Abstract

Background

The objective of this study was to develop instrumental protocols for evaluating physicochemical characteristics of plant biostimulant/biofertiliser formulations. Six formulations (Rygex, Algavyt, Ryzoset, Manek, Ecoryg and Algavyt Zn/Mn) containing algal/plant extracts, humic and amino acids, lipids and inorganic components were assessed for particle size distribution and zeta potential (ZP) by dynamic light scattering (DLS) and gross compositional differences by thermogravimetric analysis (TGA), Fourier transform infrared (FTIR), and pyrolysis-gas chromatography/mass spectrometry (Py-GC/MS).

Results

The six commercial formulations were assessed by mung bean root and wheat leaf senescence bioassays to determine auxin- and cytokinin-like activities. Among them, Rygex, Manek and Ecoryg showed significant auxin-like activities compared to the other formulations. Only Manek showed very low cytokinin-like activity. In combination, the four instrumental techniques highlighted gross differences in the particle sizes, ZP and compositions of the products, and provided key results on the physicochemical characteristics of the formulations including potential stability of the products.

Conclusion

The three techniques (TGA, FTIR and Py-GC/MS) require no sample preparation beyond drying of the materials. The activities of the plant growth hormones have been compared to show advantages of the growth hormone bioassay methods for selecting better formulations.

Examples of macro-algae and plant species used in the processing of plant biostimulants.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Background

“Plant biostimulant is defined as a material which contains substance(s) and/or microorganisms whose function when applied to plants or the rhizosphere is to stimulate natural processes to benefit nutrient uptake, nutrient use efficiency, tolerance to abiotic stress, and/or crop quality, independently of its nutrient content” [1]. The global biostimulants market is projected to reach $2241 million by 2018 [2] with Europe contributing a maximum share in the global market sector. The demand for biostimulants is increasing in the marketplace, and companies are actively introducing innovative products with different ingredients to satisfy the requirements for arable, horticultural and viticultural crops [3, 4].

During a growing season, crop plants are subjected to abiotic and biotic stresses that adversely affect growth, metabolism and yield. Recent reviews on the field performance of biostimulant/biofertiliser products to minimise impact of abiotic and biotic stresses of crop plants have shown positive results from trials carried out by research groups [3–5]. Major constituents include humates, plant and algal extracts, and amino acid-containing products. [2, 3, 6].

Humates, rich in carboxylic and (O- and N-containing) aliphatic functional groups, can influence plant growth indirectly by complexing with a nutrient cation in the growing medium resulting in enhanced uptake of nutrient by plants [7]. Alternatively they can effect plant growth by directly interfering with the metabolic processes, such as respiration and protein synthesis [8]. Humic acids have been used as an additive to formulate biostimulants for improving the antioxidant response in plants subjected by abiotic stress due to enhanced hormonal activities [9, 10]. Under drought conditions, treatment with humic acids can increase leaf water retention and antioxidant metabolism [11].

Formulations with growth hormone-like activities, such as macroalgal extracts, show identifiable amounts of active plant growth substances with the ability to enhance antioxidant activities in plants under abiotic stress by improving physiological fitness of the treated crop plants. These formulations are a complex mixture of components (i.e. laminarin, fucoidan, alginates and minerals) that may vary according to the macroalgal source, the season of collection and the extraction process used [3, 4, 12, 13]. Auxin- and cytokinin-like activities of algal extracts have been demonstrated by Stirk and van Stadden [14].

The amino acid-based products consist of a balanced mixture of free and short chain peptide-bound amino acids [15]. These fractions (i.e. proline and arginine) including polypeptides have been demonstrated by foliar applications, to regulate biochemical and physiological functions in the plant resulting in improved resistance to abiotic and biotic stresses [16]. Protein hydrolysates containing amino acid and peptides can be of either animal or plant origin, manufactured by chemical or enzymatic hydrolysis [6, 17–19].

The constituents such as humic acids, alginates, mannitol, amino acids (proline arginine and tryptophan), sugars (glycosides and polysaccharides), vitamins and betaines have been identified as stress signalling and response molecules [20–23]. In addition to their effects on plant stress tolerance, these biostimulants may stimulate nutrient uptake and translocation [21, 24]. Although biostimulants are widely used in high-value crop production systems such as horticulture and viticulture, little is known of their efficacy or mode of action [5, 24]. The raw materials (i.e. macroalgae and plant species) used by the biostimulant manufacturers are subject to considerable compositional variations which will impact on the amounts and the compositions of major components [12]. Therefore, biostimulant manufacturers require tools for evaluating the formulations.

The objective of this study was to compare the physicochemical characteristics of the biostimulant formulations and demonstrate the feasibility of using analytical tools, such as dynamic light scattering (DLS), thermogravimetric analysis (TGA), Fourier transform infrared spectroscopy (FTIR), pyrolysis-gas chromatography and mass spectrometry (Py-GC/MS) and plant growth hormone bioassay to characterise the formulations.

Methods

Biostimulant formulations

The six commercial biostimulant formulations evaluated in this study were prepared using extracts of macroalgal species (Ascophyllum nodosum, Laminaria hyperborea, Fucus spp. and Spirulina sp.), plant species (Sapindus mukorossi, Quillaja saponaria, and Allium sativum) and leonardite [12, 13, 25, 26]. The major and minor (humic acids, algal extracts, amino acid, plant extracts, fatty acids, peptides and minerals) constituents of the six products and their recommended application range or rate as recommended by the supplier are shown in Table 1. The reference materials of carbohydrates: alginic acid from brown seaweeds (A-7003), laminarin from L. digitata (L-9634), mannitol (M-4125), fucoidan from F. vesiculosus (F-5631), humus, glycoalkaloid saponins and indole butyric acid (IBA, Sigma) were obtained from Sigma-Aldrich (UK).

Sample preparation

The pH and electrical conductivity (EC) of the formulations were measured using 1 % concentration of the original product. Auxin- and cytokinin-like plant growth hormone assays of the products were carried out at 0.1, 1.0. 5.0 and 10.0 g/l dilutions. Samples for DLS analysis were diluted to the mid-point of recommended field application range or the rate. Freeze-dried samples were used for FTIR, TGA and Py-GC/MS. For all other chemical analyses, the samples were oven dried at 75 °C to constant weight and milled (Foss Tecator 1093 Cyclotec mill) to pass through a 1.0-mm screen. One formulation (Manek) was not suitable for mechanical milling, and it was hand ground in a mortar and pestle. The milled samples were stored in plastic jars at room temperature for further analyses.

