white light becomes too much greenish or yellowish. Those white light with Δ u v≥0.02 could not be acceptable in indoor lighting, but might still acceptable in outdoor lighting for the consideration of energy saving.

The luminous efficacy of radiation (LER) versus Δ u v for different phosphor recipes corresponding to Figure 10 .

On the other hand, for outdoor lighting during most nighttime, human eyes use mesopic vision. The peak wavelength of the mesopic spectral luminous efficiency is between 507 nm and 555 nm wavelengths. Therefore, using lamps with more greenish content shall have the energy-saving potential in mesopic illumination condition. Prior studies have shown that lamps with higher scotopic/photopic (S/P) ratios appear brighter than the ones that provide with the same illuminance but of lower S/P ratios [40],[41]. One intuitive way to raise the S/P ratio is to add green light into white-light lamps, but the visual acceptability of greenish color has to be examined. A preliminary study compared five LED packages with different proportions of green to white LED chips [42]. The result of psychophysical experiments shows that adding a small proportion of green chips into white LEDs could yield the same visual acceptability as that of pure white LEDs. Further investigations are required to find the optimal green-to-white proportion for energy saving and visual acceptability.

Limit of luminous efficacy of pcW-LEDs

Luminous efficacy of a pcW-LED is a key factor in consideration of energy saving and cost. In neglecting the electrical power loss and thermal loss, luminous efficacy of a pcW-LED is determined by the EQE, the PkE, the CCT, and the luminous efficacy of radiation (LER). The “luminous efficacy of a source” is a measure of the efficiency with which the source provides visible light from electricity. The “luminous efficacy of radiation” describes how well a given quantity of electromagnetic radiation from a source produces visible light [38]. It is noted that once the CCT is changed, the phosphor particle number should be changed accordingly [37], and then the PkE is also varied.

In the viewpoint of human factors, the white light needs to perform high CRI at a specified CCT. However, in the viewpoint of energy saving, the spectrum of a pcW-LED may perform the highest luminous efficacy of a source as the Δ u v is larger than 0.02 while with acceptable color appearance to the users.

To estimate the limit of luminous efficacy of a pcW-LED, we assume that the highest IQE reaches 90% and highest LEE reaches 90%, so that a limit EQE is around 81%. The scenarios are focused on the effect by the PkE, the CCT, and the LER. The first scenario is that there is no geometry loss and phosphor quantum loss, so Stokes loss is the only factor counted in the PkE. The second scenario is a more practical case, where the phosphor quantum loss is counted, and the geometry loss is also applied according to the lowest loss in the Type VII shown in Figure 9.

To show the possible limit in luminous efficacy of a pcW-LED in all scenarios and all cases, we summarize all calculated numbers based on the best performance case with Type VII in Table 1, and Figure 12 is a figure to show the capability of each case, including the LER (the end of the yellow bar), the limit of luminous efficacy of a pcW-LED with only Stokes loss (the end of the blue bar), the possible practical limit of luminous efficacy of a pcW-LED with additional 4% loss for phosphor quantum loss and geometry loss (the end of the green bar) based on Figure 12, and the corresponding CRI and phosphor in the brackets. From the observation in Table 1 and Figure 12, we may conclude that:

-

1.

If Stokes loss is the only loss in packaging level, it is possible to use green YAG phosphor to perform a limit of luminous efficacy of a pcW-LED as high as 300 lm/W, but the color appearance might not be white, and the CRI could be below 30.

-

2.

If 4% of phosphor quantum loss and CCT-dependent geometry loss are counted, the practical limit of luminous efficacy of a pcW-LED for greenish white or yellowish white is about 260 lm/W for very low CRI and is about 240 for CRI around 60.

-

3.

For the yellow phosphor, it is possible to reach the limit of luminous efficacy of a pcW-LED in a range from 200 lm/W to 250 lm/W of a well-defined CCT around 6000K to 6500K and CRI around 70.

-

4.

To increase the CRI to 80 or even above, two phosphors must be used. Then, the limit of luminous efficacy of a pcW-LED in a range from 160 lm/W to 200 lm/W with a well-defined CCT around 4000K to 5000K. It means that better color performance will dramatically sacrifice luminous efficacy.

