Abstract

High purity polyunsaturated fatty acids (> 95%) are essential for the synthesis of specialized pro-resolving lipid mediators (SPMs), such as protectins, resolvins, and maresins, which are used for clinical application. To date, high purity (> 95%) eicosapentaenoic acid (EPA; C20:5n3) and docosahexaenoic acid (DHA; C22:6n3) have been produced through various manufacturing steps using fish oil. In this study, we optimized preparative high performance liquid chromatography (HPLC) process to purify high-purity DHA ethyl ester (DHAee; > 98%) from oleaginous microalgae Shizochytrium sp. SH103 containing at least 34% DHA content. The purity and yield of DHA were determined by reverse phase chromatography with changing the mobile phase velocity, loading amount, and mobile phase composition. On a semi-preparative scale, optimal DHA separation in isocratic elution was obtained with a mobile phase velocity of 0.5 mL/min, a loading amount of 10 mg/mL, and mobile phase composition of methanol/water (96:4, v/v), wherein the purity of DHA was 98.5%. This separation was scaled up to a preparative column, resulting in 99.0% DHA fraction with a yield of 79.8%. This result suggests that a large amount of high purity DHA can be produced from microalgae when scaling up a preparative column to an industrial column.

Similar content being viewed by others

Introduction

The intake of polyunsaturated omega-3 fatty acids, including eicosapentaenoic acid (EPA; C20:5 ω-3) and docosahexaenoic acid (DHA; C22:6 ω-3), has been shown to benefit for human health through a variety of clinical studies. It makes several highly beneficial effects on the prevention against hypertriglyceridemia, atherosclerosis, and cardiovascular health [1, 2]. Several reports have suggested that these compounds are also effective against a variety of other diseases such as asthma, Crohn's disease, Parkinson's disease, Alzheimer's disease, rheumatoid arthritis, skin diseases, and metabolic syndrome [3, 4]. In particular, DHA is an essential constituent in the brain and eye development during infancy and has been shown to help improve the learning ability of preschool children through clinical trials [5, 6].

Recently, many studies have been carried out to produce omega-3 fatty acids on an industrial scale as sources of fatty acids replacing fish. Microalgae are the primary producer of marine ecosystems that accumulate polyunsaturated fatty acids (PUFAs) containing EPA and DHA in cells [7, 8]. In particular, Schizochytrium is a potential omega-3 fatty acid producer whose lipid content in dried biomass is higher than 30%. Fish oil usually contains 10% to 20% DHA, while Schizochytrium lipid contains more than 25% DHA [9,10,11]. Unlike fish-derived oils, Schizochytrium lipid contains less PUFAs similar to DHA, which is useful for separating DHA with high purity [12].

Most of the unrefined oils extracted from fish and microalgae contain fatty acids EPA and DHA attached to glycerol. In general, the method of increasing the omega-3 fatty acids content in triglyceride-type lipids extracted from fish and microalgae is very limited, so lipids must be converted to fatty acid ethyl ester (FAEE) form. Since esterified oil contains other impurities as well as target fatty acids, and methods have been proposed to increase the purity of the specific fatty acids by removing impurities. These methods include molecular distillation, low-temperature crystallization, urea adduct formation, simulated moving bed chromatography (SMB) and supercritical fluid chromatography [13]. However, other methods except for chromatography, could not produce omega-3 fatty acids with a purity of 90% or more [14, 15]. Although the urea adduct formation is a cost-effective method, it can produce carcinogenic alkyl carbamates [16]. In addition, molecular distillation requires high temperature under vacuum to remove undesirable impurities, which creates the risk of oxidation, polymerization and production of trans-isomers of omega-3 fatty acids [17]. This indicates that chromatographic method is suitable for obtaining pharmaceutical levels of high purity omega-3 fatty acids. In particular, preparative high performance liquid chromatography (HPLC) has been extensively studied to separate and purify EPA or DHA. Dillon et al. [18] reported that 95% EPA and 99% DHA were obtained from fish oil ethyl ester using HPLC equipped with a column filled with silver thiolate material. Giménez et al. [19] obtained 94.3% of EPA and 81.4% of arachidonic acid by reversed phase chromatography using a column with octadecyl bonded silica stationary phase.