Chemical analyses

Nitrogen (total N) and carbon contents were determined by elemental analysis (LECO CN-2000) in duplicate [27]. The ash contents were estimated by heating the samples overnight in a muffle furnace maintained at 600 °C and crude lipids were extracted from the samples with chloroform/methanol [28]. The carbohydrate content of the formulations was measured by anthrone method [28]. The elemental (Ca, Cu, Fe, K, Mg, Na and P) compositions of the samples were quantified by inductively coupled plasma-optical emission spectroscopy (ICP-OES, Perkin Elmer) [29]. The dry matter (DM), density, chemical analyses were repeated on three production batches to assess the consistency of the formulations. All determinations were performed in triplicate unless specified.

Dynamic light scattering

The liquid biostimulant formulations were diluted with deionised water to the mid-point of the recommended range or the suggested application rate listed in Table 1. The particle sizes of the filtered samples (200 ml × 3 replicates) were measured at room temperature (25 °C), with a Zetasizer Nano ZS (Malvern Instruments, UK) equipped with a He–Ne laser (l = 633 nm) and a backscatter detector at an angle of 173 u, using a disposable plastic cuvette. The instrument recorded the intensity autocorrelation function, which was transformed into volume functions to obtain information on particle size. The zeta potential (ZP) of the formulations was measured in pH 3, 5, 7, 9 and 11 using 1 M acetic acid and 1 M NaOH, to determine mobility of the particles undergoing electrophoresis. Aqueous suspensions (1 %) of the samples (50 ml) at acidic and alkaline pHs were prepared and filtered using a 0.2-mm filter (Whatman, UK). ZP of the formulation is a measure of the magnitude of electrostatic interactions between charged surfaces at the interface of a particle and the surrounding liquid [30]. A large ZP value (30–50 mV) is indicative of a well-dispersed and stable colloidal solution thus overcoming the tendency to agglomerate.

Thermogravimetric analysis

The samples were prepared by freeze drying for 2–3 days, followed by grinding in a mortar pestle to reduce particle size. Analysis of the test and reference samples was carried out using a TGA/DSC1 thermo gravimetric analyser (Mettler Toledo, Switzerland). The freeze-dried samples and reference materials were analysed in triplicate (3 mg) by heating at 50 °C for 45 min initially to remove residual moisture left in the sample and this was followed by heating to 105 °C in alumina crucibles at a heating rate of 20 °C min−1 in nitrogen (BOC, UK) at a flow rate of 50 mL min−1. The thermal weight loss characteristics were observed as thermograms and quantitative evaluations were carried out on the curves using STARe (9.30) evaluation software as derivative thermograms.

Fourier transform infrared spectroscopy

The FTIR spectra of the freeze-dried samples and reference materials were obtained using a spectrum one FTIR spectrometer (Perkin Elmer Inc., USA) equipped with an attenuated total reflectance sampling device containing a diamond/ZnSe crystal. Spectra were scanned at room temperature in transmission mode between 4000 and 650 cm−1 at a scan speed of 0.20 cm s−1 and 60 accumulations at a resolution of 4 cm−1. Triplicate scans of each sample after repacking were used to obtain an average spectrum, and the background spectrum was scanned under the same instrumental conditions. The spectra were acquired using Spectrum software version 5.01, base line corrected and normalised with zero point at the peak ca 900 cm−1 over the wave number range of 4000–650 cm−1.

Pyrolysis gas chromatography and mass spectrometry

Py-GC/MS was carried out using a CDS 5200 series pyrolyser linked to an Agilent Technologies 5975 GC/MS system. The freeze-dried samples (0.3 mg) were pyrolysed at 600 °C at a ramp rate of 20 °C ms−1 for 20 s. The GC/MS was operated with a split ratio of 150:1. The pyrolysis products were separated on an Agilent Technologies HP5-MS (60 m × 0.25 mm × 0.25 μm) capillary column. The column was initially held at 40 °C for 2 min and then ramped at 5 °C min−1 to 300 °C and held at this temperature for 5 min with a constant flow rate of 1.8 ml min−1. The MS was operated in the full scan mode scanning the mass range of 30–700 amu. Compound identifications were obtained using the Wiley library with some assignments drawn from the scientific literature.

Plant growth regulator bioassay

The test solutions of each biostimulant formulation were prepared by diluting them in deionised water by weight of product (0.0, 0.1, 1.0, 5.0 and 10.0 g/l). A water control was used for comparison because it gave a background level of adventitious root formation in the absence of external auxin-like stimuli. Positive auxin controls would only be necessary to check the response of mung bean tissues in experiments where none of the treatments stimulated root production. In this assay, 5 and 10 µM IBA stimulated increased rooting above the water controls of 2 and 15 roots per cutting, respectively. The auxin-like activities in the commercial preparations were determined by measuring root formation and root length in mung bean stem cuttings [14]. Auxin-like activities in the commercial preparations were determined by assessing root initiation and growth in mung bean hypocotyl cuttings. Mung bean seeds were imbibed for 5 h in deionised water and then sown in moist vermiculite in plastic boxes with loose-fitting lids to allow ventilation. The germinating seeds were incubated at 20 °C in a growth room with a 16-h photoperiod supplied by cool white fluorescent lamps giving a light intensity of 100 μ mol m−2 s−1 at bench height. For the first 5 d, the germinating seeds were shaded with three layers of tissue paper, to reduce the light intensity to one tenth and encourage hypocotyl elongation. The seedlings were ready for use after a further day with the shading removed. Cuttings were prepared by cutting the hypocotyl 4 cm below the point of cotyledon attachment. Each treatment was replicated four times, and an experimental unit consisted of four small vials each containing four hypocotyl cuttings and 8 ml of test solution. The cuttings were incubated under the same conditions as used for germinating the seeds, and the vials were topped up with deionised water every 2 d. After 8 d, counts were made of adventitious root production, and the lengths of the longest root in each vial was measured.