Introduction of illumination luminous efficacy and the impact

Table 1 and Figure 12 describe limits of the luminous efficacy of pcW-LEDs in different CCTs and recipes. Those limits are for the light sources rather than for the illumination, which is more related to the practical application and human factors. In order to figure out the effect on illumination, an optical utilization factor (OUF) [43],[44] is introduced in Eq. (5).

where P T and P LED are the power on the target illumination area and the emission power of the pcW-LED. OUF is a factor to know how the light source can be effectively utilized in an illumination system. OUF thus depends on the optical design with the characteristic of the light source and the illumination application. In order to describe the effective luminous efficacy in the practical illumination, we define a new factor, illumination luminous efficacy (ILE), which is written in Eq. (6).

where η e and R TL are the electrical injection efficiency and power loss ratio with thermal effect, respectively. To know the ILE in general application, in this paper, we will discuss three kinds of application, i.e., light bulb, automotive head lamp and street light.

Most of the designs of light bulb, the pcW-LED is faced up to illuminate the diffusive shell so that the emitted lights can be directed to a wide viewing range. A special design is needed to fit omni-directional light pattern and thus the optical efficiency decreases. A good design of the LED light bulb must keep the cavity of the light bulb in high reflectivity so that all the backward lights can be recycled [45]. A reasonable optical efficiency is 90%, and all the emitted lights by the bulb can be utilized. Therefore, the potential OUF is 90% in this case, and also CRI above 80 is suggested for indoor lighting.

In the case of automotive head lamp, the optical design is to project the lights into a plane at a distance at 25 m as described in the regulation. In order to have function of anti-glare to the people on the road way, a cut-off line with high contrast is required. To meet the regulation of the low beam, optical loss outside the target region could reach 40% and higher in most cases, depending on the head lamp size. Therefore, OUF of 60% is regarded as a high standard. To achieve higher luminous efficacy, CRI around 60 could be adopted.

In the case of street light, the optical design is used to project the lights on the roadway. A special design to reach an OUF as high as 81% is proposed with beam shaping technology [46],[47]. In general, the light pattern is projected on the roadway but with more diffusive light pattern. Typically, the OUF is between 35% and 45% in the roadway area around the location of the street light [43]. Therefore, the OUF in street light could be set 45%. To achieve higher luminous efficacy, CRI could be sacrificed. Green-white or yellow-white is potential to be adopted in street light for energy saving purpose.

Incorporated with 5% in electrical injection loss and 5% in thermal loss, the illumination luminous efficacy in the three cases can be summarized as Table 2 and Figure 13, where the right ends of the light-grey, dark-grey and black bar are 90%, 60% and 45% in OUF, respectively, and respond to the applications in light bulb, automotive heal lamp and street light. The yellow star indicates the potentially achievable ILE for each recipe. It is interesting to find that owing to human factors, the yellow-white and green-white LEDs is not acceptable in indoor lighting, and could be adopted in some specific outdoor lighting, such as street light with lower OUF, so the ILE is around 100 lm/W. In contrast, although two-phosphor recipe performs lower luminous efficacy, the ILE could achieve as high as 120 lm/W and above since the application to indoor lighting has larger OUF. A source with lower luminous efficacy can perform higher ILE owing to human factors. Therefore, it is important to use ILE rather than luminous efficacy of a source when a light source is practically applied to lighting.

A comparison of the calculated limit of illumination luminous efficacy of the pcW-LEDs in different phosphor recipes. The right end of red bar is the luminous efficacy with 5% in electrical injection loss and 5% in thermal loss. The right ends of the light-grey, dark-grey and black bar are 90%, 60% and 45% in OUF, respectively, and respond to the applications in light bulb, automotive heal lamp and street light.