Although many drugs using high-purity EPA are currently being developed, DHA is also a potential candidate for the treatment of various diseases. In addition to DHA, specialized pro-resolved lipid mediators (SPMs) derived from DHA are also promising candidates, which are potent bioactive lipids that relieve inflammation and modulate transient receptor translocation channels [20]. Through a series of bioconversion processes, DHA is converted to mediators such as D-series resolvins (RvD1–RvD6) and protectin D1 [21]. A recent study has shown that D-series mediators, including the intermediate hydroxy DHA (17S/R-HDHA), inhibit the production of inflammatory cytokines and are effective against a variety of diseases including lung injury, peritonitis, and atherosclerosis [22]. Protectin D1, a dihydroxy DHA, has also been shown to reduce oxidative stress-induced apoptosis in retinal pigment epithelial cells, and enhance phagocytosis of macrophages [23].

In this study, we established a process to produce API-grade high purity DHA (> 97.5%) from DHA-rich Schizochytrium sp. SH103 using preparative HPLC equipped with a large-scale column. For this purpose, DHA separation conditions such as mobile phase velocity, sample loading amount, and mobile phase composition were first investigated on a small-scale column, and the purity and impurities of DHA were determined by gas chromatography (GC). Furthermore, repeated production of high purity DHA was carried out using large-scale HPLC to confirm the reproducibility of established separation conditions.

Materials and methods

Reagents and chemicals

All solvents used in this study were analytical reagent grade for GC or HPLC. FAEEs and methyl tricosanoate for GC analysis were purchased from Nu-Check Prep. Inc., USA. Butylhydroxytolune and trimethylpentane were purchased from Sigma-Aldrich (St. Louis, MO, USA).

Microorganism and sample preparation

Microalgae and culture conditions

The microalgae used in this study was Schizochytrium sp. SH103 (KCTC 21861BP) donated by Microbiological research center, Korea research institute of bioscience and biotechnology (KRIBB) [24]. Seed culture was performed as follows; the cells were grown in a basal medium (60 g/L glucose, 10 g/L yeast extract, 9 g/L KH2PO4, 10 g/L sea salt, 2 mg/L tetracycline, vitamin mixture [thiamin 9.5 mg/L, biotin 0.2 mg/L and cyanocobalamin 1.0 mg/L]) for 2 days at 28 ℃ and 125 rpm on a rotary shaker. Batch fermentation for the production of lipids containing DHA was performed using a 5 L jar fermenter. Five hundred milliliter of the seed culture was inoculated into the jar fermenter containing 3 L of the basal medium. The cultivation was carried out for 60 h at 28 ℃ with 200 rpm and 3.5 v/v/min. pH was initially adjusted to 6.0 by adding ammonia solution and 0.5 mL of antifoam agent per hour was added to prevent the foam formation.

Lipid extraction and transesterification

The fermentation broth was centrifuged at 6000g for 15 min at 4 °C to remove the culture supernatant. The recovered cells were washed twice with distilled water and dried for 24 h using a vacuum freeze dryer. The resulting dried cells were extracted with a 20-fold volume of chloroform:methanol (2:1, v/v) for 20 min. The extract was filtered through Whatman No. 1 filter paper to remove cell debris and then separated into two liquid layers by centrifugation (1000g). The lower chloroform layer containing lipids was pooled and concentrated using a rotary evaporator.