Cytokinin-like activities of the formulations were assayed using detached wheat leaf senescence test [31] as modified by Wilcox et al. [32]. and as described below. Wheat seed of the variety “JB Diego” was imbibed in water for 6 h, and then grown at 23 °C for 8 d in moist vermiculite, under a 16-h photoperiod, supplied by cool white fluorescent lamps, producing 100 μ mol m−2 s−1 at bench height. Leaves were trimmed to 6 cm from the tip and any parts of the next leaf discarded. An experimental unit consisted of three trimmed, pre-weighed leaves floated on 20 ml of test solutions in a 9 cm Petri dish. Dishes were incubated in darkness at 25 °C, and water, 10 μM and 30 μM kinetin controls were established for comparison. After 4 d the leaves were rinsed in water, blotted dry, cut into short lengths and pigments extracted in 5 ml of N, N-dimethylformamide in the dark for 2 d at ambient temperature. Absorbance of the resulting extract was measured at 480, 664 and 647 nm against a solvent blank, and chlorophyll and total carotenoid concentrations were calculated using the equations of Porra et al. [33] and Wellburn [34], respectively, as quoted by Minocha et al. [35].

Statistical analysis

Results of particle size, ZP and chemical parameters were averaged and standard deviations of the means calculated. The continuous TGA weight loss values of the test formulations were evaluated by principal component analysis (PCA) using The Unscrambler (Camo Norway) multivariate statistical software package to examine distinguishing features of the products. The results from the mung bean and wheat leaf bioassay experiments were analysed as factorial experiments (ANOVA) and comparisons of root numbers and length, total chlorophyll content and carotenoids were presented as the measure of least significance difference at 5 % level.

Results and discussion

Product formulation

There are numerous reports in the literature of biostimulants increasing crop yields, improving growth, enhancing plant resistance to frost and protecting against pathogens [4, 5] but very few studies reported on the formulations used and bioactivities of plant growth hormones [26]. It is significant that six formulations are highlighted in this report to show the range of components used for different crop sectors and field applications. Humic substances were the major components of Rygex with additional algal extracts of A. nodosum, Fucus spp. and Laminaria spp. and amino acids as minor additives for use in the horticulture sector (Table 1). The major component of Algavyt was algal extracts of the three species listed above with A. sativum extract as a minor component for protecting fruit trees and vegetable crops from abiotic stress. Ryzoset was formulated to enhance root growth of crop plants, and major components were plant extracts of A. sativus, Q. Saponaria and S. mukorossi for treatment of cereal, field vegetables, flower and fruit trees (Table 1). In contrast, Manek was formulated using a mixture of organic fatty acids and alkaloids from processed vegetable oils as major components and plant extract as a minor component. The oily product was optimised for use in fertigation treatment of fruit trees to stimulate plant growth by promoting plant growth promoting rhizobacteria in the soil rhizosphere [36]. The major constituents of Ecoryg were amino acids, peptides and proteins extracted from plants along with mineral additive as a minor component, and the formulation is non-oily and optimised for foliar application. An additional formulation was Algavyt fortified with Zn/Mn (5 %) for control of biotic stress of field crops (Table 1). Some of the raw materials, such as macroalgae, animal tissue, shrimp carcasses and bark from woody plants used in the production of biostimulants would have been from marine or farm waste materials. However, transformation of the raw materials by microbial treatment and/or green extraction protocols reduces or completely eliminates the need for disposing large volumes of wastes, allowing sustainable recycling of biomaterials to reduce carbon foot print of food production [37]. The biostimulants sector needs better products for enhancing crop productivity [3, 26].

Chemical composition

The compositions of the six formulations are summarised in Table 2, and analyses were carried out using specific sample preparation protocols. The dry matter (DM) content of the formulations ranged between 20.1 % for Ryzoset and 62.2 % for Manek, and in contrast, ash contents of the formulations were between 1.5 % (Rygex) and 15.4 % (Algavyt Zn/Mn) (Table 2). The pH, EC and total N ranges of the products were from 3.1 (Ryzoset) to 11.1 (Algavit), 0.4 (Manek) to 19.8 dS/m (Ecoryg) and 0.2 (Manek) to 9.1 % (Algavyt), respectively. Lipid content for Manek was the highest at 56.1 % compared with the other five formulations at less than 0.1 %. As expected, C:N ratio for Manek was the highest (196.5) and the lowest (2.2) for Algavyt. The carbohydrate contents of the formulations ranged between 1.2 (Manek) and 35.35 (Algavyt, Table 2). Densities (g/l) of the six products were 1170 (Rygex), 1220 (Algavyt), 1050 (Ryzoset), 1012 (Manek), 1270 (Ecoryg) and 1410 (Algavyt Zn/Mn) indicating that Algavyt Zn/Mn was more dense than the rest (Table 3). Variations in the macro and micronutrients are listed in Table 3, showing a relationship between high ash contents of the formulations (Table 2) and high concentrations of Na, K, Zn, Cu, Fe and Mn. The concentrations of S, Zn and Mn were the highest in Algavyt Zn/Mn, and Algavyt contained high concentrations of Na and K (Table 3). Nelson et al. (2014) have demonstrated in laboratory bioassays that Algavyt Zn/Mn is highly inhibitory to Fusarium sp. which causes foot rot of stock flowers.