Conclusion

In this paper, we start from the study of packaging efficiency with phosphor-converted white LED. The PkE can be obtained through a new way to measure and calculate the blue light from the blue die to the encapsulation lens. Then we investigate the PkE in seven types of pcW-LED to figure out what the most efficient is among them. In order to know the details of the PkL, we analyze the PkL budget, which contains Stokes loss, phosphor quantum loss, and geometry loss. The Stokes loss depends on the blue spectrum and the spectrum of the down-conversion. The geometry loss is more complicated, and it relates to the phosphor, the reflective surface in the packaging volume and the absorption of the active layer of the blue die. The simulation shows that phosphor particle size could induce different backward scattering, and so does the geometry loss. The simulation and corresponding experiment shows that the phosphor with small particle size, Type I and Type VII are the best in PkE. As for larger particle size, Type VII could be the most appropriate one. The corresponding experiment shows that the highest measured PkE is 63% for Type VII with 6 μ m of particle size, and 66% for Type VII with 15 μ m.

Since the CCT is an essential factor in luminous efficacy with human eye response, and thus we calculate the luminous efficacy for yellow YAG phosphor, green YAG phosphor and yellow YAG mixed with red Nitride phosphor. We introduce Δ u v to distinguish the defined white light from the yellow-white and green-white light. Also, CRI is introduced to describe the color performance. We find that the color coordinate within the deviation range of 0.02, the largest LER is only around 357 lm/W when the CCT is 5872K. In contrast, outside the range in 0.02, the largest LER can reach as high as 466 lm/W when the CCT reduces to 4892K.

Based on the analysis above, we try to estimate the limit of luminous efficacy of a pcW-LED with Type VII structure. In the calculation, with the EQE of 81% of the blue die and Stokes loss, we obtain the limit of luminous efficacy of pcW-LEDs. The largest one is larger than 300 lm/W and occurs for green-white recipe with CCT between 4000K to 5000K. To have more practical limit of the luminous efficacy, we count the additional 4% phosphor quantum loss and CCT-dependent geometry loss. The highest luminous efficacy drops to around 270 lm/W, and the CRI is below 30. To increase the CRI to around 60, yellow-white recipe can reach 240 lm/W in the practical limit of luminous efficacy. In order to reach CRI of 80 and above, two-phosphor recipe has to be used. The practical limit of luminous efficacy reaches 175 lm/W when the CCT is near 5500K. The summary here seems that the limit of practical limit of the LED will be sacrificed in obtaining higher CRI. To approach the optimal luminous efficacy and the optimal CRI in the same time always put us into a dilemma. For various applications in the daily life, it might be a good strategy to keep a minimal requirement on CRI first, then to optimize the luminous efficacy as possible. That will bring us as higher luminous efficacy but will not lose CRI too much in any specific application.

In order to know the real optical flux on the illuminated target, we introduce OUF. Three application cases are discussed. The OUFs for light bulb, automotive head lamp, and street light are 90%, 60% and 45%, respectively. Incorporated with 5% in electrical injection loss and 5% in thermal loss, the illumination luminous efficacy in the three cases can be summarized. In considering human factors, it is interesting to find that the yellow-white and green-white LEDs are not acceptable in indoor lighting, and could be adopted in some specific outdoor lighting, such as street light with lower OUF, so the ILE is around 100 lm/W. In contrast, although two-phosphor recipe performs lower luminous efficacy, the ILE could achieve as high as 120 lm/W and above since the application to indoor lighting has larger OUF. A source with lower luminous efficacy can perform higher ILE owing to human factors. Therefore it is important to use ILE rather than luminous efficacy when a light source is practically applied to lighting.

In summary, the study of the PkE clarifies the PkL budget of a pcW-LED, so that the limit of the luminous efficacy and illumination luminance efficacy can be estimated. It will be much helpful for the people in the field related to pcW-LED to figure out what/how luminous efficacy can be achieved and what/how the people can do in the next.