The acid-catalyzed transesterification was carried out to convert the extracted lipids to fatty acid ethyl esters (FAEEs). The reaction mixture contained lipid, ethanol and sulfuric acid at a ratio of 1:10:0.4 (w/w), and the reaction was performed at 70 °C for 2 h. After completion of the reaction, the reactants were transferred into a separating funnel and separated into two phases by adding water. The lower layer was discarded and 500 mL of hot water was added to the upper layer (FAEEs layer) [25]. This process was repeated until only a clean upper layer was obtained, and the final solution was dried in a vacuum.

Semi-preparative HPLC system

The small-scale separations were carried out with an Agilent 1100 HPLC system (Agilent, USA) equipped with binary pumps and UV detector. Considering the fact that the fatty acid converted to the ethyl ester form was non-polar, it was separated using a reverse phase chromatography column (C18 column; 250 mm × 4.6 mm × 20 μm; Young Jin Biochrom Co., Korea). To optimize separation conditions on a semi-preparative scale, two small columns were connected by a connector with a dead volume of 20 µL, then the mobile phase velocity, sample loading amount, and mobile phase composition were varied as shown in Figs. 1, 2, 3 and 4. The purity of DHA in each fraction was confirmed by gas chromatography-flame ionization detector (GC-FID) and expressed as an area %.

Preparative HPLC system

The preparative-scale separations were conducted on a preparative HPLC system (Prominence module system, Shimadzu Corporation, Japan) consisting of manual injector, UV–VIS detector, binary pumps, and fraction collector. Chromatographic analysis was carried out using a large-scale C18 column (500 mm × 50 mm × 20 µm). The column temperature was maintained at 40 °C; detection was carried out at 210 nm. Sample was directly injected into the injector using a 10 mL sample loop. Lab solutions software version 5.58 was used for HPLC control and data acquisition.

Analytical methods

Analysis of FAEEs composition

The FAEEs were determined by using GC-FID (6890N, Agilent, USA) equipped with a capillary column HP-5 (30 m × 0.32 mm × 0.25 mm; Agilent, USA). The initial column temperature was 150 ℃ for 2 min. The temperature was then increased to 270 ℃ at a rate of 10 ℃/min and held for 1 min. The injector and detector temperatures were 250 ℃ and 300 ℃, respectively. N2 was used as carrier gas at a split ratio of 50:1. Injection volume was 1 µL. FAEEs were identified by comparison of retention times with standards and quantified by directly taking area % as weight %.

Quantitative determination of DHAee content

To determine the content of DHA in the lipid extracted from Schizochytrium sp. SH103, the analysis was carried out by the method of European Pharmacopoeia 5.0 01/2005: 20,429 using GC-FID (7890N, Agilent, USA) with a capillary column CPWAX (30 m × 0.32 mm × 0.25 mm; Agilent, USA). The column temperature was maintained at 170 °C for 2 min, increased to 240 °C (5 °C/min) and held for 2.3 min. The injector was maintained at 250 °C and detector at 270 °C. The carrier gas was helium at 0.6 mL/min. The sample injection volume was 1 µL, and the injector was operated at a split ratio of 200:1.

Methyl tricosanoate and DHAee were used as internal and external standards, respectively. A reference solution was prepared as follows: 60 mg of DHAee and 70 mg of methyl tricosanoate were accurately weighed into a 10 mL volumetric flask. The standards were dissolved with a 50 mg/L solution of butylhydroxytoluene in trimethylpentane and diluted to an appropriate volume. The test solution was the same as the reference solution preparation except for the addition of 250 mg of samples instead of DHAee. To calculate the concentration (mg/g) of DHAee in total lipids, the following equation was used [26]:

where m1 and m2 are the weight (mg) of the internal standard and the sample in the test solution, respectively, m3 is the weight (mg) of the internal standard in the reference solution, mx,r is the weight (mg) of DHAee in the reference solution. Ax and Ax,r are the peak areas corresponding to DHAee in the chromatogram obtained with the test solution and the reference solution, respectively, and A1 and A3 are the peak areas corresponding to the internal standard in the chromatogram obtained with the test solution and the reference solution, respectively.