Dynamic light scattering

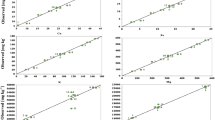

The particle size distribution of the six formulations was measured by estimating hydrodynamic size distribution with the aid of photon correlation spectroscopy and the results are presented as Z average particle size [38]. Rygex, Algavyt, Manek and Ecoryg showed a lower average particle size (244–374 nm) compared to significantly (P < 0.01) larger particle sizes of Ryzoset (1458 nm) and Algavyt Zn/Mn (2824 nm). ZP values of the six formulations were also measured, and Manek gave ZP values of −0.02, −0.61 and +1.35 mV at pH 3, 4 and 7, respectively. However, at pH 9 and 11, the ZP values of Manek were reduced to −35.06 and −37.86 mV, respectively, indicating the presence of acidic sites which can be dissociated in the alkaline pH (Fig. 1). The ZP values of Algavyt were at −20.7, −29.77 and −27.7 mV at pH 3, 5 and 7, respectively and further reduced to −31.66 and −41.73 mV at pH 9 and 11, respectively. Since ZP is a function of the surface charge, a property that all materials possess, or acquire, when suspended in a fluid, the magnitude of ZP affects the process and quality control and is determined using the Helmholtz–Smoluchowski equation [39]. The changes in ZP values of the other four formulations were less than −27.5 mV at the pH 3–11 range (Fig. 1), indicating lower stability of the suspended particles [30]. The differences in the ZP values of products are likely to be influenced by the treatment conditions employed during processing to reduce particle size, additives and the interactions of cations and anions in the water phase. An understanding of the complex interplay of factors, including particle size, concentration, contact angle, surface tension, optimal ratios and compatibility of the components, is necessary to improve effectiveness of the formulations [40]. Currently, the products may be formulated by the manufacturers without considering the requirements of a specific treatment application. If the final concentration of active ingredients in a formulation is not optimal during foliar application to crop plants due to high or low surface tension, the bioactive fraction(s) in the product may not be able to modulate the plant by up regulating metabolites (e.g. salicylic acid) needed to overcome biotic and abiotic stresses. ZP characteristics of the formulations can be optimised for imparting sufficient electrostatic repulsion to maintain stability during transportation and storage. Among the six formulations, Algavyt and Manek are likely to retain product stability as a result of low Z average particle size and moderate ZP [30]. Particle size and ZP can guide processing of ingredients, formulation development and quality control protocols.

Thermogravimetric analysis

Thermal degradation of the formulations was detected over a wide range with several weight loss steps evident on derivative thermograms. A weight loss of (0.3–7.9 %) was observed between 50 and 160 °C which could be attributed to low molecular compounds including sugars and acetic acids [13, 41]. In the active decomposition band of 160–600 °C, pyrolysis (46.6–90.7 %) of alginates, laminarin, polysaccharides, fatty acids, amino acids and humic fractions occurred, [12, 13, 42, 43] followed by char formation in the pyrolysis temperature band of 600–1050 °C leaving a mineral- and carbon-rich residue in the crucible (Figs. 2, 3). Humic fractions have been reported to undergo a slow decomposition showing two distinct peaks at 299 and 470 °C [42]. Evaluation of reference materials showed that decomposition of alginates (150–400 °C), amino acids (200–400 °C) and humic acid (200–600 °C) overlapped at nearly 225, 300 and 470 °C, respectively. The information from reference materials allowed interpretation of the compositional differences between the six formulations. Thermal weight loss pattern indicated that decomposition of the six formulations was a three-step process but showed distinct differences in the decomposition bands and peak temperatures providing possible parameters for identifying the formulations from only the TGA data. Among the six formulations, Manek exhibited a 90.7 % weight loss in the active decomposition band confirming high (36.2 %) lipid content (Table 2). Unlike the other formulations, this product showed little weight loss below 300 °C indicating the more thermally stable nature of glucosinolates and other components (Table 1) and lack of plant extracts/polysaccharides.

High-temperature weight losses at >650 °C in Rygex, Ryzoset, Algavyt, Algavyt Zn/Mn and Ecoryg were mainly due to decomposition of calcium and potassium carbonates [44]. However, no significant high-temperature weight loss was observed for Manek (Fig. 3). Rygex, Ryzoset and Algavyt Zn/Mn showed high proportions of residue in the crucible (14.65, 23.22 and 12.60 %, respectively) compared to Algavyt, Manek and Ecoryg (6.83, 3.43 and 5.14 %, respectively, indicating fusing of minerals and carbon fractions at 1050 °C. PCA of continuous weight loss data indicated that 83 % of variations in the six formulations could be described by the first two principal components (Additional file 1: Figure S1). Manek occupied one quadrant on its own which is not unexpected given its compositional differences from the other biostimulants, whilst Ecoryg and Rygex formed a separate group in the opposite quadrant. The other formulations (Algavyt, Algavyt Zn/Mn and Ryzoset) were grouped in a third quadrant showing similar thermal decomposition steps. Formulations containing a high proportion of an ingredient(s) could dominate the thermal decomposition profiles, such as fatty acids in Manek, humic acids, algal extracts, plant peptides and amino acids in Rygex and Ecoryg, and amino acids, plant and algal extracts in Algavyt, Algavyt Zn/Mn and Ryzoset (Table 1; Figs. 2, 3). Currently, TG analysis can provide a qualitative data on the composition of a formulation with the aid of reference thermograms of active fractions. However, with additional calibration tests and integration of TGA with GC/MS, the technique has the potential to provide quantitative information on formulations.

Fourier transform infrared spectroscopy

The FTIR spectra of the six formulations are shown in Figs. 4 and 5. The identification of the absorption bands was based on reference samples and published reports of materials used in the formulations [45–47]. Most important features are (a) bands at 3600–3000 cm−1 assigned to OH stretching of OH groups; (b) peaks at 2960–2854 cm−1 due to aliphatic C–H stretching; (c) peak at 2207 cm−1 attributed to C≡N stretching; (d) strong peaks at 1731–1741 cm−1 assigned to C=O stretching of COOH groups; (e) band at 1656–1630 cm−1 due to C=O stretching of COO groups; (f) band/peak at 1620–1560 cm−1 caused by aromatic C=C stretching; (g) peak at ~1590–1560 cm−1 assigned to C=O stretching of COOH; (h) peak at 1470–1440 cm−1 associated with C=C stretching within the ring; (i) 1400–1375 cm−1 attributed to various groups including OH deformation, C–O stretching of phenolic OH, C–H deformation of CH2 and CH3 groups and COO− antisymmetric stretching; (j) 1280–1200 cm−1 linked to C–O stretching and OH deformation of COOH; (k) 1170–900 cm−1 associated with C–O stretching of polysaccharides; and (l) 900–650 cm−1 assigned to C–O, C–O–C and S=O stretching. The infrared absorption bands of Rygex, Algavyt, Ryzoset, Manek, Ecoryg and Algavyt Zn/Mn showed distinct characteristics at ~2936, 2921, 2854, 2207, 1741, 1731, 1630, 1591, 1562, 1582, 1464, 1397, 1375, 1247, 1103, 1077, 1038, 952, 856, 775 and 722 cm−1, displaying composite characteristics of major and minor components (Table 1; Figs. 4, 5). The prominent bands at 3252 with shoulders at 3064 and 2960, 1600, 1543, 1450, 1397, 1109, and 1034 cm−1 represent functional groups of humic acids [47] which are a major component of Rygex (Fig. 4). Major bands at 3345, 2207, 1593, 1448, 1396 and 1158 cm−1 for Algavyt are distinctly different from the spectra of Algavyt Mn/Zn indicating significant compositional differences, such as nitrile (at 2207 cm−1) missing in the latter formulation (Figs. 4, 5). This result is also supported by Py-GC/MS data (Figs. 6, 7). The Ryzoset peaks at 3373, 2926, 1731, 1591, 1375, and 1038 cm−1 are linked to functional groups of saponins (amino groups), aromatic and polysaccharides. The combination of spectral bands at 3386, 2921, 2854, 1741, 1562, 1464, 1102, 952, 856 and 722 cm−1 represent functional groups of fatty acids and polysaccharides, are unique to Manek and can be used to distinguish this product from the other formulations (Fig. 5). The FTIR spectra of Ecoryg are dominated by bands at 3355, 1582, 1397, 1077, 980, 934, 898 and 719 cm−1 representing functional groups of plant peptides used in the formulation (Fig. 5). Each of the six formulations can be identified by their unique combination of absorption peaks/bands to identify major components of the formulation [48].