References

Erdem T, Nizamoglu S, Sun XW, Demir HV: A photometric investigation of ultra-efficient LEDs with high color rendering index and high luminous efficacy employing nanocrystal quantum dot luminophores. Opt Express 2010, 18(1):340–347. 10.1364/OE.18.000340

He G, Yan H: Optimal spectra of the phosphor-coated white LEDs with excellent color rendering property and high luminous efficacy of radiation. Opt Express 2011, 19(3):2519–2529. 10.1364/OE.19.002519

Won Y-H, Jang HS, Cho KW, Song YS, Jeon DY, Kwon HK: Effect of phosphor geometry on the luminous efficiency of high-power white light-emitting diodes with excellent color rendering property. Opt Lett 2009, 34(1):1–3. 10.1364/OL.34.000001

Kuo T-W, Liu W-R, Chen T-M: High color rendering white light-emitting-diode illuminator using the red-emitting Eu2+-activated CaZnOS phosphors excited by blue LED. Opt Express 2010, 18(8):8187–8192. doi:10.1364/OE.18.008187

Xie R-J, Hirosaki N, Kimura N, Sakuma K, Mitomo M: 2-phosphor-converted white light-emitting diodes using oxynitride/nitride phosphors. Appl Phys Lett 2007, 90(19):191101–191101. 10.1063/1.2737375

Nizamoglu S, Erdem T, Sun XW, Demir HV: Warm-white light-emitting diodes integrated with colloidal quantum dots for high luminous efficacy and color rendering. Opt Lett 2010, 35(20):3372–3374. 10.1364/OL.35.003372

Kimura N, Sakuma K, Hirafune S, Asano K, Hirosaki N, Xie R-J: Extra high color rendering white light-emitting diode lamps using oxynitride and nitride phosphors excited by blue light-emitting diode. Appl Phys Lett 2007, 90(5):051109. doi:10.1063/1.2437090 doi:10.1063/1.2437090 10.1063/1.2437090

Schlotter P, Schmidt R, Schneider J: Luminescence conversion of blue light emitting diodes. Appl Phys A: Mater Sci Process 1997, 64(4):417–418. 10.1007/s003390050498

Nakamura S, Pearton S, Fasol G: The Blue Laser Diode: the Complete Story, Berlin, Germany: Springer; 2000.

Zukauskas A, Shur M, Gaska R: Introduction to Solid State Lighting, New York: John Wiley & Sons; 2002.

Schubert EF, Kim JK: Solid-state light sources getting smart. Science 2005, 308(5726):1274–1278. 10.1126/science.1108712

Cree: Continues to Push the Boundaries of LED Performance. , [http://www.cree.com/News-and-Events/Cree-News/Press-Releases/2014/March/300LPW-LED-barrier]

Soraa: Recognized for Development of High-Efficiency M-plane LEDs on Bulk GaN Substrates. , [http://www.soraa.com/news/doe-award-february-11–2013]

Cich MJ, Aldaz RI, Chakraborty A, David A, Grundmann MJ, Tyagi A, Zhang M, Steranka FM, Krames MR: Bulk GaN based violet light-emitting diodes with high efficiency at very high current density. Appl Phys Lett 2012, 101(22):223509. 10.1063/1.4769228

Sun C-C, Lee T-X, Lo Y-C, Chen C-C, Tsai S-Y: Light extraction enhancement of GaN-based LEDs through passive/active photon recycling. Opt Commun 2011, 284(20):4862–4868. 10.1016/j.optcom.2011.06.051

Lee T-X, Lin C-Y, Ma S-H, Sun C-C: Analysis of position-dependent light extraction of GaN-based LEDs. Opt Express 2005, 13(11):4175–4179. 10.1364/OPEX.13.004175

Lee T-X, Gao K, Chien W-T, Sun C-C: Light extraction analysis of GaN-based light-emitting diodes with surface texture and/or patterned substrate. Opt Express 2007, 15(11):6670–6676. 10.1364/OE.15.006670

Sun C-C, Tsai S-Y, Lee T-X: Enhancement of angular flux utilization based on implanted micro pyramid array and lens encapsulation in GaN LEDs. J Display Technol 2011, 7(5):289–294. 10.1109/JDT.2011.2107881

Stokes G. G: On the change of refrangibility of light. Philos Trans R Soc Lond A 1852, 142: 463–562. 10.1098/rstl.1852.0022

ShinEtsu KER-2600 Data Sheet. , [http://www.silicone.jp/e/catalog/pdf/LED_Encapsulant_e.pdf] ShinEtsu KER-2600 Data Sheet.