All experiments and analyzes were performed at least in triplicate unless otherwise specified. Experimental results were presented as mean ± standard deviation.

Result and discussion

Lipid and FAEE composition of Schizochytrium sp. SH 103

Schizochytrium sp. SH103 cultivated in the basal medium using a fermenter showed a dry cell weight of 25 g/L and a lipid content of 11.6 g/L after 60 h of incubation. GC analysis indicated that the lipid was completely converted to FAEE by acid-catalyzed transesterification, and the DHA content was 313 mg/g. As shown in Table 1, the major fatty acids of Schizochytrium sp. SH 103 were DHA 34.96%, docosapentaenoic acid (DPA, C22:5n6) 9.12% and palmitic acid (C16:0) 49.84%. These values were slightly different from the results of Ju et al. [24] in DPA and DHA contents, which was thought to be due to differences in the culture method and the culture time.

Optimization of separation conditions using semi-preparative HPLC system

Influence of loading amount

The ultimate goal of preparative chromatography is to produce the maximum amount of the target substance per sample injection. Therefore, we tried to determine the maximum loading amount of FAEEs derived from Schizochytrium sp. SH 103.

After each FAEEs sample of 5–50 mg/mL (in methanol) was injected into a semi-preparative scale C18 column and fractionated at 1 min intervals, the purity of DHA in each fraction was confirmed by GC-FID. Figure 1 shows the area % of the fraction showing the highest purity according to the loading amount; when the loading amount was 10 mg, the purity of DHA was the highest at 87.4%. Although the difference in DHA purity was not significant in the range of 5 to 25 mg of loading amount, it was found that the purity decreased sharply to 60.20% when 50 mg was injected into the column. The major impurities in all experimental groups were found to be DPA, myristic acid (C14:0), palmitoleic acid (C16:1n7), and palmitic acid; at 10 mg injection, DPA, myristic acid, palmitoleic acid, and palmitic acid were 4.59%, 0.65%, 3.30%, and 1.62%, respectively. However, when 50 mg was injected, the concentration of impurities except DPA increased (Fig. 2). On the other hand, when 50 mg was injected, the retention time of FAEEs having C14 to C22 carbon was similar to that of DHA, which was presumed to be due to a decrease in the separation ability by excessive loading amount (injection overload).

Influence of mobile phase velocity

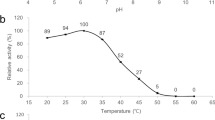

The effect of mobile phase velocity on DHA purity and retention time was investigated, and the result is shown in Additional file 1: Fig. S1. The highest DHA purity was 87.4% at 1.00 mL/min, 89.4% at 0.50 mL/min and 90.73% at 0.25 mL/min, respectively. It was also found that the retention time of the main peak containing DHA increased from 14.81 to 59.27 min as the mobile phase velocity decreased. Although there was no significant change in the purity of the DHA depending on the mobile phase velocity, slower mobile phase velocity will lead to longer production time and lower productivity.

Influence of mobile phase composition

To investigate the effect of mobile phase composition on DHA separation, the amount of water in methanol was increased from 0 to 10% (v/v) using a binary pump, and experiments were performed at a mobile phase velocity of 0.5 mL/min. As shown in Fig. 3 and Additional file 1: Fig. S2, the retention time was rapidly delayed from 29.33 to 117.63 min as the ratio of water to methanol increased. In addition, the height and sharpness of the main peak were reduced and the width was widened. The DHA purity increased from 89.34 to 98.51% with an increase in water ratio from 0 to 4% (v/v); further increases with water up to 10% (v/v) did not significantly affect the DHA purity. The column pressure also increased from 1.0 to 5.4 MPa depending on the ratio of water added.