Pyrolysis gas chromatography and mass spectrometry

The pyrograms, and where relevant, identification of the peaks within them, may be used to differentiate between the formulations and provide information on their compositions. The major peaks found in Rygex occur in two regions of the pyrogram, the majority containing nitrogen consistent with the high nitrogen content of the sample. At less than 10 min, peaks correspond to carbon dioxide at retention times of 2.53 min, pyrrole 6.15 min., toluene 7.74 min and ethyl pyrrole, 7.74 min. In the region of 30–45 min, the peaks found were 2,5-diketopiperazines (DKPs) which are cyclic dipeptides, products obtained from thermal treatments of amino acids and proteins [49]. Major peaks included two isomers of cyclo(Pro-Ala) at retention times of 32.20 and 33.76 min; cyclo(Pro-Gly), 34.34 min; cyclo(Pro–Pro), 37.95 min; and two isomers of cyclo(Pro-Hyp), 41.65 and 42.58 min identified by their elution profiles from the analytical column and their mass spectra as reported in Fabbri et al. [50]. Extraction of ion current m/z 70 which can be attributed to the pyrrolidinium ion indicated the presence of minor amounts of other Pro-derived DKPs. Another component of the sample is seaweed extract from A. nodosum, Fucus spp. and Laminaria spp., and the four main carbohydrates in these species alginic acid, fucoidan, laminarin and mannitol produce characteristic pyrolysis products which can be used to predict their presence [12, 43, 51]. No evidence was found for the presence of seaweed extract in this sample, with the exception of diannhydromannitol indicating the presence of mannitol, possibly due to seaweed extract being a minor component of the formulation. The peaks of the highest abundance produced upon pyrolysis of Algavyt are the early-eluting compounds CO2 and acetaldehyde. The mass spectra of the broad peak centred at 20 min and other minor peaks identified as nitrogen-containing compounds are consistent with the high N content of the sample, 9.1 % p/p (Table 2). The broad peak was identified as urea which is present in manufacturer’s description of the formulation. The peak at 20.43 min dianhydromannitol is indicative of mannitol present as either free mannitol or laminarin [43]. Other pyrolysis products characteristic of polysaccharides were present but in low abundance. There is little diagnostic information to be obtained from the pyrogram of Algavit Zn/Mn. CO2 is again the pyrolysis product of the highest abundance. However, there is no evidence of urea, despite the relatively high nitrogen content, and only traces of diannhydromannitol in the formulation. There are present minor amounts of pyrrole and other nitrogen heterocyclic compounds. For Ryzoset, the presence of several furan derivatives, such as 2methylfuran, 2,5-dimethylfuran, furfural, Ethanone 1-[2-furanyl] and 5-methyl-2-Furancarboxaldehyde, are good indicators for the pyrolysis of polysaccharides suggesting that polysaccharides are major components of the sample. The major peaks arising from pyrolysis of Manek are late eluters with retention time of >35 min. The identity and high abundance of the volatiles produced are consistent with the pyrolysis of a product obtained from vegetable oil with a high fatty acid content. The mass spectra of these compounds are generally nonspecific due to the fragmentation of long hydrocarbon chains present in the compounds. The high abundance of these peaks can also be expected as this sample has the highest carbon content among those examined. Trimethylamine, acetaldehyde, indole and a series of substituted pyroles and other nitrogen heterocyclics comprise the majority of the peaks found in Ecoryg. The presence of numerous nitrogen-containing products is consistent with the manufacturers’ description of the product as being a mixture of amino acids peptides and proteins.

Biological activities of the detected compounds

A list of functional groups and pyrolysis products detected by FTIR and Py-GC/MS are summarised in Table 4 to show complementary results from the two analytical techniques with the biological activities of the compounds. The bioactive compounds, including humic and amino acids, peptides, saponins, alginates, mannitol, fatty acids and minerals, are incorporated in the formulations to alleviate abiotic and biotic stresses by modulating the physiology of crop plants. To date, optimal physicochemical profiles for specific products are not known due to lack of detailed study linking gene expression work with target crop response. However, some examples of reported biological activities of the compounds are as follows: humic acids act as chelating agent to enhance nutrient availability in the rhizosphere to permit rapid root growth [15]; saponins stimulate root development and boost soil rhizosphere population [52]; fatty acid increases tolerance to biotic stress [3]; and amino acids improve nitrogen uptake by plants [53, 54].