Liu Z, Wang K, Luo X, Liu S: Precise optical modeling of blue light-emitting diodes by Monte Carlo ray-tracing. Opt Express 2010, 18(9):9398–9412. 10.1364/OE.18.009398

Narendran N, Gu Y, Freyssinier-Nova J, Zhu Y: Extracting phosphor-scattered photons to improve white LED efficiency. Phys Status Solidi A 2005, 202(6):60–62. 10.1002/pssa.200510015

Luo H, Kim JK, Schubert EF, Cho J, Sone C, Park Y: Analysis of high-power packages for phosphor-based white-light-emitting diodes. Appl Phys Lett 2005, 86(24):243505. 10.1063/1.1949282

Allen SC, Steckl AJ: Elixir–solid-state luminaire with enhanced light extraction by internal reflection. J Display Technol 2007, 3(2):155–159. 10.1109/JDT.2007.895358

Steigerwald DA, Bhat JC, Collins D, Fletcher RM, Holcomb MO, Ludowise MJ, Martin PS, Rudaz SL: Illumination with solid state lighting technology. Selected Topics Quantum Electron IEEE J 2002, 8(2):310–320. 10.1109/2944.999186

Sun C-C, Lee T-X, Ma S-H, Lee Y-L, Huang S-M: Precise optical modeling for LED lighting verified by cross correlation in the midfield region. Opt Lett 2006, 31(14):2193–2195. 10.1364/OL.31.002193

Sun C-C, Chen C-Y, He H-Y, Chen C-C, Chien W-T, Lee T-X, Yang T-H: Precise optical modeling for silicate-based white LEDs. Opt Express 2008, 16(24):20060–20066. 10.1364/OE.16.020060

Chen C-Y, Yang T-H, Hsu C-H, Sun C-C: High-efficiency white LED packaging with reduced phosphor concentration. Photonics Technol Lett IEEE 2013, 25(7):694–696. 10.1109/LPT.2013.2248141

Sun C-C, Chen C-Y, Chen C-C, Chiu C-Y, Peng Y-N, Wang Y-H, Yang T-H, Chung T-Y, Chung C-Y: High uniformity in angular correlated-color-temperature distribution of white LEDs from 2800k to 6500k. Opt Express 2012, 20(6):6622–6630. 10.1364/OE.20.006622

Sun C-C, Chien W-T, Moreno I, Hsieh C-C, Lo Y-C: Analysis of the far-field region of LEDs. Opt Express 2009, 17(16):13918–13927. 10.1364/OE.17.013918

Sommer C, Wenzl F-P, Hartmann P, Pachler P, Schweighart M, Leising G: Tailoring of the color conversion elements in phosphor-converted high-power LEDs by optical simulations. Photonics Technol Lett IEEE 2008, 20(9):739–741. 10.1109/LPT.2008.921063

Sommer C, Reil F, Krenn JR, Hartmann P, Pachler P, Tasch S, Wenzl FP: The impact of inhomogeneities in the phosphor distribution on the device performance of phosphor-converted high-power white LED light sources. J Lightwave Technol 2010, 28(22):3226–3232.

Sommer C, Reil F, Krenn JR, Hartmann P, Pachler P, Hoschopf H, Wenzl FP: The impact of light scattering on the radiant flux of phosphor-converted high power white light-emitting diodes. J Lightwave Technol 2011, 29(15):2285–2291. 10.1109/JLT.2011.2158987

Mueller-Mach R, Mueller GO, Krames MR, Trottier T: High-power phosphor-converted light-emitting diodes based on III-nitrides. Selected Topics Quantum Electron IEEE J 2002, 8(2):339–345. 10.1109/2944.999189

Zhu Y, Narendran N, Gu Y: Investigation of the optical properties of YAG: Ce phosphor. Proc SPIE 2006, 6337: 63370S-1–63370S-8. 10.1117/12.682056

Tran NT, You JP, Shi FG: Effect of phosphor particle size on luminous efficacy of phosphor-converted white LED. J Lightwave Technol 2009, 27(22):5145–5150. doi:10.1109/JLT.2009.2028087 doi:10.1109/JLT.2009.2028087 10.1109/JLT.2009.2028087

Yang T-H, Chen C-C, Chen C-Y, Chang Y-Y, Sun C-C: Essential factor for determining optical output of phosphor-converted LEDs. Photonics J IEEE 2014, 6(2):1–9. doi:10.1109/JPHOT.2014.2308630 doi:10.1109/JPHOT.2014.2308630

Reinhard E, Khan EA, Akyz AO, Johnson GM: Color Imaging: Fundamentals and Applications, Natick, MA, USA: AK Peters, Ltd; 2008.