Effect of mobile phase composition on DHA purity, column backpressure and retention time using water (0–10%, v/v) in methanol at various concentrations. The mobile phase velocity (0.5 mL/min) was held constant across all trials. Filled circle—DHA; filled square—retention time; filled triangle—column back pressure. Error bars (± SDs) are shown when larger than the symbol

The polarity difference of the mobile phase according to the solvent composition was an important factor in material separation. That is, increasing the polarity of the mobile phase has been found to improve the separation efficiency by delaying the retention time of the non-polar FAEE in the column. However, it has been reported that when fatty acids are separated using HPLC, the increased polarity of the mobile phase reduces column life and pump durability due to increased column pressure [18]. This study also showed that the major impurities, DPA and palmitic acid, were completely removed in fractions 15–17 when the water to methanol ratio was 4% (v/v) (Additional file 1: Fig. S3 and Table S1). Therefore, it was thought that it would be advantageous to add water of 4% (v/v) in methanol to obtain DHA with a target purity of 98% or more.

Scale-up using preparative HPLC system

Scale-up using preparative HPLC was designed to achieve a purity of more than 98% DHA from Schizochytrium sp. SH103 oil based on the separation conditions established using semi-preparative HPLC. Equivalent theoretical numbers and retention times in columns of various scales achieve the same purification performance. Therefore, in order to apply the separation conditions established using a semi-preparative column to the preparative column, the height of the column must be the same and the diameter must be increased [27]. Since the diameter of the column is a major factor affecting the loading amount per unit area of the column, the loading amount and mobile phase velocity according to the scale-up were calculated using the following equation [28].

where M, F, and D are loading amount, mobile phase velocity, and column diameter, respectively. Subscripts s and p are semi-preparative scale and preparative scale, respectively. Ms and Fs represent the optimal loading amount (10 mg) and mobile phase velocity (0.5 mL/min) for the semi-preparative scale established in the previous section, respectively. The loading amount and mobile phase velocity calculated by these equations for the scale-up conditions were 1200 mg and 60.0 mL/min, respectively. Thus, 1200 mg of FAEEs from Schizochytrium sp. SH103 oil was injected into a preparative HPLC system and aliquoted at 40 mL/fraction using an automatic fractionation program. The purity of DHA and impurities in each fraction were then checked to determine the optimum production zone.

As shown in Fig. 4, the average purity of DHA (peak 1) present in fractions 2–5 was 99.5%. In addition, 0.25% eicosenoic acid (C20:1n9), 0.1% palmitoleic acid, 0.08% palmitic acid, 0.03% pentadecanoic acid (C15:0) and 0.03% myristic acid were detected as impurities (Table 2). Meanwhile, the average purity of DPA (peak 2) present in fractions 10–13 was 92.8%. In this study, the target purity of DHA at the preparative scale level was 98% or more, so the optimal range for the production of high purity DHA was determined in fractions 2 to 5.

The purity of DHA obtained through three repeated experiments was 98.87%, 98.88%, and 99.10%, respectively, with an average of 98.95% (Table 3). The recovery rate of DHA is another important factor, and the recovery rate calculated using the following equation was very high at 79.75%. This suggests that the separation process performed in this study is reproducible and successful.

where Wi and Wp are the loading amount (g) and product amount (g), respectively, and Ai and Ap are the DHAee content (mg/g) in the injected sample and product, respectively.

In conclusion, DHA from Shizochtriumsp. SH103 oil was highly purified using preparative HPLC in a one-step process. The optimized conditions for purifying DHA were methanol/water (96:4, v/v) as the mobile phase, mobile phase velocity of 60 mL/min, and loading amount of 1200 mg. The DHA purity separated under these conditions was 98.95% and the recovery rate was 79.75%. Omega-3 FAEEs is being separated and purified by conventional complex manufacturing processes such as vacuum distillation and urea adduct formation. Nevertheless, high-purity DHA (> 98%) production using preparative HPLC can be a very attractive method in terms of industrial-scale and economics. Furthermore, the purification method established in this study is expected to greatly accelerate the application of DHA as medical research material and drug.