Plant growth regulator bioassays

Mung bean hypocotyl cuttings were incubated in five (0.0, 0.1, 1.0, 5.0 and 10.0 g/l) concentrations of the six formulations to evaluate the number of roots developed and also length of the longest root (Table 5). The bioassay showed significant (P < 0.001) increase in the number of roots per cutting when they were treated with Rygex and Ecoryg at the three highest test concentrations (Table 5), indicating that these products are rich in auxin-like activity. In contrast, Manek significantly (P < 0.001) stimulated mung bean rooting only at a concentration of 0.1 g/l with higher concentrations of 5 and 10 g/l inhibiting rooting. This suggested that Manek may contain high concentration of auxin-like growth hormones and the higher concentrations used here were supra-optimal or more likely that Manek contains other substances that are inhibitory to adventitious root initiation. It is well known that other growth regulators such as cytokinins and gibberellins can antagonise auxin-like activities and the process of root induction in particular [55, 56]. The other three products did not stimulate rooting of mung bean hypocotyl cuttings, and Ryzoset and Algavyt Zn/Mn were inhibitory to root at the three highest concentrations tested. A comparison of the lengths of the longest roots formed, indicated that Rygex significantly (P < 0.001) stimulated root growth at 1. 5 and 10 g/l and Ecoryg stimulated root growth at 1 and 5 g/l, whereas none of the other four biostimulant formulations promoted root growth (Table 5).

The bioassay of cytokinin-like activities in the six formulations at five test concentrations (0, 0.1, 1.0, 5.0 and 10.0 g/l) is presented in Table 6. Manek significantly (P < 0.001) stimulated chlorophyll a, chlorophyll b and total chlorophyll retention in wheat leaves compared to the other products at 5.0 and 10.0 g/l. However, compared to the kinetin controls, the formulation showed much lower cytokinin activities (Table 6). Ecoryg was the only other product toAQ show any cytokinin-like activity of very low level when supplied at 10 g/l (Table 5). Ecoryg caused a small but significant (P < 0.001) retention of chlorophyll a compared to the water control. Similarly, Algavyt and Ecoryg exhibited significantly (P < 0.001) higher total carotenoids contents in the wheat leaves than the water control when supplied at 10 g/l. Again, these effects were very small compared to the kinetin controls. Among the six formulations, only Ecoryg and Rygex showed significant auxin-like activities, and the two formulations may be suitable for minimising the impact of abiotic stress in crop plants as foliar and fertigation treatments, respectively [57].

A similar study employed mung bean root extension and soya bean callus bioassays to compare auxin- and cytokinin-like activities of six commercially used macroalgae products [14]. We also found the mung bean bioassay a useful method in evaluating the potencies of various formulations. It clearly indicated products with cytokinin-like activities and probably also indicated products with the potential to inhibit growth and developments. Although further work would be needed to explore this, the wheat leaf senescence test is a very reliable for assessing the cytokinin activities of pure compounds but might be less reliable when used with complex mixtures such as biostimulants. Nevertheless, this test indicates that some of the products tested have detectable cytokinin-like activities.

Conclusions

The results presented show significant differences in the compositions such as total N, lipid, carbohydrate and minerals, and bioactivities of six formulations of diverse origin and also highlight the complexity of research utilising a range of mixes of poorly defined constituents. A mixture of major and minor constituents can stimulate complex biological activities at low concentrations which can be difficult to explain.

Recommended application rates for Rygex and Algavet listed in Table 1 would, given the nitrogen concentrations found in these products (Table 2), supply the equivalents of 1.25 kg N/ha and 11.37 g N/ha, respectively. These rates are considerably lower than the recommended fertilisation rates for most crops and would be expected to have a minimal effect on crop growth. Therefore, the increased vigour in response to biostimulant treatment of crops is due to the bioactive compounds present in the formulations rather than fertilisation. The maximum efficiency of biostimulants occurs at low dosage of treatments and is dependent on plant species, cultivars and growth phase of the crop plant [58, 59].

DLS indicated size of particles and magnitude of ZP showing potential stability of the formulations. TGA can provide information on the proportion of algal or plant polysaccharides, organic and inorganic fractions used in the formulations. The identity of the major polysaccharide and bioactive fractions can be confirmed by FTIR and Py-GC/MS. Both techniques are promising methods to identify major components in product formulations.

The three techniques (TGA, FTIR and Py-GC/MS) require no sample preparation beyond drying of the materials. The activities of the plant growth hormones have been compared to show advantages of the growth hormone-like bioassay methods for selecting better formulations.

References

EBIC. Promoting the biostimulant industry and the role of plant biostimulants in making agriculture more sustainable. 2014. http://www.biostimulants.eu.

Anon. Biostimulants market—by active ingredients, applications, crop types and geography—global trends and forecasts to 2018. Markets and markets. 2013. http://www.marketsandmarkets.com/Market-Reports/biostimulantmarket.

Calvo P, Nelson L, Kloepper JW. Agricultural uses of plant biostimulants. Plant Soil. 2014;383:3–41. doi:10.1007/s11104-014-2131-8.

Sharma HSS, Fleming C, Selby C, Rao JR, Martin T. Plant biostimulants: a review on the processing of macroalgae and use of extracts for crop management to reduce abiotic and biotic stresses. J Appl Phycol. 2014;26:465–90.

Saa S, Olivos-Del Rio A, Castro S, Brown PH. Foliar application of microbial and plant based biostimulants increases growth and potassium uptake in almond (Prunus dulcis [Mill.] D.A.Webb). Front Plant Sci. 2015;6:1–9.

Ertani A, Cavani L, Pizzeghello D, Brandellero E, Altissimo A, Ciavatta C, Nardi S. Biostimulant activity of two protein hydrolyzates in the growth and nitrogen metabolism of maize seedlings. J Plant Nutr Soil Sci. 2009;172:237–44.

Trevisan S, Francioso O, Quaggiotti S, Nardi S. Humic substances biological activity at the plant-soil interface: from environmental aspects to molecular factors. Plant Signal Behav. 2010;5:635–43.

Nardi S, Muscolo A, Vaccaro S, Baiano S, Spaccini R, Piccolo A. Relationship between molecular characteristics of soil humic fractions and glycolytic pathway and Krebs cycle in maize seedlings. Soil Biol Biochem. 2007;39:3138–46.

Canellas LP, Olivares FL, Okorokova-Facanha AL, Facanha AR. Humic acids isolated from earthworm compost enhance root elongation, lateral root emergence, and plasma membrane H+ -ATPase activity in maize roots. Plant Physiol. 2002;130:1951–7.

Eyheraguibel B, Silvestre J, Morard P. Effects of humic substances derived from organic waste enhancement on the growth and mineral nutrition of maize. Bioresour Technol. 2008;99:4206–12.