CIE 15: 2004 Colorimetry, Vienna: Commission Internationale de l’Eclairage; 2004.

Bullough JD, Rea MS: Simulated driving performance and peripheral detection at mesopic and low photopic light levels. Lighting Res Technol 2000, 32(4):194–198. 10.1177/096032710003200403

Fotios S: LRT Digest 1 maintaining brightness while saving energy in residential roads. Lighting Res Technol 2013, 45(1):7–21. 10.1177/1477153512464141

Chen H, Chang Y-Y, Sun C-C, Chen YC: Comparisons of different proportions of green to white light LEDs on energy saving and visual acceptability under mesopic vision. In The 14th International Symposium on the Science and Technology of Lighting (LS14). Como, Italy: FAST-LS Ltd; 2014. Chen H, Chang Y-Y, Sun C-C, Chen YC: Comparisons of different proportions of green to white light LEDs on energy saving and visual acceptability under mesopic vision. In The 14th International Symposium on the Science and Technology of Lighting (LS14). Como, Italy: FAST-LS Ltd; 2014.

Lo Y-C, Huang K-T, Lee X-H, Sun C-C: Optical design of a butterfly lens for a street light based on a double-cluster LED. Microelectronics Reliability 2012, 52(5):889–893. 10.1016/j.microrel.2011.04.007

Lo Y-C, Cai J-Y, Tasi M-S, Tasi Z-Y, Sun C-C: Side-illuminating LED luminaries with accurate projection in high uniformity and high optical utilization factor for large-area field illumination. Opt Express 2014, 22(102):365–375. 10.1364/OE.22.00A365

Sun C-C, Chien W-T, Moreno I, Hsieh C-T, Lin M-C, Hsiao S-L, Lee X-H: Calculating model of light transmission efficiency of diffusers attached to a lighting cavity. Opt Express 2010, 18(6):6137–6148. 10.1364/OE.18.006137

Lee X-H, Moreno I, Sun C-C: High-performance LED street lighting using microlens arrays. Opt Express 2013, 21(9):10612–10621. 10.1364/OE.21.010612

Wang K, Chen F, Liu Z, Luo X, Liu S: Design of compact free form lens for application specific light-emitting diode packaging. Opt Express 2010, 18(2):413–425. doi:10.1364/OE.18.000413 doi:10.1364/OE.18.000413 10.1364/OE.18.000413

Acknowledgements

This study was supported in part by the National Central University’s “Plan to Develop First-class Universities and Top-level Research Centers” (Grant numbers 995939 and 100G-903-2), the Ministry of Science and Technology of Taiwan (contract numbers NSC 99-2623-E-008-002-ET, 100-2221-E-008-088-MY3, 101-2221-E-008-108, 102-2221-E-008-066 and 103-2221-E-008-063-MY3). The authors would like to thank BRO for providing ASAP simulation tool.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

CC SUN leads the reach group, defines packaging efficiency and is responsible to the paper writing. YY Chang is responsible to all experiments and calculations. TH Yang is responsible to color-related study, overall technical discussion and paper submission. TY Chung and TX Lee participate most technical discussion. CC Chen is for the study of packaging efficiency. CY Lu and ZY Ting are for the partial experiment and simulation. B Glorieux, YC Chen, KY Lai, and CY Liu participate partial technical discussion. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sun, CC., Chang, YY., Yang, TH. et al. Packaging efficiency in phosphor-converted white LEDs and its impact to the limit of luminous efficacy. J Sol State Light 1, 19 (2014). https://doi.org/10.1186/s40539-014-0019-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40539-014-0019-0