Availability of data and materials

Not applicable.

References

Harris WS, Connor WE, Inkeles SB, Illingworth DR (1984) Dietary omega-3 fatty acids prevent carbohydrate-induced hypertriglyceridemia. Metab Clin Exp 33:1016–1019

Connor WE (2000) Importance of n-3 fatty acids in health and disease. Am J Clin Nutr 71:171S–175S

Lorente-Cebrián S, Costa AG, Navas-Carretero S, Zabala M, Martínez JA, Moreno-Aliaga MJ (2013) Role of omega-3 fatty acids in obesity, metabolic syndrome, and cardiovascular diseases: a review of the evidence. J Physiol Biochem 69:633–651

Janssen CI, Kiliaan AJ (2014) Long-chain polyunsaturated fatty acids (LCPUFA) from genesis to senescence: the influence of LCPUFA on neural development, aging, and neurodegeneration. Prog Lipid Res 53:1–17

Birch EE, Garfield S, Castañeda Y, Hughbanks-Wheaton D, Uauy R, Hoffman D (2007) Visual acuity and cognitive outcomes at 4 years of age in a double-blind, randomized trial of long-chain polyunsaturated fatty acid-supplemented infant formula. Early Hum Dev 83:279–284

Innis SM (2008) Dietary omega 3 fatty acids and the developing brain. Brain Res 1237:35–43

Hong W, Rairakhwada D, Seo P, Park S, Hur B, Kim CH, Seo J (2011) Production of lipids containing high levels of docosahexaenoic acid by a newly isolated microalga, Aurantiochytrium sp. KRS101. Appl Biochem Biotechnol 164:1468–1480

Gupta A, Barrow CJ, Puri M (2012) Omega-3 biotechnology: Thraustochytrids as a novel source of omega-3 oils. Biotechnol Adv 30:1733–1745

Ratledge C (2004) Fatty acid biosynthesis in microorganisms being used for single cell oil production. Biochimie 86:807–815

Raghukumar S (2008) Thraustochytrid marine protists: production of PUFAs and other emerging technologies. Mar Biotechnol 10:631–640

Strobel C, Jahreis G, Kuhnt K (2012) Survey of n-3 and n-6 Polyunsaturated fatty acids in fish and fish products. Lipids Health Dis 11:144–153

Yokochi T, Honda D, Higashihara T, Nakahara T (1998) Optimization of docosahexaenoic acid production by Schizochytrium limacinum SR21. Appl Microbiol Biotechnol 49:72–76

Dong Q, Li M, Yang Y, Bao Z, Yang Q, Zhang Z, Ren Q (2018) Separation of eicosapentaenoic acid ethyl ester and docosahexaenoic acid ethyl ester by simulated moving bed chromatography. Chin J Chromatogr 36:858–865

Li M, Bao Z, Xing H, Yang Q, Yang Y, Ren Q (2015) Simulated moving bed chromatography for the separation of ethyl esters of eicosapentaenoic acid and docosahexaenoic acid under nonlinear conditions. J Chromatogr A 1425:189–197

Kim GJ, Son HJ, Whang WS, Koo YM, Kim JI, Yang JH (2011) High-purity purification method for omega-3 highly unsaturated fatty acids. U.S Patent No. 20110091947A1.