Delfine S, Tognetti R, Desiderio E, Alvino A. Effect of foliar application of N and humic acids on growth and yield of durum wheat. Agron Sustain Dev. 2005;25:183–91.

Sharma HSS, Lyons G, McRoberts C, McCall D, Carmichael E, Andrews F, McCormack R. Brown seaweed species from Strangford Lough: compositional analyses of seaweed species and biostimulant formulations by rapid instrumental methods. J Appl Phycol. 2012;24:1141–57.

Sharma HSS, Lyons G, McRoberts C, McCall D, Carmichael E, Andrews F, Swan R. Biostimulant activity of brown seaweed species from Strangford Lough: compositional analyses of polysaccharides and bioassay of extracts using mung bean (Vigno mungo L.) and pak choi (Brassica rapa chinensis L.). J Appl Phycol. 2012;24:1081–91.

Stirk WA, van Staden J. Comparison of cytokinin and auxin like activity in some commercially used seaweed extracts. J Appl Phycol. 1996;8:503–8.

Mladenova YI, Maini P, Mallegni C, Goltsev V, Vladova R, Vinarova K, Rotcheva S. Siapton - An amino-acid-based biostimulant reducing osmostress metabolic changes in maize. Agron Food Ind Hi-Tech. 1998;9:18–22.

Kauffman GL, Kneivel DP, Watschke TL. Growth regulator activity of Macro-Sorb Foliar in vitro. Plant Growth Regul Soc Am Quarterly. 2005;33:134–41.

Chen SK, Edwards CA, Subler S. The influence of two agricultural biostimulants on nitrogen transformations, microbial activity, and plant growth in soil microcosms. Soil Biol Biochem. 2003;35:9–19.

Cavani L, Halle AT, Richard C, Ciavatta C. Photosensitizing properties of protein hydrolysate-based fertilisers. J Agric Food Chem. 2006;54:9160–7.

Ertani A, Pizzeghello D, Altissimo A, Nardi S. Use of meat hydrolyzate derived from tanning residues as plant biostimulant for hydroponically grown maize. J Plant Nutr Soil Sci. 2013;176:287–95.

Atkinson NJ, Lilley CJ, Urwin PE. Identification of genes involved in the responses of Arabidopsis to simultaneous biotic and abiotic stresses. Plant Physiol. 2013;162:2028–41.

Jannin L, Arkoun M, Etienne P, Laine P, Goux D, Garnica M, Fuentes M, San Francisco S, Baigorri R, Cruz F, Houdusse F, Garcia-Mina J-M, Yvin J-C, Ourry A. Brassica napus growth is promoted by Ascophyllum nodosum (L.) le Jol. Seaweed extract: microarray analysis and physiological characterisation of N, C and S metabolisms. J Plant Growth Regul. 2013;32:31–52.

Kissoudis C, van de Wiel C, Visser RGF, van der Linden G. Enhancing crop resilience to combined abiotic and biotic stress through the dissection of physiological and molecular crosstalk. Front Plant Sci. 2014;5:207.

Minocha R, Martinez G, Lyons B, Long S. Development of a standardized methodology for quantifying total chlorophyll and carotenoids from foliage of hardwood and conifer tree species. Can J For Res. 2009;39:849–61.

Sabir A, Yazar K, Sabir F, Kara Z, Yazici MA, Goksu N. Vine growth, yield, berry quality attributes and leaf nutrient content of grapevines as influenced by seaweed extract (Ascophyllum nodosum) and nanosize fertilizer pulverizations. Sci Hortic. 2014;175:1–8.

O’Donnell RW. The auxin-like effect of humic preparations from leonardite. Soil Sci. 1973;116:106–12.

Colla G, Rouphae Y, Canaguier R, Svecova E, Cardarelli M. Biostimulant action of a plant derived protein hydrolysate produced through enzymatic hydrolysis. Front Plant Sci. 2014;5:1–6.

Yeomans JC, Bremner JM. Carbon and nitrogen analysis of soils by automated combustion techniques. Commun Soil Sci Plant Anal. 1991;22:843–50.

Anon P. Standardised and recommended methods of analysis. London: The Society of Analytical Chemistry; 1973.

Dahlquist RL, Knoll JW. Inductively coupled plasma-atomic emission spectrometry: analysis of biological materials and soils for major trace, and ultra-trace elements. Appl Spectrosc. 1978;32:1–30.

Lyklema J. Fundamentals of interface and colloid science, vol. 1. London: Academic Press; 2000.

Rothwell K, Wright STC. Phytokinin activity in some new 6-substituted purines. Proc R Soc B. 1967;167:202–23.

Wilcox EJ, Selby C, Wain RL. The cytokinin activities of 6-α-alkylbenzyloxypurines. Annal Appl Biol. 1981;97:221–6.

Porra RJ, Thompson WA, Kriedemann PE. Determination of accurate extinction coefficients and simultaneous equations for assaying chlorophylls a and b extracted with four different solvents: verification of the concentration of chlorophyll standards by atomic absorption spectroscopy. Biochimica et Biophysics Acta. 1989;975:384–94.

Wellburn AR. The spectral determination of chlorophyll a and b, as well as total carotenoids, using various solvents with spectrophotometers of different resolution. J Plant Physiol. 1994;144:307–13.

Minocha R, Majumdar R, Minocha SC. Polyamines and abiotic stress in plants: a complex relationship. Front Plant Sci. 2014;5:175.

Dodd IC, Perez-Alfocea F. Microbial amelioration of crop salinity stress. J Exp Bot. 2012;63:3415–28.

Hillier J, Hawes C, Squire G, Hilton A, Wale S, Smith P. The carbon footprints of food crop production. Int J Agri Sustain. 2009;7:107–18.

Berne BJ, Pecora R. Dynamic Light Scattering. New York: Wiley; 1976.

Ries HE. Microelectrophoresis measurements on polymeric flocculants alone and in excess with model colloids. Nature. 1970;226(5240):72–3.

Grobler A.F. Composition in the form of a microemulsion containing free fatty acids and/or free fatty acid derivatives. Patent WO2007096833A2. 2007.