Fagan P, Wijesundera C (2013) Rapid isolation of omega-3 long-chain polyunsaturated fatty acids using monolithic high performance liquid chromatography columns. J Sep Sci 36:1743–1752

Shahidi F, Wanasundara UN (1998) Omega-3 fatty acid concentrates: nutritional aspects and production technologies. Trends Food Sci Technol 9:230–240

Dillon JT, Aponte JC, Tarozo R, Huang Y (2013) Purification of omega-3 polyunsaturated fatty acids from fish oil using silver-thiolate chromatographic material and high performance liquid chromatography. J Chromatogr A 1312:18–25

Giménez GA, Ibáñez GM, Robles MA, Molina GE, García SS, Esteban CL (1998) Downstream processing and purification of eicosapentaenoic (20: 5n–3) and arachidonic acids (20: 4n–6) from the microalga Porphyridium cruentum. Bioseparation 7:89–99

Wall R, Ross RP, Fitzgerald GF, Stanton C (2010) Fatty acids from fish: the anti-inflammatory potential of long-chain omega-3 fatty acids. Nutr Rev 68:280–289

Valdes AM, Ravipati S, Menni C, Abhishek A, Metrustry S, Harris J, Nessa A, Williams FMK, Sector TD, Doherty M, Chapman V, Barrett DA (2017) Association of the resolving precursor 17-HDHA, but not D- or E-series resolvins, with heat pain sensitivity and osteoarthritis pain in humans. Sci Rep 7:10748–10756

López-Vicario C, Rius B, Alcaraz-Quiles J, García-Alonso V, Lopategi A, Titos E, Clària J (2015) Pro-resolving mediators produced from EPA and DHA: overview of the pathways involved and their mechanisms in metabolic syndrome and related liver diseases. Eur J Pharmacol 15:133–143

Weylandt KH, Chiu C, Gomolka B, Waechter SF, Wiedenmann B (2012) Omega-3 fatty acids and their lipid mediators: towards an understanding of resolvin and protectin formation. Prostag Oth Lipid Meditors 97:73–82

Ju HJ, Oh BR, Ko DJ, Heo SY, Lee JJ, Kim YM, Yang KS, Seo JW, Hong WK, Kim CH (2018) Boosting productivity of heterotrophic microalgae by efficient control of the oxygen transfer coefficient using a microbubble sparger. Algal Res 41:1–7

Bligh EG, Dyer WJA (1959) Rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Nurnadia AA, Azrina A, Amin I, Suryati MA, Muhammad RR (2013) Quantitative determination of fatty acids in marine fish and shellfish from warm water of Straits of Malacca for nutraceutical purposes. Biomed Res Int 2013:284329

Huber U, Majors R (2007) Principles in preparative HPLC. Agilent Technologies Inc., Waldbronn

Medina AR, Giménez AG, Camacho FG, Pérez JS, Grima EM, Gómez AC (1995) Concentration and purification of stearidonic, eicosapentaenoic, and docosahexaenoic acids from cod liver oil and the marine microalgal Isochrysis galbana. J Am Oil Chem Soc 72:575–583

Acknowledgements

Not applicable.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

C-EO, S-JP, SC and M-JP performed the experiments. J-WS participated in analyzing and interpreting the results. G-JK, O-ML and H-JS designed the experiments and wrote the paper. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Additional file 1: Table S1.

Composition and content of fatty acid in the FAEEs fractions enriched using semi-preparative HPLC. Fig. S1. Effect of mobile phase velocity on DHA purity and retention time. Methanol was used as the mobile phase. ● DHA ethyl ester; ■ retention time. Error bars (± SDs) are shown when larger than the symbol. Fig. S2. Changes of chromatograms according to mobile phase composition using water (0–10%, v/v) in methanol at various concentrations. The mobile phase velocity (0.5 mL/min) was held constant across all trials. Fig. S3. Chromatogram of semi-preparative HPLC fractional sections of FAEEs derived from Schizochytrium sp. SH 103. Mobile phase (methanol-water 96:4, v/v); mobile phase velocity (0.5 mL/min); fractional interval (1 min/vial); loading amount (10 mg).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Oh, CE., Kim, GJ., Park, SJ. et al. Purification of high purity docosahexaenoic acid from Schizochytrium sp. SH103 using preparative-scale HPLC. Appl Biol Chem 63, 56 (2020). https://doi.org/10.1186/s13765-020-00542-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13765-020-00542-w