Melligan F, Dussan K, Auccaise R, Novotny EH, Leahy JJ, Hayes MHB, Kwapinski W. Characterisation of the products from pyrolysis of residues after acid hydrolysis of Miscanthus. Bioresour Technol. 2012;108:258–63.

Francioso O, Montecchio D, Gioacchini P, Ciavatta C. Thermal analysis (TG-DTA) and isotopic characterisation (13C-15N) of humic acids from different origins. Appl Geochem. 2005;20:537–44.

Anastasakis K, Ross AB, Jones JM. Pyrolysis behaviour of main carbohydrates of brown macro-algae. Fuel. 2011;90:598–607.

Mishra MK, Ragland KW, Baker AJ. Wood ash composition as a function of furnace temperature. Biomass Bioenerg. 1993;4:103–16.

Matsuhiro B. Vibrational spectroscopy of seaweed galactans. Hydrobiologia. 1996;327:481–9.

Kačuráková M, Wilson RH. Developments in mid-infrared FT-IR spectroscopy of selected carbohydrates. Carbohydr Polym. 2001;44:291–303.

Giovanela M, Parlanti E, Soriano-Sierra EJ, Soldi MS, Sierra MMD. Elemental compositions, FT-IR spectra and thermal behavior of sedimentary fulvic and humic acids from aquatic and terrestrial environments. Geochem J. 2004;38:255–64.

Pereira L, Amado AM, Critchley AT, van de Velde F, Ribeiro-Claro PJA. Identification of selected seaweed polysaccharides (phycocolloids) by vibrational spectroscopy (FTIR-ATR and FT-Raman). Food Hydrocolloid. 2009;23:1903–9.

Kruse J, Eckhardt KU, Regier T, Leinweber P. TG-FTIR, LC/MS, Xanes and Py-FIMS to disclose the thermal decomposition pathways and aromatic N formation during dipeptide pyrolysis in a soil matrix. J Anal Appl Pyrol. 2011;90:164–73.

Fabbri D, Adamiano A, Falini G, De Marco R, Mancini I. Analytical pyrolysis of dipeptides containing proline and amino acids with polar side chains. Novel 2,5-diketopiperazine markers in the pyrolysates of proteins. J Anal Appl Pyrol. 2012;95:145–55.

Ross AB, Anastasakis K, Kubacki M, Jones JM. Investigation of the pyrolysis behaviour of brown algae before and after pre-treatment using PY-GC/MS and TGA. J Anal Appl Pyrol. 2009;85:3–10.

Sparg SG, Light ME, van Staden J. Biological activities and distribution of plant saponins. J Ethnopharmacol. 2004;94:219–43.

Fan XR, Gordon-Weeks R, Shen QR, Miller AJ. Glutamine transport and feedback regulation of nitrate reductase activity in barley roots leads to changes in cytosolic nitrate pools. J Exp Bot. 2006;57:1333–40.

Miller AJ, Fan XR, Shen QR, Smith SJ. Amino acids and nitrate as signals for the regulation of nitrogen acquisition. J Exp Bot. 2008;59:111–9.

Selby C, Kennedy SJ, Harvey BMR. Adventitious root formation in Picea sitchensis hypocotyl cuttings - the influence of plant growth regulators. New Phytol. 1992;120:453–7.

Coenen C, Lomax TL. Auxin - cytokinin interactions in higher plants: old problems and new tools. Trends Plant Sci. 1997;2:351–6.

Zhang XZ, Ervin EH. Cytokinin-containing seaweed and humic acid extracts associated with creeping bentgrass leaf cytokinin and drought resistance. Crop Sci. 2004;44:1737–45.

Verlinden G, Pycke B, Mertens J, Debersaques F, Verheyen K, Baert G, Bries J, Haesaert G. Application of humic substances results in consistent increases in crop yield and nutrient uptake. J Plant Nutr. 2009;32:1407–26.

Vernieri P, Borghesi E, Ferrante A, Magnani G. Application of biostimulants in floating systems for improving rocket quality. J Food Agric Environ. 2005;3:86–8.

Ashmead HD, Ashmead HH, Miller GW, Hsu HH. Foliar feeding of plants with amino acids chelates. Park Ridge: Noyes publications; 1986.

Ludwig-Muller J, Cohen JD. Identification and quantification of three active auxins in different tissues of Tropaeolum majus. Plant Physiol. 2002;115:320–9.

Killeen GF, Madigan CA, Connolly CR, Walsh GA, Clark C, Hynes MJ, Timmins BF, James P, Headon DR, Power RF. Antimicrobial saponins of Yucca schidigera and the implications of their in vitro properties for their in vivo impact. J Agric Food Chem. 1998;46:3178–86.

Abebe T, Guenzi AC, Martin B, Cushman JC. Tolerance of mannitol-accumulating transgenic wheat to water stress and salinity. Plant Physiol. 2003;131:1748–55.

Nelson D, Beattie K, McCollum G, Martin T, Sharma HSS, Rao JR. Performance of natural antagonists and commercial microbiocides towards in vitro suppression of flower bed soil-borne Fusarium oxysporum. Adv Microbiol. 2014;4:151–9.

Authors’ contributions

HSSS coordinated the work programme; CS carried out the bioassay for biostimulant products; EC evaluated the products using FTIR, DLS and TGA; CM analysed the products by Py-GC/MS; JRR and TM organised the data and organised background literature; PA coordinated the selection of products and MC and MP analysed the products in Italy. All authors read and approved the final manuscript.

Acknowledgements

This research paper has received funding from the European Community’s Seventh Framework Programme (FP7/2007- 2013) under Grant Agreement No. 312117 (BIOFECTOR).

Competing interests

The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Additional file

40538_2016_64_MOESM1_ESM.docx

Additional file 1: Figure S1. Principal component analysis (PCA) score plot of TGA weight loss data showing three distinct clusters—(a) Manek, (b) Ecoryg and Rygex and (c) Rizoset, Algavyt and Algavyt Zn/Mn and two PCAs explained 83% of the variations between the 6 products.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Sharma, H.S.S., Selby, C., Carmichael, E. et al. Physicochemical analyses of plant biostimulant formulations and characterisation of commercial products by instrumental techniques. Chem. Biol. Technol. Agric. 3, 13 (2016). https://doi.org/10.1186/s40538-016-0064-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40538-016-0064-6